For safe operation of a gas boiler, it is necessary to ensure complete removal of combustion products. If the chimney diameter is incorrectly selected, they can enter the room, which will lead to carbon monoxide poisoning. The danger is aggravated by the fact that combustion products are odorless and colorless, so it is impossible to determine the location of the leak without a special device.

Which chimney is best for a gas boiler?

The durability of the channel depends on the material. It must withstand high temperatures, moisture and acid produced during gas combustion. The material should be chosen light enough so that you do not have to strengthen the walls and foundation of the building. For production are used:

- Stainless steel is resistant to most types of corrosion, lightweight, and is considered the best option. Provides reliable traction for 15 years.

- Aluminum is also durable, but due to its low mechanical strength it is used only for interior decoration.

- Enameled pipes are produced with built-in thermal insulation, which simplifies the installation of the chimney.

- Galvanized steel will last a maximum of 5 years, as it will lose its tightness under the influence of fumes of high acidity.

- Ceramics - the service life of such products reaches 30 years. European manufacturers reinforce them with beautiful steel frames. However, due to the heavy weight, sometimes it is necessary to take measures to strengthen the walls and foundation. Such structures provide maximum traction only in a vertical position, which is not always possible to realize.

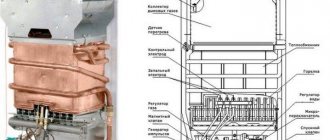

- Sandwich chimneys - consist of two pipes inserted into one another, with insulation between them. Due to 2 layers of metal they are highly reliable. Durability depends on the material of the inner tube. No additional insulation is required during installation.

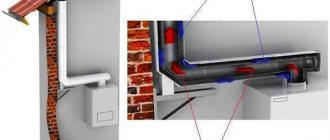

- Coaxial chimneys also consist of two pipes, but the space between them is used to supply air to closed-type gas boilers from the street. They are produced in modules, convenient for quick assembly.

- Brick chimneys are heavy, so they require a foundation. Due to the rough walls, the draft is not at its best, which leads to the accumulation of soot on them. Therefore, the pipe will have to be cleaned twice a year. In addition, brick is hygroscopic, absorbs condensation and quickly collapses. But a preserved chimney can be used as a protective frame if you insert a stainless steel pipe into it with a condensate collector at the bottom.

- Asbestos-cement channels are cheap, but are rarely used, as they are prone to cracking and the release of carcinogens when overheated.

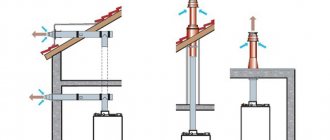

Depending on the installation method, chimneys can be external or internal. Which one is better to choose depends on the type of building and location of the boiler. External channels lead horizontally to the street and are attached to the external wall. They are easier to install; you just need to follow the fire safety rules when arranging the hole if the house is built from flammable materials. However, careful insulation and installation of a condensate collector will be required.

The internal chimney is discharged through the ceilings and roof, which is not always acceptable in multi-story buildings. Installation is complicated by the installation of several special passage units that ensure fire safety.

Errors in selection and arrangement

When building a house, errors in the selected heating system and gas equipment occur at different stages:

- the type of boiler was not taken into account during the design - after construction is completed, it may be necessary to rebuild the entire ventilation system;

- unsuccessful form - an abundance of turns reduces traction, in some cases provokes the movement of air from the pipe into the room;

- there is no possibility of cleaning, which can be hampered by sharp turns and the lack of technological holes;

- purchasing materials from different manufacturers - components for composite pipes may differ in geometric dimensions, which leads to air leaks or leaks of combustion products into the room;

- non-compliance with the height of the chimney on the roof, leading to reverse draft;

- incorrect choice of materials for the pipe;

- insufficient insulation.

Guiding documents allow independent construction of chimneys for gas boilers. The gas supply organization will not accept improperly installed chimneys for operation, and hidden defects can lead to accidents. It is necessary to study in detail the rules provided for by the governing documents; if you doubt your abilities, it is better to entrust construction to professionals.

