Since the climate in most of our country is clearly not Californian, placing insulation under the plaster is not only practical, but also profitable. How to create a “wet façade” for a homeowner is described in a separate article. Here we will consider which insulation is better to use under facade plaster in various conditions when insulating a house.

Types of facade insulation and features of their use

Insulating the facade has obvious goals: increasing the level of comfort for residents, optimizing the temperature in the premises and reducing heating costs. In fact, the use of thermal insulation solves another important issue. If the walls are cold, condensation inevitably appears on them, which gradually penetrates into the thickness of the material, freezes, and then tears it apart from the inside. Sooner or later such walls will begin to collapse. If you increase the temperature on the surface and inside, condensation will not appear, therefore, the dew point will be displayed.

The essence of using insulation under plaster is to attach any heat-insulating material to the wall of the house and then plaster it. A special construction mixture will protect the insulation from atmospheric and other negative factors and create the basis for applying a decorative coating. There are different types of insulation on sale, each of which has its own pros and cons.

Types of insulation for plaster

Mineral wool boards

The basis for the production of this insulation is basalt or other silicate rocks, as well as metallurgical slag. They melt and stretch into fibers with a large number of air channels. The fibers are then formed into slabs with different densities and a certain number of layers.

The best mineral wool insulation for the walls of a house is a two-layer slab with a density of 100–125 kg/cu. m, where the soft inner layer firmly adheres to the wall, adapts to its relief, and the hard outer layer is the basis for the plaster. Mineral wool slabs (mats) have many advantages:

- strength and vapor permeability;

- excellent heat-saving properties;

- environmental friendliness, safety;

- lack of flammability.

The disadvantage of such insulation is significant - it is not able to withstand moisture, as a result, water literally saturates it, changing its performance properties for the worse. The problem will have to be solved by impregnating the cotton wool with water-repellent compounds. Also among the disadvantages is the large weight of the insulation and the ability to cause irritation on the skin.

Ecowool

This material is also called cellulose insulation, because it is made on the basis of cellulose. Its price is quite low, it provides excellent thermal insulation, is breathable, and environmentally friendly. However, ecowool is used quite rarely for wall insulation. It strongly absorbs moisture, as a result of which mold and mildew begin to multiply on its natural fibers. You need to apply insulation to walls using special equipment, which also reduces its popularity.

Insulating the facade of a house with ecowool

Glass wool

Glass wool is a well-known fibrous wall insulation, which is a type of mineral wool. It is made from glass fiber obtained from waste from the glass industry. The insulation is characterized by high chemical resistance, increased elasticity, strength, and vibration resistance. It has optimal thermal conductivity, which allows it to serve as a heat and sound insulating material.

Glass wool is available in slabs and rolls. It can be used as facade insulation under plaster, as well as for thermal insulation of internal partitions and roofs. Disadvantages of the material:

- the need to use respirators and gloves when working (otherwise small fibers will harm health);

- crumbling and large shrinkage.

Isover fiberglass insulation

Styrofoam

Expanded polystyrene, or polystyrene foam, is a rigid polymer board consisting of small air-filled granules. The insulation on top is impregnated with fire retardants, so it does not support independent combustion, but when smoldering from another source it emits toxic fumes. The main advantage of polystyrene foam is its resistance to moisture and lightness, due to which the load on the foundation almost does not increase.

Insulating the facade with foam plastic

Polystyrene foam is a popular material for difficult climatic conditions. It does not lose properties during 80 cycles of freezing and thawing. This foam insulation is ideally combined with plaster. By itself, it is afraid of ultraviolet radiation, collapsing under the rays of the sun, and rodents can also live in it. After plastering, the material will fully demonstrate its performance characteristics, because it will be reliably protected from negative factors. The durability of such a combined insulation will increase, as will its resistance to weathering, cracks, dents, and scratches.

