To organize heating and water treatment in houses, separate rooms are often required, the so-called boiler rooms, furnace rooms or boiler rooms. Since this room is classified as potentially dangerous, it is subject to certain requirements that are designed to ensure the necessary degree of safety during its operation. Below we will try to figure out what a boiler room should be like in a private house and what requirements and standards are imposed on it.

On July 1, 2003, SNiP 42-01-2002

, which regulates the requirements and standards for installing a boiler room for a private home.

Rules for installing gas boilers

A floor-standing boiler was installed according to the rules.

Everyone knows that gas boilers in the same model range differ in the installation method. There are two groups here - floor and wall units. Their difference is not only that they are mounted differently, but also in different technical characteristics. They differ especially from each other in power.

Floor-standing units are more powerful, while wall-mounted units are low-power. Hence their overall dimensions. Therefore, wall structures are most often installed in apartments, and floor structures are installed in private housing construction.

Requirements for floor-standing units:

- Organization of a separate room where a through hole for air flow is installed in the front door, or a window with a window is installed. The ideal solution is to install a ventilation system where air is removed from the room through a hole in the ceiling.

- Installation of a sealed chimney for a floor-standing boiler. Very often, if a high-power gas boiler is used, a double chimney is installed like a pipe in a pipe. This provides a 100% guarantee of the absolute tightness of the chimney structure.

- The boiler room itself should be spacious with free access to the heating unit for maintenance and repair work. The boiler room must be provided with water supply and sewerage.

- Since floor-standing models have significant weight, a durable floor made of non-combustible materials must be constructed under them. This could be a concrete screed, stone, paving stones, ceramic tiles, etc.

- The front door must meet certain dimensions. The minimum door width is 80 cm. SNiP also determines the minimum dimensions of the room for the boiler room. But life makes its own demands, so the optimal dimensions of the furnace room for the lowest-power floor-standing units are as follows: an area of 4 m², a ceiling height of at least 2.5 m.

- All electrical wiring for the floor-standing unit must be of a hidden type. A separate distribution panel must be installed in the boiler room.

- The walls are finished only with non-combustible materials - plaster, facing bricks, ceramic tiles and so on. It is prohibited to store flammable substances in the boiler room. Do not install a chimney exhaust or ventilation air intake nearby. Both systems should be located in different parts of the room.

Requirements for wall-mounted units

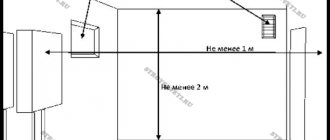

Minimum distance requirements

With this option everything is much simpler. Being installed in the kitchen, it is provided with sewerage, water supply, ventilation, and a gas line. That is, installation and connection costs are reduced significantly, and the cost of the work performed is reduced.

But there are some requirements that must be taken into account:

- Firstly, installing a wall-mounted gas boiler is only possible on a solid wall that can support its weight. Plasterboard or plywood partitions are not suitable for this.

- If the walls have already been finished before installing the gas appliance, and flammable materials were used, then a sheet of non-combustible material with a thickness of at least 3 mm must be installed under the boiler.

- There are minimum distances from the installed gas boiler to the supporting structures of the building. To the walls and ceiling - 0.5 m, to the floor - 0.8 m.

It is prohibited to connect gas boilers with your own hands. This is especially true for the gas pipeline. This has its own requirements, the main one of which is having permission to perform this type of work. If you have it, then there is no problem - you can do everything yourself.

You can adjust the boiler yourself, but we recommend entrusting the first adjustment to a professional

Here it is important to carry out everything in full compliance with the requirements specified in the instructions for the gas boiler

Easy to install

Which boiler, wall-mounted or floor-mounted, is easier to install? It would seem that this question should concern not potential owners of the unit, but exclusively the craftsmen who will be involved in deploying the heating system. However, do not forget that the buyer, that is, you, will have to pay for this, and the more labor-intensive the work, the more money you will have to part with.

In terms of ease of installation, the wall-mounted boiler is the undisputed leader. In the case of a floor-standing unit, you will have to equip an entire boiler room, because in addition to the boiler itself, you will have to install circulation pumps, an expansion tank and, perhaps, a boiler. The scope of work, as you might guess, differs very significantly, and the cost of the work will vary just as much.

