Water heating convectors built into the floor are fairly new devices for the Russian market. They compete with traditional wall-mounted or floor-mounted heating radiators, and in some cases they are the only possible technical solution for home renovation.

In-floor heating convectors, as a rule, are installed in places where it is technologically impossible to install floor or wall-mounted options. Such places are spaces next to panoramic windows (floor-to-ceiling windows), where it is impossible to hang a standard wall-mounted convector, and a floor-mounted one will spoil the view. Convectors are also built into the floor at exits to terraces or balconies, where the above-mentioned standard options will simply interfere with the passage.

Such devices are capable of creating a thermal curtain from cold air currents arising near windows and doorways. There are two types of floor-mounted heating convectors available on the heating equipment market based on the type of energy use: electric and water.

Electrical devices are not so popular when used in private homes, since they are too expensive for owners due to increased energy consumption, although they do not require communications to be connected to them. Therefore, in the absence of gas heating, it will be more economical to install an electric boiler with water heating than to use several electric convectors at once.

Water appliances are installed both in the presence of central and autonomous heating. Let's talk about them in more detail.

Operating principle of a water heating convector

In its basic version, a convector is a simple heating device consisting of a housing and a heat exchanger located in it. The heat exchanger is made up of a certain number of heat-exchange metal plates through which the heating circuit passes. The level of heat transfer of such a device directly depends on the quantity, usable area and material of manufacture of such elements.

The operating principle of water heating convectors is the same regardless of whether it is in the floor or hanging on the wall. From the school physics course we know that cold air is heavier than hot air. Heated by the heat exchanger, the air rises up the room to the ceiling, pushing cold air down from there. As the air cools, it becomes heavier and sinks toward the floor. This is how the natural and continuous movement of the air mass occurs, which turns into a circulation. The transfer of air mass is called convection, and the devices that create it are called convectors.

To a large extent, the efficiency of convection equipment depends on where it will be installed. The main sources of heat loss in the house are windows and glass doors, so water heating convectors are installed near these places. Heating devices take into their circulation not only the cooled air from the room, but also the cold air entering the room from windows and doors.

Features of choice

When choosing water convectors, you must pay attention to several important indicators:

- Control method: manual and remote. In the case of a device that needs to be controlled manually, you will need to constantly turn the device on and off; the remote method allows you to carry out these manipulations at a distance.

- Power. The rate of heating of the room will depend on this indicator. The higher the power, the faster the air in the rooms will heat up.

- The presence of a thermostat. This element is not present in all devices, but it is very useful because... it monitors the temperature and can itself determine when the device should be turned on and off. In other words, thanks to the thermostat, your unit will be protected from overheating.

- A heating element. This indicator is also very important. Its main characteristic is the area that is in contact with the environment. The larger it is, the higher the performance of the convector.

- Frame. If you want the device not to spoil your interior, but rather to fit harmoniously into it, pay attention to the appearance and material from which the heater body is made. Steel models are the most widely used because... are characterized by high strength.

There are also in-floor and baseboard electric convectors.

Design of floor-mounted heating convectors

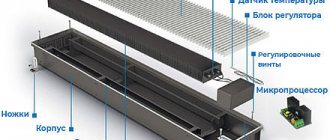

The underfloor heating convector has a simple design and consists of several components. First of all, it is a stainless steel body, which is installed on the subfloor on special adjustable legs that allow it to be leveled horizontally, and has holes for supplying heating pipes.

Inside the housing is the heart of the heating convector - the heat exchanger. The heat exchanger has a plate structure for better heat removal. Most of these heat exchangers are made of ordinary steel, but it is not the best material for such devices, as it is susceptible to corrosion and dissipates heat worse than its competitors - copper or aluminum.

The heat exchanger has terminals for connecting heating pipes. Additionally, such devices can be equipped with shut-off valves or thermostatic heads for semi-automatic temperature control.

