Warm water floors are moving from the category of exotic heating to the rank of a well-known type of heating for interior spaces for various purposes for many users. If the insulation of the building meets modern strict requirements, and the room is small, then it can be the main one. In all other cases, a warm water floor is used as additional heating.

Water heated floor control

The nature of the application is also influenced by the climatic zone of the building's location; in warm regions, water floors are in most cases installed as the main heating. In regions with cold and long winters, this option is not used; the effective power to create comfortable temperatures is insufficient. And for many reasons it is impossible to heat the floor to very high temperatures.

Warm floor design

The comfort of staying in the premises, the duration and safety of operation of the systems largely depends on the operating modes of water heating. To control and regulate operating parameters, thermostats for water heated floors are used. There are a huge number of them, but according to the principle of operation, the devices are divided into only a few large groups. Before you begin to consider the principle of operation of thermostats, you need to become familiar with the methods and parameters for adjusting the heating temperature. This knowledge will make it possible to better understand the functioning of various types of thermostats.

Heated floor thermostats

How the temperature of a hydronic underfloor heating system is controlled

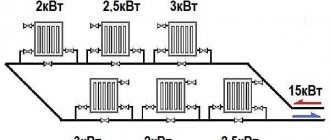

Water heating at home has several systems for each room; sometimes there can be two or more circuits in one room.

Heated floor contours

Each system and each circuit must be independently regulated. The process is carried out through a collector - a device to which the inputs and outputs of all circuits are connected.

Warm floor collector

A pump is installed to supply water; the amount of coolant supplied is regulated by various valves. To monitor temperature indicators, there are sensors; valves can be controlled by servo drives.

The system must have a pump

If the sensor shows a decrease in the floor temperature, then the amount of warm water increases and vice versa, when the temperature rises above the set parameters, the consumed volume of water decreases. Servo drives must be mounted on each circuit separately and controlled by sensors. Thermostats for selecting heating parameters are installed in rooms or in a special common control panel (if there are many rooms and a single control panel is required).

Thermostat and servo drive for water heating

To regulate the temperature you need a manifold, a thermostat and a servo drive

The use of thermostats and servo drives in thermostats makes it possible to fully automate the functioning of the system; heating is easy to maintain; thermostats are able to not only maintain temperature values in specified modes, but also independently turn on/off the heating in the event of a long absence of people. Automation saves up to 30% of energy without worsening the living conditions of people in the premises.

Operating principle and main advantages of the device

The temperature regulator is connected to a temperature sensor, which is located near the heating cable. Its operating principle is to determine deviations from specified values. If they are, then the thermostat transmits a signal to increase or decrease the temperature. After a certain temperature value has been set on the thermostat, the required amount of coolant is supplied to the cable.

| Do you dream of purchasing a good knife? Then you should definitely visit the bestblades.ru knife store. Kitchen, folding, travel, multi-item, exclusive knives from famous brands - you will find all this in this store. You can also purchase accessories for knives, everything for sharpening them and much more. The widest range and fast delivery, as well as many gifts with purchase, will certainly delight you. |

The main function of the device is to maintain a set temperature by turning the heating elements on or off. The device significantly saves on electricity costs, since the system starts working only when the temperature drops below the set temperature.

When operating a heated floor system, you should remember that it is inert: for the temperature in the coating to change, some time must pass.

Temperature regulators are considered an indispensable item for heated floors due to their many advantages. Among them:

- low price, depending on the type of thermostat;

- control is carried out using several keys;

- significant savings in electrical energy;

- the device is small in size;

- high degree of reliability of the device.

What can thermostats control?

Thermostat for underfloor heating

Depending on the type of heating, thermostats can regulate the following parameters:

- floor temperature. Sensors are installed in close proximity to the heating circuit and indicate the degree of heating of the finished floor covering. They are used in small circuits and low-power water systems used only as additional heating;

- air temperature in the room. For these thermostats, the sensors are mounted directly in the thermostat housing. The parameters are adjusted taking into account the comfortable room temperature. They are used on powerful systems and only in houses that have thermal insulation that meets the requirements of the standards. Otherwise, large losses of coolants make its operation unprofitable;

- combined. Heating parameters are controlled taking into account the readings of two sensors: in the room and next to the heating system. Rarely used only for the most modern systems. If desired, control can be carried out based on the readings of one of the installed sensors.

Warm water floor - temperature distribution

The choice of a specific thermostat takes into account the maximum number of technical characteristics of the heating system, heat saving indicators of the building, the climatic zone of the location and the wishes of the customer.

Finally, about setting the temperature

To set up each floor heating thermostat and check the performance of the system as a whole, you should turn on the heating and set all devices to the desired temperature. Please note that the house needs to be warmed up completely. The optimal boiler operating mode is 60 °C; if the heat generator starts to “clock” (frequently switch off and start), it is better to reduce the power.

The essence of the setting is to select a comfortable temperature in all living areas. The thermostat display readings do not always correspond to our feelings, so the settings will have to be adjusted during operation. A separate issue is programming heating according to a schedule; this procedure is described in the instructions for a specific device.

How thermostats work

The operation of devices is possible only in combination with additional equipment and sensors; each element performs its own functions. The equipment is installed on the wall or in a separate panel and on the switching center.

- Sensors Mounted next to the heating system or in the thermostat housing, they show the actual temperature at the installation sites. Signals are transmitted via wires or radio.

- Thermostats process the received information and send response signals to the servos.

- Pump control module. It only works when at least one heating system or individual circuit is open.

- Servo drives open/close hot water supply taps and have direct connections with thermostats.

Principle of operation

To increase operational safety, safety valves and fittings are installed to protect electrical equipment from overheating and ultra-high short circuit currents.

General information

No underfloor heating system can do without a thermostat, the connection diagram of which is identical in almost any model.

If this device is not used and the heating wire is connected directly, the system will reach its operating temperature limit. This has a detrimental effect on the screed, and in the case of a wooden floor will lead to its deformation. It should also be noted that no manufacturer of electric heated floors provides a guarantee for their product unless a heating control device is installed. Therefore, the thermostat circuit must be studied before installing floor heating.

Moreover, in this case, a regular timer or dimmer will not work. Only thermostats intended for this purpose may be used in an electrical circuit. They come with a sensor that measures temperature.

Tips for choosing thermostats

The choice of a specific model of thermostat for a water floor depends on many conditions: the purpose and size of the room, the method of connecting the coolant, the finishing materials of the floor, the climatic zone of residence, the presence of main or additional heating systems.

Selecting a thermostat

What criteria should you use to select devices?

- Price. The cheapest mechanical ones. They are reliable in operation and universally usable. In addition, such devices are very reliable, they are almost impossible to disable due to negligence. Perfect for those users who have small children.

- Electronic. They have somewhat expanded functionality and can control the temperature at floor level or in the room. In terms of cost, they belong to the middle segment of goods.

- Programmable. Expensive devices require careful attention and allow you to create the most favorable living conditions in the rooms. They can have various modifications and technical capabilities, and in terms of cost they belong to the highest category. Recommended for use during heating installation in luxury buildings. The price can reach $500 or more.

Depending on the installation site, they can be wall or panel. The first ones are installed in every room and are used for small apartments. The latter are used in large buildings; they allow you to control heating parameters in all rooms from one place. Installation and maintenance of such thermostats are expensive.

Panel regulators

Which model is better

How to use a mechanical thermostat

Mechanical regulator

A separate mechanical device must be installed on each circuit; its technical parameters do not allow controlling the temperature of several rooms simultaneously.

Thermal controller for heated floors

In order to control the heating temperature depending on the room temperature, you need to purchase a room thermostat and set the required temperature by rotating the head. Some models can be connected to chronometers, which allows you not only to maintain a comfortable temperature at different periods of time, but also save significant money.

An electric servo drive must be installed on the collector; based on the received signals, it will increase or decrease the amount of hot water supplied to the circuit. Before connecting devices to power, you need to study the diagram; it is available on the back of the housing cover.

Electric servo drive

Servo drive in section

Important. Failure to comply with the recommended scheme will not only cause incorrect operation of the equipment, but can also completely disable it.

The servo drive has a motor with two-way rotation. Depending on the phase of the signal supplied by the thermostat, the rotor rotates clockwise or counterclockwise. Accordingly, the valve increases or decreases the nominal clearance of the pipelines. All work must be carried out in compliance with the PUE; the equipment operates on a voltage of 220 V.

Installation of a regulator for heated floors

When opening the front panel of the thermostat, you must follow the procedure specified in the instructions. It should also contain a diagram for connecting the thermostat. To install a built-in type device, you first need to prepare a special recess for it. The location of the thermostat is chosen approximately at a height of 1 m from the floor. The home network must first be de-energized.

Installation of the regulator begins with connecting power to the installation box. A connected temperature sensor is placed between the thermostat and the heating elements, which is inserted into a corrugated pipe.

To correctly connect the wires when connecting them to the thermostat, you must use the diagram provided by the manufacturer. Special terminals are provided for connecting wires. Those that power the sensor are connected to sockets that have special markings. The device is placed in the mounting box, the thermostat is leveled. If necessary, an RCD and ground wire are installed. Then the control panel is put in place and secured with fasteners.