Recommendations for choosing a model and its power

According to the installation method, there are 3 types of boilers: floor-mounted, wall-mounted and parapet. Floor-standing ones are rarely used in apartments because they are less compact, require more area around them, and are not so convenient for connecting communications. The best solution for an apartment is a wall-hung gas boiler; most of these models correspond to the size of wall-mounted kitchen cabinets, have an excellent design and fit harmoniously into the kitchen. We recommend choosing a wall-mounted model.

One of the best modern wall-mounted models is Baxi ECO4S 24 F.

Parapet boilers are installed anywhere below the plane of the window sill and are distinguished by the fact that they simultaneously serve as a radiator, at the same time heating the room in which they are located. The chimney for parapet boilers is exclusively coaxial and, as a rule, is included in the kit.

There are single-circuit and double-circuit models. The former are focused only on heating, the latter are equipped with an additional hot water supply circuit. Therefore, if the apartment already has or is planning to install a hot water boiler, a single-circuit model is sufficient. If you want to heat hot water using a boiler, you need to study all the advantages and disadvantages of dual-circuit models.

The power should be chosen after deciding on the model, since in most cases the same model is produced with different thermal power. Calculating the minimum required power is simple: for every 10 m2 of apartment area, 1 kW of boiler power + 15-20% reserve is required. For example, for an apartment with an area of 120 m2, 16-20 kW will be quite enough. If the boiler is not equipped with a modulating burner (with the ability to adjust the flame), you should not go overboard with the boiler power, as this will lead to frequent clocking and faster wear.

How to accurately calculate the required boiler powerIndividual calculation, formula and correction factors

General information about boilers, their placement

Their entry into the body causes disturbances in human life processes. In large doses, the compounds provoke the development of dangerous diseases. Don’t forget about natural gas itself: it is explosive and requires special handling when used.

In private homes, various gas boilers are used, which have different air exchange requirements. For high-power floor-mounted equipment, placement requirements have been established. Such units can be installed in a separate special building, in an extension to the main house, in the attic, basement or basement.

Additional requirements apply to objects where a floor-standing gas boiler is located:

- Area of at least 4 sq. m.

- The volume of the room is at least 8 cubic meters. m.

- The ceiling height is at least 2.2 m.

- The width of the entrance opening is at least 80 cm.

- The presence of at least one window with direct access to the air with opening doors for ventilation.

- The presence of an open air supply is a gap in a wall or window profile through which oxygen constantly flows.

- Since the object is classified as explosive, the glazing area in it must exceed 0.05 square meters. m per 1 cubic meter m. room volume.

The use of a basement and plinth is allowed with restrictions, subject to a number of additional requirements. In such premises, it is necessary to equip the main and backup ventilation systems, since disruption of the air exchange structure will lead to the threat of explosion.

Most often, wall-mounted boilers of low power are used. The average power of such heating units is 30 kW. They are provided with a productive and convenient internal combustion chamber. This equipment is subject to less stringent placement requirements. Wall-mounted boilers can be placed in the utility room, kitchen or bathroom.

A wall-mounted gas boiler can be placed in the kitchen

- Delivery of the volumes of oxygen required for the direct combustion process. If there is insufficient supply of fresh air, combustion provokes the release of excessive amounts of dangerous compounds.

- Optimal conditions are created for efficient operation of equipment.

- Removal of combustion products and the gas itself from the premises in case of equipment malfunction.

Classification of ventilation systems that are used in most private houses:

- According to the principle of creating traction: natural or forced.

- In the direction of movement: supply, exhaust, combined (coaxial).

- By design: channel or integral, without channels.

Factors influencing the parameters of the air exchange system in a room with a gas boiler:

- The power of the device, its functional features.

- Room area.

- Load on the boiler (frequency of use).

- Availability of windows and doors.

- Features of the climate of the area where the house is located (temperature, wind, precipitation, humidity, etc.).

There are several factors that influence the parameters of the air exchange system in a room with a gas boiler

Choosing a boiler for a private home

It is especially important that the required power of the gas boiler is calculated correctly. If you choose a boiler that is too small, it will not be enough for full heating and the temperature in the house will be uncomfortable.