Extruded polystyrene foam

This insulation is a type of conventional polystyrene foam with a more uniform fine-porous structure. It has better technical parameters, but costs an order of magnitude more. The advantages of the material over conventional polystyrene foam are obvious:

- the strength is tens of times higher, so it can be used for cladding plinths and basement floors;

- the flammability of polystyrene foam is reduced;

- the thermal conductivity of extruded slabs is less than that of foam plastic and mineral wool;

- Thanks to the profiled edges, installation of the slabs is easy, and there are no seams on the finished coating.

Penoplex slabs made of extruded polystyrene foam

Extruded polystyrene foam does not allow vapors and gases to pass through, so the vapor permeability of the walls may be impaired. The adhesion of insulation to plaster mixtures is quite low, as a result of which its installation requires a special approach.

Sprayed thermal insulation materials

A separate group of insulation materials includes liquid sprayed materials. The most famous and popular among them is polyurethane foam in the form of foam, which is obtained by mixing two main components. It is easy to apply such insulation, the work goes quickly, and there are no seams left on the surface. It firmly adheres to all types of substrates: wood, brick, metal, concrete.

Sprayed insulation materials are very lightweight and can withstand humidity, temperature changes, and exposure to chemicals. They must be protected from direct rays of the sun, otherwise they begin to deteriorate from the action of ultraviolet radiation. In addition, sprayed insulation supports smoldering, which occurs upon contact with an open fire.

Household sprayed polyurethane insulation Polynor

Insulation for facade plaster - choosing the best option

When choosing a specific insulation for your home, you need to be guided by its durability, resistance to adverse factors, and fire safety. Many people also take into account the affordability of insulation and its availability in stores. However, these are not all the criteria that need to be taken into account. The shape of the insulation should be convenient for installation. It’s good if the material is hard enough and can be secured without much effort. The higher the thermal insulation qualities of the insulation in slabs or rolls, the better the result will be. It is important to know the load-bearing characteristics of the walls so that the finishing done does not spoil their properties.

Tips for selecting insulation for the exterior of a house are as follows:

- with low thermal conductivity of walls (made of wood, aerated concrete, cellular foam concrete), mineral wool slabs or other vapor-permeable materials can be used;

- with high thermal conductivity of walls (made of concrete, panels, slag concrete, brick), any insulation under plaster will be suitable;

- Foam plastic is considered a universal heat-insulating material, which can be used in all cases, without the need for special equipment.

Classes, thickness and grades of PPP, how to choose, which one is better to use?

At first glance, all foam plastic is the same, but this is only for those who first decided to insulate the house from the outside. Polyurethane foam is divided into classes and grades, and for this purpose the following characteristics are used:

- production features;

- material density;

- edge design method.

Expanded polystyrene classes

The material is divided into 2 classes:

- Pressed - the sheet will be marked PS. The insulation is produced using press installations. The structure of the material is smooth and it is almost impossible to distinguish polystyrene granules.

- Pressless - in this case, the PSB marking is left on the foam. To create such products, high-temperature sintering of the substance is used. Although press installations are also used. The slabs consist of round or oval granules that are easy to distinguish from each other.

Letters or numbers are added to these markings, which will help determine the density of the material, where it is best to use it and the shape of the edge. Additional letters are:

- A – the correct shape of the slab.

- B - the edge cut is similar to the letter L.

- R - slabs were cut using a hot string.

- F - the product was created using a form, or a façade purpose.

- C – polystyrene foam extinguishes on its own.

- N – suitable exclusively for outdoor use.

PPP brands

Now let's look at the grades of material. To determine the brand, manufacturers indicate a digital value. For non-press and press representatives these values are different. Let's look at each class separately in detail.

Brands of pressless polystyrene foam

On the construction market, this class of insulation is represented by the following brands:

- 15 – low-density foam. The cheapest. Most often used for packaging household appliances or fragile items. It is easy to damage;

- 25 - if the letter F is added to such numbers, then the material is suitable for finishing the facade. The density is much higher, which means the strength is improved. It is often chosen to create decorative elements in the interior or landscape - the density of the material allows;

- 35 - foam with this marking can be used for various purposes. It is a good insulation material for facades, as a component for multilayer panels (thermo, sandwich, reinforced concrete);

- 50 is the densest and most durable material, and also the most expensive. It is used for insulation of underground structures and communications.

Brands of pressed polypropylene

Using the pressing method, PVC foam is produced. Polyvinyl chloride resin is added to the composition. The material is very durable and reliable. It is used in all areas of construction and insulation. A number from 1 to 4 is added to the letters PS. The higher the numerical value, the higher the density, and therefore the strength, of expanded polystyrene.

The material of the press production method is suitable for creating containers for aggressive substances. It is resistant to most known chemically active liquids.

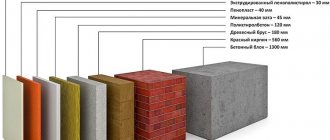

Calculation of the required insulation thickness

When performing thermal insulation of a facade under plaster, the latter is applied in a thin layer and has a minimal “warming” effect. In fact, it is needed to protect the insulation, extend its service life and improve the aesthetic characteristics of the building. The thickness of the plaster is not taken into account, but the thickness of the heat-insulating boards is selected based on special calculations.

It is not easy to calculate this indicator yourself. It is found using rather complex formulas that take into account the following information:

- type, thickness of load-bearing wall material;

- heat transfer resistance;

- interior wall finishing material;

- average air temperature in winter;

- average humidity, wind force;

- technical characteristics of insulation.

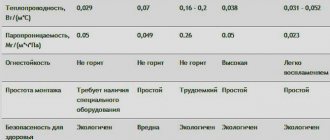

Table of insulation thickness for walls

All calculations must be made by a specialist, although in reality developers or owners rarely resort to such services. More often, the experience of friends, neighbors, and the price of insulation are taken into account. Typically, the thickness of thermal insulation does not exceed 12–15 cm for expanded polystyrene, 18–20 cm for mineral wool. In warm climate zones, these indicators can be reduced by almost 2 times.

The best mineral wool manufacturers

When choosing the necessary products, you need to pay attention to products only from proven and well-known manufacturers that have a good reputation. Popular brands include:

- Rockwool.

- Paroc.

- Izover.

- Knauf.

- Ursa.

- IZOVOL.

- Beltep.

- Senergy.

8 leaders of popular manufacturers offer to take advantage of advantageous offers and choose a product that meets all requirements and standards. The main advantage of insulation is safety, reliability, and price.

Types of plaster for insulation

Most often, the plaster layer is 3–4 mm, but taking into account the glue and reinforcing fabric, the total thickness becomes slightly larger. Many types of mixtures that can be applied in a thin layer are suitable for plastering insulation. They are smooth and textured. The latter are given relief by special fillers - mineral granules, cellulose fibers, stone chips.

Mineral compositions

Mineral compositions for facade work are made on the basis of cement (gypsum and lime mixtures are not suitable for this purpose). Water repellents and plasticizers are necessarily introduced into the composition, and microfiber fibers are often added to increase strength.

Cement-based facade plaster Knauf Unterputz

Mineral plaster is good for protecting insulation. It is affordable, environmentally friendly, vapor permeable, and sold in a wide range. However, difficulties may arise with painting it, because most mixtures have a grayish color, and the basic tone of the paint will certainly change after application. You should not purchase mineral compounds without additional additives - their service life does not exceed 2-3 years, after which they gradually begin to crack.

Acrylic mixtures

Acrylic plasters are made on the basis of acrylic resins. They are an order of magnitude more expensive than mineral ones, but their price is compensated by improved technical characteristics. The service life of the compositions is very long, they are easy to apply due to their elasticity, and do not crack even when the building shrinks. The coating will be durable, resistant to scratches, moisture, and efflorescence.

Facade plaster Caparol Capatect Fassadenputz

Acrylic mixtures are available in color variations and in white for tinting. They can be painted with any pigments, although under the influence of ultraviolet light the color will gradually fade. The coating has slightly reduced vapor permeability and is not recommended for mineral wool. If desired, acrylic plasters can be applied as decorative ones, using different effects (fleece, bark beetle, rain).

Silicone plasters

Such plasters are sold in finished form and are available in a wide range of colors. They practically do not fade, as they are not afraid of ultraviolet radiation. The finished coating is durable, vapor-permeable and water-repellent; moreover, it is capable of self-cleaning; dust and dirt practically do not stick to it. The only disadvantage of silicone compounds is their high price.

Acrylic-silicone decorative facade mixture Bark beetle

Silicate plasters

Materials under this name are made based on polysilicon liquid glass. They are expensive, but they have maximum strength, vapor permeability, and resistance to chemical, mechanical, and biological damage. The color range of silicate compounds is pastel, but the colors do not fade over time. The material is quite elastic, so it will not crack even with strong shrinkage or vibration of the walls. Applying this type of plaster requires a certain level of skill, and beginners may find the process difficult.

Facade decorative silicate plaster

Slab reinforcement

The layer of plaster on mineral wool holds quite firmly, but due to the fact that the insulation surface is not rigid enough, cracks and even peeling of the decorative finish may occur. Plaster and slabs need to be reinforced.

For this:

- Apply an intermediate thin layer of solution, at least 2-3 mm thick;

- We cut the mesh and fasten it with vertical tapes with an overlap of 5-7 cm at the edges;

- We lay the mesh on the “blots” and lightly press it into the base;

- We rub the surface first with a liquid adhesive, then with a thicker leveling glue.

The surface should be as flat and even as possible, so we level the base under the plaster using the rule, trying not to leave marks or marks.

Tools and materials for work - what else will you need?

In addition to insulation boards and plaster for covering them, for high-quality installation of a thermal insulation system, you need to prepare a number of other devices and materials:

- adhesive composition;

- disc dowels - for additional fixation of insulation;

- reinforcing mesh and putty mixture - to strengthen the wall and ensure the strength of the finish;

- primer and primer - to enhance adhesion and strengthen the base;

- façade paint - for painting plaster if it has not previously been tinted;

- facade varnish - to protect pigmented and decorative plasters;

- aluminum base profile and base dowels for its fastening - for mounting the support of the 1st row of insulation;

- docking elements - for joining the ends of the base profile;

- plastic expansion joints - for leveling walls;

- self-adhesive profile - to improve the adhesion of the reinforcing layer to door blocks and window frames;

- corner profile with mesh - to protect external corners from mechanical damage.

Tools for wall insulation

Possible errors when performing work

Most often, beginners make the following mistakes that reduce the quality of their work:

- weak fixation of insulation - causes cracks, detachment and deformation;

- poor preparation of the walls - causes a decrease in adhesion, sliding of the insulation and even a shift in the dew point;

- installation in unsuitable climatic conditions - leads to a reduction in service life;

- loose joining of insulation boards, small overlap of the mesh - provoke cracking of the finish;

- improper treatment of window slopes - allows moisture penetration;

- choosing low-quality plaster is a prerequisite for rapid deterioration of the entire finishing layer.

In order for the home insulation system to serve for a long time and actually cope with the main tasks, it is important to strictly follow the technology and not skimp on materials. Then the house will become beautiful, comfortable and reliable, and will not require repairs for decades!

Ready-made plastering systems

Often so-called plastering systems are sold in construction stores. These are kits that include glue, primer, insulation, plaster and paint, as well as other necessary materials. Usually they are produced by the same company or are ideally matched to each other in terms of technical parameters. The most famous plastering systems are:

- Rockwool. Includes several types of systems based on basalt wool with a thin or thick layer of plaster, as well as for facing with clinker tiles.

- "Senergy PPS". Ideal for low-rise buildings, it includes polystyrene foam insulation, adhesives, primers, and decorative protective plaster.

- Ceresit. Plaster complex based on extruded polystyrene foam.

- Caparol. Plaster system with polystyrene foam of different thicknesses.

Capatect facade insulation system

The cost of a plaster system depends on the manufacturer (domestic or foreign), the type of insulation, the type of plaster and the thickness of its layer. The so-called “warm plasters” for facades, into which vermiculite or perlite are additionally introduced, are more expensive.

Extruded PPS

To make this foam insulation, an extruder is used, where polystyrene balls are sintered under high pressure. The result is a board with a higher density than, for example, PSB-50, but at the same time much thinner. Therefore, if 10 cm thick foam plastic is required to insulate the facade, then 5 cm thick extruded polystyrene foam can be chosen.

He was the first to introduce such insulation to the building materials market, which is why you can often find the second name penoplex. But there are other companies that offer products of similar quality. These are Technoplex and Ursa.

Technology for creating insulated facades

In order for the thermal insulation of a house to work fully and serve for many years, all stages of its installation must be carried out strictly in accordance with the instructions.

Cleaning, priming the base and preparatory work

Thermal insulation of the facade is carried out only after completion of all internal finishing work, especially rough work. Before attaching the insulation, the inside must also be finished (paint, wallpaper, tiles). Next, perform the following steps:

- The roof of the building, window and door openings are covered, and brackets for attachments are hung (if they are intended to be used).

- The walls are measured using a plumb line or level, and all significant differences (more than 1-2 cm) are identified.

- The surface in the area of defects is leveled with rough plaster, the protrusions are cut off and sanded.

- The walls are treated with a primer to strengthen the base, bind dust and enhance adhesion to the adhesive.

- A base profile is attached to the walls, which will serve as a guide for the 1st row of insulation, and will also protect the lower ends from adverse external influences.

The base profile is mounted along a horizontal starting line, specified by level. Usually its height from the ground is 60–65 cm. The profile is attached to the wall using dowels and plastic washers, taking into account compensation for unevenness of the facade. Along their length, the profiles are connected to each other with special connecting elements.

Installation of insulation boards

Typically, adhesives for installing insulation are sold in dry form for ease of transportation. They are diluted with water immediately before use. Such compositions retain their properties for an hour, so you should not dilute them in large portions. The adhesive mass is intensively mixed with a mixer until it has a homogeneous consistency.

The finished glue is distributed on the back side of the insulation boards using a plaster spatula, and spread in a thin layer around the perimeter. In the middle of each slab, place 2 slides of glue, which, after pressing, will distribute themselves. Place the slab against the wall and immediately remove any glue that comes out with a spatula. The next row is laid taking into account the displacement of the vertical seams, controlling the position with a level.

A day after applying the glue, the insulation is additionally secured with dowels. They are selected based on the type of base and the thickness of the insulation. Typically, disc-type anchors are well suited for this purpose. They are installed in five places for each slab: along the edges and in the center, drilling holes with a diameter of 8 mm directly through the insulation. The depth of the holes should be 1.5 cm greater than the length of the dowels. First, choppers are inserted into the holes, then anchors, driving them in with a hammer until they stop.

Installation of insulation on the facade

Reinforcement of insulation boards

After fixing the insulation, the reinforcement begins. Along the perimeter of all openings, abutment profiles are placed - perforated lightweight metal strips with plastic or fiberglass mesh. First, rectangles approximately 20 x 30 cm are glued to the tops of all corners in the openings, setting them at 45 degrees relative to the top point. For gluing, use a special reinforcing putty, applying it in a thin layer and recessing the mesh. Lubricate the reinforcing material with another layer of putty on top.

In a similar way, corners with mesh are reinforced along the protruding corners of the building, at the outer corners of windows and doors, which will help protect them from mechanical stress. A day after these manipulations, they begin to strengthen the remaining area of the walls, having previously purchased mesh in rolls. To finish the first floor, a reinforced mesh is purchased, for the rest of the surface it is ordinary.

Laying reinforced mesh on insulation

Installation of the reinforcing fabric is carried out using the same putty, applying it in a layer of 4 mm and leveling it with a notched trowel. The canvases are laid with an overlap of 10 cm. The second layer of putty is spread with a layer of 2 mm already on the mesh, leveled with a smooth spatula until the flaws are eliminated. Make sure that no waves appear on the surface, and that the layer of glue is not too thick - it will quickly crack. Using this principle, the entire area of the facade is reinforced, wrapping the fabric at the corners.

Final stage

After the glue has completely dried, priming is done with a special primer, which is applied with a roller or spray. Then the plaster is spread in one layer, leveled with the flat side of a metal or polyurethane spatula by performing circular movements. The dried layer of plaster is painted with facade paint, preferably silicone-based. Such paints provide the most durable coating that is not afraid of fading, chemicals and abrasive effects.

