- A water floor is much more profitable than an electric one, and with a heat exchanger you will not depend on central heating and will be able to heat the floors at any time.

It is recommended to take the heat exchanger power for heated floors with a reserve.

- This heating system does not require large amounts of electricity and is more economical.

p, blockquote 13,0,0,0,0 —> p, blockquote 14,0,0,0,1 —>

All this allows us to conclude that it is necessary to install a heat exchanger when installing a warm water floor.

Water heated floor in the apartment - cozy warmth

It must be remembered that autonomous heating in a city apartment, which does not raise questions for you, your neighbors and the HOA, is possible only if there is a heat exchange unit. Do not confuse the heat exchange unit with the mixing unit. The mixing unit simply mixes two coolants without providing the basic properties of the heat exchange unit.

Why is it necessary to install a heat exchange unit in an autonomous apartment heating system:

— The coolant is separated by pressure.

In a central heating system the pressure is 6-8 atmospheres, and in a heated floor system no more than 2 atmospheres.

— The coolant from the central system does not mix with the coolant of the heated floor,

which prevents dirt and debris from entering the underfloor heating pipes.

— Only with a heat exchange unit installed will you be able to regulate the temperature of the coolant supply to your apartment,

and with installed automation, control the air temperature in each room.

— The presence of a heat exchanger will protect the apartment

from pressure surges that often accompany the beginning of the heating season.

heated floor project in a city apartment:

Primer. 2.39 MB pdf

Warm floor in the apartment

The quality of engineering systems in new buildings leaves much to be desired. It's no secret that developers use low quality materials. Their goal is clear - to meet the requirements of the State Commission for putting the house into operation, as well as to bring the maximum possible profit at minimal cost, but this is a topic for another discussion.

If you need heating reconstruction, our company will offer a technical solution and carry out the project. LenOtopleniye will professionally carry out installation of water heated floors, installation of radiators, with a guarantee of reliable operation.

Project

A separate apartment in an apartment building is part of one large heating system. Installing water heated floors or replacing radiators without a project is a reason for conflict with neighbors, the management company and authorities. For documentation development, the starting point is the floor plans. It contains the necessary data - placement and allocated power for devices for each room. To carry out calculations, you will need the actual internal dimensions of rooms and partitions, materials of all enclosing structures (external walls), and window sizes. Other issues are resolved as usual.

Water heated floor through a heat exchanger

A plate heat exchanger is a device consisting of soldered copper plates to transfer thermal energy from a high-temperature coolant to a cooler one, no mixing occurs during the heat exchange process, it is necessary to connect a water-heated floor to the heat supply line, without disturbing the pressure balance and without interfering in balancing the hydraulics of the whole house.

The installation of this unit cannot be neglected when installing heated floors. Otherwise, the coolant released into the floor at a high temperature will disrupt the heating supply of the building and leave your neighbors without heat. Unfortunately, it is precisely because of such negligence and neglect that the water floor causes irritation among building maintenance workers and residents who, due to the fault of such “craftsmen,” are left with batteries operating at low parameters.

Installation of a heat exchange point is a mandatory step when creating individual heating in a separate apartment of a multi-storey building.

Conclusion! The heat exchange unit switches the system to a safe mode and will help avoid conflicts with regulatory authorities and neighbors. We provide the heating unit for inspection by the HOA engineer before launch. Water heated flooring in an apartment is legal since the resistance of the heat exchanger is less than the total resistance of the radiators. With a professional approach, we did not encounter any opposition from the HOA.

Safe heated floor

A popular question is: can I flood my neighbors when using water-heated floors? Of course, no one is immune from leaks. The possibility of a breakthrough causes concern among residents of high-rise buildings. In a heated field operating through a heat exchanger, the coolant in the floor pipes circulates in a closed circuit and the volume is about 70 liters, under a pressure of 1.5 atmospheres. In a cement screed, the pipelines are reliably protected; they can only be damaged by purposefully drilling a hole in the floor. There are no connections in the heating panel circuits, the operating mode is gentle, so there is no cause for concern.