But you shouldn’t choose a boiler that’s too powerful. This results in fuel being used inefficiently and the service life of the equipment is reduced. The choice should be made with some power reserve, since constant operation at the limit of capabilities has a bad effect on the duration of operation.

To make the right choice, you should use a simple formula.

It is necessary to divide the area of the heated room by 10. Next, multiply by the regional coefficient. It directly depends on the temperature conditions of the region where the house is located.

- For temperate latitudes 1.0−1.2

- For northern latitudes 1.5−2.0

- For southern regions 0.7−1.0

These calculations give the approximate required power according to climatic conditions. For a more detailed and accurate choice, you should also take into account the volume of the heated house and the quality of insulation.

How much gas is needed for heating?

Experts in the field of heating equipment calculate the gas consumption for a specific room and recommend a suitable gas boiler. The size of the unit, of course, affects the power, but does not always affect the amount of gas processed. According to the existing formula, the required parameter is determined as:

V = Q / (Hi x ƞ), where

Q—calculated thermal power, kW/h;

Hi—heat of combustion, kW;

Ƞ—efficiency factor.

Thus, if:

- the average boiler power, usually taken as power divided in half, is 5 kW per hour;

- the specific heat of combustion per 1 m2 is determined to be 0.1 kW (for example, for a house with an area of 100 square meters it will be equal to 10 kW);

- The efficiency, according to the equipment passport, is 95%,

then V = 5 / (10 x 0.95) = 0.53 m3/h.

If we calculate that the heating season is 200 days, and more specifically, 4800 hours, then the amount of gas will be calculated as follows:

0.53 x 4800 = 2544 m3.

Rules for installing gas boilers

Before installing a boiler in a private house, it is necessary to prepare some documents and perform certain actions. What you will need:

- Contract for the supply of natural gas for an individual developer;

- The technical conditions and installation project for gas equipment must be agreed upon with the local gas service representative. Project documentation is most often developed by specialized institutes with the appropriate license for this type of activity: gorgaz, raygaz, oblgaz, mingaz, etc.;

- Installation of gas equipment must be carried out by an installation organization;

- An engineer from a district or regional gas organization must come to the site and check that the gas connections in the furnace and kitchen are correct and that they comply with the requirements. If all standards are met, he must issue a conclusion on the basis of which the gas “valve” leading to the boiler can be opened;

- The heating system must be pressurized to P = 1.8 atm (see on the boiler pressure gauge);

- De-air the heating system;

- Check all connections for leaks;

- Be sure to install a voltage stabilizer for the boiler and preferably an uninterruptible power supply;

- Do not add antifreeze to heating water. This can damage the gaskets and lead to leaks in the heating system.

Gas boilers must be installed using a special technology that ensures the safe operation of explosive units that emit toxins in the event of a leak.

The room in which the boiler will be located must meet certain requirements. When installing a heating boiler in a private single-apartment house, the furnace room, or, as it is also called, the boiler room, can be installed on any floor, including the basement, basement and even the attic or roof. Restrictions apply to living quarters, bathrooms and toilets; it is prohibited to place a boiler in them.

To calculate the volume of the boiler room, the total thermal power of the heating equipment, instantaneous or capacitive water heaters is taken into account.

The table of the required boiler room volume is given below:

Table of the required volume of the boiler room depending on the boiler power

There are exceptions: if the heating boiler has a closed combustion chamber, then the volume of the boiler room is not standardized, and the presence of a window with access to the outside is not necessary.

To supply and exhaust air, it is necessary to ensure an influx of the required volume. To provide 23.3 kW of boiler power, 2.5 m3/hour of gas must be burned. For complete combustion of this volume, 30 m3/hour of air is required. If insufficient air is supplied, the gas does not burn completely, resulting in the formation of an extremely harmful substance, the inhalation of which negatively affects human health. If inhaled within 15 minutes, death occurs. Air should come not only from outside, but also flow from other rooms of the house. This is ensured by the presence of a gap between the door and the floor and an opening with a grille in the doors.

The heating boiler is installed on the floor at a distance of 10 cm from the wall, which must be made of non-combustible material. If there are no walls made of non-combustible materials, then protection made of fire-resistant material can be installed.

Step-by-step instructions for obtaining permission to install

We go to the local gas supplier, fill out and submit an application there for the installation of a gas boiler in the apartment. After some time, they must issue a conclusion on the technical feasibility of installing and connecting the boiler unit. Now it is necessary to obtain a conclusion about the proper state of ventilation. The address of the organization involved in checking ventilation ducts can be found in the fire inspection authorities or in the housing and communal services (you can usually find out the addresses of other necessary organizations here). If the ventilation is in order, we get a permit; if it does not meet the requirements, we get a conclusion on the required list of works, carry them out and again submit them for inspection to specialists who will issue a permit. We order a project from the local Gorgaz or any design bureau that has the right to carry out such work. At this stage, it is already necessary to decide on the model of the gas boiler and meter, since the project is drawn up in accordance with their technical characteristics. It is quite difficult to make changes to the project, and after it is signed, it is completely impossible (a new one is created). It is not necessary to buy a boiler and meter yet. We head to the local heating network and submit an application to refuse central heating (and, if necessary, hot water supply). You need to come here with a ready-made renovation project (installation of a gas boiler). You will also need: title documents for the apartment; technical certificate of the premises; written consent to disconnect all family members. We turn to gas workers (“Gorgaz”) and conclude an agreement for boiler maintenance. We also submit the project for approval; after its approval, you can carry out the installation of an individual heating system yourself or entrust the work to Gorgaz. At this stage, disconnection from the heating network is carried out, a boiler and gas meter are installed

Please note that the work is carried out outside the heating season, since it is necessary to drain water from the heating system of the entire house. The boiler is installed without connecting to the gas main. After completing all the work, you must contact Gorgaz to obtain an acceptance certificate for the conversion work

Gas workers will also connect the boiler to the gas main, carry out the adjustment and first start-up of the gas boiler, and put the appropriate stamp in the model passport (without this, the warranty on the boiler unit will be invalid).

General requirements

There are certain requirements for all rooms where gas boilers are installed:

First of all, attention is paid to the lighting of the room. According to standards, one cubic meter of space requires 0.03 m² of window opening

Please note that this is a clear space through which daylight will pass. This does not take into account the window frame or partitions between the glasses. That is, the net area of double-glazed windows. A prerequisite is a supply and exhaust ventilation system. Please note that the air volume of the space should change 3 times in 1 hour. This is a prerequisite for minimizing gas pollution in the room. The window must be equipped with a window. But the exit door should lead only to the street. Many suburban developers ignore this rule and end up receiving a notification from fire inspectors about the need to comply with it. As a result, you have to break through a door in the wall, spending money, time, and effort on this.

How are the dimensions of the room and the power of the unit related?

There are also certain standards that relate to the relationship between the size of the room and the power of gas boilers.

We present to your attention several positions:

- If the power of a gas boiler for heating does not exceed 30 kW, then the volume of the boiler room can be within 7.5 m³. And this is the minimum indicator.

- If the productivity is 30–60 kW, then the volume of the room is 13.5 m³.

- If the power exceeds 60 kW, then the volume of the room is determined according to the passport data of the heating device, but not less than 15 m³.

Many consumers, especially those who decide to organize autonomous heating in a city apartment, often ask the question about the possibility of installing gas boilers for heating and determining the room for them. Let's just say that there are no strict restrictions in this regard, if all the requirements imposed by the rules and regulations of SNiP are met in these premises.

Of course, it is necessary to especially note the kitchens, where these rules and regulations are already guaranteed to be laid down by the house design. But here there is one important nuance. It is necessary to take into account the total thermal power emanating from all heating devices in the kitchen. This includes a cooking stove, heating elements, heating radiators, boilers, etc. So their total power should not exceed 150 kW.

Other requirements

Installing a gas boiler indoors

And a few more requirements:

- The ceiling height in the boiler room should not be less than 2 m.

- The boiler room must be separated from other rooms by durable fireproof partitions.

