Production features and general description

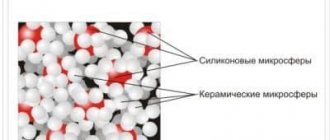

Thermal insulation Corundum is a composition based on ceramic microspheres and an acrylic binder. The last ingredient is produced using catalysts and fixatives.

The size of the microspheres varies from 0.01 to 0.5 mm. The composition of the product is also supplemented with all kinds of additives to enhance its performance properties. This composition gives the material flexibility, lightness and elasticity. In addition, Corundum is characterized by good adhesion to a wide variety of surfaces.

The consistency of this brand of heat insulator resembles ordinary paint. In fact, it is a white suspension, which, after hardening, forms a very reliable and elastic polymer coating.

In comparison with ordinary heat-insulating materials, Corundum provides not only protection against heat loss, but also against corrosion .

Initially, such coatings with heat-protective properties were created at the request of NASA for finishing spacecraft. Over time, experts adapted these mixtures for “earthly” needs. Corundum is the commercial name of a product that was developed by Russian specialists. This heat insulator has special certificates that indicate its high quality.

Work technology

Sprayed insulation and thermal paint are applied to a clean, durable base without corrosion or areas of biological damage. Painting is carried out in the same way as with traditional compositions: priming, forming a layer-by-layer coating with intermediate drying of each. The manufacturer writes on the packaging about the intricacies of the work.

Insulation of walls using insulating foam occurs in the following order:

- installation of sheathing made of lumber, metal or plastic profiles;

- spraying a heat insulator onto the working surface across the entire width of the opening in the direction from bottom to top (it may be possible to repeat the procedure to increase the thickness of the coating);

- protection and decorative finishing of the formed layer.

The sheathing serves as a reinforcing material and a guide to the thickness of the insulation. After the foam has dried, the excess foam composition is cut off along the sheathing. This results in a smooth surface, which is easier to work with later at the finishing stage.

Foam insulationSource ytimg.com

Types of heat insulators Corundum

Today you can find several modifications of this product on sale. Of these, the most popular are the following formulations:

- Classic . This is a very effective product designed for insulating walls (outside and inside), pipelines, roofs, facades, air conditioning systems, and steam pipelines. Thermal paint prevents the formation of condensation on surfaces and also reduces heat loss.

- Antikor . This type of insulation is notable for the fact that the material can be applied even to metal surfaces with traces of rust. In addition, Antikor has excellent thermal insulation properties.

- Winter . This material can be used even at sub-zero temperatures. Corundum Winter does not harden or freeze at low temperatures. The mixture includes foam glass microgranules and acrylic polymers. In addition, they contain inhibitors, pigments, flame retardants and rheological elements.

- Facade . This thermal insulation material is intended for treating concrete bases. Has high heat-reflecting characteristics. The product can be applied even in a thick layer, which makes work faster. Thermal insulating paint Corundum Facade is characterized by high resistance to climatic influences and vapor permeability.

Possible applications

The technical characteristics of the new ultra-thin insulation make it possible to use it in many areas of the national economy. The composite is most widely used in construction, industry and transport. Corundum copes well with insulating external and internal walls of buildings and structures, regardless of architectural features and general surface curvature.

It is also used for thermal insulation of roofs, attics, balconies, window slopes, concrete floors and ceilings. The thermal insulation effect from a barrier thickness of 1 mm is equivalent to the effect obtained from brickwork 1.5 bricks thick

An important feature is that the coating does not create additional load on the main structural elements

Anti-corrosion

The benefits of using insulation in industry are not limited to reducing heat loss. It successfully solves the problems of equipment corrosion protection. Thermal coating Corundum is applied to pipelines for steam, hot water and circulating water supply, as well as their piping fittings. Used to protect air conditioning and ventilation systems, as well as some capacitive equipment under suitable operating conditions. Prevents temperature deformation of metal structures.

Thermal insulation is applied to containers and tanks on railway and wheeled transport, as well as trailers, containers and refrigerators. In shipbuilding, engine rooms and holds are treated with Corundum material.

Specifications

The properties of this material allow it to be used for processing structures for various purposes and different configurations.

The characteristics of Corundum should be considered in more detail:

- Low degree of thermal conductivity. This indicator for the Corundum heat insulator is much lower than that of most classical materials, such as mineral wool or polystyrene foam.

