Most modern houses are built taking into account all the requirements for thermal insulation and sealing, which allows you to save on heating and maintain a comfortable temperature in the premises at any time of the year. But often thermal insulation work is carried out in already residential buildings, from which heat evaporates during the winter months due to thin walls or deteriorating insulation. In most such cases, it is necessary to insulate the walls from the inside. This option is less practical and effective than external insulation, but it also has the right to be implemented subject to certain conditions.

External insulation for facade finishing Source mtkservis.by

Insulating materials for internal insulation

Regardless of the method of insulation (external or internal), the materials used for this must have characteristics such as low thermal conductivity and high moisture resistance. The latter property is not inherent in all types of insulation, so the thermal insulation of walls and other structures is often made using vapor and waterproofing films.

While almost any materials can be installed outside the building, providing them with reliable protection from external influences, there are some restrictions for interior work. We propose to consider the most popular heat insulators and evaluate their effectiveness and suitability for installation inside residential premises.

Objectionable Materials

The main requirement for internal insulation is its safety for human health. Characteristics such as fire safety, resistance to destruction by biological organisms, moisture resistance, and ease of installation are also important, but they can be classified as secondary. After all, even the most environmentally friendly natural wall material – wood – does not possess most of them.

Wood burns, rots, and is damaged by insects, but remains the most popular building material Source protection-wood.rf

- Styrofoam.

Insulating walls from the inside of a room with foam plastic is undesirable because of its flammability and attractiveness to rodents. It poses a particular health hazard in the event of a fire, since when burned it releases a deadly substance - styrene. And mice, gnawing passages and holes in it, quickly destroy the insulation, depriving the walls of protection from the cold.

- Extruded polystyrene foam.

This material has a composition similar to ordinary foam plastic, but a different structure, due to which it does not burn (but melts, releasing the same harmful gases) and is not of interest to mice and rats. Foam plastic and expanded polystyrene have a common negative quality - almost zero vapor permeability. Having insulated the walls of the house from the inside with these materials, you will have to take care of high-quality forced ventilation, otherwise the air in the rooms will always be damp and stale. However, this drawback is inherent in almost all synthetic insulation materials.

Expanded polystyrene can be used to insulate walls made of concrete and other non-combustible materials with low vapor permeability Source media

For reference! This category also includes wallpaper made of polystyrene foam, used as a pre-finishing noise and heat insulation finish for painting or regular wallpaper.

- Glass wool and slag wool.

Mineral wool, made from glass fibers, releases microparticles of glass into the air, which irritate and damage the mucous membranes of the eyes, nose and mouth. Tiny fiber debris can even penetrate through exterior finishes. And this material can only be installed with protective equipment and gloves, protecting the skin with long sleeves and pants.

Slag wool is produced from waste from mining, processing and metallurgical industries and contains a lot of toxic substances.

Glass wool is usually used to insulate floors and roofs of non-residential attics Source kti.by

See also: Catalog of companies that specialize in home insulation

- Penofol.

As is already becoming clear, materials of synthetic origin containing toxic substances are poorly suited for thermal insulation of walls from the inside. These include penofol and other similar insulation materials made from foamed polymers.

In their normal state they are harmless, but become dangerous when exposed to strong heat and during fires. At the same time, such insulation retains heat well, is not afraid of moisture and insects, and does not shrink to form voids and cracks, which are corridors for the penetration of cold.

However, they need to be considered not on their own, but in conjunction with the walls and interior decoration. Low vapor permeability leads to the accumulation of moisture on the surface of the insulation, which evaporates into the room, wets and spoils the finishing materials.

Penofol and other rolled materials cannot be plastered; for finishing it is necessary to install a frame and sheathe it Source kraftika.ru

Suitable materials

If you need to insulate the walls of a house from the inside, it is better to use non-toxic and non-flammable materials for this.

- Basalt (stone) wool.