If, for example, a central heating pipe breaks, a flow of coolant under pressure from 4 to 6 atmospheres will flood an apartment with an area of 80 meters by 30 cm in 15 minutes, until the emergency service cuts off the supply through the riser.

The heated floors themselves are a closed circuit; if they are damaged, 10 liters of water will spill out. You can close the leaking area yourself within your own apartment.

Control your comfort

Install an additional electric boiler

The boiler will allow you not to depend on the heating season schedule and turn on the heated floor if desired. Having a boiler will allow you, during periods of repairs, accidents or other emergency situations, to independently decide what temperature you will maintain in the apartment. Warm up the bathroom or tiles in the kitchen in the summer.

We invite you to familiarize yourself with an example of a preliminary calculation of the cost of replacing the heating system in one of the apartments in St. Petersburg with water heated floors using a heat exchanger of the heating system, with a total area of 86.6 m².

Determining the number of radiators for single-pipe systems

There is one more very important point: all of the above is true for a two-pipe heating system. when a coolant with the same temperature enters the input of each radiator. A single-pipe system is considered much more complex: there, increasingly colder water flows to each subsequent heating device. And if you want to calculate the number of radiators for a one-pipe system, you need to recalculate the temperature every time, and this is difficult and time-consuming. Which exit? One of the possibilities is to determine the power of the radiators as for a two-pipe system, and then, in proportion to the drop in thermal power, add sections to increase the heat transfer of the battery as a whole.

In a single-pipe system, increasingly colder water flows to each radiator

Let's explain with an example. The diagram shows a single-pipe heating system with six radiators. The number of batteries was determined for two-pipe wiring. Now we need to make an adjustment. For the first heating device everything remains the same. The second one receives coolant with a lower temperature. We determine the % drop in power and increase the number of sections by the corresponding value. In the picture it turns out like this: 15kW-3kW=12kW. We find the percentage: the temperature drop is 20%. Accordingly, to compensate, we increase the number of radiators: if 8 pieces were needed, there will be 20% more - 9 or 10 pieces. This is where knowing the room will come in handy: if it’s a bedroom or a children’s room, round up, if it’s a living room or other similar room, round down

You also take into account the location relative to the cardinal points: in the north you round up, in the south you round down.

In single-pipe systems, it is necessary to add sections to radiators located further along the branch

This method is clearly not ideal: after all, it turns out that the last battery in the branch will have to be simply enormous in size: judging by the diagram, a coolant with a specific heat capacity equal to its power is supplied to its input, and in practice it is unrealistic to remove all 100%. Therefore, usually when determining the power of a boiler for single-pipe systems, they take a certain reserve, install shut-off valves and connect radiators through a bypass so that the heat transfer can be adjusted and thus compensate for the drop in coolant temperature. One thing follows from all this: the number and/or size of radiators in a single-pipe system must be increased, and more and more sections must be installed as you move away from the beginning of the branch.

An approximate calculation of the number of sections of heating radiators is simple and quick. But clarification depending on all the features of the premises, size, type of connection and location requires attention and time. But you can definitely decide on the number of heating devices to create a comfortable atmosphere in winter.

Heat exchanger for heated floors

Installation of a heated floor is possible if any source of coolant is available - both an individual heating boiler and a centralized heating system. However, if the owner of an apartment with centralized heating wants to install heating under the floor, he will have three problems:

- The coolant temperature may be too high;

- The coolant contains scale, rust, and other impurities that clog the heating pipes in the heated floor;

- The circulation of the coolant through thin tubes of complex shape leads to excess operating pressure, as well as a slow supply of heat to other apartments. This will lead to conflicts with neighbors.

To avoid these difficulties, when installing a heated floor, which will receive thermal energy from a centralized heating system, a heat exchanger for a heated floor is used.

How does a heat exchanger for water heated floors work?

