If gas is chosen for heating the house, care should be taken to remove combustion products. This means that you need to select and correctly install a chimney for a gas boiler. Compliance with the rules and regulations in this matter absolutely cannot be neglected, since this can call into question not only the health, but also the life of the residents of the house.

We are ready to share with you useful information about the rules for installing and connecting a chimney for a gas unit, and about the specifics of selecting the optimal design. The information is complemented by visual illustrations and video instructions.

Subtleties of designing a smoke channel

When designing a chimney, everything matters: its size, configuration, cross-section, slope, and other parameters. When installing a smoke exhaust from a gas boiler, it is necessary to strictly adhere to the requirements of regulatory documents: SNiP 2.04.05-91 and DBN V.2.5-20-2001.

Rule #1 - compliance with channel cross-section standards

The cross-section of the chimney duct must be no smaller in area than the cross-section of the gas boiler pipe through which the device is connected to the chimney.

When constructing and connecting chimneys for gas boilers along their entire length, narrowing of the channel, curvature and the use of modules that are not suitable for the cross-section are unacceptable.

When simultaneously connecting two devices to the chimney, the cross-section should be increased, taking into account the likelihood of simultaneous operation of two devices. Those. the cross-section of the channel must be equal to the total dimensions of the pipes of both units of equipment.

Rule #2 - ensuring condensation control

Modern gas boilers are designed in such a way that the maximum amount of heat is supplied to the heat exchanger. Such a high efficiency contributes to the production of combustion products with a relatively low temperature.

As a result, moisture forms on the walls of the chimney. An increased amount of condensate, including aggressive substances, can have a destructive effect on the integrity of the walls of chimneys.

To connect a gas boiler to the chimney structure, use a special tee on which a device for collecting condensate is mounted

At the bottom of the chimney, there must be a condensate collector in the form of a removable container made of plastic or stainless steel. A glass made of galvanized steel is also not prohibited from use, but it will have to be changed frequently.

To protect the structure, it is recommended not only to lay the chimney out of brick, but also to line it, i.e. insert a special stainless steel pipe inside. Such pipes are durable and well resistant to corrosion.

An alternative solution to combat condensate can be lining, i.e. installation of a special flexible chimney. A special container is used to collect condensate. It is installed just below the place where the boiler pipe connects to the chimney.

Rule #3 - choosing the cross-sectional shape of the structure

The traditional cylindrical shape of the chimney is considered optimal for efficient removal of combustion products. In addition, it is easier to carry out preventive cleaning in such a chimney.

Chimneys with a cross-section in the form of an oval are considered quite acceptable, although not so convenient. Square designs also have a right to exist, but their traction indicators are usually reduced.

Rule #4 - performing slopes, turns, ledges

A vertical chimney without ledges is considered optimal for a floor-standing gas boiler. In practice, it is not always possible to achieve such a design arrangement.

Deviation from the vertical is allowed no more than 30 degrees. In this case, you should make sure that the cross-sectional dimensions of the inclined section comply with regulatory requirements.

In this case, the pipe itself connecting the chimney and the boiler must include a strictly vertical section with a height of half a meter or more. Of course, if necessary, some sections of the chimney can be made horizontal, but there should not be too many of them.

When installing a chimney structure for a gas boiler, the presence of inclined sections is allowed, the slope must be 60° or more degrees relative to the horizon, the length of the inclined section is up to 1 m

For example, if the height of the room in which the chimney is installed is about three meters, then the total length of the horizontal sections of the chimney should not exceed these dimensions.

Although, as mentioned earlier, the closer the chimney design is to the vertical, the better. It is not allowed that the slope of the chimney towards the boiler be more than 0.1 degrees. As for the turns of the chimney structure, their maximum number is three turns, no more.

Rule #5 - correct pipe connection

To connect individual parts of the chimney structure, special clamps are used. The slope of the chimney structure can be 15-90 degrees. A certain distance must be maintained between the connecting pipes and other surfaces.

It depends on what materials these surfaces are covered with. In places where flammable or even difficult-to-burn materials are used, it is recommended to maintain a distance of at least 25 cm.

The distance from surfaces coated with fire-resistant materials must be at least 5-10 cm. To protect the chimney from flammable materials, use asbestos cardboard, brickwork, etc.

When installing a chimney for a gas boiler, all its elements must be securely fastened, maintaining the correct spacing between fasteners

Particular attention should be paid to the junctions of individual sections of the chimney structure. They must be made of durable materials that do not bend under external influence.

