Piping the boiler room with a 3-phase induction heating boiler VIN-10

The photo shows that the induction boiler can be placed in a convenient place on the wall. The client wished to install a separate circulation pump for each circuit (floor). The safety group and expansion (membrane) tank are compactly mounted on the outlet pipe of the VIN-10 induction boiler. The control panel is located to the right of the boiler and collectors at a convenient height (depending on the customer’s height). This boiler room was equipped with a GSM module, which allows you to control the temperature in the house and control the induction boiler through a mobile application from a smartphone, anywhere in the world with an Internet connection!

Induction boilers SAV and VIN and their advantages.

- Economical.

Induction heating boilers VIN and SAV (water heaters) are more economical than conventional heating boilers due to the use of 99% of the energy consumed. - Safety.

Induction heating is a high degree of electrical and fire safety during operation. - Durability.

The service life of induction heaters when used for heating buildings is more than 30 years. - Easy to use.

They do not require preventive maintenance during the heating season and the off-season period, do not require highly qualified personnel for installation and maintenance, and are completely autonomous. - Small sizes.

The small dimensions of the induction heating boiler VIN and SAV allow it to be installed almost anywhere.

Advantages and disadvantages

According to manufacturers, the use of induction heating boilers for heating a home is a complete advantage with no disadvantages at all.

Let's try to figure out what is the truth and what is a marketing ploy. 1. High efficiency. Efficiency up to 99% is typical for all types of electric boilers.

2. Maximum protection against scale. Since there is no direct contact of the induction winding with the coolant (unlike the heating element), scale can only form inside the pipes. But closed systems are characterized by a consistently low amount of salts. That is, there are no prerequisites for the formation of deposits.

3. Resource savings up to 35%. Before you buy an induction boiler and install it, remember that its main task is to convert energy into heat. To generate 1 kW, according to the law of conservation of energy, you also need to spend 1 kW of electricity. The only difference is the heating speed - the induction unit operates faster by about 20-30%.

4. Complete absence of detachable connections in the design, which eliminates the possibility of leakage. Not entirely true: the boiler includes 4-6 components connected into a unit. The price of the VIN induction heating system includes the boiler itself in a collapsible casing, a control cabinet, a safety group (sensors and relays) and capacitors, pressure relief valves, a set of contacts for connecting external devices.

5. High degree of electrical and fire safety. This is true, but you need to make sure that there is no leakage and that the amount of coolant remains constant. Otherwise, the device will heat up very quickly and there is a risk of explosion.

6. Does not have elements subject to mechanical wear, so the service life is more than 30 years. Firstly, the core is durable, but the varnish insulation on the primary winding (toroidal) is subject to aging. Its service life is 7-10 years. The result of destruction will be an interturn short circuit with corresponding consequences. Secondly, induction boilers are a relatively new product that has not been tested by time; the statement about 30 years of operation is unlikely to be true.

7. Compatible with other systems. You can connect heated floors, gas or wood boilers.

A clever meter that saves electricity. Pays for itself in 2 months! Everyone needs to know this in order to save!

8. They do not require a separate room or ventilation.

9. Does not require preventive maintenance. A boiler is, in any case, equipment with many sensors, relays, and terminals that periodically need to be changed and tightened. Of course, compared to gas boilers, this is insignificant.

Thus, most of the positive qualities are consistent with other types of electrical units. Now let’s analyze the shortcomings identified over several years of operation.

1. Cost. The price of the induction boiler SAV 5 kW is 40,000 rubles. Whereas the heating element Protherm Skat 6 kW is 23,000.

2. Significant weight with small dimensions. Since even the smallest unit weighs from 20 kg, it is recommended to mount them on the floor or hang them on a load-bearing wall using durable brackets.

3. The electromagnetic field generates strong interference in the long, medium wave and VHF ranges. Although manufacturers claim that they do not affect the human body, sanitary and medical officials claim the opposite. It is not for nothing that SNiPs contain standards and rules for the location of devices with high levels of radiation.

4. To operate the heating system in a house with 2-3 floors, a powerful circulation pump is required.

Savings when using electric heating

There is no gas, it is expensive to deal with diesel or solid fuel. All that remains is electricity. Can you save money by installing an electric heating system?

The new generation of heating systems using induction technology is rightfully classified as energy-saving equipment.

In most cases, induction heaters VIN and SAV reduce operating costs by 30%.