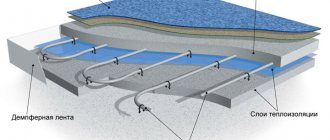

To install heated floors, different types of heat exchangers are used - from “pipe in pipe” to plate ones. The latter are distinguished by the highest energy efficiency indicators.

Two circuits are connected to the heat exchanger - external (centralized heating network) and internal (underfloor heating system). Thanks to this, it is possible to fill the underfloor heating system with a high-quality working environment. Purified water will circulate without leaving any deposits on the walls of the pipes. If you need to install a heated floor in a room that is not constantly heated (for example, on a closed loggia), you can add glycol or another component to the coolant, thanks to which the water will not freeze, and as a result the pipes will remain intact even in severe frosts.

Thanks to the regulators, more or less heated coolant can be supplied to the system. Therefore, the room will have an optimal temperature, the air will not be too dry, and high temperatures will not affect the condition of the floor covering. Typically, the coolant temperature in a floor heating system is up to 45°C.

Such equipment is quite simple to choose. Experts will calculate the required power and recommend a heat exchanger model with a suitable connector diameter for connection to the central heating pipe.

Plate heat exchanger for heated floors: advantages

Plate models are characterized by excellent energy efficiency, as well as compact sizes, which is very important if the heating system is installed under the floor, so as not to allocate space in the room for wall or floor radiators.

Made, as a rule, of copper, heat exchangers are able to perform their functions for a long time, and corrosion will not compromise the integrity of the unit.

Repairing or performing preventative maintenance on plate heat exchangers is quite simple. If the device cannot be repaired, it is easy to replace. With a “pipe-in-pipe” system, even the cause of improper functioning of the heat exchanger is not always easy to detect.

The plate heat exchanger does not have a very high casing temperature - the entire exchange of thermal energy occurs inside the unit. Therefore, touching it is absolutely painless and safe.

Which heat exchanger for underfloor heating is better to buy - collapsible or soldered?

The soldered heat exchanger has proven itself well in systems where water hammers occur quite often. It can withstand up to 35 Bar operating pressure. But there is no opportunity to increase the number of stacked plates in order to remove heat from the central heating system more efficiently. Therefore, before purchasing this equipment, it is necessary to make accurate calculations regarding the required power of the equipment.

It is also impossible to repair such heat exchangers - if a soldered plate heat exchanger leaks, it is simply replaced.

A soldered product almost always has smaller dimensions than a type-set analogue of the same power.

The collapsible heat exchanger usually withstands up to 25 Bar of working fluid pressure. Its advantages include:

- The ability to increase or decrease the number of stacked plates and thus control the power of the unit;

- Maintainability.

When purchasing such equipment, pay special attention to the quality of the gaskets between the stacked plates. The duration of operation of the product before the first breakdown depends on this.

for a heat exchanger

for heated floors

may vary. The soldered model is usually more affordable, while the kit model is somewhat more expensive. But you shouldn’t save on purchasing such equipment - a water-heated floor will provide significant savings on heating costs compared to its electric counterpart. So make sure the system is reliable and convenient by installing plate heat exchangers in key locations.

Part of the equipment

Elements of a water heated floor system

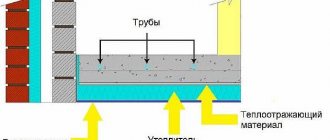

The VTP system consists of the following elements:

- a pipeline divided into equal sections (loops). They are connected in parallel to the source

- coolant to reduce the degree of cooling of the liquid during one circulation cycle;

- mixing unit. This is a separate device that is installed between the direct and return lines before feeding into the VTP loops. The task of the mixing unit is to regulate the temperature of the liquid by mixing the cooled flow with the fresh, hot one;

- circulation pump. This is a device that gives a fluid an impulse and causes it to circulate in the system at a given speed and under a certain pressure;

- collector. This is the device to which the underfloor heating loops are connected. Prepared coolant is supplied to the inlet, and pipelines are connected to the outlets. Each loop can be turned off separately, which allows you to avoid heating unused rooms.

In addition, the system uses measuring devices (pressure gauges and thermometers), temperature sensors and valves. All these elements work closely together and serve to solve a common problem.

Calculation of heat exchanger for heated floors

Calculation of plate heat exchanger

First, we will look at what types of heat exchangers there are, and then we will look at the formulas for calculating heat exchangers. And Tables of various heat exchangers by power.

AlfaLaval brazed heat exchanger - non-separable!

AlfaLaval - Dismountable with rubber gaskets

The main purpose of heat exchangers of this type is the instantaneous transfer of temperature from one independent circuit to another. This makes it possible to receive heat from central heating to your own independent heating system. It also makes it possible to obtain hot water supply.

There are collapsible and non-separable heat exchangers! AlfaLaval

— Russian production!

AlfaLaval brazed heat exchanger - non-separable!

Design

Brazed stainless steel heat exchangers do not require gaskets or pressure plates. The solder reliably connects the plates at all contact points, which ensures optimal heat transfer efficiency and high pressure resistance. The design of the plates is designed for a long service life. PPTs are very compact, since heat transfer occurs through almost the entire material from which they are made. They have low mass and small internal volume. Alfa Laval offers a wide range of devices that can always be adapted to specific customer requirements. Any problems related to heat transfer are solved by PPT in the most economically efficient way.

A brazed plate heat exchanger consists of thin corrugated stainless steel plates joined together by vacuum brazing using copper or nickel as a solder. Heat exchangers soldered with copper are most often used in heating or air conditioning systems, while nickel-soldered ones are mainly intended for the food industry and for working with aggressive liquids.

Mixing protection

In cases where operating regulations or other reasons require increased safety, patented double-wall brazed heat exchanger designs can be used. In these heat exchangers, the two media are separated from each other by a double stainless steel plate. In the event of an internal leak, it will be visible on the outside of the heat exchanger, but mixing of media will not occur in any case.

AlfaLaval - Dismountable with rubber gaskets

Heat exchanger: Liquid - liquid

1-plate; 2-tie bolts; 3.4-front and rear massive plate; 5-pipes for connecting the heating circuit; 6-pipes for connecting heating system pipelines.

Get a separate closed (independent) heating circuit of the heating system, while receiving only thermal energy. Flow and pressure are not transmitted. Thermal energy is transferred due to the transfer of temperature by heat transfer plates on opposite sides of which the coolant flows (giving off heat and receiving heat). This makes it possible to isolate your heating system from the central heating network. There may be other tasks.

1-supply pipe for heat release; 2-return pipe for heat release; 3-return pipe for receiving heat; 4-supply pipe for receiving heat; 5-channel for receiving heat; 6-channel for heat release. The arrows indicate the direction of movement of the coolant.

Heating system diagram

Each plate heat exchanger has values that are necessary for calculation.

The efficiency (efficiency) of the heat exchanger is found according to the formula

In practice, these values are 80-85%

What should be the flow rates through the heat exchanger?

There are two independent circuits on opposite sides of the heat exchanger, which means that the flow rates of these circuits can be different.

To find costs you need to know how much thermal energy is required to heat the secondary circuit.

For example, it will be 10 kW.

Now you need to calculate the required area of the plates for the transfer of thermal energy using this formula

Total heat transfer coefficient

To solve the problem, you need to get acquainted with some types of heat exchangers, and based on them, analyze the calculations of such heat exchangers.

You will not be able to calculate the heat exchanger yourself for one simple reason. All data that characterizes the heat exchanger is hidden from unauthorized persons. It becomes difficult to find the heat transfer coefficient from the actual flow rate! And if the flow rate is obviously small, then the efficiency of the heat exchanger will not be sufficient!

An increase in power with a decrease in flow rate leads to an increase in the heat exchanger itself by 3-4 times in terms of the number of plates.

Each heat exchanger manufacturer has a special program that selects a heat exchanger.

The higher the heat transfer coefficient, the faster this coefficient becomes smaller due to scale deposits!

Connection options for a plate heat exchanger, their advantages and disadvantages.

Independent single-stage parallel circuit.

Pros:

- Economical installation, saving space;

- Simplicity of design.

Minuses:

- There is no heating of the cold coolant.

Two-stage mixed scheme.

Pros:

- By heating the incoming coolant with reverse flow, efficiency increases by 40%.

Minuses:

- When designing a hot water supply system, you need to connect two heat exchangers at once, which makes the solution more expensive.

Two-stage sequential circuit.

Pros:

- The network load is stabilized and the efficiency of coolant use increases.

- Costs are reduced by 60% compared to a parallel scheme and by 20-25% compared to a mixed one.

Minuses:

- Impossibility of 100% automation.

Heat exchangers for heated floors - types, descriptions, prices

A heat exchanger for a heated floor is a device that is used to connect a pipeline circuit to the main heating system to heat the floor surface. Using a heat exchanger, thermal energy is taken from the coolant from the boiler or central heating network and transferred to the heated medium with its further supply to the underfloor heating system.

- Soldered is the most popular type for this task at private facilities, as it is compact and versatile. It is a block of metal plates soldered together with copper solder in a vacuum environment. Our catalog contains soldered specimens with connections of various diameters and types (thread, flange).

- Collapsible has an important advantage - it is possible to disassemble it for maintenance and increase power and put it back together. It is possible to replace the internal rubber plates and sealing seals with new ones.

Most often, the underfloor heating system is in demand among private customers, who organize it in their private homes and in pre-house areas, but given the increased level of comfort with this system, they are increasingly being implemented in industrial buildings and areas. is a major supplier of modern heat exchange equipment of various modifications and offers to buy a heat exchanger for underfloor heating of any size, both indoor and outdoor. Our prices for underfloor heating heat exchangers are the lowest on the market, we also provide delivery and favorable conditions with an individual approach to any client.

Are you looking for where to buy a heat exchanger at the best possible price?

Contact experienced specialists at TeploGarant

Options for using a heat exchanger for heated floors.

Floor heating in residential premises of a private house is the most common use case in which a heat exchanger is introduced into the central heating system coming from the boiler room, and a pipeline running under the flooring is connected to the heat exchanger itself. Through the heat exchange element, heat is transferred from the boiler system to the underfloor heating system, heating the medium circulating through the pump.

A heat exchanger for underfloor heating in an apartment in multi-storey or low-rise buildings is used to extract thermal energy from the coolant from the pipeline of the central heating system. With this use, an additional circuit is cut into the heating pipe (for example, next to the radiator) - a branch, which is connected to the heat exchanger and from it back into the heating system. A flexible pipeline is attached to the second heat exchange circuit, which is subsequently laid under the floor and the heated medium from the heat exchanger will circulate through it.

Heating the floor area of offices - this solution is also possible with the help of heat exchange equipment from TeploGarant. Here, as a rule, a closed main heating system comes from an individual heating point (IHP) passing through heating radiators, and it is to this main system that a heated floor circuit can be connected through a special heat exchanger.

Heating of floor coverings in warehouses for special purposes, for example, where there is strict storage of certain products or materials. This solution is very specific and individual, but is quite feasible with the help of a heat exchanger.

Possible sources of coolants

- A heat exchanger for underfloor heating from a boiler is the most common connection method in a private home or in a place where there is a private boiler room. The source of hot coolant for extracting thermal energy can be any type of boiler: gas, solid fuel or combined. Most often, such a system is organized in private houses, and the hot medium is pumped by a built-in boiler pump.

- A heat exchanger for a heated floor from a stove is another more simplified way to provide heating of the floor surface using a heat exchanger. In this case, the furnace must have a pipeline circuit for heating water or ethylene glycol, which, when heated, will enter the heat exchanger and transfer heat to the cold environment in the heated floor circuit. This system must also contain transfer circulation pumps.

- A heat exchanger for underfloor heating from central heating is an option that is suitable for residents of apartments in apartment buildings or in places where there is a pipeline from central heating. As a rule, hot water flows in such systems at a temperature of about 80C and is an ideal source of heat supply. Using heat exchange equipment, you can connect to the heating circuit and obtain uniform heating of the floor surface.

Variants of work schemes

“Water - Water” is one of the most common schemes, where ordinary tap water acts as the hot main coolant, and in the floor circuit there is standard water heated from the main coolant. To buy a heat exchanger for water heated floors, contact us.

“Water - Glycol”, here simple water from the main heating system flows from the boiler circuit into the heat exchanger, and a 40% solution of ethylene glycol (also known as antifreeze or antifreeze) is already used to heat the heated floor. In fact, there can be a huge variety of schemes, and any mildly aggressive substances can be used in our heat exchangers.

How to buy a heat exchanger for heated floors?

To buy a heat exchanger for underfloor heating from central heating, just contact and tell the specialists your initial parameters: the type and temperature of the medium in the central heating system, the heated floor area, the type of heating medium (water or glycol) and the desired diameters of the pipeline connections.

Which method should I choose?

It is important to pay attention to the specifics of your technical conditions

Selecting a connection option is a task that is usually solved by comparing technical capabilities and system performance. If you have your own heating boiler, the best option is a scheme with a mixing unit. If there is no boiler, it is most convenient to use a heat exchanger heated from the central heating network. You can feed a heated floor directly from the boiler if it produces coolant at a low temperature.

In any case, the main selection criterion is the reliability and stability of the ETP. Being left without heating your home in winter in our country is an extremely undesirable situation, therefore, you should choose the most workable option. In addition, it is recommended to have an additional option for heating the house in case of problems with the main heating circuit.

How to calculate power

What kind of boiler is needed for warm water floors - an economical one, so we choose it taking into account its performance. To select a suitable model, you need to calculate the power.

The average unit indicator for a suburban building is 1 kW of power required per 10 m2, that is, the specific productivity is 100 W per m2. But this is a fairly rough calculation, which is suitable for a brick building with minimal heat loss.

When installing gas equipment, it is necessary to prepare and coordinate the project with government agencies, and obtain permission from the gas inspectorate. The project has a section that indicates the calculation of the power of the device.

If you plan to place an electric or pyrolysis boiler, then a form is used to calculate the load of the house. The formula is suitable for midland regions; if the apartment is located in the northern regions, a correction factor of 1.2 or 1.3 is used. In case of poor insulation or DHW provision, a coefficient of 1.2 is also applied.

Mk = 0.1*Po*k1*k2*k3, where:

Using an example, we calculate the productivity of a generator for a house of 250 m2 in the northern region, with poor insulation and hot water supply:

Mk =0.1*250*1.2*1.2*1.3= 46.8 kW

If the premises are located in the central area, then the calculation indicator looks like this:

Mk =0.1*250*1.2*1.2= 36.8 kW

If the room is well insulated and hot water supply is not required, then:

Mk =0.1*250= 25 kW

It is not recommended to make a large reserve of power; in addition to increasing the cost of thermal energy, this will lead to overheating of the transformer unit and failure.

Conclusion

As you can see, in fact, there is nothing complicated in correctly calculating and increasing the efficiency of the system of negotiated systems. The main thing is not to forget that in some cases, high heat transfer from heating pipes can lead to large annual costs, so you shouldn’t get carried away with this process either ().

In the video presented in this article you will find additional information on this topic.

Actually, you are a desperate person if you decide to undertake such an event. The heat transfer of a pipe, of course, can be calculated and there are a great many works on the theoretical calculation of the heat transfer of various pipes.

Let's start with the fact that if you decided to heat your house with your own hands, then you are a stubborn and purposeful person. Accordingly, a heating project has already been drawn up, pipes have been selected: either metal-plastic heating pipes or steel heating pipes. Heating radiators have also already been looked at in the store.

But, before acquiring all this, that is, at the design stage, it is necessary to make a conditional relative calculation. After all, the heat transfer of heating pipes, calculated in the project, is the key to warm winters for your family. There is no room for error here.