Installation technology for facade insulation systems

Installation of the LNPP external thermal insulation system is carried out in the following sequence:

Scaffolding installation

Preparing the construction base

Attaching insulation to the base

To attach the insulation boards to the base, glue prepared on the basis of the LNPP adhesive composition and plastic dowels with steel rods are used.

Preparation of glue:

Installation of the bottom row of insulation boards:

Bonding insulation boards:

Insulation boards must be installed from bottom to top in compliance with the dressing rules: horizontal displacement of seams of at least 80 mm, jagged dressing at the corners of the building, framing of window and other openings with slabs with cutouts adjusted to the location. The ends of the plates must be tightly joined. Glue should not get on the ends. The leveling of the installed slabs is done using a foam float with light pressure or tapping. Control of surface flatness is carried out using a level and a 2-meter staff. The deviation from the vertical or horizontal of the finished surface should be no more than 5 mm per 1 meter when checking with a 2-meter staff; the number of irregularities of a smooth outline per 4 m2 with a depth (height) of up to 3 mm should not be more than 2.

In the LAES-P façade insulation system, surface treatment of polystyrene foam boards is allowed to correct base unevenness. The surface of polystyrene foam boards is cleaned with special graters. In the external thermal insulation system "LAES-M". Adjusting the thickness of mineral wool slabs using floats is not allowed.

Methods for applying glue to the insulation board:

Immediately after applying the glue, the insulation must be glued.

Installation of dowels

Installation of the base layer (reinforcement of insulation with fiberglass mesh)

After all the insulation boards are installed, secured with dowels and leveled, the base layer is installed. Corner fiberglass mesh should be installed on the outer corners of the building and on the slopes of openings along the perimeter. The free ends of the fiberglass mesh, left in places where the thermal insulation system breaks, are bent outward and glued over the corner mesh. On the first floors along the perimeter of the building up to a height of 2.5 m from the ground, a “shell” fiberglass mesh should be installed. Shells of armored fiberglass mesh must be glued end-to-end to each other and to the corner mesh. In the corners of window and door openings, additional diagonal sections of fiberglass mesh should be installed at an angle of 45°, the size of such sections should be at least 280 x 330 mm.

Error: Lack of diagonal sections of fiberglass mesh in the corners of the openings. This can lead to cracks in the outer textured layer at the corners of the openings.

Application of tinting primer (if necessary)

Tinting primer "LAES" is used for color preparation of the base layer before applying a textured coating. This is necessary for light colors of textured coating. The LAES tinting primer can be applied in two layers.

Preparing material for work:

Finishing the facade with textured compositions "LNPP"

Preparing the texture composition for work:

Applying texture composition:

Source

The best way to insulate a house, how to choose the right material

When purchasing insulation for a facade, you must ensure that they are components of the same system. Sometimes when purchasing you will need the help of a professional, because the materials are not always sold as a single set, but must correspond to each other according to such characteristics as:

- vapor permeability;

- frost resistance;

- thermal expansion.

And also when choosing, you should take into account the chemical processes that will occur in a single system. Materials for insulation should be selected not only taking into account the type of frame. In this case, you need to make allowances for the climatic features of the region, architectural characteristics and technical purpose of the building.

The most common materials for facade insulation are mineral wool and polymer insulators

When insulating the façade of a house from the outside with foam plastic or other material, the continuity of the contour should be maintained. There should be no cracks, gaps or breaks on the façade through which moisture or frost can enter the frame. It is also important to maintain the vapor permeability of the system. Here the main rule is that each subsequent layer from the inside to the outside must have a higher degree of vapor permeability. This is done so that the walls can “breathe” and condensation does not form on the surface.

The cost of facade insulation will depend on what material is chosen for this. The most common are:

- Mineral wool (mineral wool). Belongs to the group of fiber insulation materials. Most often made of fiberglass or basalt fiber.

- Ecowool. Modern insulating material based on cellulose.

- Group of polymer insulators. Polyurethane foam, polyurethane, expanded polystyrene.

- Bulk radiators – expanded clay, vermiculite.

- Natural traditional materials - dry leaves, reeds, straw, sawdust, pine needles, which can be used together with clay.

When insulating the facade of a house from the outside with polystyrene foam, the continuity of the contour must be observed; there should be no gaps, gaps or breaks

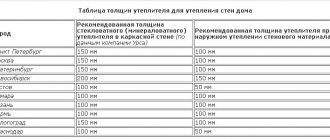

How to determine the thickness of the material for external wall insulation

Another key issue is to determine the heat transfer coefficient through the walls, which depends on the choice of specific thermal insulation material. Theoretically, the thicker the insulating material, the lower the ratio and therefore the better. In this case, it should be emphasized that the degree of insulation of mineral wool or polystyrene depends not only on their thickness (although this, of course, is of great importance), but also on the thermal conductivity coefficient. The indicator is also more favorable if its value is lower.

Insulation boards with a lower coefficient can be thinner while still maintaining good thermal conductivity. This is important because the thinner the insulation, the smaller the recess will be for window and door openings.

Helpful advice! Studies show that after exceeding a certain thickness of insulation, there is a minimal improvement in the thermal insulation properties of the wall, which is completely disproportionate to the cost of each subsequent centimeter of insulation. The thinnest insulation will be made from expensive, but perfectly insulating PIR polyurethane, offered in the form of panels. Therefore, “thicker” does not always mean “better.”

Research has proven that exceeding a certain thickness of insulation does not lead to a significant improvement in the thermal insulation properties of the wall

Each house is individual, therefore, when choosing the thickness of insulation, not only climatic features are taken into account, but also the heat capacity of the floor covering, the specifics of the thermal insulation of the roof and basement, as well as the glazing area of the house.

