How to reassemble the AOGV boiler

To reassemble the boiler, first reinstall the burner block; how to do this has already been described above.

Immediately connect all the tubes as expected, check the gaskets to ensure they are all in place and not worn, tighten the screws and nuts. Replace the turbulators. The heat exchanger channel is now clean and the edge of the gas burner is clearly visible from below. It is simply impossible to make a mistake when installing turbulators. Simply push them into the channels and they are held in place by the central metal plate extension on top. Insert so that the plate is oriented along the radius of the cylindrical heat exchanger, that is, the blades will be located approximately tangential to the circle.

The next step is to replace the heat exchanger cover. In this case, the eyes for the clamps should fit into the slots of the cover. Insert metal cotter pins into the eyelet slots and lightly tap them from the back. The lid should fit as tightly as possible to the heat exchanger. Finally, use pliers to spread the antennae - and that’s it, the lid will be securely fastened.

Next, replace the top lid of the boiler. The holes from the screws that came out normally will help you navigate with its correct position. If the traction sensor was not removed and is already in its place, all you have to do is connect its tube to the tee and tighten the nut to fix it.

Complete the boiler assembly by installing the hood. Slide it under the pipe, put it on its socket, it should fit very tightly, then carefully set it in place. Make sure that the three protrusions on the cap fit into the corresponding holes in the boiler lid. In this case, the cut out semicircular window will be above the passing tube of the temperature sensor.

After this, of course, check all connections for leaks and proceed to starting the boiler. If the wick lights up immediately, and after 15 seconds the magnetic valve operates, then the start-up went well.

Open the gas supply valve. The burner should ignite easily, and the fire should burn evenly, with the same height of flames.

Moreover, it is important that the flames are directed exactly upward, and not to the sides. This means that the automation worked perfectly, the cleaned boiler works as expected

Causes of clogged heating system

The main source of contaminants that disrupt the operation of thermal circuits is the coolant. This is most often tap water. When filling the system, small debris from the water supply can easily get in with it. As the water circulates, this debris is transferred to the radiators, where it accumulates.

Another source of contamination is scale. It is formed in the boiler, where water comes into contact with the hot walls of the heat exchanger. Gradually, the inside of the boiler becomes covered with a layer of scale, which has relatively low thermal conductivity. A heat exchanger coated with scale transfers energy to the coolant much worse. With a thickness of salt deposits of several millimeters, the efficiency of the boiler can decrease by almost a third. During the process of cyclic heating and cooling, the scale crust is destroyed. The exfoliated particles enter the pipeline and are deposited both on the inner walls of the pipes and in the radiators. Accordingly, their heat transfer decreases and there is reason to think about how to flush the heating system in a private house with your own hands.

In addition, due to the oxygen contained in the water, rust gradually forms in the metal elements of the system. Like scale, rust increases the hydraulic resistance of pipes and is an additional source of contamination.

Source

Main characteristics of gas boilers AOGV-11.6-3

Floor-standing gas boilers AOGV-11.6-3 are single-circuit units with a rated power of 11.6 kW. The device is capable of operating on both natural and liquefied gas with very economical consumption. Today this is the best option for heating a house with an area of up to 110 square meters. m. At the same time, the unit has acceptable dimensions (850x310x412 mm), which makes it easy to find a place in the house and facilitates the installation of the boiler.

In general, AOGV-11.6-3 are reliable and practical; these heating devices are time-tested and ideal for use in Russia. AOGV boilers do not require any special conditions for operation. However, after several years of operation, it may be necessary to clean the unit with all its components from soot and other contaminants.

How quickly soot will accumulate in your AOGV depends on several reasons, including the initial correct installation of the device. The process of cleaning AOGV is not so complicated, so it is advisable to carry it out regularly, at least as a preventative measure before the start of each heating season.

When starting the gas boiler cleaning procedure, pay more attention to the details of any design in the unit. Everything has its purpose, and ill-considered actions can lead to emergency situations.

Price range

The cost of the Zhukovsky AOGV 23 boiler depends on the specific model and ranges from 20-24.4 thousand rubles. This price does not include the chimney. When purchasing, you should immediately clarify the equipment of the unit so that you do not have to urgently look for the necessary components.

In addition, additional costs will arise for concluding a warranty agreement.

It is not recommended to neglect this action, since subsequently you can spend a much higher amount on repairs.

NOTE!

Many users rely on their own skills and knowledge, intending to repair the boiler themselves. It must be remembered that unauthorized actions with gas equipment may entail administrative liability.

SAFETY INSTRUCTIONS

Persons who have examined this passport are allowed to service the device.

Installation and operation of the devices must comply with the requirements of the “Rules for the design and safety of operation of hot water boilers, water heaters and steam boilers with excess pressure”, as well as the requirements of the “Safety Rules for Gas Distribution and Gas Consumption Systems. PB 12 - 529", approved by the State Mining and Technical Supervision of Russia.

The operation of the devices must be carried out in accordance with the “Fire Safety Rules for residential buildings, hotels, dormitories, administrative buildings and individual garages PPB - 01 - 03”.

Operation of the device is only permitted with properly functioning automatic safety and thermal control.

Gas safety automatics must provide:

- Reducing the gas supply when the water temperature in the heating system reaches the set value.

- Shutting off the gas supply to the main burner when the set heating temperature is exceeded.

