The popularity of underfloor heating systems is growing every day. This is a convenient way to increase the level of comfort in your home or apartment. Warm floors are used for both primary and auxiliary heating of premises for various purposes. Ten years ago, when heated floors were rare and even considered exotic, experts recommended installing them as an additional source of heat in bathrooms, corridors, and kitchens.

But the emergence of new materials and specially designed heating mats, infrared films and polymer pipes with a high level of thermal conductivity, made it possible to install heated floors as the main source of heat in bedrooms, children's rooms, and garages. Such systems are also used in retail establishments, modern offices, hairdressing salons...

Is thermal insulation necessary for underfloor heating or not?

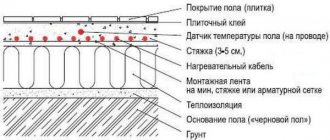

Thermal insulation in the “pie” of a warm water floor plays a huge role; the correct functioning of the entire heating system depends on it. The screed, poured over the thermal insulation, turns into a large surface that transfers heat.

The main functions that a thermal insulation flooring under a warm water floor should perform:

- distribute heat flows evenly throughout the heated room, this is especially important when laying a water structure, since the configuration of this system consists of straight and curved pipes, so the heat is not distributed evenly;

- prevent the outflow of warm air through the ceilings; it serves as a reflective screen, which also makes it possible to save thermal resources;

- act as sound insulation;

- prevent the entry of moisture and cold from below - when arranging a structure above an unheated room or on the ground;

- prevent the formation of moldy and fungal deposits.

In addition, by using polystyrene foam mats with bosses as insulation under a warm water floor, you significantly simplify the process of installing and fixing pipes.

For your information! If the thermal insulation layer is correctly selected and laid, the floor “pie” turns into a closed thermal device, where thermal radiation is distributed evenly and in the desired direction.

Using Penoplex

The name Penoplex itself is a brand. And the material itself is a high-density polystyrene board. For screed floors this is the best option.

- It has low thermal conductivity - 0.031 W/m K.

- It has a high density - 45 kg/m³, which affects the compressive strength. And for genders this is one of the important indicators.

- Does not absorb moisture.

- Does not allow steam to pass through.

- Chemically inert.

- Absolutely environmentally friendly.

- Easy to process.

Today, manufacturers produce foam boards with a tongue-and-groove connecting lock, which makes it possible to assemble a seamless coating on the floor base.

The process of insulation with penoplex is simple. It is necessary to lay the slabs over the entire surface of the concrete floor, connecting them together with a lock, then stretch the reinforcing synthetic mesh over the top, and only then you can pour the solution.

Types of insulation for water heated floors

When selecting a material for a thermal insulator for a warm hydrofloor, you should take into account the characteristics and technical indicators of the room, as well as the base on which the substrate will be installed.

For the most part, the thermal insulation material has the same degree of thermal conductivity. But the thickness of the layer is often required even in the same room.

The most common types of thermal insulation used under water-heated floors include: mineral wool, cork, expanded polystyrene, profile mats. This material has different thermal insulation characteristics and properties, and this should be taken into account when choosing and installing the floor.

For your information! When constructing a warm water structure on the ground, it is recommended to use natural raw materials for insulation: sawdust, expanded clay, washed granulated slag, expanded clay sand.

Let's take a closer look at each type of material for thermal insulation of a heating structure.

Cork backing

Cork is an expensive product because it is made from oak bark. Available in rolls or sheets, but there are no differences in technical characteristics. The only difference is the size and thickness.

Cork backing:

- has low thermal conductivity;

- waterproof;

- environmentally friendly;

- hypoallergenic;

- elastic;

- light-resistant;

- fireproof;

- resistant to sudden temperature changes;

- not susceptible to chemical influences.

A product made from cork is an ideal option for a water-heated floor system, and if funds allow, then it is better to choose it. The thickness of this substrate contributes to effective saving of heat resources, which is especially important when installed on the ground.

Cork is not subject to deformation and shrinkage when pouring concrete screeds. It cannot be harmed by insects and rodents, mold and mildew, and is also not terrible.

However, it should be noted that the use of cork as a substrate will affect the height of the ceilings, and additional reflective material will also need to be purchased.