All chimney fastening elements must have the same characteristics. Horizontal or inclined sections of the chimney should not be under load.

The chimney elements are inserted into each other to a depth that is equal to half the diameter of the pipe or exceeds this figure. No gaps in these places are allowed; the connection must be tight and airtight.

If the tightness of the connection of individual chimney elements is broken, carbon monoxide can enter the room unnoticed. Therefore, the condition of the chimney should be periodically checked, and good ventilation should be organized in all rooms where chimney pipes are laid.

Rule #6 - subtleties of pipe placement on the roof

Chimney pipes should rise above the roof ridge by 50 cm or more, while the distance from the edge of the parapet to the chimney pipe should be no more than 150 cm. If the axis of the chimney pipe is located at a distance of 1-1.5 m from the roof ridge, then it should rise above the ridge level by 50 cm or more.

This diagram clearly demonstrates how, in accordance with technical standards, the height of the chimney pipe relative to the roof ridge is determined so that it does not interfere with the formation of draft

If the work is located even further from the ridge, then it can be made the same height as the ridge. The pipe can be even lower if it is separated from the ridge of the roof by a distance of more than three meters.

In this case, you need to draw a conditional line down from the ridge at an angle of 10 degrees to the horizon. The height of the chimney pipe must reach this mark. It turns out that the further the pipe is located from the ridge, the smaller its height should be relative to the roof ridge.

There is no chimney on a flat roof, so here, in accordance with the standards, a chimney pipe with a height of 100 cm is erected. On a combined roof, the height of the chimney pipe should be about two meters.

The section of the chimney located above the roof and within the unheated attic must be insulated to improve draft and prevent condensation. One of the options for such insulation is basalt shell

The outer part of the chimney must be insulated. If you neglect this point, condensation will accumulate on its surface. Moisture can penetrate inside the chimney, which will lead to the development of corrosion processes and damage to the structure.

The part of the chimney structure that is located on the outside of the house also needs insulation. Insufficient insulation can also reduce the efficiency of the chimney and reduce its draft.

If it is not possible to remove the chimney through the upper floor and roof, coaxial chimneys are used. This option can be removed through the wall, while the intensity of removal of combustion products of blue fuel is not reduced at all.

Rule #7 - compliance with fire safety standards

At the chimney installation stage, it is necessary to take into account fire safety requirements. When the channel passes through walls made of different materials, they differ:

- if the wall is made of wood, insulation from a fire-resistant material is needed around it, and the pipe itself should be wrapped in asbestos;

- In a brick or concrete wall, foam insulation is sufficient.

The design of the chimney must comply with the requirements set out in the instructions attached to the boiler.

The chimneys of boilers that convert gas into thermal energy are predominantly of the mounted type. According to the push-on design, the channel is installed directly on the floor slab of the heating unit. However, it is permissible to connect to wall chimneys using pipes no longer than 40 cm.

If connected to a wall chimney, a gap of 14 cm must remain between the lower line of the pipe and the flammable ceiling. Between the upper line of the pipe and the flammable ceiling, a gap of 50 cm must be left if there is no fire protection, 40 cm if there is protection.

The passage of the chimney through a combustible structure is equipped with non-combustible heat-insulating materials or devices such as sandboxes

The area where the flammable floor intersects is equipped with a box of sand or a seal made of non-flammable insulation.

What is the device?

The classic chimney device of a gas boiler consists of the following components:

- The flue is the connecting link between the boiler and the chimney.

- Additional elements - tees, adapters, bends, clamps. These are the parts for forming the exhaust duct.

- Brackets - for fastening the outer part of the chimney.

- Inspection - hatch for cleaning the chimney from soot.

- Condensate collector in the form of a tee with a device for draining it.

The chimney also includes special elements:

- A device for adjusting draft in the smoke channel - it can be flat (gate) or rotary (damper).

- A deflector is a device at the upper end of the chimney that protects it from clogging. In addition, it protects the chimney from being blown in by the wind, increasing draft.

The chimney for a gas boiler can pass through the interior of the house or directly go outside

When designing a chimney, it should be taken into account that it cannot contain more than three turns of the channel. Otherwise, cravings are sharply reduced, which can lead to serious consequences.

Choosing a chimney depending on the type of boiler

Gas boilers are equipped with one of two types of combustion chambers: open or closed. Externally, the heating units are no different, but their operating principles are different. The choice of chimney design depends on the type of combustion chamber.

