Probably every stove owner eventually has a question about changing the type of fuel. This happens for various reasons. For example, someone used to use wood before, but now wants to try coal or peat to fire the stove, since these types of fuel provide more heat. Or maybe buying firewood is more expensive for someone than buying coal. But be that as it may, you still need to know how to properly heat a stove with coal. Although not all stoves are suitable for this type of fuel. For example, you cannot put coal into a Russian stove; a Dutch stove is not suitable for it, since large soot deposits and significant overheating are contraindicated for it. But coal is suitable for potbelly stoves, steel, cast iron and other heating structures.

Coal and its types

At first glance, all coals are the same. But this is far from true. Coal contains carbon and some non-combustible impurities. As a result of the combustion of these substances, a lot of heat is released and ash is formed.

Different regions produce coal with different amounts of impurities. Fuel types are determined by specific criteria. Thus, depending on age, the presence of humidity and impurities, as well as the specific heat of combustion, the following are distinguished:

- lignite coal, which is characterized by a loose structure. It is used less in everyday life, and is more often used to ensure the functioning of power plants and other large enterprises. It refers to young coals (specific heat of combustion (SHC) less than 3 thousand kcal/kg);

- brown coal, which is also called subbituminous coal or black lignite. It is, as it were, a transition phase between lignite and coal. It is usually used in small or private boiler houses. It is a good quality raw material for the chemical industry (TCV from 3.1 to 5.1 thousand kcal/kg);

- hard coal, which is a hard, combustible, mineral resource, occupying an intermediate place between brown coal analogues and anthracite (UTS from 5 to 5.6 thousand kcal/kg);

- anthracite is the oldest and best of all varieties, which is characterized by black color, shine, and high specific heat of combustion (from 7 to 9 thousand kcal/kg). The rooms, heated with anthracite, are incredibly warm and cozy.

What is produced when burning wood

Now we can answer the main question of the article.

Regardless of the size of the flame and the surrounding conditions, wood always turns to charcoal first. If at this moment the flame goes out for some reason, then coals will remain in place of the fire. When the fire burns out to the end, by this time the coals have time to become ash, which remains when the wood is burned. There is an opinion that you can get ash immediately by burning wood, bypassing the stage with coals, but this is not so. The procedure for the appearance and decay of the latter can be done as quickly as possible if there is a high temperature and enough oxygen around, but it cannot be avoided.

Whether ash or coals remain at the site where the wood was burned depends solely on the moment when the flame goes out. If the fire is extinguished early, then instead of firewood there will be coals; if you let it burn to the end, constantly maintaining the flame, only ash will remain. The latter can no longer be used as fuel, so further maintenance of the fire becomes impossible.

In which ovens can you burn coal?

Since, as a result of combustion, coal produces a higher temperature than wood fuel, stoves for combustible stone (black gold) are slightly different from wood-burning designs.

Although, you can burn with coal using an ordinary brick oven, but only with thickened walls and a 2-row grate. Plus, such a heating structure must be equipped with an additional hood that would not be connected to other channels.

There are designs with two water boilers in the furnace, with the help of which not only the room is heated, but also the brickwork is significantly cooled. Such devices require special supervision, since they must constantly contain water.

Plus, the dimensions of the grate and ash pan must be identical, otherwise there may be significant heat losses.

It will be interesting! Instructions on how to make a bell-type stove.

A little about heat transfer

Classic fireplaces with a shallow open firebox built into the wall and framed by a portal are beautiful, but not functional.

At a high cost, they have a significant flaw - low efficiency, the limit of which is 20%. Such fireplaces will only heat a small room, and it is impossible to influence the amount of heat they produce. Practical owners prefer cast iron stoves with a closed firebox, the efficiency of which reaches 80%, to classic fireplaces. Two or three stacks of logs (although they can run on different fuels - peat, coal, diesel and gas) - and a fireplace with a closed firebox warms its owner all day long. Power up to 25 kW allows you to heat an area of 250 m2. In this case, the flame strength can be adjusted using a damper. Stoves with transparent doors (the hearth in such fireplaces is covered with heat-resistant glass) are equipped with secondary combustion systems for flue gases and have an advantage in maintenance (less ash). Stoves without lining, painted with heat-resistant paint, are unlikely to decorate the interior, but they are more convenient to use. Such fireboxes are mobile (they can be placed in any desired place) and easy to install (they can easily be connected to the chimney). For zealous owners, fireplace stoves are also good because you can cook on them: some of the models are equipped with a small stove.

A set of measures before starting the fire

For the normal passage of the entire combustion process, it is necessary:

- carefully inspect the stove structure, starting from the firebox door of the stove and ending with the chimney. If cracks are found in the brickwork or chimney pipe, they must be sealed with a sand-clay mixture. Otherwise, the room will instantly fill with smoke, a large amount of carbon monoxide may appear, and small cracks will turn into large cracks and can actually damage the masonry;

- whitewash the pipe if you have not used the stove for a year or more;

- clean the chimney structure, including chimney channels, pipes from soot (if you have not used the stove for 3-4 months);

- clean slag and ash from the furnace. To avoid the appearance of dust in the room, combustion waste must first be filled with water, then raked out and taken outside;

- check for traction. To do this, insert a newspaper folded lengthwise into the firebox, set it on fire, and if smoke goes up the chimney, then everything is fine;

- use a dry cloth to wipe the outer part of the heating structure, otherwise an unpleasant odor will appear during the fire;

- Heat a little at a time 2-3 times a day, if the unit has not been heated for a long time, to prevent overheating of the stove.

*

Algorithm of actions

In fact, everything is extremely simple:

- Initially, the furnace firebox is covered with a small amount of paper.

- It is necessary to put wood chips, small wood shavings or bark on top of it; it must be dry.

- For the next layer, take logs, but their thickness should be less than those that are already used in a burning oven. This amount of materials will be enough to warm up the heater.

- When the flame is sufficient, the firebox is filled with firewood, and its level should be 20 cm lower than the firebox. With this approach, the fuel will have time to burn out even before it enters the chimney.

- When the required amount of warm air has accumulated, you can begin to add coal, starting with small pieces and throwing in more and more.

Packing in bags is the most convenient

What not to do?

When burning coal in a stove, the following is prohibited:

- use pieces of bitumen, plastic, construction and household waste as kindling material;

- leave the vent and combustion door open at the same time;

- When lighting, use gasoline, kerosene, alcohol, and other flammable substances.

It should be remembered that adults should constantly monitor the combustion process and under no circumstances transfer this function to children.

To ensure maximum heat transfer, it is necessary that the coal be in the form of not too large pieces. It is not recommended to use excessively wet fuel, since during combustion a lot of steam will be released from its surface, which will significantly reduce the efficiency of the combustion process.

Coal storage

Coal for heating WPC is easy to place on the site and store. Coal can be placed outdoors. It does not get wet and is not afraid of precipitation. Coal is quite heavy, several tons of coal takes up very little space. I dumped the coal in the area and covered it with a tarp to make it easier to get it out from under the snow. Coal is available both in bulk and in bags. In bags it is more expensive, but it is already prepared for burning, chopped into pieces the size of a nut. But unloading these bags can be a problem, whereas bulk coal can be emptied from a dump truck in 2 minutes. In loose coal there are large pieces that then have to be chopped. I chose this option. It’s even fun for me to go out into the frost in the morning and chop coal. I stab him with a cleaver (a kind of sledgehammer, one side of which is made in the form of a wedge)

Coal combustion process

Let us remind those who have forgotten, we will teach those who do not know how to light a stove with coal. The following stages of firing a furnace with coal can be distinguished:

Advice! Do not rush to part with coal dust, as it is an excellent fuel.

- Prepare coal.

- Take crumpled newspaper or other paper and place it in the firebox. Ignition can also be accomplished using wood shavings.

- Place 10-12 wood chips, for example pine or birch, on top in the shape of a well or hut. It is necessary to ensure that air can circulate freely between the firewood and the paper, which will promote more efficient combustion.

- Set the newspaper on fire.

- Close the door and at the same time open the ash pan, with which you can regulate the combustion process.

- After the wood has burned, pour fine coal on top with a layer thickness of approximately 12-15 cm.

- After the fuel burns strongly, you can continue to use fine coal, or you can pour larger coal into the firebox in a layer 20-25 cm thick (depending on the dimensions of the combustion chamber).

Important! Until the coal begins to burn well, it needs to be stirred a little from time to time to improve air circulation and prevent the formation of a homogeneous sintered mass.

* To prevent smoke from entering the room, during the next addition of fuel, you should close the ash pan with the door open.

Advice! If the metal stove is equipped with burners, then it is better to pour coal through them.

Why might there be smoke?

Even if the stove is heated correctly, plumes of smoke may form and enter the home. More often, this is caused by low quality coal. However, the causes of problems are:

- Clogged chimney or ducts.

- The appearance of cracks and holes in the masonry. The draft and smoke temperature are significantly reduced.

- Destruction of internal masonry or well.

If ignition is carried out in a cold firebox, smoke may appear. Soot will begin to form if several heating devices are connected to the chimney. To prevent carbon monoxide, smoke dampers must be installed.

Possible problems and solutions

It happens that the stove seemed to light up normally, but other problems appeared during the fire. What to do, what measures to take to eliminate them? Here are the main problems and ways to get rid of them:

- The stove structure heats up unevenly, the temperature inside the stove for burning coal is low. There may be several reasons: low quality coal, a poorly closed fire door, the presence of cracks. To improve the quality of the fuel, it must be slightly moistened with water.

- A partial burst of flame is observed. This happens in two cases: they forgot to open the smoke damper or the natural draft decreases due to strong wind.

- The presence of a white flame and a hum in the firebox indicates too much draft. To fix the problem, you need to cover the vent a little.

- Smoke returns to the room. This is evidence of cracks in the heating system. Another reason is a large accumulation of soot in the chimney, due to which smoke cannot escape outside normally.

When burning coal, you must adhere to operating and fire safety rules. It is not difficult. And if you heat it correctly, the stove will bring warmth, homeliness, joy and comfort to your family. Enjoy this family hearth for many years to come!

Advice! Do not rush to part with coal dust, as it is an excellent fuel.

Why close the damper?

Closing the damper in the furnace in the house is necessary to preserve heat and regulate draft. It is installed in the upper part of the stove, under the ceiling, at the beginning of the chimney pipe. If you leave it open, the oven will cool down quickly.

When the damper is open, ventilation occurs inside the stove: cold air from the house enters the inside of the stove through the blower, warm air comes out through the pipe. Accordingly, the bricks cool quickly.

This does not happen when the damper is closed. On the contrary, the walls of the stove heat up more strongly; it can hold heat for up to two days, providing a comfortable temperature in the house. Allows you to use the stove more efficiently and save on fuel.

Bubafonya - the most popular long-burning potbelly stove design

The practicality of the Bubafonya stove is proven by its popularity. The fact that this is one of the most popular long-burning stoves is evidenced by the fact that it is used in almost all small greenhouse farms.

The great advantage of this stove is its practicality and ease of use - it is practically omnivorous; dry firewood, sawdust, pellets and briquettes made from straw or sunflower can be burned in the firebox. This stove also shows one of the highest results in terms of fuel combustion duration.

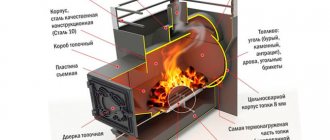

The basic concept of this heating device is that the fuel combustion process combines the process of burning conventional fuel with a controlled supply of oxygen and the process of pyrolysis. The design of the furnace is a metal body with an open top. For the body, a 200 liter thick-walled metal barrel is most often used. It contains a central rod, made of a thick-walled pipe, with a rigidly welded metal disk slightly smaller than the internal diameter of the barrel. The height of the pipe is 10-15 cm higher than the barrel. Ribs are welded on the bottom side of the disk so that there is a small space between the disk and the bottom of the barrel - this is necessary for oxygen access to the firebox. The third element of the design is a structure similar to a guide with a disk. The difference is that the diameter of the pipe is larger than the guide, and the disk itself has holes throughout its entire area. It is put on the internal guide and gradually moves down as the fuel burns. The lid is made of thick metal so that the hole allows the press to lower evenly as the fuel burns. The chimney is sealed in the upper part of the body at a distance of 5-7 cm from the top.

How bubafoni works

Before use, the central guide is inserted into the housing. The entire volume of the body is filled with fuel - firewood, briquettes, flights. The firewood is stacked vertically very tightly. The height of the bookmark should be 5-7 cm below the top cut of the barrel. After this, the upper press is installed on the guide and the cover is put on. Ignition is carried out from above. After the fuel combustion process begins, a process of gradual temperature rise occurs - oxygen enters through the pipes into the combustion chamber. When the temperature rises to 300 degrees, the process of gas formation begins. The gases rise upward and the flame moves into the space between the lid and the upper press. Thus, the process of combustion of gases begins. To regulate the burning speed, an adjustable damper is installed on the pipe of the upper press. When using such a stove, one load of firewood is enough for 48-72 hours of burning.

Tips from experienced stove makers

If you have a stove or boiler in your home that runs exclusively on coal fuel, you will still have to light the heating device using paper and firewood. Only after the required temperature has been reached in the firebox can the coal itself be poured. If you don’t know what volume to take, then you need to focus on a layer of about 5-6 centimeters.

When this volume of material burns well, it will be possible to add the remainder in such an amount that the layer is already 15 centimeters. With this approach, you can be sure that the stove will light up well and there will be sufficient temperature in the house.

When kindling, the pipe valve should be moved back slightly, and the coal itself should be placed on the grate. At the moment when the fuel has already ignited well, it is necessary to open this valve to the maximum.

At the next stage, you should add a portion of small coal (if it is large, you will have to split it). Its layer will be approximately 5-8 centimeters, and the area should correspond to the grid. When the filling is completed, the firebox door should be closed, and at the same moment the ash pan should be opened. After the material flares up, the volume is increased to 12-20 cm.

As for subsequent portions of coal that will be added after the batch of material burns out, some rules should be followed:

- A new bookmark is made only when you are convinced that the previously filled coal has already flared up well enough.

- Before adding a new portion of coal, if the firebox doors are opened at this time, it is necessary to cover the ash pit.

- You should not allow the material to burn out right up to the grate; combustion should be uniform throughout the entire layer.

If you pay attention, you will notice that purchased coal comes not only in large pieces. It may contain small particles, as well as typical dust. To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

To prevent it from combining into a single layer during combustion, the material should be moistened with water before laying.

The same applies to those who use fatty coal of the PZh or Zh brands. However, the volume of water should not be large, because the material burns better in a dry form. When lighting a stove, fuel of the PS and SS grades, where small elements predominate, must be moistened with a slightly larger volume of liquid.

There is also skinny coal, which is marked with the letter T; it is this that should be moistened generously, but long-flame material is only sprayed to remove dust. As for the “Anthracite” brand, it does not need to be wetted at all, only if it is dusty, it is lightly irrigated with water.

When the combustion process itself is underway, the combustion chamber door must be closed. It should be opened only when it is planned to throw in a new batch of coal. Unlike firewood, this material does not need to be turned over as often, otherwise the firebox will cool down and some of the material will fall through the grate.

Now it becomes clear what is the best way to heat the stove and how to do it correctly. Of course, the process may not work out the first time, but don’t despair, because after two or three attempts all actions will be performed automatically, and the house will be filled with comfortable warmth and the pleasant crackling sound of burning coal or wood.

How does a coal boiler work?

What is a coal boiler? This is a simple installation that consists of two compartments. Coal is placed in the upper firebox. After it burns out, ash and slag remain, which fall into the lower compartment and are removed from there as necessary. Between the chambers there is a regular grate made of durable cast iron.

Such furnaces can be additionally equipped with sophisticated automation, which allows the unit to switch to offline mode and control the draft. If there is no automation, coal stoves operate using natural circulation. The first type of device has several operational advantages, but

Long-burning furnaces are much larger than simple devices.

Automation works extremely simply. Thanks to it and the operation of the fan, it is easy to control the flow of oxygen into the firebox. The more it is, the hotter the coal burns, and the faster the fuel burns, giving off the maximum amount of heat. Restricting oxygen access leads to the opposite effect. The fuel burns more slowly, the amount of heat released decreases, but the burning time of the coal increases.

The heating temperature is regulated by a special temperature sensor. The boiler operating modes can be programmed. If the set temperature is reached, the sensor is triggered and turns off the fan. At the same time, the oxygen supply decreases and the furnace burns out more slowly. When the temperature drops, the fan turns on and begins to intensively pump oxygen into the firebox. The coal is actively burning again. If you take into account such features of the operation of a solid fuel boiler, it becomes clear when and how to put coal in the stove.

The most important stage

Everything is ready to start lighting the fireplace. This process is considered a highlight, as it requires a certain skill and endurance. Many hobbyists are skeptical about modern means of automatic ignition, considering it unnatural. However, not everyone is able to light firewood with one match. Therefore, you should follow all the recommendations, which begin with the methods of stacking firewood:

- If the fireplace is not being lit for the first time, then you should not remove all the ash remaining from the previous use from the grate. A small layer of it serves as excellent thermal insulation protection. It will protect the fireplace body from overheating and prevent cold air from entering the firebox through the ash pan.

- Any kindling of a fireplace begins with the stacking of firewood. The classic method involves placing thicker ones on small branches or splinters. Gradually, the wood pyramid is formed by logs of larger diameter. The most important thing is to leave enough space between layers to allow air flow.

Preparing to light the fire

- An alternative method is reverse laying. It consists in placing thick logs on the bottom. Thinner firewood is placed perpendicular to them. By alternating the direction of placement and reducing the diameter of the firewood, we come to the conclusion that there will be small kindling on top. As a result, the fire will move from top to bottom. This method gives the effect of a closed firebox, that is, longer burning of wood, and therefore greater heat release.

- Before lighting the fireplace, you need to check the draft again. If the room is cool enough, there may be no draft due to cold and damp air in the chimney. To prevent the fireplace from smoking when you light it, you need to open the direct valve in the pipe and warm the air using an old newspaper. Once the draft appears, you can begin to light the fireplace. Make sure the ash pan or ash door is open.

- It is convenient to light firewood with paper. Roll it up and light it with a match. Then take it to the wood well and slip it between it and a layer of old ash. When the wood begins to burn on its own, you will have to close the glass screen, if any, so that sparks do not fly beyond the space limited by the firebox.

Beautiful flame in the firebox

Features of kindling

If the heating device is not being used for the first time, then before igniting it, you should remove all the ash that has accumulated inside. A similar procedure should be carried out once a year at the beginning of the season. If you do not take care of the stove, then soot is deposited on the walls inside it, as a result it takes longer to warm up, requires more fuel, and the percentage of heat transfer decreases.

Ideally, dry materials should be used for the firebox, but if these are not available, then it is permissible to fill the stove space with wet wood or coal. The only thing you should know is that in this case a larger amount of soot will settle on the walls, and accordingly, cleaning will need to be carried out more often.