Expanded polystyrene

Expanded polystyrene is the most common type of thermal insulation under water heating floors, and has a fairly affordable price. It provides high-quality protection from water and steam, a high degree of sound insulation, does not deform from exposure to temperature, does not react to chemicals and resists the formation of mold and mildew.

Thermal insulation consists of many bubbles placed in a shell. To add strength to the structure with this substrate, a reinforcing mesh is used. Ease of installation, which even an inexperienced person can handle, also plays an important role in its popularity. In addition, the service life is several decades.

The main disadvantage of polystyrene foam is a fire hazard, so it must be insulated with a foil backing.

Expanded polystyrene comes in several types, which differ in production technology and properties:

- Extruded polystyrene foam is durable and better performs its main function - thermal insulation. It has increased strength, since the particles are tightly bonded to each other. But the vapor permeability indicator is almost zero. Its thickness is at least 3 cm. The slabs are often colored.

- Foamed - also called polystyrene foam. It has a low specific gravity and a high degree of vapor permeability. It is not recommended for foundation insulation, as it is destroyed by moisture. The color is usually white. It is produced in a non-extruded way, that is, the structure has cells with air channels.

- Penoplex - its cost is not high. It has good performance in terms of reflecting heat flows, therefore it is considered one of the best insulation materials. During installation, a waterproofing substrate is not required, and the process itself is not complicated; it is easy to do the installation yourself. Available in slabs of various sizes, the thickness of which ranges from 20 to 100 mm. The package contains from 4 to 20 sheets - it depends on the thickness of the product.

Penoplex - types, scope, characteristics, advantages and stages of laying thermal insulation.

Main advantages:

- high heat and vapor insulation;

- absence of emissions containing harmful substances;

- resistance to the effects of microorganisms;

- does not allow moisture to pass through;

- has high strength.

- Profile mats - they are also based on polystyrene foam. They are stamped using a special technological method and covered with a film for waterproofing. The slabs are high-strength products that can withstand mechanical loads. They are equipped with protrusions; water heated floor pipes are laid in them, which facilitates the process of placing the circuit. They have side locks - this simplifies installation and minimizes the presence of seams. The model is considered the most profitable, in terms of financial investments, when constructing heating.

Mineral wool

Mineral wool is fireproof, unlike polystyrene foam insulation, but its price is more expensive. It is manufactured in slabs, making it easy to install.

When installed on an aluminum underfloor heating base, this insulation has high efficiency, even when placed on the ground. In addition, it has good noise and heat insulation, increased rigidity, and is resistant to chemicals.

The main disadvantage of the product is that it contains carcinogenic and toxic substances that are dangerous to human health. In addition, cotton wool is hygroscopic and vapor-permeable, and when laying it in a screed, care must be taken to protect it from moisture and steam emissions.

Rolled thermal insulation made of foamed polyethylene

Foamed polyethylene (penofol) is gaining popularity today. It is sold in rolls and has a thickness from 3 to 10 mm. The product is equipped with a foil surface, it reflects heat and allows you to significantly reduce the thickness of the “pie”, since there is no need to lay additional waterproofing made of lavsan or thermal insulation.

There are the following types:

- A - one side has a layer of foil;

- B - foil on both sides;

- C (self-adhesive) - there is foil on one side, glue is applied on the other;

- “ALP” - one side is foil, the other with a special film.

Each type is suitable for use under heated floors, and almost completely copes with the thermal insulation of the device.

The technical indicators of foamed polyethylene and polystyrene are largely similar, the thermal conductivity coefficient ranges from 0.037 - 0.049 W/m °C.

It is worth mentioning the ability of the material to absorb water, which results in a decrease in its thermal insulation properties.

In addition, under the influence of a wet screed containing chemicals, the aluminum foil layer becomes unusable. To combat this problem, manufacturers began to produce the product in sheets with a film-like coating on top of the foil.

Metallized lavsan film is capable of qualitatively protecting the screed and flooring from the effects of alkali. Insulation with an aluminum layer without a thermally resistant coating is not used. The positive side of the product is its high degree of heat reflection.

Important! When laying, the foil side of the product should face up.