The material is made from molten rocks transformed into fine fibers. It, like stone, does not burn and does not attract interest from rodents and insects. But due to its fibrous “cotton” structure, it is afraid of moisture, or rather, it easily absorbs it, losing its thermal insulation properties. Therefore, it needs protection from the penetration of moisture-saturated air accumulating in the house.

Preparation for installation of insulation

Before insulation, it is necessary to carry out preparatory measures, as in any other construction process. First of all, all defects and weak points are eliminated. After which the wall is thoroughly treated with antiseptic agents.

Having assessed the condition of the wall that will be insulated, it is worth sealing the cracks and removing bad plaster. If this is not done at this stage, over time the condition of the wall will worsen significantly and lead to destruction.

If mold was identified on the wall during the preparation stage, it is worth eliminating it immediately and effectively. You cannot begin the insulation process without solving the existing problem.

Once the wall is in proper condition, it’s time to start installing the sheathing.

- The distance between the beams must correspond to the dimensions of the insulation boards.

- When choosing beams, you should give preference to dry wood, without knots and cracks.

- Anchors are installed between them, which will hold the correct direction of the material.

Video description

The advantages of stone wool are described in this video:

- Ecowool.

The basis of this insulation is made up of cellulose waste, treated with substances that prevent rotting and burning, damage by microorganisms and insects. Subject to the production technology, its composition does not contain toxic substances. Internal insulation of the walls of a house with ecowool is carried out by spraying using special equipment, and floors and ceilings can be covered manually with dry material.

- Warm plaster.

Plaster with perlite or vermiculite not only helps retain heat, but is also an excellent finishing material, which allows you to solve several problems at once: insulate, level and decorate walls. The material is non-flammable, non-toxic, and resistant to moisture, mold, and insects.

This category of insulation also includes liquid ceramic insulation - an acrylic-based material filled with small expanded clay granules.

A thin layer of liquid thermal insulation allows you to save the usable area of the room Source kraski-net.ru

Consumables and tools

The tools and consumables that will be required during the work differ, depending on the type of insulation .

If installation is carried out from sheet material, it will not be possible to do without the following devices and tools:

- Tile adhesive.

- Primer.

- Insulation.

- Sealant.

- Reinforcing mesh.

- Spatula.

- Brushes.

- Drill.

- Dowels.

- Glue and container for diluting it.

When using wallpaper or paint as insulation, some tools, such as a drill or tile adhesive, will not be needed. For some materials, for example, mineral wool, beams will be required to construct the frame.

Video description

Answers to many questions about cork flooring can be found in this video:

- Polyurethane foam.

This insulation is ideal for external thermal insulation, but is also suitable for internal insulation. Like other “foams”, it is airtight, but thanks to a special method of application by spraying, it creates a seamless coating through which moisture from the house does not penetrate to the walls. Therefore, a vapor barrier is not needed.

When polyurethane foam burns, water, carbon dioxide and carbon monoxide are released, but they are also formed when wood burns. However, this polymer is more difficult to ignite and supports combustion less well.

What to choose

When choosing what and how to insulate a wall from the inside, it is worth assessing the initial data: climatic conditions, the required degree of thermal insulation, wall material. For example, in regions with a warm climate or if you want to raise the air temperature in the building by only 2-3 degrees, warm plaster, cork panels or polystyrene foam wallpaper for painting will be sufficient.

Decorative foam wall panel Source allegroimg.com

Particular care should be taken when insulating a wooden house. When the wall material gets wet and excess moisture cannot evaporate, it will quickly begin to rot, mold and collapse, so it is better to cover them with vapor-permeable materials and leave the outside without an airtight finish. The best options would be stone and ecowool. Synthetic insulation is more suitable for concrete and stone walls.

Whatever material you choose, insulating the inside of the room should begin with eliminating any gaps and cracks in the walls through which cold air can enter. To seal them, special materials are produced - fibrous (felt, jute, tow) and sealing (sealants, polyurethane foams, mastics).

Sealing cracks in timber walls Source tildacdn.com

Cracks in wooden walls can be repaired with a homemade mixture of small wood shavings or sawdust mixed with wood glue. It is especially good for repairing facade surfaces that will not be hidden by finishing.

