During the construction of a building or insulation of walls, it is very important to ensure high-quality hydro, wind and vapor insulation of the structure using a calculator to calculate the thermal insulation of pipelines.

Reliable protection from the negative impact of environmental factors increases the service life of the insulation, prevents its destruction, increases the heat-insulating properties of the material, and protects the structural parts of the building from corrosion.

Using the Izospan membrane from the inside

A special vapor-permeable membrane called Izospan is in particular demand in construction today. It is this material that can guarantee the durability and warmth of structures. Let's try to figure out what this film is and what its operational features are.

By category

First of all, you must follow the manufacturer's instructions, which clearly describe which side to lay the windbreak on. If there is no such instruction, there are a number of general recommendations applicable to windproof films:

- the wind protection spreads towards the insulation with the “fleecy” side, unless otherwise specified in the instructions;

- if both sides are the same, the film is attached with the manufacturer’s logo on the outside;

- wind protection without markings and distinctive qualities of one of the sides can be installed in any convenient way.

Manufacturers often roll rolls in such a way that the wind protection can be laid as simply as possible - as the roll unwinds.

Features of installation

Before laying the canvas, you need to decide on the side that should face the heat insulator. Vapor-permeable samples are free to retain water on only one side due to the cone-shaped pores. As a guide, the manufacturer leaves a color indicator on the outer surface, often in the form of a logo, name or instructions. If there is no print, then the canvas acts equally on both sides.

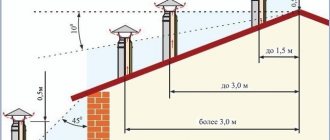

Wind protection of the roof is carried out with the installation of two ventilation gaps. The design is obtained with a membrane core. On one side of it there is insulation, on the other - the roofing. The distance is maintained at 50 mm. In the case of vertical structures, the gap is 30 mm; it is formed only on the outside. The membrane is attached closely to the thermal insulation.

Layout of hydro-windproof film in a frame wall Source eco-kotly.ru

There is a generalized version of the instructions for installing windproof film for roofs, walls or ceilings. Let's look at the procedure step by step:

- Tools.

It is easier to use small staples to secure the canvas. You can shoot them using a construction or furniture stapler. It is more convenient to attach the counter grille to form a ventilation gap with self-tapping screws using a screwdriver. Nails and a hammer are used less often.

- Blanks.

On the inside, the insulating sheets can be fastened with a slight sag, since when tensioned there is a risk of rupture in places with fastenings. From the outside on the roof, this approach is not recommended. This is justified by the fact that water can accumulate in the recesses and subsequently freeze. And this in most cases leads to a breakdown of the protection.

In any case, it will be more convenient to install it not by rolling out a roll on the work site, but by prepared sections. This will prevent the appearance of folds, deep depressions and distortions.

Working with finished pieces makes it easier to align the canvas Source doerken.com

Content

Windproof films of different types are laid in different ways:

- Simple wind protection. These are perforated single-layer films that can be placed on either side of the insulation, as they have double-sided vapor permeability.

- Wind and moisture protection. These are two-layer films that are laid with the moisture-repellent side facing out. This side is smooth, often with manufacturer’s markings or painted in a different (non-white) color.

- Superdiffusion membranes. This material has a multilayer structure with high water resistance and vapor permeability. It is necessary to lay the membrane on the outside of the insulation and only with the marked side facing out.

Purpose

Facade systems with an air gap, under the influence of wind flow, allow moisture to pass between the joints, which falls on the insulation, moistening it, thereby worsening its properties. The windproof membrane performs a protective function in relation to the insulation of walls and internal elements of the roof, preventing a reduction in the heat-saving characteristics of the premises. In addition to its main purpose, the material has other important properties:

- Resistant to ultraviolet radiation;

- Capable of passing steam;

- Resistant to active chemicals and bacteria;

- Chemically inert and does not emit harmful substances;

- High tensile strength characteristics;

- Non-flammability.

A layer of wind insulation is required for the roof. Without it, water penetrates into the attic and rapid destruction of structures. The membrane allows water vapor to pass out and keep structural elements dry. A properly installed roof wind barrier will keep the attic dry and free of condensation, extending the life of the entire building.

Is the windbreak attached to the ceiling?

Double-layer films are fixed to the ceiling with the smooth side facing the room. It is important to remember that in residential premises, windproof film can only be attached between floors with the same temperature and a vapor-permeable floor layer. If there are unheated rooms on the top floor, the insulation on the warm side is protected exclusively by a vapor barrier.

In the process of building a house, every owner or developer pays special attention to heat and waterproofing functions. Most people give preference to the highest quality and most expensive materials, thereby striving to achieve maximum comfort, warmth, high energy efficiency, and high-quality moisture protection for their housing. For these purposes, facade technologies are used that imply multi-layer wall structures: frame walls, curtain ventilated facade technology. One of the layers of such structures are wind- and moisture-proof membranes. Windproof film is used both to protect private housing construction and high-rise buildings. Of course, these are different types of membranes. More details about everything.

First mistake - wooden beams were wrapped with vapor barrier

If you study the topics on the portal about vapor barrier films and diffusion membranes, a paradoxical situation arises. The more a developer reads, the more confused he becomes. Cause? A huge amount of conflicting information from different manufacturers and builders. The situation is getting worse because... There are dozens of materials on the market with different technical characteristics.

vasooFORUMHOUSE Member

I am building a one-story house with a cold attic. The ceiling is made of wooden beams with a section of 100x250 mm. I want to leave some of the beams, about 15-20 cm, open, as in the photo below. So they look beautiful in the interior. I'm thinking of putting a vapor barrier film on the beams. Place 300 mm of mineral wool insulation on top. But after reading the portal, I doubted it. People write that if you cover the beams on top with a vapor barrier, then at the point of contact with the film, the wood will not “breathe.” This will lead to moisture accumulation. Is it so? Or is it better to lay plasterboard on completely exposed beams, then a vapor barrier, and only then lay mineral wool?

vasoo

By the way, I found one picture. Tell me, wooden beams can be wrapped with a vapor barrier, provided that part remains visible in the interior. In my opinion, the film prevents water vapor from escaping from the wooden floor. Or, am I misunderstanding something?

Questions are answered by a member of the Dragofol portal, who professionally installs roofing and vapor and waterproofing films. First, the “pie” of the attic floor, which he recommends to vasoo:

- Exposed wooden beams visible in the interior.

- Wooden flooring.

- Vapor barrier, with gluing of overlaps and junctions to walls.

- Insulation on the frame.

- On top of the insulation is a dust- and windproof material that releases water vapor. Moreover, there is no need to chase expensive branded films. It is enough to use inexpensive domestic nonwoven materials.

- Wooden platforms on a frame for free movement around the attic and preventive inspection of the under-roof space.

In the attic, due to the insulation, it is not recommended to lay continuous flooring.

Now the answer to the second question is vasoo. Wooden beams can only be “wrapped” with a vapor barrier with variable vapor permeability , the so-called. a film with adaptive properties, which, when air humidity increases, allows water vapor to pass through.

Such a vapor barrier can only be used over rooms with normal humidity, and not over bathrooms, toilet rooms and kitchens.

Important! If the vapor barrier is ordinary, then you cannot bend the beams with this film , because it will “lock in” the steam, which will lead to moisture accumulation and rotting of the wood.

What is wind and moisture protective film and where is it used?

A moisture and windproof membrane is a fireproof construction fabric that protects insulation from moisture and heat loss during air movement.

In general, windproof film is used in various areas of construction: in roofs, ceilings, partitions, floors, and in finishing bath walls. But we, as professionals in the field of facade construction, are only interested in membranes laid on insulation in ventilated facades, frame walls, and in any wall cladding with external insulation, but without a ventilation gap.

Bottom line

There is a FAQ. For example, which side should windproof membranes be attached to? If mineral wool is used as insulation, the product must be attached from the outside. In most cases it's the other way around.

How to attach this product? It is necessary to tighten and fix it using a construction stapler. But this is only for a while. You also need to screw the slats on top. If you are working with curtain facades, the fastening procedure is more complicated.

For what period of time can the film be left open? Although manufacturers claim that the film can remain open for quite a long time, nevertheless, after just six months the film will lose its technical qualities.

Therefore, it is advised to cover the material with cladding almost immediately after installation. This must be done because frequent rains can cause the product to begin to leak moisture. Therefore, after installing each element of the house, cover the film with cladding.

The windproof membrane is suitable for walls, facades, roofs, and partitions. These simple tips will help you install a windproof membrane.

Why do you need a windproof layer?

Moisture and windproof films protect the surface of the insulation from water and moisture, from mechanical damage, and also prevent heat loss due to longitudinal filtration of air in the insulation. Protection is especially important during slanting rain, then the insulation is abundantly wetted and, if there is no ventilated gap that quickly dries the surface, there is a risk of freezing of the walls. Wet insulation loses up to 90% of the energy saving characteristics declared by the manufacturer. The vapor barrier film must be laid with the smooth side facing out.

Is it possible to do without it?

Wind protection for walls in a frame house is not mandatory. But, if you do not install additional protection on the house, then heat will begin to escape through the cracks along with the air. Savings during the construction of a house will result in more significant costs during its operation for heating.

Another reason for using wind protection is the prevention of mold and mildew due to the fact that the wall is exposed to temperature changes from inside and outside, which causes condensation to form on it.

Does the wind membrane burn?

The windproof membrane for cladding the facades of expert buildings must correspond to the group of non-combustible materials - NG. All manufacturers declare compliance with the NG group. Has anyone tried to set fire to a piece of vapor barrier film with a lighter? Those involved in the construction of facades have probably tried everything. The film burns out, the flame dies out, it does not support combustion, but there is a certain emotional moment in the subjective assessment. Porcelain tiles, metal bracket - NG, which is logical. Set fire/don’t set fire, at most the element will become smoky. But the membrane behaves differently, it burns down to the base, but fades out. It turns out that the film itself does not burn, but with an external source of fire, the flame will spread across it. However, there are permits issued by competent and authoritative authorities.

The permitting documents for windproof membranes used in facades are:

- Technical certificate of suitability for use in construction (specifically for the installation of a wind-waterproofing layer in the construction of suspended facade systems);

- Certificate of compliance with the requirements of TU 8390-001-96837872-2008 as amended. No. 1

- Fire test report for assigning a group and flammability class in the system

- Durability test report

- Test report for determining vapor and air permeability

- Sanitary and epidemiological conclusion

Based on an analysis of the permitting documentation from a number of manufacturers, it is possible to come to conclusions regarding the typical properties and characteristics of windproof membranes.

Consequences of refusing vaporization

A lack of understanding of the importance of vapor barrier for a roof often leads to attempts to save money or speed up the construction process. Many users believe that the material can be installed later if the need arises

Other owners rely too much on ventilation. They are confident that increased air exchange in the attic will help remove moist air and solve all problems. However, in practice, the lack of vapor protection affects the same way. Condensation appears, the heat insulator gets wet, and the rafters rot.

The biggest danger is that the process proceeds quite smoothly. The owner observes the condition of the attic for a week and draws conclusions about the normal condition of the insulation pie. The cladding is installed, the room is finished and put into operation. This deprives the user of the ability to control the condition of the materials hidden behind the skin. When destructive processes become apparent, the problem becomes critical. Usually a major overhaul or complete replacement of rafters, roofing, and other roof support elements is required.

Characteristics and properties of building fabrics

The requirements for windproof membranes used in private and public buildings are different. At a minimum, because public buildings are subject to state construction expertise. The scale of the consequences of using low-quality film when cladding high-rise buildings is more extensive. By not very high-quality film, the editors first of all understand that it does not comply with the flammability group NG is a non-flammable material.

- The ability to resist fire determines the material’s compliance with a certain flammability group. Films approved for use in ventilated facades have a flammability group of NG - non-flammable. Consequently, the fire hazard class of building materials is “KM-0”.

- Vapor and air permeability is determined by the fabric’s properties to resist air penetration under wind loads and when warm steam escapes outside. A good vapor-permeable membrane corresponds to a vapor permeability value: 0.1 m2*h*Pa/mg. Air permeation resistance: 1500 m2*h*Pa/mg.

- Windproof films for walls must have low water permeability to protect against rain and snow.

- The fabric must have high tensile strength. This value affects the determination of the number of sheet attachment points. The number of attachment points will increase in proportion to the height of the building, this is due to an increase in wind load.

- Each linear meter of fabric must be able to elongate by at least 6 cm both lengthwise and crosswise before breaking. Elasticity ensures the safety of the fabric when stretched.

- Durability of at least fifty conventional years.

Material selection criteria

One of the main parameters for choosing building materials for a home is environmental friendliness. Some types of wind protection are used for interior work. The absence of toxic emissions is especially important here. Information about this can be found in the certificates for specific samples.

The next criterion is technical indicators. Here we consider options for which wind protection to choose for the roof and facade. Important parameters are strength, resistance to ultraviolet rays, and temperature limits acceptable for operation. In the case of interior work in wet rooms, vapor permeability is additionally taken into account.

The third point is durability. In most cases, it is important that the material lasts as long as or longer than the structures being protected. But there are projects where isolation is needed temporarily. Budget solutions are more relevant here.

Glassine Source ygozapad.ru

Instead of an epilogue

The use of building films and membranes is a prerequisite for the correct functioning of multilayer structures. Only with their help can one ensure proper temperature and humidity conditions inside the building. When working with membranes, there is usually no particular difficulty; you just need to choose the right material needed in a particular case and install it correctly.

Practice has shown that it really makes sense to protect insulation, especially when you consider that the cost of films and membranes during the construction of a cottage does not exceed 0.5% of the total estimate. But there is a lot at stake - the microclimate of the premises, the durability of building elements, the level of energy costs.

In order for a building to serve for a long time, while creating comfortable conditions for people to work and live, one cannot do without high-quality insulation. Nobody argues about this in the construction world anymore. It is necessary to insulate any buildings, regardless of their purpose, since building structures are not able to withstand high temperature loads.

If insulation is not carried out, the structures will freeze during the cold season. However, just using modern insulation is not enough. The developer must work thoroughly to create a full-fledged thermal insulation “pie”. The windproof membrane plays an important role in its composition. Many people use the Izospan moisture-proof membrane, which provides good protection from moisture and wind.

Is a layer required for ventilation?

At the bottom of the membrane vapor barrier there is a 5-centimeter ventilation gap, which helps prevent the formation of condensation on surfaces and the heat insulator.

Diffusion membranes can be attached to insulation, plywood sheets or OSB. In a membrane with an anti-condensation layer, gaps up to 6 cm wide are located on both sides.

To create a gap for ventilation when insulating the roof structure, a counter-lattice is used. In the process of fastening a ventilated facade, a technological gap is created when installing racks located perpendicular to the vapor barrier.