Calculation of the chimney cross-section for a gas boiler

To accurately determine the parameters of the system through which combustion products are removed, complex calculations are made. This takes into account the shape and material of the pipe, the average temperatures outside and inside, the roughness of the walls, and more. However, the cross-section of the chimney (F, m²) can be calculated with sufficient accuracy for practical purposes using the formula:

F = (K ∙ Q) / (4.19 ∙ √ˉ N),

- K – coefficient from 0.02 to 0.03;

- Q – boiler power in kW, indicated in the data sheet;

- H – chimney height in meters.

The result obtained must be checked for compliance with SNIP 2.04.05-91 and, if necessary, adjusted. The regulatory document states that, depending on the power, the internal cross-section of a round chimney should be:

| power, kWt | Diameter, mm |

| 24 | 120 |

| 30 | 150 |

| 45 | 170 |

| 55 | 190 |

| 80 | 220 |

| 100 | 230 |

For gas boilers with a rectangular chimney, the size is selected:

| power, kWt | Section, mm |

| less than 3.5 | 140×140 |

| 3,5 — 5,2 | 140×200 |

| 5,2 — 7,3 | 140×270 |

It is possible to install square-shaped pipes if their parameters meet the requirements, but it should be taken into account that they tend to accumulate soot. Therefore, such products will have to be cleaned more often, otherwise reducing the hole will negatively affect the operation of the system. If two boilers are supposed to be connected to the chimney, the cross-section is calculated based on their total maximum power.

Formula for calculating the optimal design

The formula for calculating the parameters of a chimney combines several conditions, each of which is calculated separately, analyzed and added to the marking scheme during installation. This formula shows:

- flue gas movement speed;

- chimney length;

- sectional shape of the structure;

- channel area;

- room height;

- chimney material;

- average internal and external temperatures;

- how much does free fall accelerate?

- pipe wall smoothness coefficient.

For example, the pipe cross-section (F) in m2 is calculated using the following equation:

(КхQ)/(4.19х√ˉh)=F,

in which K is a coefficient (calculated empirically), Q is an indicator of the degree of performance of a gas boiler (power, kW, indicated in the technical data sheet of the boiler), and h is the height of the chimney.

To calculate the value of gravity (mm water column), the effective height of the chimney is multiplied by the difference between the air density and the density of the flue gases.

Calculation formulas identify new parameters and check the correctness of the calculation. This is how they check the correctness of the calculations of the dimensions of the chimney length using the formula:

P*L>S,

in which P is the perimeter of the cross-section of a square pipe, L is the length of the chimney, S is the area of the inner surface of the pipe. For a pipe with a round cross-section, the P indicator is replaced by I. I can be calculated using the formula I = 2пR, where R is the radius of the pipe.

Other indicators regarding the technical characteristics of the boiler, the gas supply rate to the device, which will be needed for calculations, are in the passport documentation.

Dependence of length on boiler power and pipe cross-section

“Smoke stack” in section or “Where is the diagram, brother?”

This paragraph provides a diagram of a chimney for a solid fuel boiler - it is quite universal and can be used in many installation cases. This option is suitable for installation in any type of house, with any type of wall material - from brick and monolithic concrete to a wooden frame.

A typical chimney diagram for a solid fuel boiler implies the possibility of leading the chimney through the wall to the side and then upward, or through the ceilings vertically upward and then through the roof.

If we talk about the effective removal of flue gases from the furnace, the main factors influencing the efficiency of this process will be:

- Chimney height

- Chimney diameter

- Length of acceleration section

- Chimney insulation

These 4 points are important, the rest are optional.

Pipe material requirements

In addition to supplying air to the burner and good draft, the chimney exhibits:

- corrosion resistance;

- endurance under extreme temperatures;

- resistance of the coating to aggressive chemical environments.

The indicators of these quantities are taken into account in the calculations and influence the choice of chimney material and the operating features of the gas boiler. So, the combustion products emitted by the device are at a low temperature (about 150 ° C compared to 300-600 degrees for solid fuel boilers) and the rate of their removal through the chimney is also low. The smoke cools down faster than it reaches the dew point and forms condensation inside the chimney. Therefore, important quantities for calculating the dew point are:

- density of water vapor in combustion products;

- fuel composition and moisture content;

- excess air and temperature in the coefficient.