The heat exchangers themselves are mounted in the housing in compliance with the necessary clearances provided for by the design. This is done to provide the air space necessary for proper circulation of air masses.

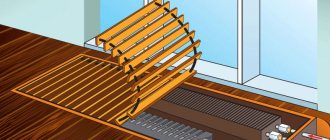

The design of the floor-mounted heating device is completed by a decorative grille, which covers the heat exchanger radiator, but allows air to pass through it. There are two types of convector grilles:

- roll;

- whole.

The following materials are used for the manufacture of such gratings:

- tree;

- stone;

- steel;

- aluminum;

- plastic.

There is no fundamental difference between the roll-up and monolithic options, except that the roll-up grille can be easily rolled up, providing easy access to the convector for inspection or cleaning. However, when using trench convectors in walk-through areas, grilles made of more wear-resistant materials should be used, without using a large number of plastic moving parts.

When installing a built-in convector, the level of the finished floor is calculated in advance. This is necessary so that a part of the convector casing remains above the poured concrete floor screed, which will be covered by the final floor covering. As a result, the finishing surface, be it laminate, parquet or tile, should lie flush with the decorative grille in order to achieve comfort when walking on it.

Manufacturers

The number of recognized companies producing trench convectors includes Russian ones, in particular, the “Breeze” models.

Depending on the power, modifications are available with natural convection and with a tangential fan. The heat exchanger is made of copper-aluminum alloy, and the grille is made of duralumin. The coolant temperature can reach 130C, and the operating pressure can be 15 atm. Trench convector "Breeze"

Among the domestic products, the “EVA” collector is also known, designed for heating small rooms. The use of stainless steel parts, modern manufacturing technologies and the ability to independently select equipment make this heating option widely in demand. It all depends on financial capabilities and taste.

Water convectors “Kermi” (Belgium) are very popular in terms of wide selection and high reliability. They can be used as the main heat sources. The low height of the housing makes it possible to easily install in-floor convectors that are built into any floor. The range of product sizes and capacities is large, and the warranty is 10 years. They are equipped with thermostats and can work autonomously. The fans are powered from a 12 V source. Manufacturers produce in-floor water convectors to order.

High quality and reasonable prices have made the Czech brand “Minib” popular in Russia. Convectors reach maximum power in 10-15 minutes. If we compare them with radiators, then this requires 30 minutes.

It should also be noted the popularity of German convectors “Varmann”, where the latest innovations are used that do not significantly affect the final cost of the models. The product range has a wide range of possibilities. They are made in straight and semicircular shapes, in the form of corner structures or passing through columns.

Water heating convectors with forced circulation

One of the limitations of underfloor convectors is that they only work effectively in small rooms with not too high ceilings. This happens because the convection process itself is quite slow, so in high rooms the air has time to cool down before it has completed a full revolution. This leads to the fact that either the room warms up slowly, or you have to increase the temperature using a thermostat (which is not always possible).

Where it is necessary to heat large and spacious rooms, convectors equipped with a forced air circulation system are most often installed. Simply put, an electric fan is installed to help the natural process of air mass movement. To power the electric motors of such combined devices, a voltage of 12V is used, which is quite enough to ensure normal operation and complete electrical safety.

To increase the effect, in some cases double-row heat exchangers are used, but this solution requires more free space than in the standard version, which is not always possible.

When installing combined convectors, even at the design stage it is necessary to provide space for installing a step-down transformer with a rectifier that converts the household voltage into direct current to power the device. Typically, the fan is installed inside the device case, which makes servicing the entire system easier.

As an alternative solution that accelerates the movement of air masses through the convector, a system of hidden ventilation ducts is sometimes used. In this case, cold air enters the heat exchanger either independently or by forced injection.

In many houses where a large number of windows are installed, built-in heating convectors are also placed in the niches of the window sills, ensuring the movement of air masses along the window glass, forming a kind of thermal curtain. At the same time, the effect of glass fogging is almost completely eliminated, improving visibility and preventing the formation of condensation.