Reliable and durable induction heating systems guarantee warmth and durability - “set it and forget it for 30 years.”

Savings compared to a conventional heating element – 266,218 rubles over 5 years.

Whether the price of an induction boiler is high - judge for yourself!

How does an electric induction heater work?

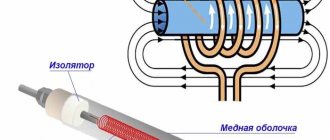

Heating water using electromagnetic induction is based on the property of electrically conductive materials to heat up when in an alternating magnetic field. More precisely, the energy of this field is absorbed by the conductor object and converted into heat. Consequently, an object surrounded by a coolant (in the case of boilers, water) transfers its thermal energy to it. An electric induction boiler for heating works on this principle . A device that heats water by induction must consist of three components:

- electric current with alternating voltage;

- cylindrical inductor coil;

- ferromagnetic core (the material must be attracted to the magnet).

Induction electric boilers for home heating, the prices of which are gradually decreasing, are designed according to the same scheme. Only the design is supplemented with a control unit, inlet and outlet pipes, a terminal box and other auxiliary devices.

The heating of the liquid itself occurs as follows:

- First, an alternating current passing through the inductor generates a magnetic field.

- Under the influence of a magnetic field, Foucault currents are formed on the surface of the core. The Joule heat emitted by them at this time causes an increase in the temperature of the material.

- The heated core, due to its high thermal conductivity, transfers energy to the coolant.

In most boilers, the coolant is clean water, which constantly circulates in the system. A system is being created in which the energy obtained from electricity is contactlessly transferred to the core. By the way, particles can settle on its surface, forming scale. It slightly reduces the thermal conductivity of the material, but has virtually no effect on efficiency.

Water heaters type VIN

The heart of the unit is a coil consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical housing in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed at the top and bottom with welded lids, and the terminals for connection to the electrical network are brought out. Cold coolant enters the vessel through the lower pipe, which fills the entire space inside the body. Water heated to the required temperature goes into the heating system through the upper pipe.

Coolant heating circuit

Due to its design, when connected to the network, the heat generator constantly operates at full power, since it is irrational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown/on with a water temperature sensor. You just need to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the water heating induction element when it is reached. After the time has passed and the water has cooled by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the heat generator winding provides a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying large cross-section cables, which in itself is very expensive. To increase power, it is enough to put three water heating units in a cascade and use a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each device in the cascade; the photo shows a similar example of the operation of induction heating.

Heating with induction boilers

Design features of heaters of the “Sibtekhnomash” type Using the same effect of electromagnetic induction, another company develops and produces water heating devices of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial shape and spreads from it in all directions. If in VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides a spiral-shaped heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the turns of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate, collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- Heat exchanger piping is accessible for cleaning and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its operating efficiency is 98%, as in heaters of the “VIN” type, this efficiency value is declared by the manufacturer itself. The durability of the units in both cases is determined by the performance of the coils, or more precisely, by the service life of the winding and electrical insulation; manufacturers set this indicator within 30 years.

Advantages

One of the main arguments why many people now want to buy an electric induction heating boiler is efficiency, which can reach 99%. Moreover, such productivity is maintained throughout the entire operation. In addition, this equipment is universal; it operates on both direct and alternating current. Boilers of this type have a long service life, which is facilitated by:

- No moving parts of the structure. Most of them do not wear out and do not require frequent replacement.

- The absence of heating elements eliminates the need to constantly check their performance and update them.

- Permanent connection. No joints, welds, etc. eliminates the occurrence of leaks.

Induction electric heating boilers are energy-saving units that provide high electrical and fire safety. The risk of short circuit or fire is eliminated by the fact that there is no direct connection between the heated core and the inductor.

The advantages of these devices include smokeless operation - the room for the boiler does not need to be prepared in a special way and preventive maintenance is carried out.

Other functional and operational advantages:

- no noise;

- protection against accidents and overheating;

- control automation;

- service life up to 25 years with high-quality installation;

- compatibility of cores with water, oil and antifreeze;

- stable operation in a closed system.

