Modern technologies make it possible to ensure maximum efficiency of the smoke removal and ventilation system of the house regarding the one-way removal of air media outside the serviced premises. One of the means of optimizing processes is to install a deflector on the chimney pipe or ventilation duct. Let's consider the design features and operating principle of various models of this group of devices. Let's get acquainted with the basic principles and rules for carrying out installation work.

The simplest alternative to a factory chimney deflector Source pxhere.com

Popular types of traction enhancers

In modern designs, there are different types of deflectors, so you can choose a model for a house made in any architectural style.

Structurally, these devices differ:

- flat top;

- two slopes;

- semicircular lid;

- folding top.

Each of them has certain advantages: the opening lid on the deflector allows you to control the process of removing combustion products.

A flat top is perfect as a decorative element for a roof made in the Art Nouveau style; the best protection from weather conditions is a gable mini-roof. The material used for their manufacture is mainly galvanized metal, but sometimes it is coated with a layer of plastic or enameled.

What is a deflector?

Strong winds can disrupt the stable operation of a gas boiler. In such conditions, the automation often works and the boiler turns off. Combustion products from a gas boiler, when removed ineffectively, pose a threat not only to health, but also to people’s lives.

To enhance traction by optimizing air flow, draft stabilizers or deflectors are used. Translated, its name sounds like a reflector, a deflecting device. His work uses the Bernoulli effect, which is based on a decrease in pressure during an air flow around an obstacle. It deflects air masses, increasing the strength of the main flow of the chimney.

The chimney of a gas boiler, equipped with a deflector, will not go out during strong gusts of wind. The design becomes more efficient because traction force increases up to 20%

The traction amplifier operates effectively in any wind force and even during strong gusts, if there is wind, the traction will not topple. But in complete calm, this aerodynamic device acts as an umbrella and is practically inactive, and sometimes reduces thrust. For this reason, many experts do not recommend installing deflectors on gas chimneys.

Despite the increased requirements for a deflector installed on the chimney of a gas boiler, in some cases this is the only solution to the problem. If this device is not included in the project, it is necessary to coordinate its installation with the gas workers. Only after fulfilling this condition can you begin installing the deflector.

According to the specifics of the device and the operating principle associated with this, deflectors are divided into the following types:

Image gallery

Photo from

Traditional umbrella-shaped deflector

H-shaped deflector devices

Deflector-weather vane with sail effect

Model with spark arrester

Diffuser for ventilation

For more efficient ventilation in the room, the supply air should not flow in a stream, but should be evenly distributed throughout the entire space of the room.

After all, when the air flows in one stream, drafts are created, and they negatively affect people’s health. In addition, with a jet air flow, only a certain part of the room is ventilated. Therefore, in order to ventilate the space as efficiently as possible, ventilation diffusers are installed. Ventilation diffuser - what is it? This is part of the ventilation system, the purpose of which is to disperse input/output air flows throughout the room.

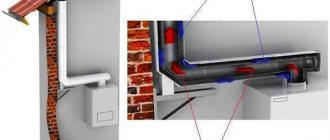

Deflector design

The deflector prevents direct air flow from entering the chimney.

In the standard version it consists of 3 parts:

- The upper cylinder (diffuser), expanded at the bottom. It is attached to the bottom using special racks.

- The lower glass is made of metal, ceramics or asbestos cement.

- A cap in the form of a cone-shaped umbrella.

The upper part and the lower cylinder are equipped with annular bumpers that deflect the air flow. Some models do not have a top element. Then the lower cylinder is installed on the pipe, followed by a diffuser and caps - forward and reverse.

The device works on a simple principle:

- the walls of the cylinder located at the top absorb the wind blow and direct the air flow around;

- Due to the sliding of individual air jets over the surface and their rise upward, gases coming from the chimney are sucked in.

The thrust increases in any wind direction except horizontal. In the latter case, air turbulences form inside the device, cutting off the smoke exit paths. This significant drawback is eliminated by adding an additional element - a reverse cone.

Structurally, the deflector consists of a diffuser (2) with a frame (3) installed on a pipe (1). These elements are located in the shell (4). Above the diffuser there is an umbrella (5) with thermal insulation (6) and a screen (7). Replaceable filter (10) is installed on supports (9) and secured with bolts (11)

The reverse cone is installed below the cap. The purpose of the deflector is to ensure that air flows are removed to the outside by crushing them.