- The material from which the combustion chamber is constructed must have a temporary fire resistance limit of at least 45 minutes. That is, in the event of a fire, the walls, floor and ceiling must contain the flames of the fire during this time.

- The optimal layout option should be such that the fire from the boiler room does not spread to other rooms of a private house or apartment.

Kitchen requirements

When it comes to a private home, or more precisely, the installation of gas boilers in it, problems with requirements are solved easily and quickly. Organizing a separate furnace room will not be difficult. You will need to build a small room with your own hands that meets the necessary standards. This will have little effect on the cost of construction.

But installing a gas boiler in an apartment is much more complicated. The optimal room for this is the kitchen. But even this has certain requirements. We will not once again remind you of the norms that have already been described above. All of them must be implemented in full without any deviations.

But there are additional requirements:

Firstly, only a wall-mounted gas boiler can be installed in the kitchen, and it is better if it has a closed combustion chamber and a coaxial chimney. Currently, manufacturers offer dual-circuit models that can provide an apartment not only with an autonomous heating system, but also with full hot water. Secondly, in addition, to increase air exchange in the room, you need to make a hole in the front door and install a grille on it

The opening area should not be less than 0.02 m². If the kitchen space does not fully comply with the requirements of SNiP, then the installation of a gas boiler for heating is possible (note - POSSIBLE) if the gas regulatory authorities give permission to do so. If the kitchen in your apartment has a volume of less than 7.5 m³, then you cannot install two heating elements in it.

Development and approval of the project

Installation work without a design permitting the installation of a heating boiler is prohibited. First of all, this is due to the high degree of danger of the work being carried out and the further operation of the equipment.

When drawing up design documentation, the features of the premises are taken into account. It must comply with all the requirements specified in the technical specifications. In addition, the project indicates a drawing for laying gas supply communications:

- in private houses - along the entire site up to the front door in a residential building;

- in apartments - from the front door to the point where the boiler is connected to the gas network.

When installing heating boilers, it is necessary to create a project, this is due to the high degree of danger of this structure.

The preparation of such documentation can only be carried out by authorized persons who have received a license for such work and are responsible for all calculations. The owners of the premises are prohibited from editing anything or making adjustments at their own discretion. Prepared project documents are subsequently sent for approval. This issue is dealt with by the gas supply technical department. Review may take from several days to several months, depending on the complexity of the drawings and the characteristics of the premises.

Along with the project for which boiler equipment will be installed, the following must be submitted for approval:

- technical passport of the unit;

- installation and operating instructions;

- certificates confirming the boiler’s compliance with sanitary and technical standards;

- confirmation of an examination of the boiler, revealing its compliance with safety standards.

When choosing heating equipment, you need to know what gas boilers are and their characteristics

The buyer receives all these documents when purchasing equipment

If it was not possible to achieve a positive decision on the installation, you need to pay attention to the reason for the refusal. Specialists reviewing the project are required to list the actions, the implementation of which will subsequently allow obtaining permission

Once the documents are approved, you can proceed to installation work.

Basic regulatory documents

Household automatic control system for gas pollution

The basis of regulatory documentation for the construction of a boiler house is SNiP documents. The list includes:

- paragraph 6.17-25 in SP 42-101-2003;

- clause 6.29-48 from the joint venture dated 2.04.08-87;

- Chapter 4 in SP 41-104-2000;

- clause 7 from SP 62.13330.2011;

- clause 6.6 from SP 60.13330.2012;

- clause 6.12 from SP 55.13330.2011;

- MDS instruction 41.2-2000 for the placement of gas boilers.

SNiP standards are constantly updated and changed. Since 2022, equipping a gas boiler room with a gas sensor has become a mandatory element.

Ventilation device for a room with a gas boiler

ideal boiler room ventilation

There are the following types of ventilation for a gas boiler in a private house:

- Natural and mechanical based on the principle of traction;

- Exhaust, supply and combined according to purpose;

- Duct and ductless according to the design solution.

When installing ventilation in a room with a gas boiler with an open combustion chamber, the following is taken into account:

- In the room with a gas boiler, a ventilation chimney is installed to remove carbon monoxide to the street;

- A general exhaust ventilation system is installed from the room with a gas boiler;

- Supply ventilation is provided in the boiler room for a gas boiler, supplying fresh air and oxygen from the street.

