Today, gas boilers and water heaters are used everywhere both for heating water and for heating houses. For the most part, separate single-circuit boilers or one single-circuit boiler and an indirect heating boiler are used for heating and hot water supply, which creates certain inconveniences in their placement. Therefore, in houses and apartments with low hot water consumption, the installation of double-circuit gas boilers, which combine water heating for both household needs and heating, is becoming increasingly popular. The installation of gas boilers is associated with a number of specific difficulties, related more to compliance with the norms and requirements for boilers than to the process of their installation.

Double-circuit boiler design

The design of double-circuit gas boilers is essentially similar to the design of a conventional single-circuit boiler, where a gas burner heats a heat exchanger with a coolant. The main difference is the ability of double-circuit boilers to simultaneously heat water for heating the house and for household needs. This is achieved through the combined placement of pipes for heating and hot water supply in the heat exchanger.

At first glance, the heat exchanger of a double-circuit boiler looks like an ordinary coil with a radiator grille. But it is necessary to note the following: the coil of a double-circuit boiler is most often a combination of 2 in 1 pipes. Inside the main pipe through which water for heating flows, there is another one for hot water supply. At the same time, one more very important point should be noted. Water in such a double heat exchanger circulates in opposite directions in each of the circuits. This was done specifically to improve heat transfer and this must be taken into account when designing and connecting the water supply and heating system to a double-circuit boiler.

The presence of two heating circuits at once also affected the number of connected pipes. In contrast to the single-circuit one, where there were only three pipes, supplying and discharging water and one supplying gas. There are five such pipes in a double-circuit boiler. The diagram depicting a double-circuit gas boiler shows the following (from right to left):

- pipe with incoming coolant for heating;

- supply pipe for hot water supply;

- gas supply pipe;

- pipe with outgoing hot water for water supply;

- pipe with outgoing coolant for heating.

Important! Before using the above diagram when connecting your own boiler, carefully study the manual for it. It is quite possible that your boiler will be connected slightly differently. For example, both inlet pipes are on the right side, and both outgoing pipes are on the left.

It is also worth noting that today on the market you can find a double-circuit gas boiler, both wall-mounted and floor-standing. In addition to the installation method, the difference between them is that the floor-mounted one requires a separate room - a boiler room, while the wall-mounted one can be installed in the kitchen or in a place reserved for the boiler. We will look further at where exactly and how to install gas heating boilers.

Standards and requirements for the installation of gas boilers

It should be noted right away that the installation and connection of a double-circuit gas boiler can only be carried out by specialized organizations that have permission and a license for this activity. Self-installation and connection is fraught with fairly high fines. But still, you will have to do some work on preparing to connect the boiler and obtaining the necessary permits yourself.

The following recommendations and rules are excerpts from the main regulatory documents, such as SNiP 42-01-2002 “Gas distribution systems”, as well as SNiP II-35-76 “Boiler installations”, Code of rules for the design of autonomous heat supply systems SP-41-104 -2000. These regulatory documents describe in detail what can and cannot be done when installing gas equipment. We will consider the main most important requirements for installing gas boilers.

1. The room where the gas boiler will be installed must be at least 4 m2 with ceilings not lower than 2.5 m;

2. The doorway in the room must be at least 80 cm wide;

3. The room must have a window opening. The size of the window is calculated based on the following requirements: for 10 m2 of area, a window with an area of 0.3 m2;

4. It is necessary to have high-quality ventilation in the room to ensure constant gas combustion. The hole area should be 8 cm2 per 1 kW of boiler power. This also applies to boilers with a closed combustion chamber, for which coaxial chimneys are used, combining the functions of removing combustion products and supplying air to the boiler;

5. The diameter of the chimney is selected according to the power of the boiler itself and is calculated using a special formula. In general, boilers from 30 kW to 40 kW are most often used for heating a house. Accordingly, chimneys with a diameter of 130 mm and 170 mm are installed;

6. The upper end of the chimney should protrude 50 cm above the roof ridge. If a coaxial chimney is used, its outlet end should protrude from the air intake by at least 20 cm;

Standards for private houses

According to the regulations, gas heating equipment can only be placed in rooms with good ventilation, which are located:

- On the first floor of the building;

- At the plinth level or in the basement;

- In the attic;

- In the kitchen (only boilers with a power of no more than 35 kW are suitable for installation in kitchens).

In the latter case, it is necessary to take into account not one standard, but two at once. The first of them allows you to install units with a power of up to 35 kW, and the second - up to 60 kW. These standards refer only to heating equipment - no requirements are imposed on any other devices using gas.

To know exactly what standard needs to be followed in a particular situation, you need to contact your local gas service - it is their employees who will put the equipment into operation after installation. Information about current standards can also be obtained from the designer - in the end, the source of information is not particularly important, only the result is important.

The result in this case is an understanding of the rules for installing gas boilers. In addition, you need to have an idea of what kind of room is needed for a gas boiler so that it can be installed and put into operation, having gone through the stage of coordination with the relevant services.

The placement of a gas boiler in a private house, depending on its total power, should be carried out as follows:

- Power up to 150 kW - installation is possible on any floor where there is a free separate room;

- Power from 150 to 350 kW - equipment can be installed in a separate room no higher than the first floor, as well as in extensions.

If the equipment power exceeds 350 kW, then it is prohibited to use it in private homes.

Easily removable window structures

An easily removable building envelope (ELS) is window glass that easily breaks under excessive pressure in the event of an emergency. The window opening is completely freed, while all the supporting structures of the building maintain their integrity.

Easily removable window designs

The use of reinforced glass for glazing LSC is prohibited, since it is too strong and does not collapse under the influence of loads. The same goes for polycarbonate, triplex and stalinite.

According to GOST standards, special elements can be used instead of simple glass in light-removable structures.

It could be:

- a rotating flap, which, in the event of a gas explosion, even with a slight excess of pressure, swings outward or rotates around the fastening elements;

- a displaceable element that includes a window frame with a double-glazed window - in the event of an emergency, the structure falls apart and flies out onto the street.

To equip window units with a combustion chamber operating on gas, safety locking mechanisms, latches and self-destructive fasteners are used. Their function is to ensure the smooth release of the displacing or rotating device under the influence of excessive pressure.

Thus, it is not only the size of the window unit that matters. With its help, an opening is cleared for the release of the energy generated during the explosion of the combustion equipment.

Standards for installing a gas boiler in the kitchen

If the kitchen is selected as a site for installing gas heating or water heating equipment with a power of no more than 60 kW, the room must meet several requirements:

- The total volume of the room for installing a gas boiler must exceed 15 m3, and another cubic meter is added for each kilowatt of boiler power;

- The height of the room must exceed 2.5 m;

- The ventilation system must provide exhaust volume three times the size of the room;

- The air flow through the ventilation system should also be three times the volume of the room, and this value does not include part of the air spent on the combustion process;

- The room under the gas boiler must have a window with a window (the area of the window is selected depending on the thickness of the glass);

- The room door should not be located close to the floor, but at such a distance that the total gap area exceeds 0.025 m2.

There is an additional rule that is not noted in the standards, but requires fulfillment - gas heating equipment can only be installed in those rooms that have a door. Failure to comply with this rule (as well as all others) always leads to refusal to put the boiler into operation.

Today, meeting the requirement for a door in a room with a gas boiler can be problematic. In modern construction there is a tendency to remove most partitions and form arches in doorways. The solution to the problem may be non-standard door options. Glass doors are also a good option, as they do not overload the interior, but still perform their function.

Requirements for individual premises

Boiler rooms located in separate rooms must meet a number of requirements, which are very similar to the previous ones:

- The ceiling must be at a height of over 2.5 m;

- The area and volume of the room are selected depending on individual preferences, but the minimum allowable volume is 15 m3;

- Each boiler room wall must have a fire resistance limit of 0.75 hours and no flame spread (brick, concrete and building blocks meet this requirement);

- Ventilation is subject to the same requirements as when installing a boiler in the kitchen - three times the outflow and the same amount of air intake, increased by the volume of oxygen consumed during the combustion process;

- The room must have at least one window with a glazing area of 0.03 m2 per 1 m3 of room volume.

When installing gas boilers with a power of over 150 kW, it must be possible to exit the boiler room directly onto the street. Placing a gas boiler in an individual residential building assumes that the equipment cannot be adjacent to living rooms. In any case, the boiler room must be equipped exclusively with fire doors.

An important point is that the room standards for installing a gas boiler take into account the glazing area, and not the size of the window itself. In some situations, it is regulated that the room must have at least one glass with an area of more than 0.8 m2. If necessary, such a window can even be placed in the door - there are no rules about its location in the regulations, and in this case there is no need to track the distance from the boiler to the window.

Glazing material

When installing a window for a gasified boiler room, special requirements are also imposed on the frame material. They must be resistant to high temperatures and made from environmentally friendly materials.

Aluminum or metal-plastic is used to construct the window structure. The aluminum profile protects the heated compartment from adverse climatic conditions. It provides reliable sealing that prevents the formation of drafts and prevents the fire in the boiler from going out even with strong gusts of wind outside.

Metal-plastic frames are no less reliable and help retain heat in the furnace room.

Plain sheet glass is used as a glazing material. It is also allowed to install double-glazed windows that meet the requirements of GOST and act as easily removable structures.

Extension of boiler rooms

Of course, it is very convenient to have a separate room for gas equipment, but this is not always possible, and you have to think about where to place a gas boiler in a private house under such conditions. The solution to the problem is to add a boiler room.

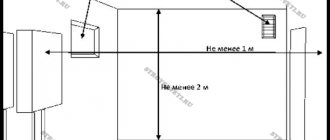

The standards in this case coincide with those described above, but there are a number of additional requirements:

- The boiler room can only be attached to a solid wall;

- The distance between the nearest window or door should be more than one meter;

- The boiler room can only be laid out using non-combustible materials that can last at least 0.75 hours before ignition;

- The walls of the boiler room itself must be erected separately from the main building - i.e. you will need your own foundation and four new walls.

In order for a gas line to be installed into an equipped boiler room, the building must be registered. In the absence of appropriate documents, representatives of the gas service will simply refuse to approve the equipment, even if all standards are met.

If the main building has not yet been built, then during the design process you need to find out what the room for the gas boiler should be like and comply with all the requirements, otherwise putting the boiler into operation will be impossible. When installing a boiler in an already constructed building, you can allow small deviations in some parameters, but they must be compensated for by others.

Safety regulations

Gas is a cheap type of fuel, burns without residue, has a high combustion temperature and, as a result, a high calorific value, however, when mixed with air, it is explosive. Unfortunately, gas leaks are not a rare occurrence. In order to protect yourself as much as possible, you must strictly follow the safety rules.

First of all, it is necessary to study the operating instructions for gas equipment and follow them, monitor the normal operation of gas appliances, chimneys and ventilation.

Owners of residential premises are prohibited from disturbing the ventilation system of residential premises during redevelopment and reconstruction of the apartment. Before igniting the gas stove, the room must be ventilated, leaving the window open for the entire time you work with the stove. The tap on the pipe in front of the stove is opened by moving the handle flag to a position along the pipe.

The flame should light up in all burner holes and have a bluish-violet color without smoking tongues. If the flame is smoky, the gas does not burn completely, you need to contact the specialists of the gas supply company and adjust the air supply

Please note: if the flame comes off the burner, this means that too much air is coming in, and under no circumstances should you use such a burner!

If you notice the characteristic smell of gas in the room, you should not turn on or turn off any electrical appliances to avoid causing an electric spark, which could lead to a gas explosion. In this case, it is urgent to shut off the gas pipeline and ventilate the room. If you go to the country or on vacation, you must turn off the gas by turning the tap on the pipe. Ideally, you should turn off the gas valve after each use of the stove or oven.

You must immediately contact the emergency gas service in the following cases:

- you can smell gas in the entrance;

- if you discover a malfunction of the gas pipeline, gas taps, gas appliances;

- when the gas supply suddenly stops.

Remember that inspection and repair of gas equipment can only be carried out by gas industry workers. Their authority is confirmed by official identification, which they must present to the owner of the apartment.

Photo: ShutterStock/Fotodom.ru

Installation of a gas boiler in combined kitchens

In modern construction, the arrangement of studio apartments or layouts in which the living room and kitchen are combined into one large space is actively practiced. Of course, such a solution has a lot of advantages - for example, it opens up a large portion of free space, which is perfect for implementing all kinds of design ideas.

The problem is that gas services regard such layouts as residential, so the installation of any gas equipment in them is prohibited. In studios this problem cannot be solved, but when combining a living room with a kitchen, options are possible.

So, it is quite possible to call the room “kitchen-dining room” during the paperwork process. Thanks to this name, the combined room will not be considered residential, so you can safely install a gas boiler in it. Another option is the installation of a sliding partition between the rooms or a complete re-issuance of all certification papers.

Metal protective screens in Moscow

Metal protective screens and other products can be purchased at Leroy Merlin in Moscow at low prices. Select the product you are interested in on the website and buy it in our online store. The range of products presented in the catalog is extremely wide. Among them there will certainly be a position suitable in all respects.

All products presented in the “Metal protective screens” section are produced by well-known companies that have proven themselves to be of high quality for their products.

You can always place an order and pay for it online on the official website of Leroy Merlin in Russia. For residents of the Moscow region, we not only have low prices for goods in the “Metal protective screens” category, but also fast delivery to cities such as Moscow, Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye, Dolgoprudny, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky, Solnechnogorsk, Istra and Zhukovsky.

Gas boiler location

A gas boiler in an apartment is usually placed in the kitchen, which is determined by the presence of all the necessary communications, and the distance from the gas pipe to the boiler is maintained without problems. As a rule, wall-mounted boilers are used for apartments, which are attached to the walls using special brackets that come with the equipment.

If the house has a staircase leading to the top floor, the owners have a desire to install a boiler under it. As a rule, the volume of space under the stairs is enough for a boiler, but there are problems with ventilation, so it has to be arranged separately using large-diameter pipes.

Deciding where to install a boiler in a private home depends on the format of the equipment and the requirements specified in the attached documentation. The passport for the boiler always indicates the required distances from the walls, ceiling and opposite wall, and you should definitely focus on these indicators.

Is it possible to install the equipment yourself?

Installing a wall-mounted gas boiler is not the easiest task. The safety of the residents of the house directly depends on the correctness and quality of the settings. Therefore, the requirements for the installation of a gas heat generator are regulated by strict standards, in accordance with the legislative framework of Russia.

As a result, installing a wall-mounted gas boiler is a very difficult task, and often beyond the capabilities of a beginner. Special knowledge is required on how to properly install and connect the equipment so that it works properly and is safe.

Installation features according to SNIP

In the absence of specific recommendations in the documents attached to the boiler, it is worth using SNIP standards, according to which:

- Installation of gas boilers is only possible on walls made of non-combustible materials. The distance from the gas boiler to the wall must exceed 2 cm.

- If the walls are still subject to combustion, they must be protected with fireproof material. The most common options are a layer of asbestos with a metal sheet, plaster over 3 cm thick, ceramic tiles or mineral wool cardboard.

- On the sides, the distance from the boiler to the wall must be at least 10 cm. If the walls are made of flammable materials, this distance increases to 25 cm.

- A gas boiler can only be installed on a substrate made of non-combustible material. In the case of wooden coverings, special supports are made from tiles or bricks, which provide the necessary fire resistance. The base for floor-standing devices must be at least 10 cm wider than the dimensions of the boiler itself.