Insulation process

To secure the thermal insulation material, it is best to use glue, especially for floating floors. When using glue, the risk of damage to the material is minimized. The glue should not be ordinary, but special, made specifically for the material used. The insulation must be laid as evenly as possible, and after applying the glue, press it carefully and wait a certain amount of time so that they have time to set.

Preparing the adhesive mass will not be difficult - just follow the instructions supplied with the product. To dilute the solution you will need a construction mixer. You can also use an ordinary drill, only in this case you will need to install a “mixer” attachment on it.

The process of insulating the floor under the screed begins not with the placement of slabs of material, but with the formation of sides along all four walls. They are made from the same material with which you will insulate the floor.

After this, it is necessary to accurately determine the height of the screed, taking into account the thickness of the insulating material. The sides mentioned above are installed precisely at this height.

If you use material in the form of slabs to insulate the floor under the screed, then they must be cut to the required size. These pieces are laid over the entire surface of the floor. At the same time, carefully ensure that the material is in good contact with the sides in the corners.

Thus, anyone can insulate the floor under the screed with their own hands. The main thing in this matter is to follow the sequence of actions and existing rules. Then you will be completely satisfied with the result, and your home will always be warm and cozy.

Which insulation to choose?

As mentioned above, a warm water floor requires insulation, since without it it will not function effectively. In addition, if there is thermal insulation, the system is more economical. It is important not only to know how to properly insulate a heated floor, but also how to choose a suitable heat-reflecting material.

When purchasing thermal insulation, you need to look not only at the characteristics, heat-saving properties of the material and its parameters, but also at its service life. Since a number of products with good performance often have a short service life.

Therefore, there will be a need to replace it before maintenance of the system itself is required. This is especially important in rooms with tile flooring, because it is difficult to dismantle it. In this regard, experts advise purchasing a product with a warranty period of 10 - 15 years.

Among the properties that are recommended to pay attention to:

- level of thermal conductivity;

- resistance to mechanical loads and dynamic influences;

- density indicator;

- hydro and vapor tightness.

For rooms with high ceilings, it is better to choose durable, rigid types that have a polymer base. If you are insulating a room with wooden floors, mineral wool is an excellent option, because it is fireproof.

You should not skimp on thermal insulation material when laying a heated floor. Its cost will pay off within 3 years, and if you use natural gas for heating, the payback period will be significantly reduced.

Extruded polystyrene foam

Expanded polystyrene foam is perfect for floor screeding, as this material meets all the requirements for high-quality insulation. Compared to polystyrene foam, it has better performance.

If we talk about choosing the right component composition of EPS, then you should be guided by the following indicators of various brands of expanded polystyrene.

| Name of insulation | Density, kg/m3 | Coefficient of thermal conductivity | Tensile strength, MPa | Hygroscopicity |

| Penoplex 35 | 28 – 38 | 0.030 W/m x C | 0,4 – 0,7 | 0,4% |

| Penoplex 45 | 40,1 — 47 | 0.030 W/m x C | 0,5 | 0,2% |

| Penoplex Foundation | 29 – 33 | 0.030 W/m x C | 0,27 | 0,4% |

| Penoplex Comfort | 25 – 35 | 0.030 W/m x C | 0,18 | 0,5% |

It is not recommended to choose polystyrene foam whose density is below 20 kg/m3, since such a base will not withstand the load from furniture. Based on this, the thickness of the sheets should be at least 30 mm for standard Penoplex boards and at least 7 mm for thin sheets (for example, Pufatherm).

There is also foil-coated polystyrene foam, which, thanks to the additional layer of foil, is the best option for insulating screeds for wooden floors and when installing heating systems. Foil can not only retain heat, but also reflect it. However, this material must be laid on the screed, and not under it.

Features of laying insulation

The principle of installing a thermal insulation layer is simple, no special tools or special experience are needed, the main thing is to follow the technological process.

Watch the video on how to choose insulation:

How to choose insulation for a heated floor. Lifehack from Design.rf

Installation of polystyrene foam boards

The work of installing polystyrene foam boards under a heated water floor is as follows:

- Regardless of the type of thermal insulation product, you need to start by preparing the subfloor. It should be smooth, without cracks. If irregularities and flaws are found in the surface, they need to be repaired.