Advantages

It is impossible not to point out the points that, when talking about induction electric boilers, are considered as disadvantages:

- large mass - even a compact boiler weighs about 20 kg;

- To operate, the system must be powered from the mains via a closed circuit;

- During operation, interference occurs in the radio range, which can have a bad effect on people and pets;

- it is necessary to install good air vents in case of air jams;

- A strong magnetic field in the house slightly impairs the performance of wireless networks (Wi-Fi, cellular communications).

It is believed that the main disadvantage that induction electric boilers have is the price . But in practice it is not as high as it seems. The initial cost of the equipment is offset by further savings on maintenance and energy bills.

Internal structure and principle of operation

The design of the induction heat generator is a transformer located in a welded metal housing. The inductor is placed in a separate sealed compartment, which completely eliminates contact with the coolant that circulates in the heating circuit. The role of the secondary winding is performed by a pipe or core, which, when heated, transfers heat to the coolant flowing inside or around the secondary winding.

Attention!

An induction heating boiler does not have a heating element, unlike heating element heat generators, and a dissolving electrode, as in electrode units. This design feature ensures constant efficiency of the heating installation regardless of its service life.

Such units can operate both at a current frequency of 50 Hz, usual for a household network, and at high frequency currents, which are generated by special converters.

Attention!

The use of high frequency currents makes it possible to reduce the size of heating installations.

Recommendations for selection

To choose the right electric induction boiler for heating a private household, you need to correlate its power with the total area of the premises. The standard is 60 W/m2. This means operation in a building with low heat losses during the cold season. The worse the insulation, the higher the power should be. On average, 6 kW models are now in demand for heating private homes, taking into account the fact that their automation maintains a low temperature in unused rooms.

Equipping an induction water heater for heating with an electronic programmer makes it possible to set the operating mode for several days in advance. For those who choose a device for a home heating system, it is better to give preference to cores with thick walls.

Before buying an induction heating boiler , you should make sure that the manufacturer provides a guarantee for its products. Typically it is 3 years for the boiler, and 1 year for the component equipment.

The catalog on our website presents electric induction heating boilers of various models, which makes it possible to choose heating equipment for housing of any size. You can get all the necessary information on products from our managers by contacting us by phone number or ordering a call back. They will be happy to help you choose a boiler taking into account the client’s requirements and the characteristics of the home.

Design of a vortex induction boiler

In fact, this technical solution is far from new; the phenomenon of electromagnetic induction, due to which electric induction heating boilers operate, was discovered by M. Faraday back in 1831. It’s just that thanks to modern materials and technologies, the phenomenon was taken as a basis and implemented in water heating installations relatively recently.

Heating of water occurs due to eddy currents (Foucault currents) appearing in the core of the coil. They are formed under the influence of an alternating electric field created by the turns of a coil with an alternating current of 50 Hz. The core is made in the form of a pipe, through which the coolant flows when heated. In essence, the device is an induction converter of electrical energy into thermal energy with an efficiency of about 98%. The diameter of the wire from which the coil is made, the number of turns and the dimensions of the core are designed in such a way as to heat the water to a maximum temperature of 95 ºС and at the same time prevent overheating of the winding.

DESCRIPTION OF THE WINE BOILER

VIN vortex induction boilers for heating and hot water supply systems. Used in houses, townhouses, industrial premises, etc. where there is electricity.

Induction boilers are gaining more and more popularity among electric boilers. In comparison with a heating element boiler, a vortex induction boiler does not form scale due to the lack of contact of the coolant with the heating element, thereby it does not lose efficiency throughout its entire service life. In this regard, it is economical and safe compared to heating element boilers. The power of the boilers presented on the website is up to 20 kW, but if necessary, we can provide a boiler with a higher power rating.

The boiler operates on the basis of an induction current created in the VIN body itself, heating the coolant passing through the pipe between the walls to the desired temperature.

Our company is a direct supplier and dealer of the Alternative Energy plant in MOSCOW. You can buy or order a VIN induction boiler on the website or call our specialists.

Why do you need an inverter?

