Heating of country houses is provided by installing boilers. They are used due to the inability to connect buildings to centralized heating mains. To remove smoke, homeowners increasingly began to install a coaxial chimney. Let's figure out what he is. Let's consider the principle of its operation, which boiler units it is connected to, types, regulatory installation requirements, main options and moments for installing such smoke exhaust pipes.

One of the options for a coaxial chimney kit Source dmworld.ru

General information

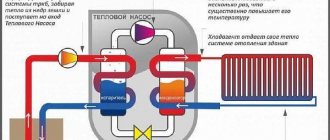

The coaxial type smoke exhaust duct has a simple design. It consists of two pipes. They are inserted into each other. Thanks to this design, two circuits are formed.

Regardless of the material used in manufacturing, coaxial smoke exhaust ducts are installed during the construction of houses or after installation of the boiler unit. Any of the mounted options is manufactured in production shops.

To ensure effective smoke removal, you need to know not only general information, that is, a coaxial chimney - that it is a structure of 2 pipes located inside each other. It is also necessary to understand how such smoke exhaust ducts function and where they are installed.

Two-pipe system for smoke removal Source torange.biz

Estimated cost

The cost of a coaxial chimney largely depends on the configuration. For example, a basic kit may vary in cost depending on the diameter of the pipes. The most popular kit can cost from 4 thousand rubles to 13.5 : which chimney pipes you need to purchase. Additional elbows can cost from 1.5 to 3 thousand, a condensate collector - about 3 thousand.

If you want to buy a protective grille for the chimney outlet, its cost is approximately 3 thousand rubles.

As can be seen from our review, the coaxial chimney system is a new word in the construction of chimneys; it is completely autonomous and easy to use.

Principle of operation

In private buildings, a coaxial chimney is installed in order to remove smoke through one system and supply the air required for combustion of fuel in the boiler from the street. Such processes provide two channels in the design.

Street air enters the boiler through the space between the two chimney pipes. Through an internal channel, combustion products are removed from the unit outside the building. Therefore, the street air is heated before entering the firebox. This increases the boiler gearbox.

Due to the movement of initially cold air, the coaxial pipe has its own cooling system. Therefore, the surface of the structure heats up less. This is the main reason why it is less fire hazardous than a single-channel chimney.

On a note! Coaxial smoke exhaust ducts can be installed in wooden houses when performing a smaller volume of work, the purpose of which is to protect buildings from fire. Manufacturers produce this type of chimney additionally with a heat-insulating layer of basalt wool. Therefore, the designs differ not in two, but in three channels - for smoke, street air and heat insulation.

Part of a coaxial system without insulation Source ooopipe.ru

Features of operation

First of all, you need to pay attention to the noticeably higher efficiency of stoves with such devices for removing combustion products. The efficiency increases due to the optimal fuel combustion mode.

With normal heating of a home, the air in it does not deteriorate, remaining clean, since oxygen from the outside air is used for combustion. There is no need for mandatory organization of supply ventilation, although it is usually created anyway; it will not be superfluous.

Coaxial chimneys are characterized by long-term operation because the pipes, which are constantly cooled by an influx of air, do not overheat.

Boilers for the use of coaxial chimneys

Coaxial type smoke exhaust ducts are mounted on condenser and turbine boiler units. Such chimneys are installed on equipment with closed chambers where fuel is burned. In this case, smoke removal from boiler units can be carried out by force or naturally. Gas boilers meet these conditions.

This type of chimney is also one of the best smoke removal options for convectors and units using pallets. If the smoke exhaust duct is made of stainless steel, then it is allowed to be connected to boiler equipment that is equipped with an atmospheric burner.

Two-channel smoke removal systems are suitable for almost all modern models of gas boilers. Coaxial-type channels are installed when installing double- and single-circuit units. Such boilers can have any operating principle. Coaxial systems are even installed regardless of the design of the combustion chambers.

Wall-mounted gas boiler with a connected coaxial channel Source baltgazservice.ru

Important! Experts take into account the parameters that the unit manufacturers indicate in the equipment documentation to determine whether a coaxial pipe is suitable for a gas boiler.

Boiler models with two pipes are produced. One of them is needed to remove smoke, and the other is used to supply air to the combustion chamber. It is not advisable to connect two-channel smoke removal systems to such units.

Types of coaxial chimneys

When experts select a coaxial smoke exhaust duct for a specific gas unit, they take into account that for some models only chimneys that are manufactured by the same manufacturer as the boiler itself are suitable. After all, such equipment has non-standard diameters.

When choosing, the material used in the production of pipes of the two-channel system is also taken into account. In the manufacture of structures, manufacturers often use aluminum alloys, plastics and stainless steel. Basically, the first and third options are found in private homes.

Plastic and metal channel for smoke removal Source ventilyaziya.ru

Plastic chimneys

To make such channels, manufacturers use special heat-resistant plastic. It can withstand temperatures of a maximum of 205°C. Channels made of this plastic are intended for condensing-type gas boilers. These chimneys are different:

- affordable price;

- low weight;

- easy installation.

A plastic coaxial chimney for a gas boiler has disadvantages. One such disadvantage is the short service life. These pipes are connected to units operating exclusively in low-temperature smoke exhaust mode.

See also: Catalog of companies that specialize in autonomous gasification of country houses and related work

Stainless steel chimneys

Coaxial type smoke exhaust pipes, made of stainless steel, can withstand temperatures of a maximum of 550°C. They are products that are resistant to acids. Manufacturers produce them with or without insulation.

Stainless steel coaxial chimneys without thermal insulation material are often additionally insulated to reduce the volume of condensate. The advantage of such smoke exhaust ducts is their long service life.

Stainless steel coaxial type channel Source aliimg.com

A vertical coaxial chimney for a gas boiler is created from factory-insulated pipes. Due to the presence of heat-insulating material in the design, the aerodynamics of the smoke exhaust channel improves. This system is connected to boilers from which combustion products are removed forcibly or naturally.

Installation standards

Professionals always install chimneys in accordance with the rules. When the installation is carried out for a boiler with a closed chamber where fuel burns, then they are guided by SNiP 42-01-2002. If you do not follow the established rules, the gas service will not allow you to operate the system.

During installation, be sure to maintain the distance from the coaxial chimney to the window, door, and even a nearby building. Each of the values should never exceed the values indicated in the standards.

Standard values of installation distances for the smoke exhaust duct from a gas boiler Source teploknam.ru

Thus, SNiP says that the head of the chimney must be at least 2000 mm relative to the ground. When the channel is mounted in a brick wall, it is necessary to create an opening in it with a diameter of 10 mm larger than the same pipe size. At the same time, for a wooden enclosing structure the standard is already 50 mm.

SNiP also states that the horizontal distance from the chimney to the window and door must be at least 500 mm. At the same time, the minimum standard to the window opening above the pipe is already 1000 mm. At the same time, the distance to windows and doors of other structures must be at least 1500 mm.

Important! It is allowed to connect more than one unit to a double-circuit smoke exhaust system, but only if all models have forced or exclusively natural draft. The maximum length of a coaxial chimney for a gas boiler must be 3000 mm. Moreover, for turbine units, from which smoke is removed forcibly, the value of this standard is a maximum of 5000 mm.

Standard lengths of smoke exhaust pipes for De Dietrich PLUS MSL units Source duim24.ru

Basic installation options

Factory chimneys are supplied with detailed installation instructions. Effective operation of double-circuit pipes is ensured only if all specified recommendations are fully observed.

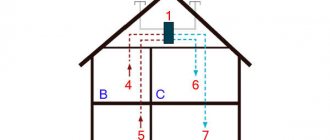

Horizontal installation

This installation option is carried out taking into account the characteristics of a private home. First, you always select a place where the smoke exhaust system will go outside. It is taken into account that the height of the pipe will be at least 1000 mm if the gas boiler is mounted on the floor. This value is measured from the unit's nozzle to the street opening in the wall.

Important! The pipe must not go directly to the street. When a wall-mounted boiler is mounted, then the distance from its nozzle to the hole in the wall can be reduced to 500 mm. In this case, the maximum number of rotary bends should be 2 pieces.

Conventional diagram of horizontal installation Source legkovmeste.ru

When horizontal installation of a coaxial chimney is carried out, never forget about the maximum length of the pipe. This standard depends on the model of the boiler unit and is from 3000 to 5000 m.

If it is necessary to lengthen the channel, couplings are used. They must have heat-resistant rubber seals. During installation, it is prohibited to use any sealants or sealing materials based on silicone.

Vertical installation

When a vertical coaxial chimney is connected, its maximum length can be 7000 mm. This value allows the use of double-circuit pipes in two-story buildings.

When a building is built from aerated concrete blocks, the system is laid inside the building. The reason for this is the inability of such walls to withstand heavy loads. For brick houses, the location of the smoke exhaust does not matter. However, it is always additionally insulated.

Important points for installing double-circuit smoke exhaust

To ensure that smoke is removed effectively, certain standards must be observed during installation. So, when connecting a gas boiler to a coaxial chimney exiting through the wall, then a slope of 3° must be made. At the same time, strictly follow the manufacturer's recommendations.

When connecting the chimney to the boiler, use a special adapter. In this case, it is prohibited to use pipes that are made at the installation site using improvised means.

Important! After the outlet pipe of the boiler, a tee with a condenser collector is most often installed and only then the coaxial pipe is raised to a height of 500 to 1000 mm. Before starting the system, be sure to first check the traction.

If it is necessary to extend the chimney, the pipes are collected using condensate. Their installation is carried out according to the “mother-father” principle. At the same time, the number of turns of the double-circuit pipe is reduced as much as possible so as not to worsen traction. To secure the chimney, special clamps are used.

Installation specifics

Correct design and installation of a standard coaxial chimney system involves taking into account the dimensions of the structure. Vertical structures are installed where it is impossible to install an outlet channel through the wall. For example, the chimney can go directly onto a small busy street or be located near a window. Naturally, this is unacceptable, although in some cases it is possible to install pipes at a certain angle.

It is worth choosing a coaxial chimney based on the data from the technical data sheet. The connection between the chimney and the boiler must be made using a tee or elbow. Each structural element must be fastened so that there is no obstacle to the removal of exhaust gases.

Based on where the outlet pipe will be located, certain components are selected. If the pipe is at the top, then there should be no problems with the installation of the chimney. If it is located on the side, then the structure is brought into a vertical position using special brackets.

Pros and cons of double-circuit chimneys

All coaxial chimneys for wall-mounted gas boilers or floor-mounted units are more expensive than conventional stainless steel smoke exhaust ducts. In this case, it often becomes necessary to lengthen double-circuit pipes. In this case, their price increases. In addition, you still need to attract professionals to properly assemble and install the smoke removal system.

Despite the higher cost, all chimneys are of the coaxial type:

- quickly assembled and installed;

- create good traction if installed by professionals;

- do not clutter the façade of the house;

- take outside air rather than the environment from the room, which reduces the ventilation requirements of the boiler room.

Double-circuit pipe from the boiler for simultaneous removal of smoke and air flow Source tm24.by

However, there are other disadvantages of using double-circuit smoke exhaust pipes. Their installation must be coordinated with the gas service, which will definitely advise you to take measures for the correct disposal of condensate. After all, according to sanitary rules, highly toxic liquid should not fall on the ground, but this requirement does not apply to private houses.

Advice! To avoid serious installation errors and ensure efficient operation of double-circuit chimneys, it is better to entrust the installation work to specialists. Professionals will organize the correct condensate drainage, taking into account the features of the smoke removal system and boiler unit.

Condensate should not drain into the boiler Source mystroy24.ru

Incorrect slope problem

It is recommended that the chimney tilt angle is no more than 2-3° towards the heating device. With another option, conditions are created for possible condensation to drain onto the ground of the adjacent area, which is strictly prohibited, since it is saturated with toxic substances.

Also, if the calculation is incorrect in winter, frost and even icicles form on the tip, which lead to damage to the part if too much ice has accumulated and shutdown of the gas boiler. The reason for this phenomenon is that the outer part of the device heats up slightly and cannot quickly melt the ice. Therefore, large icicles can form on a pipe that slopes toward the ground in winter.

There has been a long debate about whether the amount of condensation formed is actually inversely proportional to the diameter of the outlet. But the problem was solved by creating a special part of the device - a condensate receiver. Together with a three percent slope, it completely eliminates the problem of leakage of droplets of the resulting liquid.

Briefly about the main thing

The dual-circuit smoke removal system structurally consists of 2 pipes. Removes smoke through an internal channel. In this case, the space between the two pipes is used to supply air to the firebox. Such systems are connected to gas boilers. Manufacturers produce them from stainless steel and plastic.

Vertical and horizontal installation of coaxial chimneys is possible. Their maximum height can be 7000 mm. In this case, the greatest length relative to the ground is 5000 mm. These standards depend on the specific model of the installed boiler unit. Condensate is not allowed to enter the boiler. For this purpose, condenser collectors are installed. At the same time, in country houses it is allowed to lay a chimney sloping towards the street.

Ventilation

According to the rules, such systems can be installed even in completely enclosed spaces. But there is a need to maintain air circulation in the room to regulate humidity, which increases the risk of corrosion processes.

Corrosion over time leads to destructive changes in the equipment body, and ultimately to its failure and shutdown. In this case, some toxic gases may still enter the room. To avoid poisoning by them, regular ventilation and a good mechanical exhaust ventilation system are recommended. For example, duct centrifugal fans, domestic and industrial, are perfect for these purposes.

Air conditioning in rooms with a boiler room is not required. In a small room, simple but regular ventilation through a window or door will be sufficient.