Classification

Types of diffusers for ventilation

The ventilation equipment market has a fairly wide range of diffusers. They are divided into several types according to the following characteristics:

According to case material

Plastic diffusers for ventilation.

Such devices are made of plastic and are resistant to corrosion and rotting processes. These air diffusers are very lightweight and come in different shapes and colors.

Metal diffusers for ventilation

Such air distributors are made of aluminum or steel. The advantage of these products is their high strength. They are reliable in operation and have an optimal design. Metal diffusers are much heavier than plastic ones. Also, sometimes problems with their installation may arise.

Do not confuse a metal supply anemostat and a diffuser. Unlike a diffuser, using an anemostat you can control the volume of circulating air flows (this is not possible with diffusers). Also, the body of the device is made only in a round shape, and the diffuser can have various shapes (both round and rectangular).

The price of the device depends on the material from which the diffuser body is made. Steel fixtures are much more expensive than plastic ones.

By shape

Round (swirl) diffusers for ventilation

Such models are divided into:

Slot diffusers for ventilation

The boxes for installing such devices are very compact and almost invisible on the surface. Due to their shape, they allow you to adjust the direction and angle of air flow.

Installation of such units will not require much effort. It is done using brackets.

By purpose

Supply diffusers

Devices for supply ventilation are designed to draw and quickly deliver a flow of fresh air masses from the outside into the room or ventilation unit and their uniform distribution.

Exhaust diffusers

They are used for prompt removal of exhaust air from the premises. At the same time, they promote uniform distribution of air throughout the room and ventilation of its maximum area.

Universal (supply and exhaust) diffusers

Such units are used for the influx and outflow of air into the room, as well as for circulation through the ventilation system.

Nozzle diffusers

Such units are used to create jet air streams of narrow direction.

At the installation location

Ceiling diffusers for ventilation

Since the mixing of air flows in the room is carried out at the top (under the ceiling), such air distributors are very common in operation - 95%. They are used for both supply and exhaust ventilation systems.

Floor diffusers for ventilation

This type of device is used for rooms in which supply ventilation is carried out through the basement.

Wall diffusers for ventilation

Such diffusers for ventilation are quite rare in operation, since ventilation grilles are mainly used for walls.

Basically, such units are installed when it is necessary to install ventilation through a hole in the wall.

Design features

Vortex

The external design of such distributors for air flows consists of partitions and grilles, which are located in such a way as to create turbulence in the air masses. This allows you to speed up the movement of air masses and increase the efficiency of such a system.

Often in swirl diffusers the placement of jumpers is radial. They are used in rooms with large areas and high ceilings. Also, such units are well suited for rooms that require rapid air change (bathroom, toilet, etc.).

From the inside, such a unit has the shape of a cylinder. The grille for it can be of various shapes. In this case, its holes should be located only around the circumference.

Vortex air mass distributors for the supply ventilation system have an additional impeller. It is located behind bars, in the device body. This part can be movable or stationary, controlled or uncontrolled. The controlled impeller can have several operating speeds.

Swirl diffusers can have a static pressure chamber. With its help, too active movement of air flows is eliminated, thus preventing the occurrence of drafts.

Slotted

The shape of such diffusers resembles slits. Since the distribution of air mass flows directly depends on the position of the partitions, their shape, size and direction, the design of such units is specially developed and calculated.

Such devices are used for rooms in which the ventilation system has low or medium performance.

Slot devices for dispersing air flows can be adjustable and change the direction of the supplied air masses (similar to air conditioner blinds). Such diffusers may contain a static pressure chamber.

The design of slot diffusers and grilles for them can be of various shapes.

Adjustable

These ventilation diffusers are equipped with adjustable sliding plates. This is a regulatory element of the design, through which the throughput of the device is controlled.

Such devices are called anemostats. The flow of air masses is regulated by moving the central part of the unit clockwise or counterclockwise. The slats in the device are movably fixed. This allows them to change position and open or close the gap to generate air masses.

There are anemostats equipped with presence sensors and air mass composition analyzers. Such units are connected to the room climate control system. This system operates automatically. Its task is to maintain a given room microclimate.

Characteristics of popular models

Deflector models differ in both size and sensitivity to wind. The most popular models are TsAGI, Khanzhenkov, Volpert-Grigorovich, “Smoke Tooth”, “Hood” aka “Net”, “Shenard”. The first of these models was developed at the Aerodynamic Institute named after. Zhukovsky.

TsAGI is most often used in ventilation systems due to the difficulties that arise when removing soot. The second model is essentially the same TsAGI, but slightly improved by the inventor. Essentially, this is an additional cylinder around a pipe with an umbrella cover immersed inside the cylinder at a certain distance.

Homeowners choose the TsAGI deflector most often. It has a cylindrical shape. The device is made of galvanized or stainless steel

The Volpert-Grigorovich deflector has proven itself well as a draft amplifier on chimneys. It works effectively in areas with prevailing low winds. The design includes 2 cylinders - the lower one with two outlet pipes and the upper one with a cover.

The “smoke tooth” is mounted in a door specially provided in the chimney. Due to the fact that the design includes 2 handles, you can regulate the air flow.

Covers for chimneys are made in a variety of shapes. Sometimes they are coated with heat-resistant enamel. Some specimens look very decorative

The “Hood” deflector has a rotating design. It consists of a semicircular trough-shaped air trap mounted on a rotating rod mounted inside the pipe. An increase in traction power by installing a weather vane deflector occurs due to turbulence that occurs under wind load.

How to calculate a static deflector?

When making a deflector yourself, you need to perform calculations and sketch a sketch of the future product. You need to proceed from the internal diameter of the chimney pipe.

The photo shows the dependence of the size of the deflector on the diameter of the chimney. To determine the lower diameter of the diffuser, the basic parameter is multiplied by 2, the upper one - by 1.5, the height of the diffuser - also by 1.5, the height of the cone, including the reverse one, the height of the umbrella itself - by 0.25, the entry of the pipe into the diffuser - by 0.15

For a standard device, parameters can be selected according to the table:

| Pipe inner diameter (cm) | Deflector height (cm) | Diffuser diameter (cm) |

| 12 | 14,4 | 24 |

| 14 | 16,8 | 28 |

| 20 | 24 | 40 |

| 40 | 48 | 80 |

| 50 | 60 | 100 |

The table will allow you to select the dimensions of the deflector without performing calculations. But if there are no suitable sizes in it, you will still have to arm yourself with a calculator or find the appropriate program on the Internet.

When manufacturing a deflector with individual parameters, these special formulas are used to determine the dimensions: • D diffuser = 1.2 x din. pipes; • H = 1.6 x din. pipes; • Cover width = 1.7 x din. pipes.

Once you know all the dimensions, you can calculate the development of the umbrella cone. If the diameter and height are known, then the diameter of a round workpiece can be easily calculated using the Pythagorean theorem:

R = √(D/2)² + H²

Now we need to determine the parameters of the sector, which will subsequently be cut from the workpiece.

The length of a complete circle of 360⁰ L is equal to 2π R. The length of the circle underlying the finished cone Lm will be less than L. From the difference of these lengths, the arc length of the segment (X) is determined. To do this, make up the proportion:

L/360⁰ = Lm/X

The required size is calculated from it: X = 360 x Lm/ L. The resulting X value is subtracted from 360⁰ - this will be the size of the cut sector.

So, if the height of the deflector should be 168 mm and the diameter 280 mm, then the radius of the workpiece is 219 mm, and its circumferential length Lm = 218.7 x 2 x 3.14 = 1373 mm. The required cone will have a circumference of 280 x 3.14 = 879 mm. Hence 879/1373 x 360⁰ = 230⁰. The cut sector must have an angle of 360 – 230 = 130⁰.

When you need to cut a workpiece in the form of a truncated cone, you have to solve a more difficult problem, because... the known value will be the height of the truncated part, and not the entire cone. Regardless of this, the calculation is performed on the basis of the same Pythagorean theorem. The total height is found from the proportion:

(D – Dm)/ 2H = D/2Hp

This implies that Hp = D x H / (D-Dm). Having found out this value, calculate the parameters of the workpiece for the full cone and subtract the upper part from it.

With known parameters: the height of the cone - full or truncated and the radius of the base, using simple calculations, simply determine the outer and inner radius (in the case of a truncated cone) and then the initial angle and the length of the generatrix of the curve

Let's say you need a truncated cone with H = 240 mm, a diameter at the base of 400 mm, and the upper circle should have a diameter of 300 mm.

- Total height Hp = 400 x 240/ (400 – 300) = 960 mm.

- External radius of the workpiece Rz = √(400/2)² + 960² = 980.6 mm.

- Radius of the smaller hole Rm = √(960 – 240)² + (300|2)² = 239 mm.

- Sector angle: 360/2 x 400/980.6 = 73.4⁰.

It remains to draw one arc with a radius of 980.6 mm and a second with a radius of 239 mm from the same point and draw the radii at an angle of 73.4⁰. If you plan to overlap the edges, add allowances.