Many people still remember color tube televisions, which weighed up to 60 kilograms. It was possible to reduce their dimensions and weight thanks to the use of inverters in power supplies. The inverter converted the network voltage with a frequency of 50 hertz into a high frequency voltage of several tens of kilohertz. This voltage was supplied to a transformer, the distinctive feature of which was a core made of a special ferromagnetic alloy. The physical properties of the ferromagnetic material used made it possible to significantly reduce the dimensions and weight of the power transformer. The conversion of the mains voltage of 50 hertz to high frequency is used in vortex induction boilers - these are new generation induction boilers for heating homes. The voltage is supplied to them from the inverter, the transformer coil is a winding on the central pipe made of a ferromagnetic alloy, and the secondary short-circuited winding is the pipe and the body of the induction boiler. This technical solution made it possible to make the boiler compact, reliable and economical. But on the other hand, the use of expensive copper for winding and special alloys for heat exchangers, the automation unit and the inverter made the cost of the product high. Therefore, the price for any induction boiler will be significantly higher than for an electric heating element boiler.

INSTALLATION OF BOILER ROOM

- Installation of induction heater VIN, connection of electrics and automation.

- Piping of boiler room equipment - expansion tank, flow switch, gr. security, etc.

- Installation of a collector system, if there is a need for it.

- Pumping and startup of the system, commissioning.

Installation of the boiler room is carried out with a connected radiator system or heated floors, pipes brought into the room or place where the boiler and equipment are planned to be installed. The price starts from 15,000 rubles. depending on the amount of work.

INSTALLATION OF THE ENTIRE HEATING SYSTEM

- Installing radiators or laying heated floors.

- Pipeline piping of heat exchangers (reinforced polypropylene pipes, metal-plastic pipes, polyethylene pipes) to the boiler room.

- Installation of a collector system, pumps and flow sensors.

- Boiler room piping, pumping and commissioning.

The price depends on the size of the house and the choice of type of heating system.

If you have a need for installation or installation, you can use the table, which is located in the left block of the entire site, select items of interest in it and send a request for a cost estimate.

We provide a guarantee for our work and provide a full range of equipment necessary for heating installations:

Installation of induction device

The system with an induction boiler is equipped with a circulation pump, expansion tank, shut-off and adjustable equipment (ball valves, etc.). In private homes, as a rule, a standard connection diagram is used.

Installation of induction boilers is carried out in accordance with the instructions or technical data sheet. The device is positioned strictly vertically, the lower inlet pipe is connected to the return pipe, the upper one is connected to the supply pipeline. Only metal or metal-plastic pipes are used.

If you decide to install an induction electric boiler with your own hands, do not forget about grounding. A safety group, a control cabinet, and at the inlet - filters, a circulation pump and a flow sensor are installed in close proximity.

Review of induction boilers

On the Russian market, induction-type electric boilers are represented by CJSC NPK INERA (brand SAV), LLC Alternative Energy (brand VIN), NPK Miratron (brand Miratron).

Reviews about SAV induction electric heaters are equally positive and negative:

“The SAV boiler heats up the water in the heating system faster than a heating element, but it also cools down immediately - this is due to its low inertia. Savings are achieved by automatically adjusting the performance: first it heats at maximum, and then, to maintain the temperature of the liquid, it turns on at half power.”

Sergey Boldovsky, Alexandrov.

“According to the sellers, the CAB 5 boiler operates from an outlet. In fact, to operate above +60 °C, it needs a three-phase power line and an RCD. After a failure or decrease in voltage in the network, the automation turns off and you have to start it manually. When contacting the manufacturer they offered to replace it. I have the same problem with the boiler I received.”

According to reviews, the VIN vortex induction heater to a certain extent corresponds to the declared characteristics.

“I installed VIN-7 2 years ago. There are no complaints, it functions normally. I didn’t notice any savings as such, but scale did not form. In general, apart from the price, it is no different from conventional boilers.”

Alexander Sokin, Rostov-on-Don.

According to buyers, the noiselessness of induction boilers is a relative value.

“I connected a heated floor system to the Miraton 6 boiler. It warmed up very quickly, but the hum is constant and unpleasant. The controller is faulty and does not maintain the set temperature level.”

Recommendations for selection

1. When selecting a boiler, emphasis should be placed on the correct technical calculation of heat loss at home. This is the first and main parameter.

2. The second criterion is the number of phases. Single-phase ones can be connected directly to the outlet, three-phase ones - only a separate power line. Grounding is carried out in any case.

3. You should also take into account how the induction boiler will be used. If it is required to maintain a reduced, stable temperature, a low-power device of 2.5-6 kW is sufficient.

4. Some manufacturers offer to separately purchase a mode programmer, GSM remote control unit and others. With their help, the operation of the boiler is optimized, and the cost increases accordingly.

We invite you to watch an introductory video review of induction electric boilers: