Installation of boiler equipment and its efficient operation is impossible without a chimney.

The correct choice of materials and compliance with standards when connecting is the key to your safety.

Gas services strictly control the commissioning process and may fine violators or forcibly disconnect the user from the gas supply.

Requirements for chimneys of gas boilers

Heating with main gas is the most convenient and cheapest (the cost of connection is included in brackets); If the homeowner has the opportunity to install gas into the house, he rarely doubts. But, speaking in the dry language of official interviews, “for the safe operation of gas equipment, the removal of gas combustion products must be ensured, which is why such great importance is given to the proper operation of smoke channels.” Not even the quality of life, but life itself depends on the quality of the chimney of a gas boiler, which is why compliance with the requirements for the smoke ducts of gas boilers is so strictly controlled both in Moscow and in the most remote village.

These requirements are specified in a number of documents, including SNiP 2.04.05, SNiP-91. SP 7.13130.2013 and clause 5.1.1.VDPO. The manufacturer's recommendations are also always taken into account. Here are the main provisions from these documents:

- The draft must be such as to completely remove exhaust gases;

- The chimney must be resistant to high temperatures;

- According to SP 7.13130.2013 Heating, ventilation and air conditioning. Fire safety requirements, the height of the chimney cannot be less than five meters. It should protrude no less than 50 mm above the flat roof; no less than 500 mm - above the roof ridge or parapet (if located at a distance of up to 1.5 m from them); be not lower than the ridge of the roof or parapet (if located at a distance of 1.5-3 m from them) and not lower than a line drawn from the ridge down at an angle of 10° to the horizon (if it is located at a distance of more than 3 m from the ridge.

- If exhaust ventilation ducts are located near chimneys, they should be the same height as these pipes.

- The components of the chimney along its entire length must be sealed, and where it passes through the ceilings the pipe must be solid and without joints;

- The smoke exhaust system must include a condensate collector;

- The wall of the metal pipe is made of high quality alloy steel with an anti-corrosion coating.

During installation work, the following rules are taken into account:

- Each boiler must have a single chimney;

- The height and cross-sectional size of the chimney pipes must be correctly selected for free and complete smoke removal;

- The distance between chimney pipes and surfaces depends on the materials from which these surfaces are made; For non-combustible materials, a gap of 50 mm or more is established, for flammable materials - 25 cm or more.

Mr LeshiyFORUMHOUSE Member

For a gas boiler, 0.5 mm thickness is enough - the main thing is that the steel is grade 300, AISI 304, 316, 321.

- To clean smoke channels from soot, you need recesses of about 250 mm;

- There may be bends on the chimney pipes, but no more than three, their rounding is equal to the diameter of the pipe, there should be inspection hatches at the bends;

- It is recommended to install umbrellas and caps on chimneys.

Region190FORUMHOUSE participant, master inspector at VDPO

Collect condensate. The hatch for cleaning the chimney must be 25 cm lower than the tee (15-20 cm will be accepted, 10 cm will be clever). The acceleration section (straight pipe from the boiler) is at least 700 mm. Smoke turn - no more than three (a tee and two elbows, it is better to have two). The horizontal section is no more than 3 meters. Tee - 90 degrees (not all gas trusts will accept 45, they have their own recommendations and rules and they don’t care what is written in the boiler instructions). The distance of the monopipe from flammable materials is 25 cm, from non-flammable materials is 5 cm; thermal pipes - 5 cm. Do not touch the gas pipe under any circumstances; the chimney - gas duct is at least 5 cm from it!

Fire requirements

According to SNIP, the chimney and ventilation ducts must be checked and cleaned:

- Before the start of the heating season - chimneys in which boilers and heating devices operate seasonally.

- At least once a quarter - combined and brick chimneys.

- At least once a year - asbestos-cement chimneys and channels, pottery, made of heat-resistant concrete .