- Turning off the gas supply to the device in the following cases:

- when the gas supply to the device is stopped (within no more than 60 seconds);

- in the absence of draft vacuum or in the boiler furnace (for a period of no less than 10 seconds and no more than 60 seconds);

- when the pilot burner flame goes out (within no more than 60 seconds).

When operating the device, the hot water temperature should not exceed 95 °C.

Prohibited:

- operate the device with the heating system partially filled with water;

- use other liquids instead of water as a coolant**;

- install shut-off and control valves on the supply line and pipeline connecting the heating system to the expansion tank;

- operate the device if there is a gas leak through the gas pipeline connections;

- use an open flame to detect gas leaks;

- operate the device if there is a malfunction of the gas network, chimney or automation;

- independently eliminate malfunctions in the operation of the device;

- make any design changes to the apparatus, gas pipeline and heating system.

When the device is not working, all gas valves: in front of the burner and on the gas pipeline in front of the device, must be in the closed position (the valve handle is perpendicular to the gas pipeline).

Any malfunctions when operating the device on gas must be immediately reported to the emergency service of the gas operating company.

If gas is detected in the premises, you should immediately stop supplying it, ventilate all premises and call emergency or repair services. Until the malfunction is eliminated, it is prohibited to light matches, smoke, or use

** It is allowed to use household coolant “Olga” (manufacturer: ZAO Organic Products Plant) according to the instructions for use. After a period of operation, the coolant must be drained and disposed of.

The manufacturer reserves the right to make changes to the design and appearance of the product. This technical documentation may differ from the description above; see the operating manual enclosed with each boiler upon purchase.

Types of devices

All single-circuit and double-circuit AGVs produced by Zhukovsky have three main varieties, which allow customers to choose a heating column depending on their available budget:

- “Economy” modification - has a set of equipment necessary only for safe operation: domestic automation, temperature sensor, heat exchanger.

- The “Standard” variation is also capable of modulating the burner flame, is controlled by a foreign control system, and can turn off when overheated, preventing damage.

- The Comfort boiler complex is distinguished by the presence of a remote control unit, technology for maintaining the set temperature, and a room thermostat.

Working with AOGV

It begins when the gas supply is blocked - the corresponding valve closes. And this is a general principle for similar work with any boilers and columns.

How to clean the burner of an AOGV gas boiler? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the next two models.

First. AOGV 11.6-3. This is a reliable and practical device.

But after a certain period of operation, it is thoroughly cleaned. The process goes like this:

The burner block is removed

To do this, the pan of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples. Carefully unscrew the nuts located on the fittings of the automation mechanism. The paronite gasket on the main gas pipe is removed and its conditions are studied. If it is damaged, it needs to be replaced. The marked pallet is taken out through the groove, which is as close as possible to the tubes

The casing is also pulled out along with it. When fixing the lower part of the tray, point it towards you and remove the remaining holders (two pieces) from the engagement. This entire assembly falls to the floor. The main burner is examined and cleaned. The igniter nozzle is inspected. The wick and thermocouple are unscrewed. The box-shaped casing is separated from the pilot burner. This clears the way to the nozzle. If it is brass and there is plaque on it, it can be removed with fine-grained sandpaper. Cleaning the nozzle. To do this, thin copper wire and a blowing method under high pressure are used. The second action is carried out by a special pump on the side where the tube is connected to the tee. The same sandpaper is used to very carefully clean the bend of the thermocouple tube.

After this work, all the parts are assembled using the reverse algorithm. Smoothly, avoiding distortions, lift the entire block. The burner should be inside the housing, and the igniter and thermocouple should not touch the casing flange.

From the side of the tubes, the entire assembly should be tilted towards itself with a slight downward slope. The opposite side of the tray should rise.

Then feed it forward and simultaneously put on a pair of distant holds. They should be on the casing flange. The nearest hook goes to a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise direction. The gas pipe should be positioned only under its branch pipe of the automation unit.

Next, it is tested how correctly the gaskets fit, and all the tubes are returned to their places. The wrench tightens the nuts on two tubes: the igniter and the gas tube.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut here is tightened with your fingers.

The final stage is to check the tightness of all connections for potential leaks. If they are absent, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes through.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the set stretch outward and extend to the side towards the user. If there are difficulties with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Disassembly of burners. To do this, unscrew 4 pins on both sides.

- The plates with slots are removed from the top of the burners, then the springs. All parts are thoroughly cleaned.

- Reassemble all elements in reverse order.

After reassembly, a leak test is carried out to examine how tightly the burners adhere to the body.

Question about Danko

This brand has models with different automatic systems “Eurosit” and “Kare”. Below is an example of working with the second option on the Danko 24 model.

- Removing the cover. The screws on the back and front are unscrewed, two at a time.

- The American unscrews.

- The two nuts that secure the burner are unscrewed.

- The contact terminals are removed.

- The clamp is removed. The thermocouple is pulled out.

- The burner block is removed.

- Cleaning burners. Surfaces are cleaned with a brush or toothbrush. Holes - with a vacuum cleaner.

- Reassembly.

- Leak test.

The mechanisms of Ross boilers from the “Lux” series, where tubular burners are arranged, are disassembled using a similar principle.

Functions and principle of operation of security automation

In accordance with regulatory documents, automation equipment for boiler installations must stop their operation by cutting off the fuel supply in the following situations:

- the draft in the chimney is insufficient and there is a danger of burning;

- the gas pressure in the supply pipeline is too low or, conversely, too high;

- The flame on the igniter went out.

The listed situations can lead to the main burner going out and the room becoming gassed, which is unacceptable. For this reason, safety automatics for gas boilers must be installed on all old-style boilers where it was not provided by the manufacturer. Although it is often cheaper to replace a heater than to purchase and install automation on an old one. In addition to preventing gas contamination of the room or fumes, its functions also include maintaining the temperature of the coolant at a certain level specified by the user.

To understand how the automation of a gas boiler works, let’s briefly analyze its structure. It should be noted that both foreign and Russian manufacturers use the same operating principle in their products, although the design of the devices may differ significantly. Automatic gas valves from Italian manufacturers are traditionally considered the simplest and most reliable, which is why they are most common.

A prominent representative of such gas appliances is the Italian automatic SIT, or rather, its most popular modification 630 EUROSIT, whose device is shown below.

All structural elements are placed in one housing, to which gas pipelines are connected. In addition, a capillary tube from draft and temperature sensors (thermocouples), a gas supply line for the igniter and a cable from the piezoelectric element are connected to the device. Inside there is a shut-off solenoid valve, whose normal state is “closed,” as well as a gas pressure regulator and a spring valve.

Any automatic gas boiler equipped with a combined gas valve EUROSIT or another is started manually. Initially, the fuel path is blocked by an electromagnetic valve, which opens by pressing the adjusting washer, after which the fuel fills the chambers of the device and goes through a small gas pipeline to the igniter. While holding the washer, press the button of the piezoelectric device and ignite the igniter, heating the temperature-sensitive element for 10-30 seconds. This, in turn, generates a voltage that keeps the solenoid valve open, after which the adjusting washer can be released.

Then everything is simple, we turn the washer to the required division and thereby open access of fuel to the burner, which is independently ignited by the igniter. Since the automation of gas boilers is designed to maintain the set temperature of the coolant, human intervention is no longer required. The principle here is this: when heated, the medium in the capillary system expands and acts on the spring valve, closing it when it reaches a high temperature. The burner goes out until the thermocouple cools down and the gas supply resumes. You can study the operation of Italian SIT automation in detail by watching the video.

Types of pollution

For the operation of a solid fuel boiler, raw materials are required, due to which the combustion process will be carried out. Firewood, coal, peat and pellets act in this capacity. Each type of raw material has its own advantages and disadvantages. A common property is that during operation of the boiler, combustion products are released, which gradually accumulate on the internal parts of the chamber.

There are three main substances that pollute a boiler. The presence of each of them is due to certain factors:

- soot. Appears when the temperature during combustion of raw materials is not high enough. This is also affected by a lack of oxygen;

- resin. As a rule, its occurrence is due to various problems with the fuel: it may be too wet or of poor quality. Or you simply loaded too much raw material into the combustion chamber. A negatively influencing factor is also insufficiently high temperature;

- tar. The appearance of this substance indicates possible problems with the equipment itself. Either errors have crept into the design of the boiler, or the chimney was made too short, or the air flow is pumped into the chamber too weakly - the last factor is relevant for pyrolysis equipment.

Someone might think that a dirty boiler is not so bad, because all the deposits are hidden inside. In fact, the consequences can be quite negative. The performance of a solid fuel boiler depends on its cleanliness. With a high level of pollution, it will greatly decrease, as a result of which the house will become much colder, since the equipment simply will not be able to cope with heating the required volume of coolant.

In addition, such an attitude towards the boiler will lead to increased costs. First, fuel consumption will increase more and more as deposits accumulate inside the combustion chamber. Secondly, the boiler itself will quickly fail, and you will have to spend money either on repairing it or purchasing new equipment.

All these problems can be avoided quite simply:

use only high quality fuel; Initially, when choosing a boiler, pay attention to the compliance of its design with technical parameters; Perform preventative cleaning regularly. All this will significantly extend the service life of the equipment.

All this will significantly extend the service life of the equipment.

Disassembly and soot removal

For efficient operation of the equipment, it is necessary to clean the gas water heater. The deposits formed on the walls can disrupt the uninterrupted operation of the device, so there is no need to wait for the equipment to completely fail; preventive cleaning should be carried out periodically.

Before dismantling, it is necessary to block access to gas and water. Do-it-yourself cleaning of a gas water heater begins with removing the boiler doors and disconnecting the auto-ignition wire. Then the thermocouple, piezoelectric element and burner tube are removed

Carefully remove the nozzle and the burner itself

The thermometer sleeve, boiler lid, and flue are removed. Cleaning the geyser is done using a brush and brushes, which clean all internal and external elements. The nozzle hole is cleaned with a needle with a smaller diameter to avoid enlarging the hole and disrupting the combustion mode. The internal channels of the heat exchanger are blown out with a vacuum cleaner and wiped with a damp cloth.

At the same time, you can carry out minor repairs to the heat exchanger yourself: replace the gasket under the pilot burner, check the thermocouple, which is prone to breakdowns due to the specifics of its operation, and so on. Such work does not require large investments, but maintains the boiler’s performance at a high level, and the thermocouple device is quite simple, and replacing the element will not be difficult.

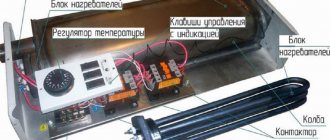

Structure of a gas boiler

Assembly is carried out in reverse order. When connecting the piezoelectric element, it is recommended not to use a tool to avoid damaging the ceramic base; it is better to tighten it by hand.

When installing, you need to check the thermocouple on the gas boiler; you need to know that the end of the conductors must be at the level of the place where the flame appears.

Cleanable nodes

Gas boiler installation. (Click to enlarge)

This type of equipment contains the following components that need to be cleaned periodically:

- igniter;

- burner with nozzles;

- gas filter;

- heat exchanger;

- firebox;

- chimney.

It is worth noting that cleaning each component of a gas boiler has its own specifics, which we will dwell on in more detail.

Igniter

When the igniter is functioning normally, its flame should look like a cone with a blue tint. If the flame turns yellowish, this means that the burner is dirty.

The cleaning procedure occurs in the following sequence:

- shut off the gas supply to the boiler;

- unscrew the igniter;

- Clean thoroughly using a wire brush;

- perform purging;

- Reinstall the cleaned igniter.

Burner with nozzles

This part is the main one in the design of wall-mounted and floor-standing gas boilers, since it is intended directly for supplying fuel.

The sequence for cleaning the burner with nozzles is as follows:

the gas supply valve closes; the burner is removed from its installation location; the location of the nozzle is noted, and then it is carefully unscrewed; You need to carefully clean the nozzle with a brush; the burner is cleaned with a brush, and its hole is purged using available pumping equipment; the nozzle is inserted into the burner according to the mark; the burner is installed in place.

Gas filter

This device is designed to purify incoming gas from various types of contaminants and impurities.

Therefore, it is very important to regularly clean the filter from accumulated clogging.

Heat exchanger

It is worth knowing that the main purpose of the heat exchanger of a double-circuit boiler is how much water will be heated and at what speed.

It is also necessary to understand that this element of the boiler unit can become clogged both inside and outside.

The outer part of the heat exchanger becomes contaminated with soot, which negatively affects its functioning. This boiler unit can be cleaned of soot mechanically, in other words, cleaning is done with your own hands.

To do this you will need the following set of tools:

- scrapers;

- metal brush;

- various shapes of brushes;

- power tool with cleaning attachments.

The cleaning procedure is as follows:

- gas supply and power supply from the boiler is turned off;

- the heat exchanger is carefully removed;

- cleaning is carried out using convenient tools;

- the device is installed again in its place.

As a result, the throughput of the heat exchanger decreases, which generally affects the functioning of the entire gas boiler. The most optimal way to clean the inside is to flush the gas boiler heat exchanger using chemicals.

Among the reagents that are used to clean the internal walls, the following products can be distinguished:

- adipic acid;

- sulfamic acid solution;

- special gel.

The booster consists of the following elements:

- circulation pump;

- reagent container;

- electric heater.

The principle of cleaning the heat exchanger using a flushing device such as a booster is as follows:

- to improve cleaning properties, the reagent is heated in a container;

- Using a pump, the solution is supplied under pressure directly to the heat exchanger.

As a result of the circulation of the chemical, the scale lags behind the internal walls and comes out along with the waste solution.

Firebox and chimney

Although gas is a clean fuel, over time soot still accumulates on the walls of the firebox and in the chimney. The accumulation of this combustion product interferes with the normal functioning of the boiler, as draft is lost.

Therefore, it is recommended to carefully monitor the formation of soot and regularly clean the chimney and firebox. We hope that the information presented in the article will be useful to you when cleaning your gas boiler.

Watch the video, which shows in detail how to properly clean a gas boiler at home:

How to clean an AOGV boiler

For this operation you will need a regular plastic bottle cleaning brush. It can be purchased at a hardware store and is perfect for cleaning vertical channels. Tie it with electrical tape to a wooden stick so that you can easily go through the channels along their entire height. In order not to spread excess dirt in the boiler room, take everything that can be moved out into the yard for cleaning.

- Start cleaning from the top plane of the heat exchanger, clean off and sweep down all the soot.

- Then comes the turn of cleaning the channels. The soot will come off the walls quite easily if it has not yet hardened, otherwise you will have to make some effort.

- After completing the cleaning process of the boiler itself, proceed to the removed components and parts. Clean the top cover of the heat exchanger. After this, remove layers of soot on the top cover of the boiler itself and from the hood.

- Lastly, use a brush to brush away the soot that has accumulated from above from the burner block; the burner itself is already clean.

Immediately lightly clean the tube with fine sandpaper. This completes the process of cleaning the boiler and its parts. Proceed to reassembling the AOGV boiler.

Mechanical cleaning of plate heat exchangers

You can clean the boiler from soot without removing the heat exchanger. To do this, just remove the cover, arm yourself with a stiff nylon brush and close the gas injectors so that dirt does not get in there. The whole process is clearly shown in the video:

https://youtube.com/watch?v=ccEAX_yoExc

If soot has stuck to the surface and is not removed by mechanical treatment with a brush, then the heat exchanger is removed and soaked in special cleaning solutions for several hours. Such products are available for sale in a wide range, examples include Fauch and MAZBIT+ products. But you can also use household chemicals - gels for cleaning grills and ovens.

Before disassembling the boiler, you need to disconnect it from gas and the igniter from electricity. In addition, it is necessary to drain the water from both circuits and the expansion tank. The secondary heat exchanger is removed first; it is located immediately behind the boiler lid. The primary (main) one is more problematic to remove, since you will have to disassemble the combustion chamber.

The nuances of cleaning a gas boiler

When starting cleansing you need to know that:

Boilers should be flushed when they are completely disconnected from electricity, gas and water. When dismantling the heat exchanger, you must try not to damage the sealing elements; failure to seal will lead to leaks and breakdown of the unit. Care must be taken when cleaning the heat exchanger; the thin tubes on the inner surface may be damaged. A control check for the tightness of connections can be carried out by coating the joints with a soap solution. When washing, it is recommended to add stabilizers to aggressive solutions. reducing the acidic effect on the metal and forming a protective film on the surface of the element.. It is best to rinse the heat exchanger of a gas boiler with special reagents that will be gentle on the material of the unit and qualitatively remove all contaminants

It is best to rinse the heat exchanger of a gas boiler with special reagents that will be gentle on the material of the unit and efficiently remove all contaminants.

Master Boiler Power - the product removes iron oxide and calcium carbonate deposits, does not affect gaskets and seals, the process is accompanied by active foaming, works at a temperature of 20 - 40 ° C. Cleaning is considered complete when foaming stops.

Zinconex Powder - removes almost all deposits, contains a color indicator that allows you to control the degree of washing. Compatible with aluminum, galvanized, copper, steel and cast iron surfaces.

Fauch 200, Fauch 610 – spray (aerosol) designed to remove soot from the walls of boilers and heat exchangers.

Effective soot remover HANSA - is a mixture of crystals that burn in the firebox when ignited. It is designed to clean boiler and chimney elements from soot and resinous deposits; it reacts with them, destroying the structure of deposits.

Periodically washing the heat exchanger of a gas boiler with your own hands will save costs on electricity, fuel and replacement of expensive parts, and will also extend the life of the unit.

Do-it-yourself booster for washing heat exchangers

clean the gas water heater

heat exchanger for gas boiler

Why does scale appear?

This type of contamination is the main problem in boiler operation.

Scale forms wherever hot water circulates. In other words, it settles as a hard layer on the inner walls of the boiler equipment.

What causes scale to appear? The reason for this clogging is very banal - the use of hard water as a coolant, which is well saturated with magnesium ions, calcium carbonate, iron oxide, as well as various other impurities.

When these elements interact with the internal walls of the heat exchanger, salts or bicarbonates are formed, which are the source of scale. It is also worth noting the important fact that on the walls that are covered with this contamination, scale will appear even faster and faster.

What needs to be cleaned

If the heating system is clogged, the following elements must be checked:

- burners and jets;

- heat exchanger;

- igniter;

- gas filter;

- firebox;

- chimney channels.

If they do not work correctly, it is necessary to clear the blockages.

Igniter

A yellowish, uneven flame from the pilot light signals the boiler owner about the need to clean it. To do this you will need:

- close the gas valve, stopping the fuel supply to the boiler;

- remove the igniter;

- blow out and clean the part from debris;

- install in place.

Burners and jets

If the gas burner of the boiler operates unstable, cleaning becomes necessary. Algorithm of actions:

- shut off the gas supply to the boiler;

- remove the burner;

- We mark the position of the injectors with a marker, and then dismantle them;

- we blow through the inlet and outlet openings of the burner using a pump;

- carefully clean with a brush;

- we install the nozzles back, focusing on the marks left by the marker;

- return the burner to its original position.

Chimney ducts

Interruptions in the operation of the boiler affect not only the heating circuit and the pump. The chimney begins to become more clogged with soot, which increases the risk during its operation. Reduced draft can result in carbon monoxide entering the room, which negatively affects human health. Clean the chimney using a regular brush.

Be careful when cleaning the outlet. It is usually located at a high altitude, which creates an additional risk to human life. Don't forget about safety rules. If possible, hire professionals who have all the necessary skills and tools.

Heat exchanger

Cleaning the heat exchanger on your own comes down to mechanical action on the part, due to which excess dirt and scale are removed. You will need:

- brush;

- metal brush;

- wrench.

We turn off the gas supply to the boiler, remove the protective cover of the boiler and deactivate the temperature sensors. Afterwards the heat exchanger is dismantled and cleaned. Do it carefully so as not to damage the part. It is not recommended to use tools with sharp edges that can damage the heat exchanger.

Gas filter

The gas supplied to the boiler through public pipes carries many harmful impurities and debris. The task of the gas filter is to separate them at the inlet, preventing them from entering the heating system. A clean filter provides:

- stable operation of the device;

- slows down the appearance of plaque on system parts and the internal walls of gas pipes.

Firebox

Note! If you are not confident in your own abilities, do not risk cleaning yourself and seek help from specialists

Cleanable nodes

Gas boiler installation.

(Click to enlarge) This type of equipment has the following components that need to be cleaned periodically:

- igniter;

- burner with nozzles;

- gas filter;

- heat exchanger;

- firebox;

- chimney.

It is worth noting that cleaning each component of a gas boiler has its own specifics, which we will dwell on in more detail.

Igniter

The cleaning procedure occurs in the following sequence:

- shut off the gas supply to the boiler;

- unscrew the igniter;

- Clean thoroughly using a wire brush;

- perform purging;

- Reinstall the cleaned igniter.

Burner with nozzles

The sequence for cleaning the burner with nozzles is as follows:

the gas supply valve closes; the burner is removed from its installation location; the location of the nozzle is noted, and then it is carefully unscrewed; You need to carefully clean the nozzle with a brush; the burner is cleaned with a brush, and its hole is purged using available pumping equipment; the nozzle is inserted into the burner according to the mark; the burner is installed in place.

Expert advice: cleaning the burner with nozzles should be done once a year, preferably before the heating season.

Therefore, it is very important to regularly clean the filter from accumulated clogging.

Heat exchanger

It is also necessary to understand that this element of the boiler unit can become clogged both inside and outside.

The outer part of the heat exchanger becomes contaminated with soot, which negatively affects its functioning. This boiler unit can be cleaned of soot mechanically, in other words, cleaning is done with your own hands.

To do this you will need the following set of tools:

- scrapers;

- metal brush;

- various shapes of brushes;

- power tool with cleaning attachments.

The cleaning procedure is as follows:

- gas supply and power supply from the boiler is turned off;

- the heat exchanger is carefully removed;

- cleaning is carried out using convenient tools;

- the device is installed again in its place.

An important point: try to use a tool for cleaning that does not have sharp edges. Otherwise, you may cause damage to the heat exchanger, which may cause corrosion of the product in the future.

Here

As a result, the throughput of the heat exchanger decreases, which generally affects the functioning of the entire gas boiler. The most optimal way to clean the inside is to flush the gas boiler heat exchanger using chemicals.

Among the reagents that are used to clean the internal walls, the following products can be distinguished:

- adipic acid;

- sulfamic acid solution;

- special gel.

Specialist's note: the choice of reagent for flushing should depend only on the degree of contamination of the heat exchanger.

The booster consists of the following elements:

- circulation pump;

- reagent container;

- electric heater.

The principle of cleaning the heat exchanger using a flushing device such as a booster is as follows:

- to improve cleaning properties, the reagent is heated in a container;

- Using a pump, the solution is supplied under pressure directly to the heat exchanger.

As a result of the circulation of the chemical, the scale lags behind the internal walls and comes out along with the waste solution.

Experts advise: using a booster, you can clean not only the circuit of hot water boilers, but also the pipes of the entire heating system.

Firebox and chimney

Therefore, it is recommended to carefully monitor the formation of soot and regularly clean the chimney and firebox. We hope that the information presented in the article will be useful to you when cleaning your gas boiler.

Watch the video, which shows in detail how to properly clean a gas boiler at home:

When cleaning is necessary

A gas boiler is a complex device, and disassembling it without a good reason is too expensive. To avoid taking unnecessary actions that could cost you a pretty penny, check out a number of signs that indicate a clogged heating element:

- The boiler does not produce the required amount of heat, while consuming a large amount of fuel.

- During operation of the device, extraneous noise appears, the presence of which was not observed before.

- The water pressure from the tap decreases significantly.

- The heating process of the batteries is slower than usual.

Gas consumption has increased

One of the key reasons why gas consumption increases significantly compared to the norm is the clogging of the heat exchanger with scale. The boiler requires more fuel to heat the exchanger to the required level. After cleaning the part, the consumption returns to the basic values.

Burner always on

A clogged heat exchanger means that the water takes a long time to heat up, and the turbine constantly pumps in new liquid.

Because of this, the burner is constantly working, trying to bring the water temperature to the required value.

Descaling solves the problem, allowing the boiler to operate normally, without interruptions.

Rumble and interruptions in the operation of the circulation pump

A clogged system makes it difficult for fluid to circulate, causing the pump to overload during operation. Because of this, the following appear:

- extraneous noise;

- interruptions in the operation of the device;

- engine overheating.

Reduced pressure in the DHW circuit

A decrease in pressure in the DHW circuit is possible due to:

- incorrect operation of the heat exchanger;

- leaks in the pipeline system;

- The hot water supply circuit is depressurized.

Preparing the cleaning solution

The detergent (powder or liquid concentrate) is poured into the expansion tank gradually, in accordance with the recommendations for preparing the solution.

If we talk about Kratol K, we recommend using an 8-10% solution at a temperature of about 60°C. Those. for 9 liters of water you pour 1 kg of Kratol K

Attention! The reaction releases carbon dioxide, which squeezes water out of the boiler. That is why we said that the intermediate tank should be larger than the volume of the boiler being washed

Therefore, pour in carefully, let the powder gradually stir, and you will control the process of gas formation.

You can judge the effectiveness of the reaction by the gas that will be released into the intermediate tank, foam will form, and the washing solution will darken and become cloudy.

Keep an eye on these indicators. In principle, you can increase the temperature to 60°C (but no more, otherwise acid hydrolysis will begin and the effectiveness of chemical washing will decrease) and increase the concentration of the solution to 10%. Don't worry, nothing will happen to the boiler, especially if you use our detergent. Monitor external parameters. Dilute the acid gradually. Heat gently. In our practice, it also happened that we overheated the boiler, and then boiling acid gushed out in all directions. Not particularly dangerous, but unpleasant.

By the way, about gases. In order to squeeze out the gases that accumulate in the upper part of the boiler and are formed during the reaction of the flushing liquid with scale, we practice periodic stopping of the pump. In this case, a small water hammer is created (for the coil being washed it is not scary, since in such pumps the maximum pressure does not exceed 2 atm) and the air is gradually pushed into the expansion tank. Those. During flushing, we stand nearby, watch the liquid level in the expansion tank and periodically turn the pump on and off.

The most common automation malfunctions and methods for eliminating them

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that will require specialist intervention. The adjustment can also be entrusted to a gas technician. Or you can do it yourself by reading the instruction manual.

Attention! Before each seasonal operation, it is necessary to check the operation of the safety sensors. Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected.

Proper cleaning of the filter should be done by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected. Proper cleaning of the filter should be done by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler.

In order to replace the temperature sensor, you need to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, remove the PTV adjustment screw. Remove the sensor bellows with the support washer. Unscrew the union nut of the sensor thermal bulb. Install the thermal bulb of a working sensor into the boiler jacket and screw it tightly. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If problems arise with igniting the igniter, then one of the possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, checked contacts, cleaned, and, if necessary, replaced with a new one.

Also, common reasons why the pilot light does not light may be:

- gas valve malfunction;

- clogging of the hole in the igniter nozzle (it can be cleaned with wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, and the gas pressure at the inlet to the gas boiler.

Attention! To diagnose and repair the gas boiler automation, you must invite a specialist. Inept actions can aggravate the problem and lead to undesirable consequences.

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element.

In Arbat and Orion, you can only replace the thermocouple and draft sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In Arbat, the system shutdown button often breaks down.

Typical problems for SABC automation are damage to the main valve membranes and drying out of the thermostat stuffing box, resulting in gas leakage. Impulse tubes, bimetallic plates, and ball valves are subject to control.

In conclusion, I would like to emphasize once again that automation is designed to maintain the operation of heating equipment in a safe mode. Therefore, it is simply necessary for owners of gas boilers.

This video shows how to troubleshoot an automatic boiler AOGV, step-by-step assembly process and testing the result.

All modern heating installations using natural gas as an energy source have a high level of safety, which is achieved through the introduction of automation equipment. They monitor and manage the operation of heating units. In this material we will consider automation for gas boilers from the most famous manufacturers, which is most often installed on domestic and imported boilers.

Manufacturers

If you want to purchase a higher quality and more expensive AGV, you can pay attention to the products of foreign companies:

- BAXI and FERROLI. These devices have a good design and an electronic control unit.

- RINNAI. Devices of this brand are distinguished by quality, reliability and ease of use.

- ANIERIA. Relatively inexpensive, but very reliable boilers made in Korea.

Imported devices outperform domestic ones in efficiency, but lose due to their dependence on electricity. Before you turn on a foreign-made AGV, you need to connect it to the power grid. Considering that there are often power outages in the domestic space, this factor cannot be ignored when choosing a suitable device.

The choice of AGV is often based on the cost of equipment and operation. Domestic-made boilers are cheaper on their own, and they are much more profitable to operate. The total savings are approximately a third, based on similar indicators of imported devices.

How to reassemble the AOGV burner block

Carefully reassemble all components in reverse order. Slowly, without distortion, lift this entire block so that the burner goes inside the housing, and the igniter and thermocouple assembly does not cling to the casing flange. Standing on the side of the pipes, slightly push the entire assembly towards you with a slight downward tilt so that the opposite edge of the pan rises slightly.

As you feed the pallet forward, simultaneously put on the two farthest hooks so that they engage the casing flange. Direct the hook closest to you into the cut-out groove, and when it fits into it, turn the entire pallet counterclockwise. The gas pipe should be directly under its branch pipe of the automation unit.

Check the presence and correct fit of gaskets and reinstall all tubes. Tighten the nuts on the igniter pipe and on the gas supply pipe with a wrench

Before reinstalling the thermocouple tube, very carefully clean its contact pads. It is recommended to tighten this nut not with a wrench, but with your fingers.

Check the tightness of the connections for possible gas leaks and start the boiler.

Prerequisites for the cleansing procedure

It must be promptly implemented when the boiler:

- It begins to weakly heat the room.

- Consumes a lot of electricity and gas.

- It works in such a way that a burning smell appears in the room.

As a rule, such failures are caused by blockages. And it is necessary to thoroughly clean all the important components of the boiler, and especially the burner.

These elements include: igniter, filters, combustion chamber, heat exchanger and chimney.

Cleansing should be done 1-2 times a year. This will be the key to safe and reliable operation of the equipment.

How to proceed with models of certain brands is shown below.

How to clean a floor-standing gas boiler: step-by-step instructions

Before any action, you should turn off the gas supply valve (or make sure that it is turned off). Let's look at the process using the example of the widespread Danko non-volatile boiler. The design of all floor-standing gas boilers is not fundamentally different, so you can easily adapt the instructions to any model and identify all the key components.

| Photo (click to enlarge) | Process description |

| Disassembly. Open and remove the door, then disconnect all the components shown in the photo: (1) gas supply; (2) burner block mounting; (3) terminal contacts; (4) thermal bulb. Now you can remove the burner and automation unit. We also unscrew and remove the boiler cover (2 screws in front and 2 in back) | |

| From above, to get to the heat exchanger, you need to remove the thermal insulation layer, the chimney mounting cover and the metal plate. All components are usually arranged in series and secured with bolts. | |

A special brush for cleaning the fire tube channels of the heat exchanger. | Cleaning the heat exchanger. The heat exchanger channels (they can be round, as in the photo, or rectangular) contain swirlers. We take out each one in turn and clean it of soot and dirt. It can be done:

To clean the fire tube channels of the heat exchanger, you need to use a special metal brush, lowering it to the very depths. After mechanical cleaning, it is good to vacuum up any loose debris and proceed to cleaning the burner block. |

| Cleaning the main burner. The main burners are practically not dirty; use a cloth for cleaning, or metal brushes for more severe contamination. Clean the external and internal surfaces of the burners, make sure that all openings are in proper shape and are not clogged. |

| Cleaning the igniter and automation. It is recommended to entrust the cleaning of these elements to specialists; otherwise, carefully study the exact location of all elements relative to the main burner, photograph the components from different sides. Based on the photo, remove and clean: (1) piezo ignition electrode; (2) a pilot burner, also known as an igniter; (3) thermocouple. This must be done carefully, using zero-grit sandpaper or a soft brush, without leaving scratches. Also an excellent remedy is cotton wool and alcohol. | |

| When cleaning the igniter, thoroughly blow out the nozzle; if it is heavily soiled, punch a hole with a wire or needle, and under no circumstances allow damage or deformation. | |

| Assembly. We install all the elements in their places; in most models, the piezoelectric ignition electrode must have a small amount of free play (play) so that it does not break when heated. |

Other models

In practice, cleaning burners follows the same principles. The differences lie in their removal and reassembly.

The following examples are provided:

For example, the Helios AOGV 4 parapet apparatus is equipped with Eurosvit 360 automation and burners of the European brands Bray and Polidoro.

The burner set is removed following the example of the Zhitomir process. A pump is used to clean the nozzle, and hard brushes are used to clean the surfaces.

The Conord line stands out in particular.

The automation variations here are:

The most popular is the second variation:

It includes a sectional burner, Polidoro tubes, igniter, thermocouple, gas valve, temperature indicator and wires.

A similar system is available in the Lemax Premium 12.5 model.

Only the burner here is micro-flare. The mechanism is very easily removed by removing the top cover and lightly unscrewing the fixing bolts.

Its analogues are also found in the Siberia models.

Ecological burners "Vorgas" are used here.

Does not lag behind in this regard. Here its models Novella Maxima 108 N RAI and Mynute Boiler stand out.

Honeywell automation looks like this:

It has a similar operating principle to the Eurosvit system. The differences lie in the materials of some components.

It is often found in wall-mounted modifications, for example in Baksi Fortech 24

It also has an ecological burner that leaves no combustion products.

An equally popular device is the Ariston ALTEAS X 24 FF NG.

Many Daewoo models operate with similar automation. For example – DGB 200 MSC.

Whatever model or brand you have, strictly follow the suggested instructions for removing and financial assistance grants for reinstalling the burner unit. Clean it thoroughly with the right products 1-2 times a year. Maintain other mechanisms as well. And then your boiler will work properly for a long period.

An indispensable attribute of any heating system is a boiler, which acts as a heat generator for heating the home.

The modern heating equipment market is saturated with a very wide range of boiler units of various types. But a special place in this range is occupied by gas boilers, which are becoming more and more popular every day.

This trend is due to the fact that units of this type are very effective and economical devices for heating a country house or even an apartment. In order for a gas boiler to function smoothly and stably, it is necessary to properly care for it.

One type of such maintenance is cleaning the gas boiler from soot and other contaminants. Let's talk in more detail about why to clean a gas unit, as well as in what ways this can be done.

VodoGazServis LLC is a wholesale and retail company organized by qualified water and gas specialists who have many years of experience in this industry. During its work, the company has established itself as a reliable partner, ready to serve the most demanding client in all corners of our country from Kaliningrad to Yuzhno-Sakhalinsk. VodoGazServis LLC opened branches in Krasnoznamensk, Vladimir, Volgograd and Krasnodar. Based on knowledge of the consumer market in its field and the experience of its employees, the company regularly studies new products, monitors the modern market of domestic and imported water-gas equipment and is ready to offer the buyer only high-quality and reliable products that meet modern requirements for quality and safety.

The warehouse always has gas meters, bimetallic and aluminum heating radiators, plumbing and gas shut-off and control valves, sanitaryware, and electrics. The range includes storage water heaters (boilers) with a capacity from 10 to 500 liters, as well as safe-to-use modern instantaneous gas and electric water heaters of various capacities, imported and domestic. All products we sell have the necessary certificates and licenses.

The products offered by our company are of appropriate quality, have the latest release dates and are provided with warranty cards.

The retail store "VodoGazServis" is open seven days a week, phone number, directions and opening hours in the "Contacts" section

more about the company

Let's consider the method for finding the above fault.

When repairing a gas boiler, testing begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6...12 months of operation it becomes “overgrown” with a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to deterioration of contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special “Contact” spray. It contains substances that actively destroy the oxide film. After cleaning, apply a thin layer of liquid lubricant to the plate and contact.

The next step is to check the serviceability of the thermocouple. It operates in severe thermal conditions, since it is constantly in the flame of the igniter; naturally, its service life is significantly shorter than other elements of the boiler.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) increases sharply. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetallic plate will be below the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the rod (Fig. 5).

Video text

How to clean a gas boiler, how to clean a pilot burner, how to clean a gas boiler heat exchanger. All this is described in detail and shown in my video. After watching my video, you can clean your boiler yourself without calling gas service representatives.

SAVE GAS by correctly setting up the boiler

How to LEGALLY reduce GAS consumption without stopping the meter

Detection and elimination of GAS LEAKS in the apartment

How to choose a gas boiler - 20 POINTS

Why does the boiler blow out and go out? 8 reasons

Did you like the video? Like and subscribe!