Manufacturers supply the market with many models of gas boilers. When choosing a unit for heating your home, you need to decide in advance what is more suitable for a particular home - an open or closed type burner. Ignorance of these subtleties can create problems during operation

The location of the chimney must also be determined in advance. It can be either internal or external. Projects for new houses usually include the installation of internal chimneys. When old houses are converted to gas heating, an external chimney is installed.

Chimney for a boiler with an open burner

A simpler device has an open chamber. It consists of the burner itself and the coil located under it. The latter consists of thin tubes through which coolant circulates. The device only works when air is present, which is why the burner is called atmospheric.

Such a boiler receives air from the room where it is installed, although there are models that are mounted on the wall and make an air intake hole in it.

The wall-mounted boiler does not make noise during operation. The parts included in its design are practically not subject to wear. Maintenance is extremely simple - check the ignition, but as for fuel consumption, these boilers cannot be called economical

For a boiler with an open chamber to work well, it needs a pipe going outside and excellent draft that occurs when air moves through the smoke exhaust channel. The unit is well suited when you need to heat a large house located outside the city limits.

There are 2 solutions:

- The straightest possible pipe, located horizontally, is passed through the wall, and from the outside it is directed up along the wall to the desired height. This type of chimney is called external.

- The pipe is pulled upward from the boiler. It must pass through the ceilings and exit above the roof surface. In such a chimney it is permissible to make 2 bends of 45⁰ each.

The first option is simpler in execution, but high-quality insulation will be required. This will reduce the amount of condensation, but get rid of it completely. At the outlet you definitely need a condensate collector and a tee.

The use of the second option is complicated by the fact that the chimney passes through the ceiling and roofing pie. Therefore, in these places, in accordance with fire safety requirements, the installation of ceiling-passage units will be required.

Factory pass-through unit. It is installed by first performing thermal insulation from foil-clad basalt wool that can withstand temperatures above 150⁰. If this requirement is neglected, the material will sinter and lose its thermal insulation properties.

There are terms such as installing a chimney “through smoke” and “through condensate.” Assembly according to the first method is carried out when constructing an internal chimney, and according to the second - when an external chimney is being erected.

In the first case, the already installed lower element is inserted into the upper one, which will prevent gases from leaking into the room. In the second, they do everything the other way around.

Assembling the chimney “by condensate” will prevent moisture from penetrating into the insulating layer, and therefore will prevent corrosion of the pipe. Furnace masters advise assembling a chimney according to 3 - a combined option: “for smoke” horizontal sections, and “for condensate” those that pass through the attic or second floor rooms that are not heated

If the pipe is led to the residential 2nd floor, it must be brought into an aesthetic appearance. For this purpose, special screens are used, which are attached to the floor with self-tapping screws. When the chimney opens into the attic, no additional work is required.

Chimneys for turbocharged boilers

Boilers with a forced-air burner are called turbocharged. This is a more progressive design with forced injection of oxygen into a closed chamber with a nozzle located in it. The air comes from an externally installed fan through a special channel.

The heating block has double walls with water between them. The liquid heats up when the gas burns, and the combustion products are forced out by the blower into the chimney.

In the classical sense, there is no chimney as such - the pipe is simply taken out into the street, although some place it in an atmospheric chimney

A coaxial chimney is suitable for the turbocharged boiler. Through one of its pipes, exhaust gases are removed at a distance of up to 3 m, and through the other, the air necessary for the combustion process is supplied.

In terms of ecology, such a unit is safer; the combustion process is controlled by automation for gas boilers. The fuel in it burns almost 100%. The efficiency is greater due to the fact that the water is in contact with the walls of the chamber.

It is possible to use horizontal short chimneys. As a result of the use of a double pipe, the air coming from the street is heated due to heat transfer from the exhaust gases.

Specifics of chimney arrangement for two boilers

Each device using gas as fuel must have an individual chimney. In case of urgent need, as an exception, it is permissible to connect 2 units of simultaneously operating gas-consuming equipment. The main condition is to maintain a distance of at least 0.7 m between the points where pipes are inserted into the chimney.

If the house has not only a gas boiler, but also other heating or water heating equipment, the following standards should be taken into account:

- No more than two such devices, located on the same floor or on different floors, can be connected to one chimney.

- In this case, the openings for removing combustion products for these devices must be at different levels.

- The chimney entrances must be separated by a distance of 50 cm or more.

- Input of combustion products from two devices at the same level is allowed only if there is a special cutting insert inside the chimney.

- In this case, the height of the parallel inlets into the chimney, equipped with a divider, must be at least one meter.

Of course, the construction of several chimneys will cost more than just one structure, but you should not neglect the requirements of building codes and safety rules for the sake of dubious savings.

Building regulations allow the option of connecting two heating units to one chimney duct. In such cases, a 12 cm thick cut is made at a height of 1 m from the lower pipe connection point

When creating a chimney, you should not use materials with low density and high porosity, which are characteristic of foam and slag concrete blocks. The chimney should not pass through living spaces.

Installation of such structures on closed loggias or balconies is also not allowed. In all rooms where there is a chimney, it is necessary to organize proper ventilation.

Make it yourself or order it

Order a chimney from professionals or do it yourself – it’s up to you.

Proper independent installation of a smoke exhaust system will definitely save the family budget. When installing, be sure to comply with all requirements of SNiP and fire regulations.

Despite the fact that the temperature of the exhaust gases is low, the harm from them is no less than from any other emissions. Therefore, special attention should be paid to the tightness of joints.

It is also mandatory to organize a condensate collection system.

Preliminary calculations of chimney parameters

The selection of a chimney should begin only after purchasing the boiler, otherwise it is impossible to select its cross-section and calculate the dimensions. The best shape is round, although a rectangle is also acceptable.

Indicative list of chimney structural elements:

- adapter connecting the boiler pipe to the chimney structure;

- a tee with an inspection hole and a fitting designed to collect condensate;

- clamps for connecting individual elements of the chimney;

- brackets and other fasteners;

- conical tip;

- telescopic pipes;

- bends;

- feedthrough pipe, etc.

It should be remembered that it is usually recommended to install bends at a distance of no more than two meters from the gas boiler pipe. This will ensure the most effective traction.

Individual elements of the chimney structure for a gas boiler can be purchased ready-made. The main thing is to correctly calculate the dimensions of the structure and comply with safety requirements.

For proper installation of the chimney, it is recommended to first calculate the cross-sectional area of the outlet.

The following formula is used:

F = (K ∙ Q) / (4.19 ∙ √ˉ N),

Where:

- K is a constant coefficient, its value varies between 0.02-0.03;

- Q is the performance of the gas boiler, indicated in the technical data sheet of the device;

- H is the estimated height of the chimney.

After the cross-sectional area is calculated using this formula, it is necessary to compare the obtained data and correct them if necessary.

For example, according to the requirements for the chimney of a gas boiler, for round structures the recommended cross-section depends on the power of the boiler and can be:

- 120 mm for a 24 kW boiler;

- 130 mm - for 30 kW;

- 170 mm - for 45 kW;

- 190 mm - for 55 kW;

- 220 mm - for 80 kW;

- 230 mm - for 100 kW.

If a chimney with a rectangular cross-section is installed, the thermal power of the gas equipment is taken into account:

- for devices with a power of less than 3.5 kW - 140x140 mm;

- for devices with a power of 3.5-5.2 kW - 140x200 mm;

- for devices with a power of 5.2-7.3 kW - 140x270 mm, etc.

If asbestos-cement pipes are used, the cross-section of the chimney duct must be at least 100 mm. Vertical sections of the chimney are fixed to the wall in increments of 2.5 m, and in areas with a slope the increment should be more often - 1.5 m.

Chimney pipes for a gas boiler can have a round or square cross-section, but the dimensions of such a cross-section must comply with established standards

The height of the chimney is selected depending on its location in relation to the ridge of the roof.

The chimney height shown in the table is the minimum. You can increase this parameter, but you cannot decrease it.

If, during the calculation, it turns out that the condition under which the useful cross-section of the pipe should be greater than the internal area of the heating unit is not met, you should take a pipe of a smaller cross-section, but of greater length.

Conclusions and useful video on the topic

Video #1. How to provide for all the nuances when installing a boiler room:

Video #2. More information about installing natural ventilation:

https://youtube.com/watch?v=LqBV3Ih5-yM%2520

Video #3. Review of coaxial chimney:

The principles of installing boiler room ventilation for gas equipment are similar to equipping other rooms with air ducts, so for experienced craftsmen most of the work is quite accessible and feasible.

The most difficult stage concerns design and calculations - in order to avoid making mistakes, we recommend contacting heating engineers or qualified gas installers.

Please leave comments in the block form below, ask questions about points that interest you, and post photos related to the topic of the article. Tell us about how you installed the ventilation system in your own boiler room. Share useful information that will be useful to site visitors.

Installation options for chimneys

It is necessary to build a foundation under the internal chimney. If you also add a protective brick channel, this will minimize the amount of condensation. Sometimes chimneys are attached from the outside to the wall behind which the unit is located.