- Moisture resistance. Corundum does not allow moisture to pass through its structure and is not damaged by it. This brand of heat insulator is not even afraid of saline solutions.

- Fire resistance . The heat insulator Corundum does not burn. When exposed to high temperatures, it decomposes, releasing nitrogen and carbon oxides.

- Vapor permeability. This type of paint does not form an airtight film on the surface. It provides effective air exchange, creating an optimal microclimate in the room.

- UV resistance. The structure of the material is not damaged by exposure to the sun's rays. Therefore, it can be used even without additional protection.

- Biostability . Rot, fungi and mold will not appear on elements that are treated with Corundum thermal paint. The material is not afraid of rodents and insects.

- Ecological cleanliness. Liquid heat insulator does not release toxins into the environment even with strong heating. You can work with it even without using personal protection.

- Durability . This coating has a long service life. It does not lose its operational properties for 10-15 years. No defects or cracks appear on it.

Is this really so - we need to look into it in detail

First of all, it’s worth starting with the correct definition: corundum is not insulation, but a thermal insulator!

The difference is that the first name denotes a material that is intended for some noticeable insulation of the room. That is, in this case, the temperature inside should improve by at least a few degrees.

But the second concept should be interpreted in the literal sense of the word: an insulator is isolation. In essence, this means that it will not become significantly warmer, but it is also unlikely to become colder. But at least there is a chance to get rid of condensation, fungus or gradual “wetting” of the walls, for example.

Moreover, in the case of insulation (or rather insulator) KKrund, it is possible to eliminate such problems quite cheaply!

Therefore, in principle, it is possible to pay attention to this decision. The main thing is to understand well the technical parameters of the material and become familiar with the application features. This will be discussed below.

Advantages and disadvantages of the material

Thermal paint of this brand carefully fills the micropores of the surface that is being processed. In addition, liquid thermal insulation has the following advantages:

- Retains heat perfectly. Even 1 mm of the composition can be compared in terms of efficiency with 40 mm of roll-type insulation, for example, mineral wool.

- Easy to apply. The mixture is applied to the surface like regular paint: with a roller, brush, or spray. At the same time, it does not emit any harmful substances, so it is not necessary to use protective equipment when working with it.

- Provides protection against destruction. Metal surfaces treated with Corundum will never rust, and wood will not dry out or rot.

- Does not attract rodents, insects and bacteria. The coating will not mold or rot.

- Small mass. The weight of the heat insulator cannot be compared with classic rolled material. This type of thermal insulation will not load the foundation and supporting structures. Therefore, even fragile and unstable elements can be treated with Corundum.

- No cold bridges or seams. Using Corundum you can create a reliable coating without any seams.

- Durability and safety. During the entire service life, no harmful chemical compounds will be released from the material. Therefore, they can also insulate living spaces where allergy sufferers live.

- Does not affect geometry. Compared to traditional materials for thermal insulation, Corundum does not have any effect on the geometric parameters of the building.

This type of isolation is not without its disadvantages. First of all, this concerns high cost . This material appeared on the Russian market relatively recently, which is why it still has a high cost. However, this “minus” is fully compensated by the durability of the coating and excellent thermal insulation properties.

The disadvantages also include the rapid polymerization of thermal paint, so you will have to work with it very quickly.

Briefly about the main thing

The group of liquid insulation materials includes thermal paints and polymer foaming compounds. This also includes moistened ecowool, as it is applied by spraying.

The main advantage of the materials: high energy efficiency of thin-layer coating. The main disadvantage is the total cost according to the estimate. More often, spraying is carried out using special equipment that is not purchased for home use. Therefore, we have to hire craftsmen. If you purchase the material in gun cylinders, you can do the work yourself. But here there is a large consumption of expensive foam.

The insulation technology consists of 3 stages: surface preparation, application of insulation, decorative finishing. The base must be clean, strong and “healthy”. A sheathing is installed under the sprayed compositions. The finish can be anything: painting, paneling, plastering, cladding. Less commonly, thermal insulation coating is used as an independent coating.

Criterias of choice

The patent for the material belongs to. This organization has several official dealers, for example, “ServisInvestProject”, “TeploTrade” and others. You should not buy products from sellers with a dubious reputation.