- Waterproofing measures consist of arranging a layer that protects against moisture, this can be a polyethylene film.

- Sticking damper tape around the perimeter of the room is necessary to compensate for temperature fluctuations.

- Laying insulation boards over the entire area - the sheets are fixed to the base using plastic staples or dowels; the product can be installed with glue.

- Spreading foil film and installing reinforcing mesh over the insulation.

- Installation of heating elements (pipes) - they are attached to the grid according to the planned scheme. The seams between the plates should be taped with tape, this will help retain heat.

- Pouring concrete screed over the pipeline. To ensure surface strength, it is recommended to add plasticizers to the solution. It is necessary to let the mixture harden, this will take about a month.

- The last step is the installation of the finishing coating.

For your information! It is worth considering that underfloor heating pipes with the coolant inside have significant weight, plus the screed and finishing coating, all of this together will push through the insulation over time.

To avoid this, high-strength thermal insulation is required. In addition, to strengthen the structure and distribute the load evenly, it is recommended to reinforce or lay polystyrene foam slabs with bosses. In addition, such mats facilitate the process of placing pipes and fixing them.

Laying rolled polyethylene foam

Installation work on the construction of a water-heated floor using rolled polyethylene as insulation begins with leveling and cleaning the base.

At the second stage, the heat-insulating material is prepared. This consists of cutting the heat insulator into strips of the required length using a stationery knife.

Next, the foil product is placed on the prepared base with the metallized surface facing up to ensure the best reflection of heat. The canvas should extend onto the walls, this is necessary to compensate for the expansion of the screed when heated. The insulation is attached to the floor using glue or double-sided tape. And the seams should be taped using single-sided tape.

The process of installing a water circuit on polyethylene rolls is facilitated by the presence of installation markings printed on it, which show the distance between the pipes. Heating elements on penofol can be placed in a “snail” or “snake” pattern.

Further work on the construction of water heated floors consists of installing reinforcing mesh, pouring a concrete screed and laying the floor covering.

For your information! For use in a warm water device, ALP brand penofol is recommended.

Laying mineral wool

Mineral wool cannot be crushed, so the most optimal way to install it is on the floor, with the installation of logs.

Step by step, the installation of the “pie” of a warm system with a thermal insulation substrate made of mineral wool is as follows:

- Preparation of the base is a mandatory stage of work when installing any heated floors. If the floors in the house are old, then it is better to completely remove them down to the concrete floor or rough wooden floor. The surface must be inspected for irregularities and cracks; if any are found, they are repaired.

- Laying a hydro- and vapor barrier substrate is a necessary step when using mineral insulation, as it is resistant to moisture. For these purposes, roll-type waterproofing - roofing felt, or other modern materials - is suitable. The sheets are fixed to the base using polymer or bitumen mastic. The material is laid in an overlap, the seams should be coated with mastic.

- Arrangement of wooden logs - they are attached to the subfloor over the entire area. Blocks measuring 5 by 6 cm are taken and installed on a concrete surface, secured with dowels, and on a wooden floor with self-tapping screws. The pitch between the fasteners depends on the flooring that is planned to be laid; it ranges from 40 to 80 cm. It requires making cuts in the joists to rotate the contour.

Important! If mineral wool is used as insulation, then the distance between the logs should exceed the width of the material by 1.5 - 2 cm.

- Laying insulation - mineral wool is installed in the spaces between the bars. It is necessary that it sinks at least 5 cm, as a ventilation gap is required.

- Installing a second waterproofing layer is necessary, because cotton wool is not moisture resistant. An ordinary polyethylene film is used, which is placed in a stretch on the logs and fixed with a stapler.

- Preparing the substrate for pipes - slats are used that are nailed across the logs, with a distance of 30 cm from the walls. There should be grooves between the slats in which a metal profile for laying pipes will be placed. Their size depends on the step of laying the contour.

For your information! The metal profile can be replaced with foil in which the pipe is wrapped.

- Installation of the heating circuit - heating pipes are laid into the installed profile according to the planned layout.

- Installing interior flooring - this can be chipboard or plywood.

- Finally, the floor covering is laid.

At this point, the warm floor with a thermal insulation backing - mineral wool, is ready for use.