General points of the technological process of arranging insulation from inside the room

General points include not only the choice of insulation and preparation of walls, but also the mandatory availability of construction tools, without which it will not be possible to complete the process quickly and efficiently.

Before you begin, it would be a good idea to study the features of the material and the installation process itself. Today, enough information has been collected on the Internet to make your own thermal insulation layer.

Of course, the hand of a non-professional worker will be traced, however, the main thing is the result and the creation of comfortable conditions inside the room. If you have doubts about your abilities, you can contact a private construction company.

The corner installation of sheathing and insulation has some features. It is worth paying attention to this issue so that there are no uneven joints and, especially, holes. Otherwise, you will soon have to redo all the repairs.

Treating the wall and neutralizing the fungus before starting work is a must

Why is external insulation better than internal insulation?

Internal insulation has clear advantages:

- the ability to complete work at any time, regardless of weather conditions and daylight hours;

- the ability to preserve expensive facade finishing - decorative plaster, brick cladding, etc.

But this method has more disadvantages. This is a reduction in the usable area of the house due to the thickness of the insulation, the need to empty the premises of furniture and dismantle the existing finishing. And the choice of thermal insulation materials is limited.

With a wall thickness of 10 cm, the area of a 20-meter room decreases by approximately 1 sq.m. Source homestratosphere.com

But there is a much more compelling argument why you can’t insulate the walls from the inside of the house if it is possible to do it outside. If the reduction in space and the hassle associated with repairing and cleaning rooms can be survived, then a change in the microclimate in the house and the risk of destruction of walls under the influence of moisture is already a big problem. And it occurs precisely when the insulation is attached to the inside of the walls.

With external insulation, frosty air must first overcome the barrier of the “fur coat” in order to reach the walls, but with internal insulation it acts straight through. The walls freeze from the inside, since they are almost not heated by warm air from the house, cut off by the internal insulation.

But the most unpleasant thing happens at the border of heat and cold - condensation forms here. In the first case, it accumulates in the thickness of the outer heat-insulating layer and does not harm the walls, gradually eroding outward. And in the second, moisture forms in the walls themselves or at their junction with the internal insulation.

Heat conservation without costs

There are always simple ways to help keep warm, while spending on them will be minimal or not at all:

- Try to clear the window facing south as much as possible so that the sun's rays penetrate it and heat the room;

- Windows are often covered with thermal protective film. It does not affect visibility, but helps keep the room warm;

- Block the flue of a stove or fireplace that is not currently in use. A third of the heat may escape through it;

- If additional heating sources are needed, install oil radiators or ceramic panels. They are safe and can quickly heat up a room.

Briefly about the main thing

Internal wall insulation is carried out only in cases where it is not possible to do it outside or when external thermal insulation is not enough to maintain a comfortable temperature in the house. Not all materials are suitable for this. Thermal insulation for walls from the inside must be selected taking into account the basic requirements: to be safe for health, preferably non-flammable and durable, so that in a few years you will not have to make major repairs. These requirements are best met by basalt wool, ecowool, cork and warm plaster coatings.

Technology

To insulate panel walls inside a house or apartment yourself, you need to follow the instructions. The step-by-step algorithm of actions is as follows :

- Calculate the required amount of material and purchase it.

- Prepare the surface for upcoming work. To do this, the walls are thoroughly dried.

- Remove old coverings in the form of wallpaper, paint and other decor. If plaster has been applied to the wall, it is removed down to the concrete panel.

- Clean the wall from dust and other contaminants.

- Prime the surface using a deep penetration solution. It is recommended to apply at least 2 coats of primer.

- Leave the walls until completely dry.

- Formwork is installed into which layers of insulation, for example, mineral wool, are installed.

- If formwork is not needed, insulation is attached. There is a specialized adhesive for each material.

- Seal the joints with sealant.

- Cover the structure with slabs or other finishing material.