Gaps in windows and doors, gaps through which air can enter the room, are quite suitable as supply ventilation for a room with a gas boiler. This is especially true for private houses, where a separate room is allocated for the boiler.

When choosing equipment, you should take into account the power of the boiler, otherwise the cost of installing gas ventilation will not be justified. The oxygen supply must be sufficient to maintain a normal flame. Otherwise, soot accumulates on the heat exchanger and heating performance decreases. If there is no air flow in the room with a gas boiler, the atmosphere in it is discharged. The oxygen level drops, and reverse draft may appear, that is, combustion products will be drawn into the room. The situation is dangerous when the boiler is installed in the kitchen. By absorbing oxygen, it will cause oxygen starvation in people: pain in the eyes, headache, malaise.

When calculating the air flow, the volume of the room in which the boiler is installed is also taken into account.

Air movement principle

With mechanical draft, the air is driven by a fan. It is located in the ventilation grille at the entrance of the air duct to the room. With natural draft, air moves due to the difference in pressure outside and indoors. And even if there is good natural draft, it would be useful to install a small exhaust fan that will support air movement.

If you equip a mechanical air supply, then increased pressure is created in the room and the exhaust air is pushed out through the air duct.

There is another type of ventilation for a gas boiler room - supply and exhaust or combined. In this case, it is a combination of the previously described systems.

Duct or ductless ventilation

Ductless ventilation for a gas boiler in a private house consists of holes in the ceiling or walls. Openings connect adjacent rooms. For example, a hole is made between the bathroom and the toilet, and a ventilation duct is led out from the toilet.

Duct ventilation of a room with a gas boiler is a complex system of ventilation pipes running throughout the house. This type is most relevant for damp and dusty rooms.

Buderus Logamax UO72-18K

One of the budget options for German double-circuit gas boilers. The dimensions of this sample are much smaller than the previous Italian bestseller. Dimensions of 700x400x300 mm reduce the weight by 2 times, which allows you to look at the boiler from a different angle and find additional advantages in it in the form of:

- Safety systems that prevent emergencies due to a drop in pressure or an extinguished flame.

- Power 18 kW.

- Heating temperatures from 40 to 82 ˚С.

- Economical.

- Ease of use and settings.

- Switches off the device when the water overheats or freezes and in the absence of traction.

- Low noise level.

Some consumers complain about the poor quality of the plastic latches and the insufficiently detailed instructions for the unit regarding the recognition and repair of minor breakdowns.

Chimney installation standards

The material for the chimney is selected depending on the fuel being burned and the type of boiler. For a gas boiler, the pipes must be cylindrical and made of metal, preferably stainless steel. Such chimneys are the safest, most durable and reliable.

The chimney is installed above the ridge of the house. A hatch for cleaning the chimney must be installed. In order to ensure convenient collection of soot during cleaning, collection and removal of condensate, an empty space under the chimney inlet is necessary.

Gas boiler chimney diagram

When installing a chimney, there should be no more than three elbows and turns. The pipe connecting the boiler and the chimney should be as short as possible, no more than 25 cm.

The vertical section at the boiler outlet must be equal to at least two diameters. Beyond this vertical section, the pipe of the connecting section must necessarily rise upward with a slope towards the boiler.

Smoke removal in this case is carried out due to natural draft through the chimney.

Following all the requirements and rules for installing gas boilers will ensure their efficient operation, durability and fire safety.

Viessmann Vitogas 100-F 29

This sample is considered the cheapest of the expensive models of the Viessmann brand. The price in this case is reflected in the quality and provides reliable heating in any conditions.

Non-volatile boiler type, floor installation, high efficiency, noiselessness, low fuel consumption - this is the minimum of the many advantages available. The manufacturer positions the boiler as a good option for providing heat with a long service life and full automation of most processes.

The average dimensions of a floor-standing gas boiler allow its installation not only in a separate boiler room, but also in the kitchen, of course, if there is free space. Professionals call weather-adjusting automation, an electronic control system and an additional electronic cascade control unit the advantages of the unit.