The initial inspection of gas boiler chimneys should cover the following points:

- correct use of materials is carried out in accordance with the requirements of DBN V.2.5–20;

- presence of clogged channels;

- checking partitions that serve as protection for combustible structures;

- How separated are the ventilation and smoke ducts;

- how serviceable and correctly positioned the head is;

- checking the presence of normal draft, this parameter depends on the correctness of the construction, in particular, the height and cross-section of the pipe have an influence (see How to improve draft).

The ventilation and chimneys are checked again for blockages, their separation and density, and the draft is checked:

- Inspections for the first time and after repairs of ventilation and chimneys are carried out by specialists. organization with the participation of the operating organization. The results obtained are included in the act.

- If the ventilation ducts and chimneys of gas boilers are recognized as unusable and not subject to operation, the inspector is obliged to warn the owner in writing about the dangers of using gas appliances.

- Chimney SNIP in private houses allows owners to clean ventilation ducts and chimneys if they have a document confirming that they have undergone training.

- Before starting repairs of ventilation passages and chimneys of gas boilers, the operating organization, which is the owner of the apartment building, is obliged to warn residents about the start of work. After completion of the repair, all chimneys and ventilation ducts should be checked.

Requirements for premises when placing gas appliances in them

The chimney must meet established standards!

- SNiP 31-01-2003 - on multi-apartment residential buildings;

- SNiP 41-01-2003 - everything about air conditioning, ventilation and heating is stated;

- SNiP 42-01-2002 - instructions on gas distribution systems;

- SP 31-106-2002 - will talk about the creation of a project and the construction of single-family houses used for living;

- SP 42-101-2003 - on the construction and design of gas distribution systems from pipes of various inlets.

What the letter of the law says:

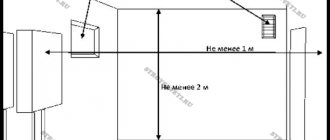

- The room in which the gas water heater will be placed and the chimney of the gas boiler will be provided for the removal of combustible products must meet certain requirements; not only the area, but also the height of the ceilings is regulated. So, the ceiling height should be at least 2 meters. The volume of space is not less than 7.5 m³ for installing one device, and not less than 13.5 m³ for two units.

- The room must also be equipped with a ventilation duct. A grate or passage between the floor and the door should be provided at the bottom of the door or wall, where the open cross-section should be at least 0.02 m² .

- Attention: It is unacceptable to exhaust smoke into the ventilation duct. It is prohibited to install ventilation grilles on smoke ducts.

- In rooms with a standard hood, it is necessary to compensate for the removed air by penetrating it from outside the room, as well as by replacing it from the remaining areas of this apartment.

- Attention: When installing airtight windows in a room, the speaker may turn off due to inconsistent air supply. This is due to the automation of the column itself.

- In the bathroom and utility rooms, doors should open outward.

- The installation of sockets and switches in the bathroom is strictly prohibited.

The principle of operation of the chimney

As with any heating system, a chimney for a gas boiler is needed to release combustion products into the atmosphere and supply fresh air for complete combustion of the fuel. How it works: in accordance with the law of physics, according to which light warm air tends upward, cold air settles below. Draft in the chimney appears due to the temperature difference: hot gases in the pipe and cold air outside.

If the chimney is installed correctly, it is not only safe, it improves the quality of the boiler’s operation and increases its efficiency, making the microclimate in the house more comfortable.

The chimney for a gas boiler is a complex structure, which includes:

- Smoke exhaust pipe;

- An adapter that connects the pipe and the boiler pipe;

- Branch pipe for passing the chimney through the wall, ceiling, roof;

- Fastening elements;

- Condensate collector;

- A tee with a fitting is necessary for draining condensate;

- Bends.

This is the basic configuration, there may be different variations.

Ventilation in the house

The house must use forced exhaust ventilation and forced supply ventilation. This is due to maintaining a normal draft level and preventing combustion products from entering the room.

It is also forbidden to combine a chimney with a ventilation duct and use the chimney as ventilation.

|

Types of chimneys for boilers

There are different types of chimneys that are used in these cases:

A brick chimney is made of fireclay bricks, which are placed either on clay mortar or glue. In most cases, it is made with a stainless or galvanized steel sleeve inside to protect the brick from the destructive effects of carbon dioxide.

Region190FORUMHOUSE participant, master inspector at VDPO

Over time, the brick will begin to crumble due to carbon dioxide, so the chimney must be lined. In the market you can be deceived with the steel grade; it is better to buy AISI 316 directly from the factory. This acid-resistant steel works reliably with any brand of boiler. Not a single inspection master will ask you about the steel grade or demand a certificate; we do not have the authority to do this, and it is impossible to visually distinguish 316 from 425.

The main disadvantage of such a chimney is that it is heavy, you will have to make an additional foundation, and it is bulky, and you will have to look for a stove maker who will lay it out. Previously, such chimneys were often made for gas boilers; now (if funds allow) homeowners prefer ceramics.

Ceramic chimney . This is a complex structure that includes a ceramic smoke exhaust duct, an air layer (or insulation) and an expanded clay concrete shell. Expanded clay concrete protects the fragile ceramic pipe and serves as insulation (and ceramics have high thermal conductivity).

Andrey50FORUMHOUSE member

Cool specialists with extensive experience in chimneys say that ceramics are the best, but unreasonably expensive.

It is much easier to install such a structure than a brick chimney; it is durable, fireproof (can heat up to 120 degrees), but it is also heavy and bulky, and also expensive.

Asbestos-cement chimney. For this type, it is important to have tight joints inside the channels and good insulation to prevent condensation from forming.

RegularUser .FORUMHOUSE

During my construction period, asbestos-cement pipe was the cheapest option. The main problem here is how to hermetically join the segments; I couldn’t get it to be hermetically sealed. Simply pouring concrete is not an option. It should be a sealed sleeve, clamp, insert, anything that provides a reliable and tight connection. Be sure to insulate your asbestos-cement pipes. Do not forget that the design of the chimney should not allow condensate to drain into the boiler and be sure to make a condensate collector at the bottom at the base of the pipe.

Single metal - chimney made of galvanized or stainless steel.

Sandwich chimney. Such a chimney is made of two metal pipes, one is inserted into the other, and insulation is laid between them. Smoke flows through the inner cylinder. This type is required for use as an external chimney and in unheated rooms.

Coaxial. In this chimney, one pipe is inserted into another without laying insulation. But this is a single rigid structure, united by jumpers along its entire length. Smoke exits through the inner pipe, and air enters the combustion chamber through the outer pipe; the room air does not participate in the operation of the gas boiler, the microclimate is maintained.

Mr LeshiyFORUMHOUSE Member

Sandwich is an insulated chimney made of two stainless steel cylinders, between which insulation is stuffed. Coaxial - the same two cylinders, but without insulation inside. Exhaust gases are removed through the inner cylinder to the outside, and air is supplied into the combustion chamber through the gap between the cylinders.

By condensation or smoke

We must not forget about the main feature of the chimney for a gas boiler: they have high efficiency and a fairly low temperature of the exhaust gases:

Condensation always and quickly forms in the chimneys of a gas boiler.

Therefore, the chimney installation must be done in such a way as to solve the condensation problem. Due to the low temperature of the exhaust gas, chimneys on modern gas boilers are made “through condensate” and not “through smoke”.

VadimProFORUMHOUSE Member

For smoke, this is when the pipe of the lower bend goes inside the pipe of the upper bend, and, accordingly, for condensate - vice versa.

Chimneys for modern gas boilers are collected strictly according to condensate.

This installation method allows condensate to flow calmly down inside the chimney without leaking out (this is dangerous and can cause a fire).

What do SNiPs say?