Often such a device becomes a favorite resting place for domestic cats, peacefully watching pigeons freezing in the snow. Convectors are also built into stair steps, wall niches and other interior details.

It is also practiced to install baseboard water convectors along the perimeter of external walls in order to normalize temperature and humidity in the room. Regardless of the type, the operating principle of a water heating convector remains the same.

What is convection

Convective heating uses the simplest laws of physics, according to which heated air becomes lighter and rises. Every heating convector is built on this principle, regardless of what it is powered from. As practice shows, this scheme is highly effective - residential premises become warm, and relatively quickly .

Convector heating allows you to heat rooms for any purpose - these can be living rooms, children's rooms, corridors and foyers, kitchen areas, bathrooms and toilets, covered balconies and loggias. It heats using heated air, quickly saturating the heated rooms with heat. Let's see how the warming up process occurs:

All convectors work on the same principle - they create air circulation in the room, gradually warming it up.

- Possessing a large working surface area, the heating element heats the air around it;

- Warm air masses rise upward, leaving the equipment (or simply going upward if convector-type heating radiators are used);

- Cold air masses replace the air that has gone up.

The process is repeated until convector heating warms up all the air in the rooms.

Heating elements can be powered by electricity or by burning gas fuel. Convector-type heating batteries operate due to the coolant entering them. By the way, the batteries do not have housings, unlike the same electric and gas convectors. But their operating principle is similar - heating is carried out due to the heating air, and the thermal radiation from them is very weak.

Pros and cons of water heating convectors built into the floor

Heating convectors built into the floor are an ideal solution for almost any interior. In aesthetic terms, such convectors have the same advantages as built-in household appliances. While fulfilling their functions, they do not occupy living space and are quite easy to hide with decorative elements.

Like any heating device, water in-floor heating convectors have their advantages and disadvantages. The advantages include the following aspects:

- Such devices have quite high efficiency compared to floor and wall-mounted analogues, since they heat the air from the floor itself. Due to this, significantly less thermal energy is required, and, as a result, lower heating costs.

- In-floor convectors free up free space in the room and allow them to be installed with panoramic glazing or on terrace exits.

- The large heat exchanger area also contributes to more efficient heating of the room.

- The light weight and simplicity of design allow installation of such devices by non-professionals, subject to safety precautions and installation rules.

- Stylish and modern appearance. By choosing a suitable decorative grille, you can successfully fit trench convectors into the style of your interior.

In addition to their advantages, such devices have a number of serious disadvantages:

- The need for a thick layer of concrete screed to ensure the installation of the convector. Due to their design, such devices require a large amount of space from the subfloor level. This limitation makes it impossible to use in-floor convectors in many houses and apartments.

- The need to accurately adjust the level of the finished floor to the level of decorative convector grilles throughout the house.

- The high price of such heating devices compared to standard wall and floor types.

- The need for frequent cleaning of premises is due to the fact that air currents passing along the floor itself often raise dust.

- The inconvenience of cleaning the in-floor convector itself and the accumulation of dust and dirt in it.

- One of the most serious disadvantages of floor-mounted convectors is the inconvenience of maintenance in the event of an accident. In the event of leaks or emergency failure, the convector niche will quickly fill with hot coolant, which will complicate access to the shut-off valves and can lead to injury. If there is central heating, such an accident may make it impossible to stop the coolant supply.

Available types

Innovative and most convenient water heating convectors are divided into several categories depending on their functionality, installation method and other parameters. They can vary in size, power, control method, design, many manufacturers offer a large selection of available options, but it is worth remembering that currently there are three main types of such devices that you should focus on. This list includes:

- Wall-mounted devices, the power of which can be quite high, in addition, they are usually light in weight and compact in size, which allows them to be easily mounted on any wall. Quite often such devices are installed under windows or in other more suitable places; everything will depend on the decoration and layout of a particular room.