If all technologies are followed, a comfortable temperature will be maintained inside the room. Wall insulation is good not only because it prevents its deterioration in winter, but also helps to maintain coolness in summer.

Important ! You can start insulating walls only in summer or early autumn. During the cold season, this work is not done.

Finishing stage

The glue must be applied to the surface of the top sheet, its width must correspond to the reinforced mesh;

- it is necessary to apply a mesh and hide it under a layer of mixture;

- the wall must be allowed to dry and only then begin finishing work.

Attention! There should be no folds on the mesh; they dry out very poorly in the future.

Thanks to this insulation, the apartment will become noticeably warmer and more comfortable. You should not skimp on materials; the main thing is to choose the right foam for insulation and all the components for its installation.

Dew point - physics of the phenomenon

Cold walls are not the only problem in old panel buildings. Wet surfaces are susceptible to the growth of fungus. The optimal solution to such problems is external thermal insulation, specified in the requirements of SNiP. And if it is impossible to insulate the building from the facade, internal work will need to be carried out. But in this case, some nuances appear.

Even if the cold structure was previously dry, after installing the insulator it may become damp, which is explained by a shift in the dew point.

This concept refers to the conditional boundary at which water vapor is cooled to the temperature of condensation. This phenomenon is aggravated in winter. If the house design is done correctly, then the dew point is located in the middle of the thickness of the facade material with a uniform structure.

Dew point is an important parameter that should be taken into account when carrying out thermal insulation.

With external insulation, the conditional value shifts to the area of decreasing density (towards the outer part of the wall).

If insulation is done from the inside, it ends up in the room and condensation accumulates in the insulator or on the main wall.

To avoid freezing in the future

You can insulate your apartment as much as you like, but this will not help if the heating system is outdated or the walls in the house are frozen. To avoid problems, it is worth attending residents’ meetings and asking the management company what the funds collected from residents are used for. If your house is old, you need to demand that the management company speed up major repairs.

Take an interest in the life of the house, make sure that your neighbors do not make illegal alterations that could affect the heat. For example, if neighbors connect a loggia to a room and move heating radiators onto it, this will destroy the thermal circuit of the system. This should not be allowed; if you know that someone is destroying your home, contact the housing inspector.

Source: j.etagi.com

What is the end of a building?

The end of the building is the narrowest side facade of the house.

It is clear that in square-shaped buildings there is no end, as such. In a house that has a long and narrow shape, in which the main entrance is located on a narrow wall, the end coincides with its main facade.

Architecturally, it always looks richer ; in comparison with other external walls, its decoration should attract attention, and in the old days it was decorated with stucco and various niches.

The current town planning legislation defines the front façade as a façade that is clearly visible from the main street or highway. Provided that such a facade is located on the narrow outer wall of the house, then it is impossible to say about such a structure that the house has ends. It has only facades - the main one, as well as the side and rear ones.

If the utilities are to blame

During the heating season, the temperature in apartments should not be lower than 18 degrees. The temperature should be measured in the middle of the room, no less than one and a half meters from the walls and floor.

If the temperature in the apartment is below normal, write a statement to the management company. They should come to you with a check within 24 hours. After the inspection, a report must be drawn up. Without the act, you will not be able to prove or achieve anything later.

If you do not agree with the results of the inspection, do not sign the act and contact the housing inspectorate, which will conduct a second inspection based on your request.

If the inspection confirms that your apartment is colder than normal, utility services must take action within a week. After this, another check should be carried out and a report should be drawn up, which should indicate how long you did not have sufficient heat.

Based on this act, you can demand from the management company a recalculation of heating fees, since you were provided with poor-quality services.

Insulating walls in a panel house is the key to creating heat in the apartment

Problems of this kind must be dealt with. First you need to carefully examine the room and find out where the source of the cold is. Mainly such sources include windows, cracks in entrance doors and frames for them. However, all this refers to unimportant problems. The walls of the apartment are a global problem; it is because of them that the room becomes much colder.

Some common reasons for a cool home:

- First of all, owners of apartments located on the ground floor suffer from mold.

