Requirements for ventilation of a gas boiler room

Small capacity boilers (up to 60 kW) are located in the kitchen, provided it meets certain requirements:

- room dimensions of at least 7.5 m3 when installing one heating device, and at least 13.5 when installing two;

- the ceiling is at least 2 m when installing one heating device, and at least 2.5 when installing two;

- glass area in windows is at least 3 cm2 per 1 m³ of room;

- mandatory presence of frames and vents in windows;

- the distance between the heating device and the wall structure is at least 100 mm;

- the wall is covered with fire-resistant material;

- supply of fresh air naturally (through the lower gaps in the doors or special holes in the wall).

For more efficient boilers over 30 kW, a separate room with an area of more than 15 m2 is required.

Features of the boiler room depending on the type of fuel

Let's consider what features there are for different types of solid fuel used, what a boiler room should be like for a solid fuel boiler using different types of burned materials.

Wood boiler room

Actually, a wood-burning boiler room is a classic room for a solid fuel boiler, which can have minimal dimensions. The main differences between different rooms are the size from the firebox door to the wall or boiler room doors. It depends on the length of the log used.

If long logs are used, then the distance is at least 2 meters. After all, you will not only have to load logs into the firebox, but also open / swing open the firebox door.

If you heat with briquettes or eurowood, then this distance may be minimal. Just don’t forget that in addition to loading firewood, you will also have to remove the ash, which will also require free space in front of the firebox / ash pan.

Pellet boiler room

The size of the pellet boiler room will depend on how the pellet hopper is installed. A pellet boiler room will not only differ in floor area, but also in the height of the boiler room.

Since with a high hopper of 400-600 liters or a hopper of 150-200 liters installed on the boiler, such as the Kupper, you will need more space above the hopper to load pellets.

If the hopper is high, it is best to make a small ladder or use a short, stable stepladder to load pellets. Because lifting 40 kg bags of pellets over your head for loading is unrealistic.

Coal boiler house

A coal boiler room is different in that it is very convenient to have a capacious coal fire nearby. And don’t carry coal in buckets from the barn, but shorten the path from the coal fire to the boiler firebox as much as possible.

The size of a coal-fired boiler room will be approximately equal to that of a wood-burning boiler room, with the understanding that when loading vertically, it would be nice to have more space on top to operate a bucket.

Sawdust/wood waste boiler room

The dimensions of sawdust or wood waste boilers are slightly larger than the dimensions of conventional wood-burning heat generators. Fuel agitation systems on grate bars allow efficient combustion of such fast-caking fuel. The sawdust boiler is also distinguished by the large size of the bunker or firebox for one load of fuel.

The firebox is located on top of the firebox, which means that a boiler room using sawdust or wood waste should have a greater height than a standard boiler room.

Biofuel/husk boiler room

If a biofuel or husk boiler room is equipped with pneumatic supply, then the room with the boiler itself may have small dimensions. If the husk supply is used with a circular turner, then such a boiler room will have a large husk bunker.

And the minimum effective bunker is 2.0 by 2.0 meters. This means that the husk boiler room will have a minimum size of 4.0 by 4.0 meters.

Requirements for ventilation of a solid fuel boiler and room

The main conditions for ventilation in a boiler room in a private house are compliance with a certain area and volume. This is caused by the required frequency of air exchange per unit of time, fire safety and regular inspections of equipment. Therefore, for normal ventilation of the boiler room, the distance of the boiler from the walls and free access to it must be ensured depending on the performance of the unit:

- For a boiler with a capacity of up to 30 kW, at least 3.5 m2.

- For a thermal device from 30 to 60 kW – 5 m2.

- If the unit has a power of more than 60 kW, then the boiler room area is over 6 m2.

In addition, the height to the ceiling should be 2.2 m.

Why is it needed?

Proper ventilation is an important factor that affects the indoor microclimate. If it is regularly ventilated, the risk of mold and mildew on the walls and ceiling is significantly reduced. There is a low probability of allergic reactions, asthma, and other diseases in people who spend most of their time in such a room (live or work in it).

It is especially important to organize proper ventilation with an influx of fresh air in those rooms where it is not possible to open windows for ventilation or in those not equipped with windows at all, in apartments and offices with plastic windows (how to arrange fresh air ventilation with your own hands?).

Chimney outlet of a heating device in a private house

Chimneys and their installation require a specialized approach and compliance with certain requirements. The walls of the chimney are usually made resistant to temperature changes, corrosion and chemical compounds.

The hood for boilers in a private house must meet building regulations:

- SNiP 41-01-2003 “Ventilation and heating of residential premises.”

- SNiP 42-01-2002, 42-101-2003 “Recommendations and requirements for gas distribution complexes”

Thus, while maintaining these legislations, it is necessary to ensure that smoke removal corresponds to the required air exchange and air safety. And to do this you need to calculate the height and cross-section of the chimney and air duct. During installation, the following conditions must be observed:

- the pipe must be positioned strictly vertically;

- rise above the roof ridge no more than 0.5 m;

- the total height of the vein channel is no more than 5 m;

- The joints in the channel are insulated with heat-resistant sealant.

If the above requirements are met, you can install the ventilation pipe for the heating device yourself.

How to choose material for the hood

To solve such problems, brick, stainless, galvanized steel or ceramic material is used. Let's analyze each of them in more detail.

Coaxial ventilation

This gas boiler hood in a private house consists of a short outer and a long inner pipe. In addition, it includes all sorts of accessories: clamps, elbows, gaskets, as well as a condensate receiver. This design is also called “pipe in pipe” and is used in gas heating appliances with a closed combustion chamber.

The design and principle of operation are the same for all boilers of this type:

- The pipe located inside is connected on one side to the boiler pipe, and its other side is led out to the street and combustion products exit through it. It is made of stainless steel and can withstand high temperature changes.

- The pipe, located outside, is connected at one end to the inlet, and the other end is taken outside the room. Fresh air enters through this channel.

- During operation of the unit, the exhaust combustion products are discharged outside due to draft through the internal channel, and at the same time fresh air is supplied to the combustion chamber through the external channel.

This coaxial device has the following advantages:

- The chimney is safe. This is possible because the escaping hot combustion products are immediately cooled by cold air coming from outside.

- Increased productivity. Fresh air heats up when supplied and increases the efficiency of the unit.

- Environmental friendliness of the system.

- Installation in the kitchen. Such a wall-mounted heating device does not spoil the overall interior of the room.

Another feature of installing such boilers with coaxial air circulation is that in a private home, the chimney can be installed both vertically and horizontally.

Brickwork

Nowadays brick is used less and less for ventilation shafts.

This is caused by two main reasons:

Firstly , due to its fragility, after 7-10 years the brick begins to crumble, and the masonry loses its tightness, which means it loses its purpose. It is destroyed due to the fact that the temperature in the channel changes and as a result condensation forms, which freezes in winter. It is more acceptable to make chimneys from this material when the walls are constantly in contact with hot waste.

Secondly , brickwork is a labor-intensive process; such a ventilation duct has a complex design and unjustified costs.

In this regard, a better option would be a brick shaft with a galvanized pipe inside for ventilation. It is assembled in parts from 2-meter contours, and the thickness of the walls is selected taking into account the temperature of the exhaust gases.

Steel hood

The exhaust gas during operation of a gas boiler has a temperature of about 430 degrees, and even more when operating solid fuel boilers. Therefore, the exhaust pipes for a gas boiler in a private house are made of stainless steel with a wall thickness of 0.7-1 mm. These products are quite stable to the action of condensation on the surface of the walls.

It should be noted that the service life of these ventilation pipes is significantly shorter than that of brick and ceramic ones. At the same time, standard steel hoods are easier to replace because they are lighter and do not require specialized foundations to provide strength.

Such channels are manufactured in different versions:

- Placement in a specially laid brick well;

- From factory circuits. In this case, each circuit is a sandwich pipe with two walls. Here one pipe is located inside another, and the gap is filled with heat-insulating material.

The use of such hoods simplifies installation, and they can be mounted both indoors and outdoors.

Ceramic hood

It should be appreciated that a ceramic channel is an ideal solution for all types of boilers in a private home. This material is resistant to high temperatures. It is also neutral towards toxic chemical compounds that can be formed during the combustion of various fuels. Ceramic hood channels are mainly arranged vertically in modules with one or two recesses.

In the latter version, the second channel is used to ventilate the boiler room or to supply air to the boiler burner. Typically, such sandwiches are insulated with mineral wool to protect them from cooling and condensation. In addition, natural draft increases in an insulated pipe. When installing such a ceramic hood, there must be a gap for free passage of air between the insulation and the surface of the well.

On the building materials market you can find sets of ceramic hoods in a metal casing. This model does not require ventilation gaps and is mounted on a heating device both inside and outside the house. They can be operated with exhaust gas temperatures up to 450 degrees.

At the same time, ceramics absorb moisture well, so they usually have a tray to collect condensed moisture. And the channel itself is provided with free access for airflow. Thanks to the smooth surface in the pipe, it is resistant to contamination and easy to clean during maintenance.

To operate solid fuel boilers in a private home, pipes are used that can withstand temperatures of 650 degrees. In addition, they must be neutral to soot combustion and operated in a dry condition.

Tips for use

For normal operation, clean and inspect it before each heating season. It is possible to replace some parts and elements. Deterioration in functioning is associated with a decrease in the useful diameter of pipes and the emergence of new air routes. For example, through open doors and windows.

Natural systems fail under strong winds and sudden pressure changes. Another reason is the difference in temperature outside and in the extension. Therefore, they need to be compensated by compulsory devices. Check for normal rotation speed of the impeller. The first sign of a malfunction is the appearance of noise.

Incorrect operation of air exchange leads to a decrease in heating efficiency and interruptions. This may be one of the failure factors. Check for tightness and absence of dirt and debris.

Calculation of the ventilation system

It is recommended to calculate ventilation in a room with a gas boiler, taking into account the following parameters:

- boiler room volume;

- air mass speed;

- air exchange rate;

- number of family members.

Taking these parameters into account, the required exhaust cross-section for a gas boiler is calculated, while there is no need to calculate the diameter of the inlet opening, since these dimensions must be equal. If the boiler room already exists, but the diameter of the exhaust duct is less than the calculated one, additional forced ventilation must be done. You can use different methods for calculation, two of them are given below.

Calculation of ventilation based on the number of air exchanges:

L = N × S × N, where:

L—boiler power kW/h;

N is the air renewal rate;

S—boiler room area;

H - height to ceiling in m.

Calculation of ventilation by number of family members:

L = N × Lн, where:

L—boiler power kW/h;

N is the number of family members in the house;

Lн - minimum air consumption per person:

during rest - 20 m³/h;

with passive activity - 40 m³/h;

during physical activity - 60 m³/h

Selection and installation of equipment

Natural air exchange in the boiler room is achieved through supply and exhaust ducts.

When installing the supply duct you must:

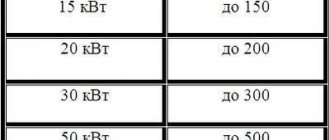

- Prepare a piece of plastic pipe, filter mesh and check valve. The cross-section of the pipe is selected depending on the power of the boiler. In the case where the productivity is less than 30 kW, then 150 mm is enough. The greater the power, the larger the cross-section.

- To create the correct combustion process and appropriate exhaust in a private house, the air supply must be created as close as possible to the boiler firebox. Therefore, a hole in the wall must be punched opposite the burner, but not above its working area. A piece of pipe is inserted into the hole, and the cracks are sealed with foam.

- The outside of the pipe is covered with a mesh to protect it from insects and small animals. A check valve must be installed inside the pipe to protect against backdraft to the street.

- Exhaust pipes in the boiler room with natural ventilation are installed only vertically, and their height should not be less than 3.5 m.

Nowadays, many users do not question the choice of one or another supply ventilation, since the optimal solution would be to install a combined air exchange system.

Chimneys

Chimneys are divided according to the type of installation: - External attached - Double, horizontal, that is, coaxial turbocharged - Internal vertical - Horizontal chimney Horizontal chimneys are very easy to implement, you just need to make a hole in the side wall of the boiler room. Such chimneys are made only with forced ventilation of exhaust gases. Since side winds can disrupt the natural release of gases. The height from the exit pipe from the building to the street floor (ground) should not be less than 2 meters. It is especially problematic to do this in basements, where when exiting through the side wall we do not have enough height from the street floor. The low altitude is fraught with the possibility of snow accumulations in winter, which may prevent exhaust gases from escaping.