The installation of smoke ducts for gas boilers is regulated by SNiP 2.04.05-91 , as well as DBN V.2.5-20-2001

- One boiler - one chimney. Combining, installing tees, etc. is prohibited.

- Combustion products must be periodically cleaned out ; for this purpose, pockets with a depth of 250 mm are equipped.

- Pipe height is at least 5 meters.

- The elevation of pipes above the roof must be arranged taking into account clause 3.73. from SNiP 2.04.05-91.

- The diameter of the chimney pipe must be no less than the diameter of the pipe outlet of the boiler itself.

- checked and cleaned annually before the heating season.

How to choose the type of chimney

Choosing a gas boiler chimney for our user with the nickname gladiator was not easy, there was too much to consider, and the initial data did not allow us to arrive at the optimal result.

You can lay out a brick chimney and then insert a stainless steel sleeve into it, but according to calculations, a floor made of floor slabs simply will not withstand the load from a brick chimney;

You can install an expensive ceramic chimney system from a well-known one.

You can make a sandwich, but if it’s inside a building, but how can you secure the floors between floors and then not think about what the temperature is there; and how do you know when it’s time to remove the pipes from the wall and change the system? You can make an external chimney, but it would be a pity to spoil the appearance of a private house.

GladiatorFORUMHOUSE Member

Previously, a simple galvanized or brick chimney was made for a gas boiler, but now you don’t know what to choose from.

When choosing a chimney for a gas boiler, experts on our portal recommend taking into account:

- type of combustion chamber, boiler power;

- design features of the house;

- reasonable combination of price and quality.

The choice of boiler depends on the type of gas combustion chamber.

An open firebox is often found in floor-standing gas boilers. Such devices always need good draft, and here a brick and ceramic chimney is preferable; although a sandwich will work too. And we must take into account the design features of the building: a brick chimney is difficult to install and is hygroscopic; and the ceramic chimney is very heavy.

Closed combustion chamber . According to our experts, such devices need a coaxial chimney or sandwich.

The sandwich for a gas boiler looks like a universal model; everyone recommends it.

Alexey TeleginForumHouse user

For gas, a sandwich is ok, but it’s better to make it from acid-resistant 316 steel.

Teplov and SukhovFORUMHOUSE user

For a gas boiler in home use, a sandwich made of 316 steel will last a very, very long time. But change the boiler.

But it is better to choose a chimney for a boiler together with a specialist - this is a more responsible and mature approach. As our experts say, the approach to choosing a chimney system for a gas boiler must be comprehensive, “design/installation/operation” must be taken into account. And it is advisable that everything is done under the guidance of an invited professional.

TraksFORUMHOUSE User

The chimney will be assigned to you by gas workers and reflected in the design. But in addition to a specialist who will accept the completed work, a third-party professional is needed here.

Answers to any complex chimney questions can be obtained here: “Consultations on design standards and rules. If you have any questions about chimneys, just ask.”

Calculation of the required chimney height

When choosing a chimney, its height is taken into account. To determine this parameter, a simplified calculation scheme is often used. However, before calculating the height of the chimney, you need to accurately determine the power of the boiler installation. Therefore, a boiler selection is always carried out first.

The combustion process in a furnace largely depends on draft. It also affects the efficiency of smoke removal. In this case, draft will be present in the pipe only with a constant supply of air to the boiler unit. Its entry into the equipment is carried out forcibly using a special pump or naturally.

Why insulate a chimney pipe

If the chimney pipe for the boiler is cooled in the cold, then the temperature of the exhaust gases decreases - which means the draft decreases. This problem can be solved by insulating the pipe. How to insulate depends on the material from which the chimney is made:

- Brick structures are plastered, and if the attic is not insulated, then stone or basalt wool with foil on top is used;

- Ceramic chimneys are protected from the cold with mineral wool and ceramic blocks, metal ones are insulated with any non-combustible materials;

- The most difficult thing is with asbestos structures - they can explode if they overheat, so they must be insulated competently and carefully.