Read on to learn more about how to build a chimney deflector yourself.

Self-assembly of the device

First, the patterns are prepared, then they are laid out on a sheet of metal and the parts are cut out using special scissors. The body is rolled up and the edges are secured with rivets. Next, the upper and lower cones are attached to each other, using the edge of the first one. it is larger and you can cut special fastening cuts about 1.5 cm wide in several places and then bend them.

Assembling a simple deflector is not difficult, but if a rotary-type device is to be installed, you will have to deal with many parts

Before assembly, 3 racks are installed in the lower cone, evenly distributing them around the perimeter and using threaded studs for this. To connect the umbrella with the diffuser, loops made of metal strips are rivet-fastened to the latter. The posts are screwed into the hinges and secured with nuts for greater reliability.

Next, they carry out the installation of a self-made deflector onto the chimney of a gas or other type of boiler. The assembled device is placed on the pipe and secured using clamps, avoiding gaps. Sometimes the joint is treated with a heat-resistant sealant.

Assembling a simple dish model

The easiest project to implement is making a dish-shaped deflector model. You can easily make such a chimney cap yourself. Its geometric parameters depend on the diameter of the pipe:

Image gallery

Photo from

Deflector design for round pipe

Diameter of the clamp for mounting the deflector

Chimney cap size

Distance between umbrella and mounting clamp

In order not to make mistakes in manufacturing and to accurately adjust the parts to the required size, it is advisable to first make a model of the deflector from cardboard. At this stage it is simpler and easier to make adjustments to the design. Cardboard blanks will also serve as a kind of patterns when cutting out the elements of the future deflector:

Image gallery

Photo from

Making a pattern for a chimney deflector

Assembling a metal chimney umbrella

Device of remote racks

Attaching the deflector fixing clamp

Do-it-yourself production

We propose to explain the technology for assembling the cap using the example of a TsAGI type nozzle. The parts are cut out of galvanized steel 0.5 mm thick and fastened together with rivets or bolts with nuts. The design of the exhaust element is shown in the drawing.

To make it you will need a regular metalworking tool:

- hammer, mallet;

- metal scissors;

- electric drill;

- vice;

- marking equipment - scriber, tape measure, pencil.

The table below shows the dimensions of the deflector parts and the final weight of the product.

Reference. The most common diameters of ventilation ducts are 100 or 110 mm, when the hood is made of a plastic sewer pipe.

Pattern and drawing of an umbrella with a cap with a diameter of 100 mm

The assembly algorithm is as follows. Using scissors, we cut out the blanks of the umbrella, diffuser and shell using the developments, and fasten them together with rivets. Cutting the shell is not difficult; the development of the diffuser and umbrella is shown in the drawings.

The finished deflector is placed on the head, the lower pipe is tightened with a clamp. For a square shaft, you will have to make or buy an adapter, whose flange is attached to the end of the pipe.

Features of installation of a rotary deflector

Turbo deflector, rotary deflector, rotary turbine, Turbovent - all these names refer to one type of mechanical device for increasing traction. It consists of a static part connected to the chimney and an active head with ball-shaped blades.

The rotary deflector is the only device that is not recommended for installation on chimneys of stoves heated with solid fuel and wood-burning fireplaces. Turbovent has a characteristic feature - it removes air from the pipe even during periods when the heating is not working.

The direction of rotation of this nozzle does not depend on the strength or direction of the wind. It occurs in only one constant direction, creating the effect of an incomplete vacuum. As a result, the traction power increases in rarefied air conditions, and the risk of the traction capsizing is practically equal to 0.

On chimneys of gas boilers, Turbovent copes with its functions perfectly and can serve as a decoration for any facade. If we compare it with other types of deflectors, it is twice as effective as them.

The base of the rotary deflector can be round, square, or flat square. Head sizes range from 100 – 680 mm. Its service life is up to 15 years.

Despite all the advantages of a rotary turbine, there is one significant drawback - the device stops when there is no wind. If at this time there is precipitation at a temperature below 0, the head may freeze and measures will have to be taken to start it.

Despite the relative complexity of the design, installing a rotary deflector is not difficult. The device is lightweight, so installation requires only one person and takes about 2 hours. A suitable place is the highest point of the roof. This arrangement will prevent snow from getting into the pipe if precipitation accumulates around it.