- Floor heating convectors, which in their design are practically no different from wall-mounted devices. They are solid blocks with a low level of fire hazard, which allows you to place almost any object near them. Their power is also quite high, but at the same time they do not dry out the air in the rooms and are able to maintain heat even in the most spacious room.

- Innovative and extremely convenient, built-in options can fit perfectly into almost any interior due to their versatility and the variety of options available. A convector built into the floor is usually installed in a special niche or floor plinth. In one room there may be several such devices that maintain the temperature at the most optimal level.

Of the entire list of available types, it is especially worth noting modern floor-mounted water convectors, which can be moved from one room to another, especially if the dimensions of a particular device allow this. Their power is quite high, in addition, many models are capable of fully heating even large rooms.

How to choose an in-floor water convector

Having assessed and analyzed all the advantages and disadvantages, you need to competently approach the choice of a convector manufacturer. Prices for in-floor convectors are high, but saving on such devices can lead to serious consequences.

There are many manufacturers on the market, but the most proven, producing high-quality products are “VARMANN” (Russia), “PRIMOCLIMA” (Russia), “KZTO Radiator” (Russia), “EVA” (Russia, Sweden), “MINIB” ( Czech Republic), "MOHLENHOFF" (Germany), "SIEMENS" (Germany).

In addition to price and manufacturer, your choice should be based on the required power of the device. With a simplified approach, the standard heating power in a private house is taken to be 1000 W per 10 sq.m. room area. In stores and construction supermarkets you can find many models with power ranging from kilowatts and small dimensions to large devices of several kilowatts.

It is necessary to take into account the fact that, due to design features, “adding power” by adding elements (sections, as in a radiator) will not work. If the glazing of the house is significant or the ceiling height is more than 3 meters, you should not resort to a simplified scheme; you must entrust this important task to professionals.

Installation and operation

By following the installation instructions, you can independently install floor, wall, and baseboard convectors.

More difficult is the installation of in-floor convector models.

The following recommendations must be followed:

- The edges of the box should be flush with the main floor;

- Installation of devices should be carried out in enclosed spaces;

- It is necessary to install the convector at a distance of 25-30 cm from the window.

- A mounting niche should be provided. Moreover, its dimensions should be 1.5 cm larger than the dimensions of the device itself.

- The height of the convector is adjusted using bolts located in the bottom of the device.

- It is necessary to fix the unit with foam or cement mortar.

- At least once every two months you should clean the heat exchanger and the inner surface of the device from dust, crumbs and other debris with a vacuum cleaner or a wet cloth.

- After three years of operation of the convector it is necessary to carry out a full inspection.

Convector before pouring screed.

Other types of water heating convectors

Floor water convectors

Floor convection devices are attached to the floor using reliable brackets or decorative legs. The usual place for installing floor convection devices are spaces near glazed walls or in rooms with panoramic glazing

Well-known manufacturers make sure that their products look aesthetically pleasing and that the materials meet all sanitary standards. Typically, floor-standing devices are painted using a powder coating method, which creates a durable and resistant paint coating. Floor convectors usually do not have much power and are compact in size.

Material of manufacture is always important

When choosing, you should pay attention to the material of manufacture - it affects efficiency, cost, durability and even decorative qualities. Moreover, the last point has become one of the most important today.

For example, devices can be:

- steel;

- aluminum;

- bimetallic - in this case, two types of metals are used for manufacturing.

Copper is also often used. Bimetallic and aluminum devices are considered the most effective today. But steel devices also have a significant advantage - their cost is the most affordable.

The built-in convector can fit perfectly into any interior thanks to the rich color palette available from most equipment manufacturers

It is worth paying attention to the decorative elements of the equipment; they can be different: metal, wood. And for painting, powder paints of various colors are used, which makes the offer even more diverse.