Number of stoves per chimney

The main rule of SNiP for chimneys: each stove must have its own chimney. If the stoves are located on the same floor of the same house, their chimneys can be combined into a common channel. In this case, a cut of one meter in height is used inside the channel.

According to the requirements, on one floor one stove can heat no more than three rooms and it must have one chimney.

For a two-story house, you can use a two-tier oven. In this case, the stove must have two fireboxes, each firebox with its own chimney.

If you are using a two-tier oven, the house should not have wood floors between floors.

For two-story apartments, a different rule applies. The stove can be used with one firebox on the ground floor.

Gas and smoke: the most important

Here are the most important things to remember when installing a chimney for a gas boiler:

- It has its own characteristics, which are associated with the low temperature of the outgoing smoke, so it must be installed along condensate lines, and a condensate collector must be provided as part of the chimney structures.

- The type of chimney is chosen depending on the power of the boiler and the type of gas combustion chamber; most homeowners like ceramic chimneys, but they are heavy and expensive; Our experts consider sandwiches to be a universal solution, but the quality of the steel is critical here: it should be grade 300, AISI 304, 316, 321.

- Many experts give the following advice: in a private house under construction it is better to provide a ceramic chimney, in an existing one that is connected to a gas pipeline - a steel one;

- The chimney should not come into contact with the gas pipe; a distance of at least 5 cm must be maintained;

- When installing the chimney of a gas boiler in a private house, you must observe all the distances stipulated by regulatory documents (the installation pipe must be no less than 25 cm from flammable materials, and the distance of the thermal pipe from surfaces is 5 cm).

It is recommended for all homeowners to study the regulatory documentation for chimneys, but especially for those who decide to make a chimney with their own hands. Information from our forum on quality criteria for stainless steel chimneys and a thread about a brick chimney system for a gas boiler will help here. Read our article on how to choose a boiler for heating your home. Watch our video on how to properly maintain your chimney to extend its life.

Subscribe to our Telegram channelExclusive posts every week

Installation: recommendations and diagrams, main stages of chimney installation

Chimney installation is divided into several stages - preparatory work, installation itself, then connection, startup and, if necessary, debugging of the entire system.

General requirements

When several heat-generating installations are combined, each of them creates its own chimney. In exceptional cases, a tie-in to a common chimney well is allowed, but a difference in height of at least one meter must be maintained.

First, the chimney parameters are designed and calculated, which are based on the recommendations of gas boiler manufacturers.

When summing up the calculated result, the internal cross-section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to testing according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m/sec. And besides, the cross-section of such a channel must correspond to the overall performance of the unit (8 cm 2 per 1 kW of power).

Installation steps

Chimneys for gas boilers are mounted outside (attached system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney

Installing a chimney on a wall-mounted boiler is done as follows:

A hole is cut in the wall. Then a piece of pipe is inserted into it.

The vertical riser is assembled.

The joints are sealed with a fireproof mixture.

Fixed with wall brackets.

An umbrella protecting from precipitation is fixed on top.

An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and does not allow soot to accumulate. Installation performed by specialists will significantly reduce the cost of maintaining this system.

When constructing an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

The material from which the pipe is made.

External design of the chimney.

Type of roof covering.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced assembly system is considered to be in segments, where all elements are assembled using the cold forming method.

Connecting a ceramic chimney

Ceramic chimneys themselves are practically eternal, but since this is a rather fragile material, you need to clearly understand how to correctly connect (docking) the metal part of the chimney and the ceramic one.

Docking can only be done in two ways

:

By the smoke

– a metal pipe is inserted into a ceramic one. It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply rupture the ceramic one.

For condensate

– a metal pipe is placed on a ceramic one.

For both methods, specialists use special adapters, which, on one side, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped in a ceramic cord.

The joining should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little by the time it reaches the adapter, which ultimately extends the service life of all materials.