The movement of the rotary turbine head is carried out using bearings. The device operates autonomously and copes very effectively with the task of removing gases, but in calm weather it is useless

For different models of rotary turbines, there is one requirement: the temperature of the combustion products above the chimney should not exceed 150-250⁰. The dimensions of the base must be precisely adjusted to the chimney. The turbocharged deflector must match the characteristics of the boiler, and this point must be taken into account when choosing a device.

There are turbo deflectors from different brands on the market. Among the most reputable are Turbovent, Turbomax, Rotowent. The first manufacturer produces products with bases of various geometries.

They can be identified by the markings TA-315, TA-355, TA-500. The number in it indicates the diameter in the case of a round cross-section or the dimensions of a rectangular base.

The Turbomax deflector is produced by a Belarusian company. The devices are made from high-quality material - stainless steel from a European supplier. Rotowent is also made of stainless steel supplied from Poland. Looks harmonious on any type of roof. Suitable for both chimney and ventilation pipes. Withstands high operating temperatures - about 500⁰.

Turbo deflector performance

There are quite a large number of estimates of the efficiency and performance of a turbocharged deflector, from advertising statements about increasing pipe thrust by 4-6 times, to minimalist estimates of 20-30%.

In reality, the increase in thrust using a turbo deflector in ideal conditions and with average winds is 150-250%.

As can be seen from the graph, the theoretical performance of the device increases almost linearly with increasing wind speed over the pipe. In practice, such growth is only possible if it is possible to place the turbo deflector in the most favorable location on the roof.

Deflectors-vanes for chimneys

Structurally, the chimney weather vane is designed so that gases, escaping freely from the leeward side, increase the draft force in the chimney pipe. The device is made of heat-resistant steel, which has proven itself in conditions of high temperatures and condensation formation.

Under the curved visor of the weather vane there is a bearing assembly that protects against problems with rotation. The bearing assembly is bolted to the chimney. A vacuum zone is created when the air flow passes through the space under the visors.

During installation, the base of the device is placed on the round chimney until it stops, and then secured with 3 bolts. The bolts should be tightened with great care because... the pipe may be damaged. Installation is completed by checking the verticality and rotation of the housing

The disadvantage of chimney weather vanes is that in strong winds they work unstably. The moving part must be periodically cleaned and lubricated. Moisture often accumulates inside the device, and flue gases leave a trace in the form of deposits.

Manufacturers themselves advise using their devices if the chimney is located in an unfavorable location. It, in fact, does not increase draft, but only protects the chimney.

Rotary turbines for the exhaust system

These are the most popular devices for this purpose. Compared to other designs, their productivity is 20-25% higher.

The advantage of using them is that they do not use any energy source during operation.

Always rotating in one direction under the influence of the wind, the turbine head creates a vacuum inside the ventilation pipe, which promotes the active process of air circulation.

In addition, elegantly made of steel, it also serves the function of protecting the pipe mouth from atmospheric precipitation.

The head part is made of aluminum strips up to 0.5 millimeters thick, and the base is made of steel sheet painted in RAL colors.

Rotary turbines can be used on round, square or rectangular ducts or chimneys. In addition, they can be used for chimney systems.

Conclusions and useful video on the topic

Is it worth installing a traction amplifier at all if you have a gas boiler? You will find out by watching this video:

Making a turbo deflector with your own hands is not easy, but some craftsmen still do it and successfully operate it. Watch this video:

There are a lot of deflector designs, but we must not forget that gas is used for heating. Not all models can be used. Some of them are not suitable in principle because... designed for ventilation. In order not to block the smoke removal system, you must consult with a specialist and obtain permission to install the deflector.

Looking for a chimney deflector? Or do you have experience in manufacturing or installing this device? Please share it with our website visitors. Also, in the comments block, you can ask questions about the topic of the article.

Classification of wind nozzles

When choosing wind nozzles, you need to decide on a number of important points in order to make the best option for yourself. It is necessary to determine the following characteristics:

The first thing you need to pay attention to is the material from which the deflector is made. Stainless or galvanized steel, ceramics, plastic, copper are used in production.

You may be interested in the article “Sewerage for a private house: stages of construction, which septic tank to choose” Go>>

More often they choose steel or aluminum nozzles; they are not very expensive and are not inferior in quality. Copper models are used less frequently due to their high price. A good option for quality and decorativeness are metal attachments coated with plastic. When choosing a material and color for the deflector, it is advisable to match it to the facade of the house.

The next criterion for choosing a nozzle is the operating principle. Depending on the functionality, deflectors are divided into 4 types: