If the home is not connected to centralized heating, then it becomes necessary to provide it yourself. An effective option is to install a gas boiler that will heat the coolant for the radiators. Modern industry offers a large number of options, among which the owner must choose the appropriate one. One of the most effective is the use of a convection gas boiler.

Convection gas boiler needs fine tuning Source boilervdom.ru

Convection and condensation gas boilers: differences

Gas boilers can be convection and condensation. The first type refers to traditional models that are used by the majority of Russian consumers. The second is an improved example of household appliances, which can increasingly be found among residents of Russian homes.

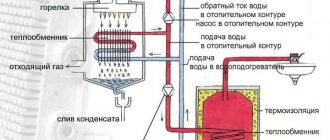

Externally, convection and condensation boilers are practically no different. But if we talk about their elements, the difference becomes obvious. Condensation equipment consists of 2 heat exchangers, a cooling chamber, a container for accumulating condensate, a circulating pump, a fuel combustion chamber, a fan, and a burner.

If we talk about characteristics, then for buyers the most significant difference is in price. The cost of updated units is twice as high as equipment of the first type. This difference is due to high productivity.

Traditional equipment is distinguished by its affordable price and simplicity of design. The coolant is heated by the heat generated by burning fuel. Part of the heat comes out with smoke, and therefore the efficiency is achieved no more than 92%.

Condensing boilers have an efficiency of about 110%, due to the updated design. An additional heat exchanger uses heat from fuel combustion and steam energy.

How does such a boiler work?

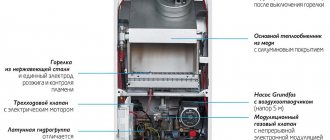

Externally, it looks like a parallelepiped with several pipes. A heating system is connected to them, where the heated coolant flows. After giving up its heat, it cools down and goes back into the boiler. Then it is heated again and used for further heating. Natural gas enters the boiler, and a chimney is laid outside through which combustion products exit.

The boiler uses a steel chimney Source boilervdom.ru

There is a place inside where the gas burns. There is an ignition device designed to automatically ignite the fuel. Above it is a container of water that is heated. There are double-circuit designs in which not only the coolant is prepared for heating, but also the supply of hot water to residents is ensured.

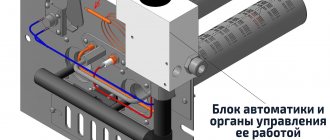

Depending on the configuration, there are additional components. Sometimes it is possible to install an expansion tank. A safety group can be installed - devices that will reduce the risk of an accident. They include a pressure gauge, steam release valve and air vent. This reduces the likelihood of a situation where heating creates pressure that could damage the equipment.

The presence of a circulation pump allows for uniform passage of water through the pipes of the heating system. There are varieties where water movement occurs naturally. In this case, a pump is not required.

Some models use a closed combustion chamber. Its peculiarity is that it does not take air from the room where it is located to operate. Here a chimney of a special design is used, in which another is located inside one pipe. In this case, air leaves the boiler through the narrower one, and enters the combustion chamber through the space between them.

Gas convector takes up little space Source boilervdom.ru

This type of chimney is coaxial. Most models use an open combustion chamber. A convector boiler can work not only with a centralized gas supply, but also from cylinders.

Condensing boilers can operate not only on gas, but also on liquid fuel. However, in the latter case, combustion products contain more sulfur, creating chemically aggressive compounds. Gas appliances compare favorably with their low cost of fuel.

Compact model of convection gas boiler Source teplogidromash.ru

Convection gas boilers

Such heating devices provide room temperature when gas burns. They appeared to replace stove heating. Equipment with an open chamber is more in demand, but there are also closed models. With the chamber open, atmospheric burners are used and air is drawn from the outside world. For the operation of gas equipment, it is necessary to build a chimney with natural draft, install a hood and select a place with the optimal area for installing the unit. Boilers with closed burners do not require additional ventilation, since the operation of the structure is automated.

Although such equipment is time-tested, it has a significant drawback. Along with the gases, a lot of heat escapes into the atmosphere, and therefore the room has to be heated often. The resulting condensation can cause irreparable damage to traditional equipment.

The manufacturer produces single-circuit and double-circuit equipment. The first type is mainly used for heating country houses and heating an indirect heating boiler. Double-circuit boilers are often installed for residential heating, where it is not possible to place a boiler.

When installing convection boilers, it is necessary to ensure that the combustion products at the outlet remain at least +57 degrees. If you do not adhere to this recommendation, then condensation will form on different parts of the boiler, due to which the service life of gas equipment will be reduced.

Electric heaters

This group of heating devices independently produces heat by converting electricity. The heart of the device is the same finned heat exchanger, only inside it, instead of pipes with water, a heating element is installed. The element is placed inside a metal case, where slots are made in the lower and upper parts for air passage. The electric convector is automated from the very beginning, since even the cheapest version is equipped with a thermostat that controls the operation of the heating element.

It should be noted that heating with electric convector heaters is not only convenient, but also effective. The efficiency of the devices reaches 98%, and a high degree of automation allows you to save electricity, this is achieved by programming the heater for different operating modes at certain times of the day. According to their design, electrical appliances are:

- wall-mounted;

- floor (mobile);

- baseboards;

- intra-field.

If you study all the reviews about such heaters, the negative is expressed only in one respect: it is expensive to pay for electricity. Otherwise, there are very few complaints, which is not surprising, because the price of the equipment and its installation is quite affordable for a wide range of buyers. There are also no problems with the heating speed; any convectors are famous for this.

Condensing gas boiler

An improved boiler is more expensive, but during operation you will be able to spend less money. On average, you will have to spend 15-20% less on fuel consumption. Such equipment was produced in order to save fuel burned and protect the environment.

Other advantages of such a unit include:

- reducing the amount of exhaust gases released into the atmosphere;

- high corrosion resistance;

- the ability to switch the equipment to automatic operation mode;

- long service life due to the use of durable materials;

- a large selection of models from economy to premium class;

- compactness;

- the ability to use a plastic chimney, which also saves money.

Customer Reviews

Oleg D.

Lemax Premium-30N, 30 kW, single-circuit

For a private home, the choice is good: for this price we get both decent assembly and good power. This Lemax series has no special bells and whistles, just a good boiler without unnecessary electronics. The protection works when the gas workers on the main were working, it turned off normally, and the gas was turned off. In my opinion, this is the most important thing for a gas boiler; there is no need to joke with gas. I wanted to get a cast iron one, but I couldn’t afford it. I decided to believe the reviews and took a steel Lemax. Well, what can I say - it worked for three years without a hint of leakage. I have enough power to spare, my house is always warm. I took the boiler to put it at the dacha, where we visit with the child all year round, incl. The dacha has an area of 120 square meters, and we needed it to be really warm everywhere, after all, we are traveling with a child and spending the night. Well, I was specifically looking for a reliable option, because after all, it’s a dacha, outside the city, and we often leave leaving the boiler to work, they said that Lemax is perfect for such cases (when reliability is important) (and there really are no problems!). I was pleasantly pleased with the price, I thought I would have to pay more for this. Well, and convenient, of course, where without it, and the kit includes a clear instruction manual in the passport. It’s really not difficult to deal with it) So far there have been no failures, there’s not even anything to scold about.

Valentin Ya.

Lemax Patriot-12.5, single-circuit

Assembled with high quality. As installed a year and a half ago, it did not cause any problems. The design is simple but reliable - no fancy electronics, it works without being connected to an outlet. The ignition is well done. Warms up quickly. But last winter it was a little cold, I saved in vain - I should have added Lemax’s “Patriot 20” to the same one, it would have been warmer with it. 12.5 kilowatts is still not for my area, and the walls don’t have proper thermal insulation. It's a shame, the boiler itself is excellent.

Anton Ashurkov

Buderus Logamax U072-18, 18 kW, single-circuit

When I moved to a new house, I started looking for a good gas boiler. I wanted it installed before the cold weather. The installers took me to this model. Before buying, I decided to look at reviews about this model on one review site. It seems that people advised everything. Yes, the boiler had some minor flaws, but this was not fatal. The manufacturing company is the German concert Bosch. And for me, everything is German, it immediately refers to quality and durability. Just out of curiosity, I read the history of the brand. Now about the boiler itself. There were no problems with the installation. The boiler itself is white, attractive, and equipped with a special panel. It is with the help of this panel that the control is carried out. My house is big. The boiler completely copes with heating my mansion. When it’s severely cold outside, naturally, you have to set the temperature higher. If it gets warmer, you can do less. After the old model, the new boiler, for me, works almost silently. So far during operation, I haven’t found anything to complain about. Everyone at home is warm. In case of any malfunction, the boiler is equipped with various protections and interlocks. It’s scary, nothing will happen for sure. I recommend.

Pavel Alexeev

BAXI ECO-4s 1.24F, 24 kW

People! Don't take 2 contour lines! Take a single-circuit unit (like this one) plus an indirect heating tank plus a three-way valve. Yes, you will overpay about 17 thousand rubles, but you will have a normal system with hot water of the same temperature, you will be able to circulate hot water and your boiler will not switch to hot water every time you need to wash a mug. A bonus is the absence of scale, since the water inside does not leave the heating/heating circuit. And don’t buy condensers unless you know EXACTLY what you need. Update. A year of work - everything is fine.

Volodya Z.

Lemax Leader-25, 25 kW

I have a two-story house with an area of 185 sq.m. There is enough space in the house, but to heat it, we needed a powerful and efficient boiler. After searching on the Internet, I liked the Lemax Leader-25 floor-standing boiler, designed for heating areas up to 250 sq.m and with a modern security system. I took it with a reserve, in case we decide to finish building something. The boiler has been working for me for the first heating season, and so far it has shown its best side. It warms up the house quickly, and when you start it up two hours later, you can feel the living spirit in the house. The panel has a temperature regulator, which makes it easier to select the appropriate thermal mode.

Evgeniy S.

Gas boiler Lemax Patriot-12.5, single-circuit

Lemax Patriot-12.5 installed in a three-room apartment. I am completely satisfied with the operation of the boiler. It does an excellent job of heating the apartment, it works completely silently, you need to listen to understand when it started, the external appearance of the boiler is compact and of a modern design. This is an excellent option for apartments that are not equipped with chimneys. The boiler has served me for two years and so far I have not found any flaws in it.

Maxim K.

Buderus Logamax U072-24

Advantages: The boiler is designed very simply, which makes it quite reliable. I understand both its operating principle, indicated in the instructions, and the controls. Perfectly suited to a 150l indirect boiler and a 200m2 heating system. Disadvantages: Structurally, it is not designed for a sudden power outage. Like many others. When the power is cut off at the very peak of heating of the indirect heater, for example, an overheating error of the heat exchanger appears, because the boiler no longer circulates water, and the heat exchanger remains very hot.. After turning on the power, an overheating error appears and the boiler will not turn on until you reset it manually.. That is, if you left for several days and your power was turned off, you you can return to a cold house with a boiler stopped by an error.. Comment: In general, this is what my project needed. The boiler copes with its tasks perfectly. Heating a 200m2 house with heated floors, an air heater and heating water in a 150l indirect heating tank. By the way, it heats this volume of water from +9° to the calculated +55° in about 15 minutes. That is, from a completely icy state. I connected an indirect boiler to the boiler. By the way, who doesn’t know, a simple NTC 10kOhm thermistor, which costs 50 rubles on a well-known Chinese website, can serve as a boiler temperature sensor for the Buderus Logamax U072-24 boiler. The sensor is sold with wiring, and the boiler already has a connector for it. The boiler perfectly sees the current temperature of the water in the boiler and controls its heating.

Gennady Dick

Buderus Logamax U072-18, 18 kW, single-circuit

This brand of boiler was recommended to us by the gas workers who gasified our house. They also calculated that for a house whose total area does not exceed 120 sq.m. The power of this boiler is enough even with a reserve. Therefore, we tried to buy a boiler before all installation work was completed, so that it would be immediately connected to the heating circuit. There were no special problems connecting the boiler, except that we had to install an additional 3/4″ adapter, since our heating circuit was routed with inch pipes. They hung it on the wall using the standard hooks that came with the kit. The gas was connected by specialists, they also checked the gas control protection and gave us a brief instruction on how to use the system. There is nothing particularly difficult about operating the boiler. I set the required temperature on the remote control using buttons, and the automation will monitor everything else. The latter, by the way, is quite strict about compliance with safety regulations. A couple of times she signaled to us that we needed to clean the chimney, where foreign objects had gotten into. And it works very stably. It was always warm in the house, even when the frost outside reached -35 degrees.

Alexey K.

Lemax Leader-25, 25 kW

I'm surprised that the material is cast iron, which lasts forever, and costs the same or even less than some with a steel heat exchanger. I took Lemax precisely with the expectation that I would get more at a lower price. Turned it on, turned it off - and all the trouble. Installed in a separate room, away from living rooms. It does not make noise, does not require settings - everything is automatic. The cast iron heat exchanger will outlive me. But without the circulation pump the coolant barely moved, with the pump it was ok, but that’s the only way electricity is consumed.

Dmitry Sirenko

Buderus Logamax U072-18, 18 kW, single-circuit

For a small private house, what was required, first of all, was a reliable gas boiler that could reliably perform its main function throughout its entire service life, and maybe longer. Before this we had a Chinese-made boiler, which we had a lot of trouble with. We didn’t want to step on the same rake again and again, so this time we chose a boiler from a well-known German brand. Since all our communications were already connected and the boiler was hung in the place of the old one, there were no special problems with the connection. Moreover, the boiler is not very heavy and compact in size. The controls are simple and intuitive. You can quickly figure out the settings without even reading the instructions. Although I still advise you to read the instructions for the first time, they are written in clear Russian. After reading it, you will definitely have no more questions. The boiler has a copper heat exchanger and a relatively small storage tank, but at the same time it reaches the temperature set on the control unit relatively quickly. This winter we also experienced frosts of 20 degrees, but even at that time we did not freeze at all, despite the fact that the temperature on the control unit was above 60 degrees. were not exhibited.

Sergei Brodsky

Buderus Logamax U072-24, 24 kW, single-circuit

We installed this boiler in conjunction with an indirect heating tank. In the service parameters (L.2; 2.4E) the value was set to “2”, i.e. “single-circuit boiler + indirect heating tank”, however, after just 2 weeks of operation, the setting spontaneously reset and switched to “1”, i.e. “double-circuit boiler”. All other settings, oddly enough, have not changed. I don’t know what the control board saw there, what connections were there, but the boiler is single-circuit + tank. As a result, the hot water supply disappeared early in the morning, and with it the whole day of nervous study of those. documentation and the Internet in attempts to understand what happened to it, since there were no errors on the display. It’s good that I came across the correct information, otherwise I was already planning to disassemble and clean the three-way valve, and blow out the sensors...

Features of the condensing boiler

The equipment has a second heat exchanger designed to accumulate condensate. Its body is made of material resistant to high acidity.

In order for condensation to form on the walls of the element, the water must be colder than the dew point. Dew point is the temperature of water at which steam turns into a liquid state.

Condensing equipment has a complex accumulation principle. After combustion, combustion products do not enter the atmosphere, but cool and turn into condensate. It needs to be recycled so as not to harm the environment.

Efficiency comparison

When burning the same amount of gases, condensing boilers produce 20% more heat than convection boilers. This can be achieved through heat exchangers. One of the main advantages of the latest equipment is the ability to achieve an efficiency of 110%. If we apply the laws of physics, such a parameter cannot be achieved. But this phenomenon is easily explained. The calculation does not take into account all the heat that is released during the combustion process.

If we take into account all the heat when calculating, then a condensing boiler will have an efficiency of 95%, and a convection boiler will have an efficiency of 83-85%. Many countries adhere to the improved counting system, and therefore efficiency values for boilers with the same power may differ.

Which is ultimately better: a convection or condensing boiler?

You need to choose gas equipment according to your budget. It is also worth considering the cost of installation and maintenance. On the one hand, the savings are obvious, but the high cost, the need for disposal and the list of operating requirements do not make these equipment models popular. If we take into account European countries, then the payback on expensive boilers occurs after 4-5 years. In Russian conditions, this period is different for several reasons:

- Fuel prices in Russia are several times lower than in Europe, which is why users are hesitant to buy expensive equipment.

- During operation, additional costs for boiler maintenance arise.

- The highest efficiency can be achieved only when using boilers in low-temperature mode, when the house has heated floors and several wide radiators.

If we talk about safety, condensing boilers are practically harmless to humans if the condensate is properly disposed of. Convection equipment does not correspond to energy-saving trends and causes damage to the environment.

But condensing boilers also have disadvantages. Most often, people refuse to purchase due to the high cost of equipment. But due to fuel savings, this difference becomes obvious. If we ignore disposal costs, then such units are beneficial even for residents of Russia. It is advisable to buy expensive gas equipment if you have a large house and live in a region with a predominance of cold days a year. Then the difference in fuel consumption will be obvious.

It is difficult to give exact payback periods for a boiler; they depend on the area of the house, type of equipment, power, and cost of the boiler. But under normal Russian conditions this period is 6-10 years. Purchasing a condensing boiler is only relevant when using it in low-temperature conditions. But if we take into account that the cost of gas is constantly increasing, soon all people will switch to a new heating system.

The most important thing when choosing a gas unit is to determine the power of the equipment. On average, 100 W is required per 1 m2. But this figure can rise to 150 if the house has high ceilings and a large area of window openings.

conclusions

If you need to purchase a single-circuit heating boiler, you should listen to the recommendations of specialists and remember that:

- When choosing equipment, you need to decide in advance which device is more suitable: condensing, gas, combined, solid fuel or electric;

- the basic criteria for choosing a unit are indicators of maximum thermal power, coolant temperature and expansion tank capacity;

- Particular attention should be paid to the fuel used, type of control and design dimensions.