- And also the most popular phenomenon for them is dampness.

Apartments that are located at the edges of the house are also susceptible to freezing; these are the apartments that are most in contact with the street, which causes greater freezing.

Detailed instructions for doing the work yourself

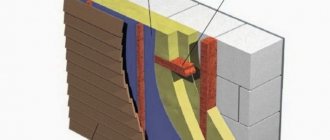

After preparation is completed, you can begin installing the ventilation gap. This procedure is combined with the stage of laying waterproofing. Some forums publish opinions that insulation can be done without organizing a ventilation gap. However, this scheme leads to the accumulation of moisture between the surface of the wall and the insulation.

The ventilation gap is arranged according to the following scheme:

- Wooden slats with a thickness of 2 cm or more are attached to the walls. They need to be fixed horizontally in increments of 1 m. Dowel nails are suitable for fixing. Before laying, the slats are treated with protective impregnation.

- Further, several vents are made in the wall for normal air exchange. This is done by drilling holes with a diameter of about 20 mm. To prevent them from clogging, you need to provide a protective mesh.

- Then a vapor barrier film is attached to the resulting frame. It is installed tensioned to form a ventilation gap.

Diagram of the ventilation gap.

The next stage involves installing a frame of vertical posts. They are fixed in increments equal to the width of the insulation boards. For denser material, you can reduce the step by 1 cm.

Insulation is attached to the finished frame. If the design is done correctly, the mineral wool slabs will be held in place without additional fixation. But to eliminate cold bridges, you need to fill the voids between the studs and the wall with thermal insulation material. Drywall is used to cover the frame.

Difficulties and errors

When insulating panel walls, novice repairmen often make the following mistakes :

- They begin work in the cold season.

- They do not pay enough attention to the quality preparation of the wall.

- The glue is applied incorrectly (it is applied to the slabs along the perimeter in the form of strips about 4 cm wide, and dotted along the rest of the surface).

- The seams between the insulation are left empty.

- Install the insulation on an undried wall.

Consequences of errors

Mistakes made during the process of wall insulation lead to serious consequences:

- If the walls are cold or poorly prepared, the glue between the insulation and the wall will dry out quickly, which will impair its adhesion. As a result, the entire structure will be unreliable, and there will be a risk of mold and mildew growing.

- If the glue is applied to the insulation incorrectly, the material will deform, bending in one direction or another.

- If the seams between the slabs are not filled with sealant, cold bridges will form in the wall, through which warm air will escape.

- If the wall is wet, then soon a fungus will appear under the insulation.

Getting rid of freezing corners

This problem can be solved positively if you know how to insulate a panel house from the outside and, in particular, an apartment.

Let's consider how and with what panel houses are insulated. There are several schemes and methods of insulation using various materials.

The question of how to insulate corners in a panel house is especially acute. The corner room, due to its design specifics, has not one in common with the street, but two, which significantly increases heat loss. In addition, such rooms contain two windows, one on each of the existing external walls. This fact is remarkable only in terms of illumination, but in terms of heat retention - so-so.

Residents of such apartments are trying to solve the problem by increasing the number of heating devices in the room. But, as everyday experience shows, problems often arise with freezing of corners between external walls and, as a result, condensation appears on the wall and the consequences are not long in coming:

- the wallpaper is coming off;

- walls previously painted with water-based paint are covered with stains, and the enamel peels off in patches;

- the plaster is destroyed, which will lead to damage to the main wall;

- fungus appears, which looks unsightly and is harmful to health.

The conclusion suggests itself - high-quality insulation of the corner room is necessary and it is better not to limit yourself to just improving the corners.

You can insulate a corner room:

- outside;

- from the inside.

If insulation is not available from the outside, the issue of internal thermal insulation is considered. Condensation is an obvious “bottleneck” of internal insulation, therefore, it is necessary to protect the main wall from water vapor.

Today two solutions are known:

- the use of insulation characterized by low vapor permeability;

- protection of insulation directly with a vapor barrier film;