Rough screed using beacons

If the screed is made with a cement-sand mortar, then metal beacons are required, which are shown, and their installation in the room is shown.

The beacons are installed along a horizontal line previously drawn for the subfloor. To level them horizontally, use a ruler-level and place the same solution under them as for the screed. The distance between the beacons determines the length of the rule with which the solution will be distributed between the beacons. However, in the absence of experience, this distance should not be greater than 1.5 m. Composition of the solution: 1 part M300 cement, 3 parts sand, 1/10 part lime paste. Water must be added in such an amount that the solution is thick and does not spontaneously spread over the surface. No more than 2 hours should pass from preparing the solution to its use.

The ready-made mixture for screed can be purchased at a retail chain; it is prepared according to the attached instructions.

https://kuhnyamoya.ru/youtu.be/Jtw7-0XAyQo

Lay the mortar with a shovel, starting from the wall. Liquid cement is first applied to the surface. The solution should rise slightly above the beacons and occupy an area of approximately 1 m2. Distribute the solution, removing the top layer, using the rule rack shown. The lath near the wall is removed, the place is filled with mortar, smoothing it with a trowel. The areas of the beacons to be removed are also filled with solution.

The hardening time of the screed is approximately 1.5 days. After that, you can walk on it, but you can lay the insulation on the rough screed in a week.

If in a newly built house the concrete floor of the room does not require leveling, then the subfloor is not made. It is enough to properly seal the cracks, remove debris from the floor and wipe with a damp cloth to remove dust.

If insulation is done during the construction process, then there is no need for all the operations described above. Polyethylene film is laid overlapping on the concrete slab, sealing its joints with tape. Then the foam is laid and waterproofing is placed on top of it again.

Next, a reinforced cement screed is made. The dimensions of the reinforcing mesh are 100×100 mm or 150×150 mm. If the thickness of the screed is no more than 5 cm, then the mesh must be raised so that it does not touch the waterproofing.

https://kuhnyamoya.ru/youtu.be/RRaZfW17rNw

Thus, if insulation is done during the construction of a house, then it is not difficult to complete this work yourself. It is much more difficult to insulate the floor in an already built house, especially if it was built a long time ago and has shrinked a lot.

Optimal insulation thickness

It is important to make the right choice not only of the insulation model, but also of its thickness; thermal energy savings depend on this.

For your information! If the thickness of the insulation is small, then most of the heat goes under the floor, its amount is equal to the flow of warm air rising upward.

The thickness of the insulation should be selected depending on climatic conditions. It is clear that in areas with a cold climate, the layer of thermal insulation material should be larger.

The type of room located under the warm water floor also plays an important role. If this is a cold basement, or the structure is laid on the ground, then the insulation layer should be made thicker, 100 - 120 mm. When constructing a heating floor over a heated room, a sufficient thickness of 30 - 50 mm.

Installing a thermal insulation layer under a heated water floor is not a luxury, but a necessity. Incorrectly done insulation will lead to deterioration in the quality of heating and unnecessary costs.

Filling the screed

The screed is made at above-zero temperatures. The entire area is poured at once. To prevent air voids from forming, it is necessary to pierce the surface in several places with a thin metal object, since the air itself cannot escape from under the heavy cement layer.

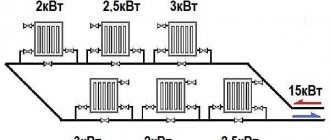

If the room area is large, after laying the heated floor, special beacons are installed, they are levels for pouring an even layer of mortar. Beacons are placed 0.5 meters from the wall, and from each other at a distance less than the size of the rule.

Concreting is done from the far corner to the door. The solution is poured between the beacons, evenly distributed and leveled, its level should not be higher than the beacons.

In order for the screed to come out of high quality, it requires care. To do this, 2-3 times a day for a week, its surface is moistened with water, since the solution must harden and not dry out. The heated floor system should be turned on after the laid screed has completely dried.

In general, the filling procedure is simple. If you follow the instructions and technology for making the solution, anyone can do everything with their own hands.