The normal state of this brand of material is a white pasty mixture. Packaging: buckets made of durable plastic with different volumes. In this case, information about the manufacturer must be indicated on the packaging.

The cost of thermal insulation varies depending on the region of sale and the type of material. The average cost of insulation is as follows:

- Classic - 390 rubles per liter;

- Anticorrosive - 440 rubles per liter;

- Winter - 560 rubles per liter container.

Distinctive features

Thermal insulation Corundum consists of ceramic particles with the addition of acrylic and water.

Externally, the material is similar to paint and is applied in the same way, but its properties and tasks are different.

Liquid thermal insulation Corundum is made from a mixture of ceramic fillers and a water-acrylic solution. Ceramic particles act as insulation, and the solution allows you to distribute the insulating elements over the entire surface in an even layer. This composition can be quickly and conveniently applied to any area in an even layer. The composition contains various connecting additives that improve the characteristics of the heat insulator. The most popular are rubber and silicone.

How to work with Corundum correctly

Liquid thermal insulation can be applied with traditional painting tools - a spray gun, roller or brush. The spray gun allows you to achieve the highest quality coating and minimal material consumption.

The layer thickness should not exceed 0.4 mm. You need to start applying the next layer only after the previous one has hardened. When used, the approximate consumption of the substance is about half a liter per square meter of surface.

To apply heat paint, you can use the following instructions:

- Pour the composition into a separate vessel and mix it until a homogeneous mass is obtained. To speed up and simplify this work, you can use a drill and a special attachment.

- Surfaces must first be degreased and cleaned of dust and dirt. If we are talking about a metal alloy, then the surface must additionally be freed from traces of rust. For degreasing, it is better to use solvent, kerosene or gasoline.

- Thermal paint should be applied only to dry areas. The thinnest layer is the first one, since it is essentially a primer.

- When using a roller or spray, hard-to-reach areas and joints will still have to be painted with a brush.

- Experts advise applying no more than three layers of material.

Warm paint Corundum looks very attractive on the surface, and therefore it can even be used for finishing cladding.

Corundum is an innovation in the field of thermal insulation materials. It can be used for effective insulation of buildings for various purposes, pipes and other elements. This is a reliable and completely environmentally friendly liquid thermal insulation.

Main modifications of modern liquid thermal insulation

Modern thermal insulation coating Corundum is presented in several modifications. Each of them has its own characteristics in application.

Let's look at each type in more detail.

- Classic

This type of thermal insulation is successfully used when processing:

- facades;

- roofs;

- concrete floors and screeds;

- interior partitions;

- pipelines supplying cold and hot water.

Eliminates the possibility of condensation and also prevents heat loss. Therefore, it is also successfully used when processing refrigerators and trailer tanks.

Coating the tank with Corundum

- Anticorrosive

A unique product that can be applied even to rusty surfaces. Neutralizes corrosion and prevents its development. The material is applicable to structures of any type.

Treated rusty metal tank

- Winter

This type of thermal insulation is designed for application to surfaces at sub-zero temperatures (but not lower than minus ten degrees Celsius). Excellent for buildings and other objects constructed or insulated in extreme conditions, because other types of Corundum can only be applied at air temperatures no lower than plus five on the Celsius scale.

The material contains the following components:

- acrylic polymers;

- flame retardant additives;

- pigmenting additives;

- foam glass microgranules and other additives.

- Facade

This type of thermal insulation is specially created for application to concrete coatings and surfaces for insulating facades. It is characterized by increased heat-reflecting properties, which is appreciated by many professionals in the field of construction and construction of any type of structure.

The material can be applied even in a thick layer, which can significantly save time on insulating the building. When used outside a building, after Corundum has dried, any decorative facing materials can be applied to it, which will in no way affect the thermal insulation properties of the coating.

Facade of a multi-storey building

As can be concluded from the presented photos, the described material really has excellent aesthetic properties. But, as already described above, its performance characteristics are at the same level.

In addition, the price of thermal insulation is relatively low, especially when you consider all the actual positive properties of the material!

Therefore, if you want the room to be warm and the water in the pipes not to freeze or cool, use modern thermal insulation! In the video presented in this article you will find additional information on this topic.