In addition, information about the technical data, materials and design of the pipes can ensure high performance of the chimney. The most preferred ones include:

- ceramic;

- steel (sandwich pipes);

- condensation

It is impossible to use a brick chimney under a gas boiler: it does not resist condensation well and is destroyed under its influence, it is not sealed and provokes the leakage of combustion products. It is undesirable to use pipes with a square cross-section; they are inconvenient to use, accumulate soot, and distort the operation of the boiler. The optimal shape is a circle or oval with smooth inner walls.

Boiler rooms for solid and liquid fuel boilers

The following types of liquid and solid fuels are used to heat residential buildings:

- coal;

- fuel oil;

- gas oil, gasoline;

- diesel fuel;

- working off;

- kerosene;

- wood waste, pellets, firewood;

- oil shale;

- peat;

- petrol;

- vegetable or machine oils.

As a rule, floor-standing units are designed for the use of solid or liquid fuel. Loading requires fairly large chambers, and after combustion, waste is generated. Therefore, such boilers are less compact than gas boilers.

When building a boiler room in a private house with your own hands, you must comply with the same requirements as for gas boiler rooms, but with some additions:

- solid fuel and liquid boilers cannot be installed in residential premises due to strong odor or dust; for this purpose, an extension or a separate furnace room must be installed;

- To install a floor-standing boiler, a concrete foundation with a thickness of at least 50 mm is installed.

- there must be easy access for loading, cleaning the boiler, repairing and replacing parts;

- there must be at least 2 m from the place where the fuel is placed to the nearest wall;

- It is advisable to place the chimney closer to the ridge to create good draft;

- smoke exhaust is arranged through a chimney in the main wall or a pipe outside the house, and it should not coincide with the window openings;

- the chimney is made of a sandwich pipe with insulation and an internal heat-resistant layer of steel or brick;

- You cannot build an attic or living room above the boiler room;

- In the room where gas equipment is installed, flammable materials and chemicals that emit flammable vapors must not be stored.

To prevent dust from accumulating in the boiler room, which adversely affects the operation of the equipment, a supply opening is installed at a height of 30 cm from the floor, and an exhaust opening is located under the ceiling. Ventilation of the room should be natural.

You can quickly build a boiler room in a private house with your own hands if you use ready-made modular structures. During their production, all standards and requirements are taken into account.

A mini-boiler house can operate on any type of fuel and heat a residential building or cottage. The structure is installed on a monolithic or prefabricated foundation and connected to the heating system of the building. When using gas, the project must be agreed upon with the gas distribution organization.

How does calculation affect installation work?

Calculating the chimney for installation is important, since this stage is fundamental and work begins with it. In addition to these nuances, SNiP requirements put forward several more points that are taken into account when arranging for the removal of combustion products during installation. These include:

- 2 gas channels can be connected to one chimney at a distance of at least 750 mm;

- when assembling the pipe, a minimum number of narrowings, bends and horizontal sections are allowed (no more than 3 on one vertical riser), otherwise the traction will be disrupted;

- the cross-sectional diameter corresponds to the dimensions of the outlet channel of the pipe located on the gas boiler;

- the drainage system is made at a height of 5 meters and is insulated with insulating materials, the joints are treated with sealants;

- in the drainage device, vertical deviations are allowed no more than 30%;

- There is a condensate collector at the bottom.

Standards for the location of chimneys relative to their height

The video below describes how the chimney height is calculated using the example of 3-D modeling.

Alternative" calculation methods

Even when correct calculations are used, gas boilers are operated correctly: do not overheat, do not set to maximum power, and are cleaned once a year. It is recommended to rely on the help of professionals for cleaning, installation and calculations.

They use consultations in centers where a gas boiler is purchased, which will provide detailed information with the installation requirements for the selected model, or use free online programs for quickly calculating chimney parameters (for example, EN13384, JEREMIAS).

Installation of boiler equipment and its efficient operation is impossible without a chimney.

The correct choice of materials and compliance with standards when connecting is the key to your safety.

Gas services strictly control the commissioning process and may fine violators or forcibly disconnect the user from the gas supply.