Manufacturers and prices

It is not difficult to insulate a concrete floor today, since the range of thermal insulation materials is very large. But you can only trust the following manufacturers in terms of choosing quality:

- Ekomix (extruded polystyrene foam) - price 1300 rubles per package.

- Isolon (foil insulation) - price 1200 rubles per roll.

- Paroc (mineral wool) – price 800-850 rubles.

- Rockwool (mineral wool) – price 1000 rubles.

- Neman (glass wool) – price 1200 rubles.

Insulation is one of the important processes in the field of construction, with which you can make any home warm and cozy

When choosing a material for thermal insulation of a concrete floor, you need to pay attention to the composition of the material, its thermal conductivity, moisture permeability and service life

Adding polystyrene chips to concrete

To give the concrete layer additional protective characteristics, granules of extruded polystyrene foam can be added to the solution (the latter can be purchased for approximately 1000-1800 rubles per cubic meter). This is done as follows.

Foam balls for concrete can be purchased pre-packaged

Step 1. A little water is poured into the prepared container, then dry cement is poured into it. All this is mixed with a mixer attachment until the consistency of thick sour cream.

Mixing the solution with polystyrene balls

Step 2. During the mixing process, polystyrene foam granules are added. The proportions of concrete can be very different - both 1:3 and 1:6.

List of possible errors

- One of the common and serious mistakes when insulating a floor using penoplex is the missing temperature gap between the screed itself and the surface of the walls. Regardless of the type and cost of the cement or concrete mixture used, the solution may expand during hardening, resulting in its displacement. In this case, a solidly poured monolith may become completely covered with cracks. The consequences will be close to catastrophic, especially if a “warm floor” system is installed - moisture can penetrate inside and damage the heating elements of the structure. The recommendations of professionals are to apply damper tape to the area where the screed meets the walls and columns. You can also leave about 1 centimeter of free space, which, after the screed has completely hardened, is filled with sealant.

- Another common mistake is the use of inappropriate mastics as moisture insulation materials. Most of them contain substances that can destroy the structure of polystyrene foam. In this case, it is safest to use modern films made of membrane material, the joints of which are simply sealed with tape.

- The question often arises about the number of layers required to protect against moisture. Penoplex slabs are often placed on top of roofing felt laid on the ground. The heat insulator manufacturer recommends installing only one vapor barrier layer, which is placed on the surface of the slabs. More powerful protection against moisture is needed only if you plan to install a heated floor. The basic principle is as follows: it is necessary to exclude the penetration of moisture from the outside, leaving the possibility for evaporation of the condensate that has fallen. If Penoplex is covered with waterproofing on both sides, this rule will be violated.

- There are also important notes regarding what kind of floor covering can be used to decorate the foam insulating layer. Often, the strength of the thermal insulation layer is greatly overestimated, and the final finishing is carried out without pouring. Meanwhile, the main purpose of the screed is to uniformly distribute loads and reduce the effects of vibration. Secondary is the protection of the insulation from exposure to ultraviolet radiation and the external environment. A good alternative would be a two-layer installation of plasterboard with a moisture-resistant coating (provided that such work can be carried out in the given room). The absence of any screed is absolutely not allowed.

Preparation of the solution

To prepare the mortar from which the screed will be made, not only the main components (cement and expanded polystyrene), but also several additional components can be used. For example, adding sand increases the strength of the floor covering. Although this reduces the thermal characteristics of the material and, conversely, increases the density. Natural stone, which increases the abrasion resistance of the material, and gravel or pebbles can be used as fillers for underfloor heating screed. It is not recommended to add concrete chips, slag and ash to the solution, which reduce the strength of the floor covering.

Another composition is possible using sand, which you can make yourself

It is important to observe the correct proportions of cement; preparation without the use of sand is possible. To save money, the composition is as follows; take 1 part cement, 2 parts sand and 5 polystyrene foam granules and mix

This composition can be used in the construction of walls.

One of the most popular ways to make a heated floor screed with your own hands involves the use of polystyrene concrete grade 300, which requires 240 kg of cement per 1 cubic meter of polystyrene granules, 0.65% by volume of SDO and up to 120 liters of water.