Internal design of the chimney

Before proceeding with the installation of the chimney, select a location for it. Then mark the places where it will pass through the ceiling and roof. Carefully check the accuracy of the markings and make openings. The next step is to connect the boiler pipe to the chimney, and then install the revision and tee.

A sheet of steel is fixed, the main bracket is installed, the pipe is extended, if necessary, “elbows” are used. In the area of contact with the ceiling, pipes are used. Take a sheet of galvanized steel with a hole such that a pipe can pass through it freely, and attach it to the ceiling. Clamps are used to strengthen joints. Every 2 m the chimney is secured with clamps, and every 4 m - with brackets.

The work is completed by checking the seams for leaks. To do this, take a soap solution and apply it to all joints. If everything is done efficiently, then when connecting the unit to the chimney, bubbles will not appear in these places.

External structure device

For an external chimney, a hole is made in a blank wall of such a diameter that a pipe with insulation can freely pass through it. Having installed the first element of the future chimney into the hole, secure it and wrap it with insulation. The next sections are added from the street side, controlling the verticality using a plumb line.

An external chimney is safer, but it needs to be well insulated. All elements of the purchased design are well matched, so assembly will not create problems

The pipe is fixed to the wall with brackets until it reaches the desired height. The process is completed by attaching the pipe to the boiler nozzle and sealing the joints. To ensure that the external chimney warms up quickly, it is insulated along its entire length with basalt wool.

Installation of a coaxial chimney

This type of chimney removes combustion products outside and at the same time supplies the boiler burner with oxygen-rich air. With this design, no additional ventilation is needed.

The chimney is made of round pipes - an outer steel pipe with a cross-section of 10 cm and a wall thickness of 0.1 - 0.2 cm and an inner aluminum pipe with a diameter of 6 cm. The pipes do not touch because there are jumpers between them.

Coaxial chimneys are installed for boilers with a closed combustion chamber, designed for wall and floor installation, as well as for water heaters and other gas units.

This gas outlet has several advantages:

- Structurally, the pipe is designed so that simultaneously with the heating of the incoming air, the exhaust gases are cooled;

- the chimney increases the efficiency of the equipment;

- It has compact dimensions, so it is used not only in private houses, but also in city apartments;

- safe - the exhaust gases do not come into contact with the room air and do not exit through the ventilation duct but directly into the atmosphere;

- easy to install.

Install a coaxial chimney both horizontally and vertically. Regardless of the installation method, the maximum length of the chimney should not be more than 4 m. There are models with solid parameters created specifically for long-distance chimney removal.

Directly for the installation of a coaxial chimney, manufacturers produce specially designed adapters used for vertical transitions through floors and roofs. To protect the system from precipitation and ensure tightness in the area where the pipe passes through the ceiling, there are special caps.

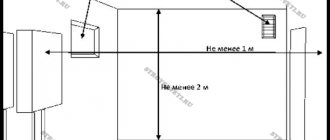

The figure shows tips and mandatory requirements for installing a coaxial type chimney. All of them relate to gas outlets for boilers whose power does not exceed 70 kW

If a coaxial chimney is used for a boiler installed on a wall, it should be positioned horizontally. In this case, it is necessary to ensure a 3-5% slope, otherwise condensation will enter the boiler.

The standards regulate not only the dimensions of the chimney itself for a gas boiler, but also the location of the hole in the wall. It should be at least 50 cm away from the window next to it and at least 25 cm if it is located above the window.

Room standards for installing a gas boiler, where it is better to install the device

The premises where the gas unit is planned to be installed are subject to the most stringent requirements.

According to current standards, it is allowed to install them in non-residential premises equipped with high-quality ventilation.

In addition to the presence of ventilation, the area of the room must correspond to the power of the unit and the design of the combustion chamber. When a boiler and a gas water heater are installed together, their capacities are summed up.

Important! According to existing standards, the installation of two gas devices is allowed in one room. The following standards have been established:

The following standards have been established:

- gas boilers with a power of less than 30 kW are allowed to be installed in rooms with a volume of at least 7.5 m³;

- boilers with a power of 30-60 kW require a space of more than 13.5 m³;

- for installation of more efficient boiler equipment, the minimum volume is 15 m³.

Standards for installing the device in the kitchen of wooden and other types of houses

It is important for homeowners planning to place equipment in the kitchen to know that there are special standards for this room:

- The area is more than 15 m².

- The height of the walls is at least 2.2 m.