Boiler room

Gas equipment is connected directly to the boiler room. Relative to the house, furnaces can be located:

- inside - built-in;

- nearby on a separate foundation - attached;

- at some distance - separate.

Depending on the location, the premises are subject to certain requirements aimed at ensuring safety during operation.

Built-in

According to SNiP, gas equipment with a power of up to 350 kW is allowed to be installed inside the house. Boilers up to 60 kW can be placed in any room. As a rule, this is a kitchen or domestic premises. More powerful heat generators are located on the first or ground floors, in the basement.

The ceiling in the room should not be lower than 2.5 meters. Ventilation is calculated to replace air three times within an hour, that is, the cross-section of the ventilation ducts should ensure the rate of natural circulation of an amount of air equal to triple the volume of the room.

The size of the window opening minus the sashes must meet the explosion safety requirements. In accordance with it, the area of easily removable structures, in this case glazing, is calculated from the condition of 0.03 m² per 1 cubic meter of room.

When the power of the heating unit is over 150 kW, the room is equipped with a separate exit. Regardless of the characteristics of the boiler, a passage along the front of at least 1 m is left.

Attached premises

An attached boiler room with heating units with a power of up to 350 kW is placed along the blank wall of the house. Set aside at least 1 meter from the nearest door or window opening. The furnace structure should not be rigidly adjacent to the foundation, walls and roof of a residential building.

The material for the walls of the boiler room is selected taking into account the minimum fire resistance limit - 0.75 hours. The structures should not burn or support combustion.

The height of the boiler room inside is at least 2.5 m. The equipment is placed so that it is convenient to service it. The size of the free area in front of the boiler is 1x1 meter.

The attached premises are equipped with a separate exit to the outside. The door should open to the street.

Natural light is a must. The glazing area is at least 0.03 m³ per 1 m³. The hood must support three hourly air exchanges.

The door leading to a residential building is made of fireproof materials. It must comply with the third type of fire safety.

Installing a gas boiler in the kitchen

When installing a gas stove, water heater and boiler with a power of up to 60 kW in the kitchen, the following requirements are imposed on the room:

When installing gas-using equipment, they are guided by the manufacturer’s passport. The walls must be made of fireproof materials, and the distance to the unit must be at least 20 mm.

It is allowed to install boilers near walls made of combustible materials, provided that the surface is protected with a 3 mm thick asbestos sheet and roofing steel or plaster. In this case, at least 30 mm should be removed from the enclosing structures. The insulation is extended beyond the dimensions of the equipment in height and width by 10 and 70 cm.

The floors under the boiler also protect against fire. Sheets of asbestos and metal are laid on them so that their boundaries exceed the dimensions of the body and protrude by 10 cm on all sides.

Material requirements

Basic requirements for materials:

- fire resistance;

- anti-corrosion properties;

- resistance to the effects of acid formed as a result of the interaction of condensate with combustion products;

- long period of use.

Brick chimney. It has low draft and is prone to rapid destruction due to the formation of abundant condensation on the surface, which turns into an ice crust during the cold season. Ideal only for fireplaces or as a kind of cover for a stainless steel chimney.

Made from stainless steel . It has a lot of advantages, which makes it one of the first in popularity among its peers. It has good traction, fire resistance and anti-corrosion, and a long service life (especially dual-circuit models). The modular assembly method allows you to create steel chimneys of different configurations and is accessible even to a non-professional. Compatible with high-power boilers. Will serve you for 15 years.

Service life – maximum 5 years.

Ceramic chimney. Externally, it is as massive as brick. The installation option is strictly vertical only. Austrian manufacturers have developed models of ceramic chimneys with an external contour not only made of ceramics, but also of metal. They are much lighter, but when installing them you need to calculate the loads on the foundation and walls. Warranty up to 30 years.

Asbestos cement pipes . Short service life (5 years), difficult to install, not environmentally friendly. Even the low price of the material cannot serve as a compelling reason to choose such a chimney. Overheating can simply rupture the pipe. Suitable for occasional use in the countryside.

Coaxial - made of aluminum in the form of two sandwich pipes with different diameters, located one inside the other. The external one is intended for supplying air, and the internal one is for removing combustion products. The structure is prefabricated. The location is most often horizontal.

Advantages of a coaxial chimney:

- Safety

- Increased efficiency of the heating system

- Environmental friendliness

Do-it-yourself air conditioner installation and rules for its use, details here.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation

Chimney elements

Regardless of the material, the design includes the following elements:

- Tee with revision - a fitting for condensate is installed at the bottom of the tee

- Adapter for connecting the gas boiler pipe and the chimney

- Fastenings - brackets and clamps

- Cone shaped tip

- Bends - installed no further than 2 meters from the beginning, otherwise the boiler draft is reduced;

- Feedthrough

- Telescopic pipes

How to calculate the chimney diameter

Key parameters are cross-sectional area (outlet F cm2).

K - coefficient calculated empirically (0.02-0.03);

Q is an indicator of the performance of a gas appliance (indicated in the technical characteristics of the boiler);

H - chimney height.

The resulting number is adjusted by building codes and regulations.

For example, if brick is used , then the cross-section is 0.5 x 0.5 material. For asbestos cement, the diameter is at least 10 cm.

The diameter of the round chimney with a boiler power of 24 kW should be 120 mm, 30 kW - 130 mm, 45 kW - 170 mm, 55 kW - 190 mm, 80 kW - 220 mm and 100 kW - 230 mm. The minimum cross-section of rectangular channels depends on the thermal power of the boiler:

- Up to 3.5 kW - 14 by 14 cm.

- 3.5 to 5.2 kW - 14 by 20 cm.

- From 5.2 to 7.3 kW - 14 by 27 cm.

Design rules for boilers with natural removal of combustion products

- The chimney pipe must be located above the roof ridge , at least 0.5 meters higher than it, provided that its axis is close to the ridge or parapet (less than 1 m and no more than 1.5 m).

- If the pipe is located further from the ridge (from 1.5 m to 3 m), then its height should be level with the ridge.

- If the chimney is located at a distance of more than 3 m , its height must not exceed the boundary of the line laid down from the ridge at an angle of 10° to the horizontal.

- If you have a flat roof , the height of your chimney should also have a minimum limit of 0.5 m, and in the case of a combined roof - 2 m.

- The system for ejecting combustion products must be fixed to the wall at intervals of no more than 2.5 meters, in areas with a slope - every 1.5 meters.

- The clamp must be used on any connecting section of an insulated chimney.

- The chimney elbow must have a slope angle of at least 15° and no more than 90° (no more than three rotary elbows are allowed in the system). The vertical section following the turn must be clearly secured with fastenings. It is prohibited to load inclined sections of the pipe or its bends.

- It is mandatory to equip the chimney with a condensate drain , which must be accessible for maintenance.

- The chimney must be insulated from flammable materials using brickwork or asbestos board . The distance from the connecting pipe to flammable surfaces must be at least 25 cm, and if a protective layer is applied - from 10 to 5 cm.

- Stable traction can be ensured if the pipe is erected above the wind support zone.

- Smoke exhaust systems built inside the building do not need to be additionally insulated , but it is necessary to take care of the tightness and ventilation system. Toxic smoke can easily seep even through the brickwork of the protective casing.

- Areas located outside the structure are insulated . In the absence of thermal insulation, the gases quickly cool, the draft decreases, and the boiler power drops. Condensation forms on the walls.

We assemble an air dehumidifier with our own hands: diagram and principle of operation.

If the air in your child's room is too dry, you should consider buying a humidifier.

Installation options for chimneys

It is necessary to build a foundation under the internal chimney. If you also add a protective brick channel, this will minimize the amount of condensation. Sometimes chimneys are attached from the outside to the wall behind which the unit is located.

Internal design of the chimney

Before proceeding with the installation of the chimney, select a location for it. Then mark the places where it will pass through the ceiling and roof. Carefully check the accuracy of the markings and make openings. The next step is to connect the boiler pipe to the chimney, and then install the revision and tee.

A sheet of steel is fixed, the main bracket is installed, the pipe is extended, if necessary, “elbows” are used. In the area of contact with the ceiling, pipes are used. Take a sheet of galvanized steel with a hole such that a pipe can pass through it freely, and attach it to the ceiling. Clamps are used to strengthen joints. Every 2 m the chimney is secured with clamps, and every 4 m - with brackets.

The work is completed by checking the seams for leaks. To do this, take a soap solution and apply it to all joints. If everything is done efficiently, then when connecting the unit to the chimney, bubbles will not appear in these places.

External structure device

For an external chimney, a hole is made in a blank wall of such a diameter that a pipe with insulation can freely pass through it. Having installed the first element of the future chimney into the hole, secure it and wrap it with insulation. The next sections are added from the street side, controlling the verticality using a plumb line.

An external chimney is safer, but it needs to be well insulated. All elements of the purchased design are well matched, so assembly will not create problems

The pipe is fixed to the wall with brackets until it reaches the desired height. The process is completed by attaching the pipe to the boiler nozzle and sealing the joints. To ensure that the external chimney warms up quickly, it is insulated along its entire length with basalt wool.

Installation of a coaxial chimney

This type of chimney removes combustion products outside and at the same time supplies the boiler burner with oxygen-rich air. With this design, no additional ventilation is needed.

The chimney is made of round pipes - an outer steel pipe with a cross-section of 10 cm and a wall thickness of 0.1 - 0.2 cm and an inner aluminum pipe with a diameter of 6 cm. The pipes do not touch because there are jumpers between them.

Coaxial chimneys are installed for boilers with a closed combustion chamber, designed for wall and floor installation, as well as for water heaters and other gas units.

This gas outlet has several advantages:

- Structurally, the pipe is designed so that simultaneously with the heating of the incoming air, the exhaust gases are cooled;

- the chimney increases the efficiency of the equipment;

- It has compact dimensions, so it is used not only in private houses, but also in city apartments;

- safe - the exhaust gases do not come into contact with the room air and do not exit through the ventilation duct but directly into the atmosphere;

- easy to install.

Install a coaxial chimney both horizontally and vertically. Regardless of the installation method, the maximum length of the chimney should not be more than 4 m. There are models with solid parameters created specifically for long-distance chimney removal.

Directly for the installation of a coaxial chimney, manufacturers produce specially designed adapters used for vertical transitions through floors and roofs. To protect the system from precipitation and ensure tightness in the area where the pipe passes through the ceiling, there are special caps.

The figure shows tips and mandatory requirements for installing a coaxial type chimney. All of them relate to gas outlets for boilers whose power does not exceed 70 kW

If a coaxial chimney is used for a boiler installed on a wall, it should be positioned horizontally. In this case, it is necessary to ensure a 3-5% slope, otherwise condensation will enter the boiler.

The standards regulate not only the dimensions of the chimney itself for a gas boiler, but also the location of the hole in the wall. It should be at least 50 cm away from the window next to it and at least 25 cm if it is located above the window.

Requirements for installation of coaxial chimneys

When installing the smoke duct of such boilers, it is necessary to keep in mind that:

- When the length of the coaxial pipe is no more than 1 meter, it is necessary to install a tapering diaphragm on the air duct . The power of the fan in the chimney is designed for a certain pipe length and, if it is less, there will be a loss of draft with all the ensuing consequences.

- The pipe is located in a horizontal plane , but still must have a slope of 1 cm for each meter of total length and no more than two bends.

- The head of the pipe can protrude outward no more than the length of its tip - to protect against freezing, and no lower than 2 meters from the surface of the earth.

What do SNiPs say?

The installation of smoke ducts for gas boilers is regulated by SNiP 2.04.05-91 , as well as DBN V.2.5-20-2001

- One boiler - one chimney. Combining, installing tees, etc. is prohibited.

- Combustion products must be periodically cleaned out ; for this purpose, pockets with a depth of 250 mm are equipped.

- Pipe height is at least 5 meters.

- The elevation of pipes above the roof must be arranged taking into account clause 3.73. from SNiP 2.04.05-91.

- The diameter of the chimney pipe must be no less than the diameter of the pipe outlet of the boiler itself.

- checked and cleaned annually before the heating season.

To learn how to choose and install a chimney correctly, watch the video:

>