Facade plaster

Basic insulation mistakes

External insulation of the walls of a country house must be carried out in accordance with the requirements and rules for installing materials. Errors that most often occur during insulation contribute to improper circulation of air flow and the formation of moisture inside the cake, which leads to a weakening of the thermal insulation qualities:

- incorrect calculation of thermal resistance;

- if there is no base strip at the bottom of the wall, the insulation may come into contact with the ground;

- Expanded polystyrene should not be left in the sun for a long time during installation;

- cracks between insulation boards lead to the appearance of cold bridges;

- Expansion dowels should be installed at the corners of the building and around doors and windows to securely fasten the material.

In addition, you should not skimp on materials, since in addition to their correct installation, the low quality of the material should not cause poor-quality insulation.

Thus, when insulating walls, the living space is preserved; careful consideration of details is required to calculate the amount of materials and determine the order of installation work.

Application of decorative plaster

Decorative plasters are often used to finish facades with installed insulation. They choose outdoor materials that are highly resistant to temperature changes and precipitation. The operating procedure will be as follows:

- start plastering at a temperature within +5...+25 degrees, humidity up to 70%, in calm weather;

- prepare the plaster mixture (dilute with water) or thoroughly mix the ready-made composition in a jar;

- spread the composition onto a wide spatula and rub it over the wall in a thin layer (up to 4 mm); the specific thickness of the plaster is determined by the size of the filler fraction: the particles must be arranged in one layer;

- after the plaster has dried, rub the base with a construction float until the desired texture is obtained;

- The finish is coated with paint or clear varnish in 2 layers.

Decorative facade plaster bark beetle

If desired, you can glue the insulation and plaster the house yourself. This work is painstaking, long, but not technically difficult, so even a novice master can do it.

What is bad about low-density polystyrene foam?

For high-quality thermal insulation of a house, it is necessary to choose the right density of the material. Low-density polystyrene foam consists of granules that are located relatively far from each other. This helps the material to better pass steam from the interior, but the granules themselves are not able to pass liquid.

Therefore, moisture gradually accumulates in the insulation and is transferred to surrounding materials:

- cladding;

- load-bearing wall.

As a result, the surrounding substances gradually begin to collapse. In addition, the strength of low-density foam is also low, so it quickly crumbles and collapses.

What is sold under the brand name PSB-25

Products that are in demand are most often counterfeited. This fact applies not only to polystyrene foam, but also to plaster mixtures, paints and even food and medicines. In addition, the conditions of production have long been no longer controlled by government agencies. Therefore, manufacturers, by reducing the cost of the material, also reduce the cost of its production, which leads to a decrease in quality.

According to state standards, polystyrene foam with a density of 15 to 25 kg/m3 can be produced under the PSB-25 brand. Having such boundaries, manufacturers will not waste money and will create an option with a lower density, which is completely legal. This means that low-density PSB-25 foam is available on the building materials market.

How to find out the density?

To prevent the seller from selling a product with a low density indicator under the guise of being expensive, you can check the value yourself. The manipulation is a little labor-intensive, but as soon as you start performing such actions, the consultant will tell you everything as it is.

So, to find out the density of the material you need to weigh 1 cubic meter of polystyrene foam. If grade 25 insulation is selected, then it should weigh exactly 25 kg. In the store we do the following:

- We calculate the volume of one sheet of selected foam.

- Let's weigh it.

- Divide volume by weight.

- The resulting value is compared with the one that should be.

Final wall decoration

Decorative plaster decorates the building and protects its walls from the appearance of fungus and mold. It is applied in one of three ways:

- Stamping. The plaster is applied with a regular roller covered with a patterned mesh;

- Trimming. To apply the plaster, use a sponge soaked in water. The surface after trimming imitates natural stone;

- Bouffant. A metal brush with bristles is used. It is used to comb the wall after applying the plaster.

After the procedure, the insulated surface should be protected from rain and snow for at least a day.