- A window opening outward, equipped with a window. For 1 m³ of room volume there should be 0.03 m² of window area.

Photo 1. Gas boiler located in the kitchen. The device is installed in a special cabinet, which is closed with a lattice door.

- If the building is wooden, then the wall adjacent to the boiler is covered with a fire-resistant shield. The size of the shield is determined so that it protrudes 10 cm beyond the boiler at the bottom and sides, and covers 80 cm of the wall at the top.

- When choosing a floor-standing model, a base made of fire-resistant material (brick, ceramic tile) is installed under it, protruding 10 cm on all sides of the boiler.

- In addition to the presence of exhaust ventilation, there is a gap at the bottom of the door for fresh air to enter. It ensures constant air circulation.

- When installing a heating unit, it is necessary to maintain a certain distance between the wall and the boiler (more than 10 cm).

Requirements for a separate boiler room

When constructing an extension to the main building to accommodate boiler equipment, the following conditions must be met:

- the foundation of the extension is carried out separately from the main building;

- the design is made of fire-resistant materials, the same requirements are imposed on the interior decoration;

- mortar is mixed on sand;

- the foundation for installing the boiler is poured separately, after the completion of the extension;

- the base intended for installation of equipment is 15-20 cm higher than the floor surface.

Further requirements correspond to the conditions for installing boilers in non-residential premises:

- ventilation system providing three air changes within an hour;

- the distance between the floor and ceiling is at least 2.5 meters;

- boiler room volume is more than 15 m³, a larger volume ensures comfortable maintenance of all equipment elements;

- Water must be installed and a drain must be installed in the floor;

- all electrical outlets in the room are grounded;

- daylight;

- When placing the boiler installation, free access to the unit is ensured.

Photo 2. Boiler room with two gas boilers. The devices are installed on a special pedestal, providing access to sunlight.

Certain requirements are also imposed on the equipment used when operating the boiler:

- only metal pipelines are used for gas;

- The device is grounded using a separate grounding circuit;

- Without a gas meter, an automatic valve that shuts off the gas supply in the event of a leak, and a gas analyzer, the equipment cannot be put into operation.

Reference. Modern gas units are equipped with protective automatic systems of varying complexity that shut off the gas supply in the event of a malfunction.

How to remodel an old chimney?

If a gas boiler is included in a long-existing heating system instead of a conventional stove, the brick chimney does not have to be completely rebuilt. It can be upgraded by sleeving. There are two ways to do this.

Method number 1. Install a stainless steel pipe at the base of the existing chimney.

The pipe should be selected so that its height is equal to the height of the old chimney, and its diameter matches the boiler pipe. The gap between the walls of the existing chimney and the pipe is filled with heat-insulating material such as foam glass, expanded clay or perlite.

Method 2. Apply Furan-Flex technology. This option is more expensive than the first, but the diameter of the chimney remains unchanged. The material is frost-resistant, does not corrode, the diameter ranges from 6 to 100 cm.

FuranFlex technology allows you to modernize or repair a chimney with a slope of maximum 30⁰ quickly and efficiently

The technology itself consists of placing an elastic pipe inside the chimney under pressure. The pipe takes the shape of a chimney, then hardens and becomes a continuous, seamless shell that does not allow smoke or condensation to pass through.

Frequent errors and problems during installation

During the installation process, a number of errors can be made, the list of which most often includes:

- Incorrect pipe size (its height and cross-section);

- Insufficient thermal insulation when installing an external chimney or in an opening in the attic;

- Violation of fire safety standards;

- Lack of liner on the pipe that removes gas from the boiler and is discharged into the brick channel shaft;

- The materials from which steel chimneys are made do not meet regulatory requirements (here it is necessary to take into account wall thickness, high temperature and resistance to negative environmental factors).

Installation work

Assembly occurs in the following order:

- Choose a location where the pipe will go straight up. There should be no obstacles along the way that have to be avoided. Any bevels will interfere with outflow.

- An elbow is installed at the outlet of the column. Installation of flexible corrugation made of steel is possible. Insulation is not needed in this place, since condensation does not form due to the high temperature.

- Now we install the chimney. It is mounted on a bracket and clamp.

- The outer part should be insulated if it is bare. This way you will get rid of excess condensation and protect the pipe from contact with moisture and the environment.

- A fuse is installed on top to protect the drain from moisture.

- A condensate collector is installed.

Installing a geyser hood is the same in both an apartment and a private house. The difference is in the installation of the chimney. In apartment buildings, a vertical chimney is made with an additional bend and a passage through the wall.