Home » Classification of gas boilers » Operating principles » Rules and regulations for installing a gas boiler

When installing gas boilers, it is important to adhere to the standards that are prescribed in SNiP-II-35-76 “Boiler installations” and the set of rules for the design of autonomous heat supply systems SP-41-104-2000. Otherwise, if they are not followed, the inspection authorities will not give permission to operate gas equipment. Let's consider what standards exist for installing a gas boiler.

…

- 1 General requirements for installing a gas unit

- 2 Requirements for the room where the gas boiler is located 2.1 Room standards for a unit with an open combustion chamber

- 2.2 Room standards for a boiler with a closed firebox

General requirements for installing a gas unit

The first standard that needs to be taken into account when choosing a gas boiler is whether the power of the device matches the area of the heated room. Optimal performance is calculated using special formulas.

There are models of gas boilers with different characteristics: floor-mounted, wall-mounted, with open or closed combustion chambers.

To install units with an open firebox (atmospheric), a full-fledged chimney is required, so such models are mainly used for heating private houses. Boilers with an open chamber may only be installed in a separate, specially equipped room - a boiler room or furnace room.

A gas device with a closed firebox (turbocharged) only needs to connect a coaxial chimney to exhaust smoke. It consists of two pipes and simultaneously ensures the removal of smoke and the flow of air masses to the burner device. Such a unit can be installed in any non-residential premises, for example, a kitchen, hallway or bathroom. The main thing is that it meets all the requirements of SNiP. However, if your device with a closed combustion chamber has a power of more than 60 kW, then you will also have to look for a separate room for it - a boiler room.

…

Note! For an apartment in an apartment building, the installation of gas devices with a total capacity of up to 150 kW is allowed.

Requirements for the room where the gas boiler is located

Depending on the power and type of combustion chamber, room standards for installing a gas boiler may differ.

Room standards for a unit with an open combustion chamber

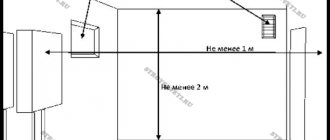

As already mentioned, a gas boiler with an open firebox must be located in a separate room, which is furnished and equipped in accordance with all standards. The boiler room must meet the following requirements:

- A room for installing the unit can be allocated on any floor of a private house, in the basement or attic. It is prohibited to install such a unit in a bathroom or toilet.

- If the power of the gas boiler does not exceed 30 kW, then the volume of the boiler room must be at least 7.5 m³. If the device’s performance is from 31 to 60 kW, then the required size is from 13.5 m³. With power from 61 to 200 kW – 15 m³.

- Ceiling height – 2-2.5 m.

- The width of the doors is not less than 0.8 m.

- The door to the boiler room should not be hermetically closed. It is necessary to leave a gap of 2.5 cm between the door leaf and the floor.

- An opening window with an area of at least 0.3×0.3 m², equipped with a window, should be provided. It provides sufficient illumination of the boiler room.

- Have a ventilation duct.

- Electrical switches located outside the boiler room.

Room standards for a boiler with a closed firebox

Technical standards for installing a gas boiler with a closed combustion chamber are not so strict. In this device, flue gases are removed from a closed firebox into a coaxial chimney, and a forced air flow is also provided through the same pipe. Therefore, gas boilers with a closed combustion chamber with a power of up to 60 kW are allowed to be installed in any non-residential premises that meet the following requirements:

- ceiling height more than 2 m;

- volume - at least 8 m²;

- well ventilated;

- The surface of the walls is made of fireproof materials.

It is even allowed to build turbocharged units into kitchen furniture.

…

Features and installation of parapet gas boilers

Read here - the stages of the first start-up of a gas boiler

Installation of a wall-mounted gas boiler with your own hands - stages of work

Regulations and design documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of technical conditions. The presence of this document gives the applicant the right to begin installation and connection of heating equipment to the central gas main. The application is submitted to the gas service, where it is reviewed by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible delays, the application must indicate the estimated average daily volume of natural gas that will be required to meet heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water supply circuit and used in central Russia, fuel consumption is 7-12 m3/day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flow-through gas heater (gas water heater) consumes 0.5 m³/day.

For a number of reasons, after the gas service has reviewed the application for permission to connect, it may be refused. At the same time, the responsible body is obliged to issue the owner of a private house a document that officially indicates all the reasons for the refusal. After they are eliminated, the application is resubmitted.

2. The next step after receiving technical specifications is an even longer but necessary process - creating a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in drawing up the project. He must have permission to do this work. It will not be possible to develop a project on your own. In any case, the gas service will not accept for consideration a document prepared by a non-specialist.

After drawing up the project, it must be submitted for approval. This is done by the gas service department that controls gas supply in a specific locality or area. As a rule, it takes up to 90 days to approve the project, and only after receiving a positive response can work on arranging the boiler room and installing the heating unit begin.

The following documents must be attached along with the project and the application for its consideration:

- technical passport (available with the equipment);

- official operating instructions (a copy is possible);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with a specialist drafting the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, just like receiving specifications, may result in refusal. At the same time, the owner is given an order indicating errors, shortcomings or inconsistencies that need to be eliminated. After corrections, the application is submitted and reviewed again.

Requirements for ventilation in the boiler room

In the boiler room or other room in which the gas boiler is located, it is necessary to provide forced and natural ventilation. Air replacement indicators are calculated based on the power of the unit.

Natural ventilation prevents the accumulation of carbon monoxide, which can be dangerous to the health and life of residents. Natural air flow is provided by windows, vents and doors.

Gas boilers with a closed combustion chamber do not require forced ventilation. It is provided by a coaxial chimney equipped with a fan, through which air is taken in from the street and smoke is removed.

In boiler rooms with an atmospheric unit, you will have to install supply and exhaust ventilation in the form of several fans that are connected to smoke detectors.

When the concentration of carbon dioxide increases, the sensors give a signal and the fans start working. Note! Good ventilation should ensure that the air in the room is replaced three times within 1 hour.

Fire safety standards

In order for a gas heating system to comply with fire safety standards, certain conditions must be met:

- Atmospheric devices can be located in the attic, basement or any other floor of the house. It is prohibited to place these units in the basement.

- Turbocharged gas boilers are allowed to be installed in any non-residential premises, as well as in the attic and basement.

- Doors to rooms containing gas appliances must open outward.

- The boiler room is finished with fireproof materials with a minimum fire resistance limit - no less than EI45.

- Turbocharged mounted gas boilers are fenced off from the adjoining wall with a shield made of non-flammable material. Floor-standing models are placed on a fire-resistant lining.

Flammable interior elements may be installed next to the boiler no closer than 30 cm.

Energy supply rules

The energy supply of a gas boiler includes the following conditions:

- Mandatory grounding of the unit - this eliminates the possibility that a spark of static electricity will cause a fire.

- It is recommended to connect volatile devices to a voltage stabilizer and an uninterruptible power supply. Otherwise, if the power goes out, the owners will be left not only without light, but also without heating.

- The socket for the gas boiler must be located close to it so that it is possible to connect the device directly. Carrying bags are not permitted.

Grounding

Between grounding and neutral, the potential must be less than 0.5 V. If this requirement is not met, there is a constant potential on the boiler grounding block, which causes a number of malfunctions: malfunctions of the automation, loss of ionization current (burner control), etc. .P. If such a problem exists, it is recommended to install a transformer with galvanic isolation. This allows you to solve problems of insufficiently competent grounding.

If the grounding is incorrect, there is a constant potential on the grounding block, which leads to failures during ignition and frequent shutdowns of the boiler

Requirements for the chimney device

The rules for installing a gas boiler in a private house are supplemented by the rules for installing a chimney if the unit has an open combustion chamber. The following requirements apply to the chimney installation:

- The pipe cannot have more than 3 turns.

- The section connecting the boiler pipe and the chimney has a length of no more than 25 cm.

- The diameter of the pipe must correspond to the power of the unit.

- The edge of the chimney is placed at least 50 cm above the ridge of the roof.

- The hole for the pipe to pass through the ceiling is made larger than the diameter of the chimney. Fire-resistant material is placed between it and the ceiling material.

- To ensure the collection of condensate and soot during cleaning, a condensate collector should be provided at the bottom of the pipe.

When installing a gas boiler with your own hands, it is important to comply with all the requirements for the placement of a specific model of the unit. Otherwise, the gas supply company will not give permission to operate incorrectly installed equipment.

Equipment Maintenance

The operation of gas equipment must be carried out strictly in accordance with the instructions. You should always remember that any violations and gas leaks can lead to tragic consequences. Worn out and damaged equipment must not be used.

Boiler maintenance must be provided at least 2 times a year . Before the onset of cold weather, it is carried out without fail and in full. The tightness of all connections, the condition of the chimney and ventilation system are checked. The filters and burner are thoroughly cleaned. If necessary, worn parts and sealing gaskets are replaced.

We recommend reading: Which gas is best for heating a private home?

Gas boilers are increasingly used to provide heating and hot water supply to private homes. They are easy to use, and safety is guaranteed if installed and used correctly. Installation of equipment must be ensured in full compliance with established standards. It is important to remember that uncoordinated connection of such boilers is a serious offense and is fraught with administrative punishment.