The ratios of components required to obtain a material of a different strength can be taken from the table.

| Brand of polystyrene concrete | Volume of polystyrene, cubic meters. m | Mass of cement, t | Volume of water, cubic meters m | Percentage of SDO additive, % |

| 200 | 1 | 0,16 | 0,1 | 0,8 |

| 300 | 1 | 0,24 | 0,12 | 0,65 |

| 350 | 1 | 0,29 | 0,13 | 0,62 |

| 400 | 1 | 0,33 | 0,15 | 0,6 |

| 500 | 1 | 0,41 | 0,17 | 0,45 |

The process of preparing the solution is quite simple - when deciding how to make the right mixture for a warm screed, perform the following steps:

- The required amount of water is added to the container;

- Cement spills out;

- The mixture is stirred using a drill until its consistency becomes similar to yogurt;

- Polystyrene is poured into the resulting solution.

At the final stage of preparation, the mixer is set to press the polystyrene granules into the solution and used until most of them are covered with cement. After this, the direction of rotation is switched in the opposite direction and additional mixing is carried out for several minutes. The result should be a material resembling coarse-grained caviar, with virtually no fluidity.

Video:

The use of lightweight heat-insulating screeds

Providing good thermal conductivity is achieved by using a similar material such as perlite sand in concrete screeds. Lightweight concrete with perlite sand is environmentally friendly, durable, and retains heat remarkably well.

The downside is that the perlite screed must be protected with moisture-repellent compounds. Perlite sand is a very hygroscopic material.

Selecting a heat insulator for a floor is a very complex process. The variety of materials and their characteristics require a careful selection approach. The price issue is also very important. Choose the optimal middle ground between purchasing qualities and cost.

Mineral wool

It should be noted that of all the insulation offered under the screed, this is the most inconvenient. The thing is that mineral wool is a hygroscopic material. It quickly absorbs moisture, becoming practically unnecessary. Therefore, it must be covered on both sides: on the side of the concrete floor with a vapor barrier film, on the side of the screed with a waterproofing membrane. Therefore, the pouring process itself begins with the installation and laying of the lower protection.

- Typically, the film is laid in strips with edges overlapping within 10-15 cm, which must be secured with construction tape along the joint. Be sure to lay it over the walls, taking into account the thickness of the entire insulated pie plus the screed.

- Next, the thermal insulation material itself is laid out. It is better to use mats for the floor. They should be laid tightly to each other so that there are no gaps left, which can later become cold bridges.

- The top film is laid, like the bottom one, in strips with overlap and installation of tape.

- A reinforcing frame in the form of a metal or synthetic mesh must be applied to such a heat-insulating cake.

Please note that if mineral wool is laid in two layers, then the mats should be offset by half the panel. The seams between the thermal insulation elements must not coincide vertically.

Polypropylene boards

One of the optimal options for thermal insulation of water heating, it is not afraid of elevated temperatures and humidity, and is the cheapest material in terms of cost. It is not afraid of aggressive chemical compounds and does not emit harmful substances during heating. It has low flammability and does not support open combustion. The reproduction of various microorganisms, including mold, is inhibited on the surface. It is approved for use by sanitary control organizations without restrictions. The slabs may have ready-made grooves for laying pipelines.

Polypropylene boards

Sheet polypropylene

Installation Tips

You should leave a gap of 1-3 cm between the wall and the floor.

To properly lay the insulation on the floor on the screed, you need to follow some simple recommendations. Every nuance can be decisive during the installation process.

When making a screed, you should leave a gap of 1-3 cm between the wall and the floor. Without waterproofing, thermal insulation for a concrete screed is not done. It is important to follow the sequence of work when organizing thermal insulation. The floor cake must consist of at least five layers.

Upon completion of laying the thermal insulation for the concrete floor screed, professionals recommend additionally installing insulation reinforcement.

Surface preparation

The installation of a water heated floor begins with cleaning the “sub-floor” of dust and dirt, which will help identify its unevenness. According to accepted standards, the height difference in the room should not exceed ±5 mm. There are two ways to achieve a flat surface:

- Having made a rough screed for a water heated floor - a layer that will hide all the unevenness of the base. It can be made from concrete (M300 grade is enough) or sand concrete;

- If the floor surface has many small irregularities, it can be leveled by scattering several buckets of sand and leveling it with a rule.