Related article:

Insulation of a wooden house from the outside: choice of material and technology

What materials are used for this purpose. Is it necessary to insulate the foundation? The best modern technologies for insulating wooden houses.

Today, when choosing an insulation material, you have to choose between three thickness standards (in centimeters):

- 50;

- 100;

- 150.

Calculating the layer thickness is easy. To do this, you need to calculate the initial wall thickness and estimate how much is missing from the norm, and then calculate how thick the facing layer should be. In addition to the thickness of the insulation, other criteria must be taken into account:

- plaster layer;

- external finishing;

- air gap.

Instructions for self-insulation of facades with mineral wool

Thermal insulation of facades with mineral slabs is one of the most common and effective ways to preserve heat in a home. The cost of such insulation is higher than that of expanded polystyrene, but the material has more advantages and this more than pays for the costs. You can read more about the properties of mineral insulation in the article “Mine wool for wall insulation.” To properly insulate building facades with mineral wool, you should first study the procedure for doing the work yourself, as well as all the nuances and subtleties of the technological process .

Finish coating

The final stage of work on creating a “wet” facade was the application of decorative plaster,

what were polypropylene graters used for? Which composition should I choose for the finishing coat - one that gives a smooth or rough surface? Experts recommend choosing the second option. This is due to the fact that the reinforcing layer is quite thin, and small differences cannot be eliminated with its help. As a result, with side lighting, all the irregularities of the wall plastered with a smooth compound are visible. If, in the architectural plan, the building has many elements that break up the plane of the facade (canopies, balconies, etc.), in this case the use of smooth plaster is acceptable. But on a large free surface at a certain lighting angle, the flaws will be noticeable.

When choosing decorative plaster with a rough texture, you should take into account that over time it becomes clogged with dust.

If the house is located near the road, then this is a critical factor. In this case, it is better to line the first floor with porcelain stoneware, which can withstand cleaning well. However, the decorative plaster used on the facades of this building can be easily washed with water with slightly alkaline compounds dissolved in it.

Many customers want to see their homes bright. But it should be remembered that such paints use synthetic dyes that are susceptible to fading. Only natural pigments are persistent, but they usually produce pastel, discreet colors.

Insulation of facades with mineral wool

Insulation technology is carried out in three ways:

Technology selection

Insulating walls with mineral wool in a wooden house cannot be done without building a suspended ventilated facade . It protects building elements from exposure to condensation and prevents the development of mold, rot and dampness. All this can lead to the destruction of a wooden structure, but the resulting ventilation gap prevents the accumulation of moisture and helps to extend its service life. Foam insulation of a wooden house is rarely used, because the material is flammable and does not allow timber walls to breathe, which contributes to the appearance of dampness and mold.

The best way to insulate a house: criteria for choosing insulation

When choosing a material for insulating external walls, you should take into account its scope of application, technical characteristics, affordability, expert opinions and reviews of people who have already used it.

Among the technical characteristics, the most important are the following:

- thermal conductivity - the ability of a material to transfer heat, the lower this indicator, the better, thermal conductivity directly depends on the thickness of the insulation and its density;

- weight - the higher the density of the insulation, the heavier it is, this complicates its installation, since, in addition to adhesives, it is necessary to use anchor dowels, the weight of the material must also be taken into account when calculating the loads of facade finishing on load-bearing structures;

- environmental friendliness - the material should not emit harmful substances even when heated for a long time in direct sunlight; biologically neutral and necessarily non-toxic insulation materials are considered optimal;

- fire safety - materials for insulating walls outside must be non-flammable or self-extinguishing, this will prevent the spread of fire along the facade in the event of a fire;

- waterproofness - insulation of walls from the outside is carried out with materials that do not absorb moisture, otherwise it is necessary to additionally use a moisture-proof membrane, because some insulation materials, when wet, lose their thermal insulation characteristics and quickly become unusable;

- vapor permeability - for “wet” facades this parameter is not particularly important, but it should be taken into account when arranging curtain wall structures and for “breathable” wall materials;

- durability - the service life of insulation is in the range of 30-70 years.

The thermal conductivity of home insulation depending on the density of the material can be seen in the table below.

| Material | Thermal conductivity of materials, W/m*S | Density, kg/m³ |

| Polyurethane foam | 0,041 | 30 |

| 0,035 | 40 | |

| 0,029 | 60 | |

| 0,020 | 80 | |

| Expanded polystyrene | 0,037 | 10-11 |

| 0,035 | 15-16 | |

| 0,034 | 16-17 | |

| 0,033 | 25-27 | |

| 0,030 | 35-37 | |

| Extruded polystyrene foam | 0,034-0,028 | 28-45 |

| Basalt wool | 0,039 | 30-35 |

| 0,037 | 34-38 | |

| 0,035 | 38-45 | |

| 0,033 | 40-50 | |

| 0,030 | 80-90 | |

| 0,029 | 145 | |

| 0,027 | 120-190 | |

| Ecowool | 0,041 | 35 |

| 0,039 | 50 | |

| 0,037 | 65 | |

| 0,033 | 70 | |

| Tepofol (penofol) | 0,037-0,051 | 45 |

| 0,038-0,052 | 54 | |

| 0,038-0,052 | 74 |

Do not think that the thermal conductivity of a material depends solely on its thickness. Some people mistakenly believe that the thicker the insulation, the better. Excessive thickness can lead to disruption of the natural removal of steam from the room, which will cause the formation of condensation on the walls. As a result, mold and mildew may develop on them.

Wet facade

In this article, we will consider insulation under plaster.

Scheme of facade insulation with mineral wool - wet facade

Surface preparation

Before starting thermal insulation with your own hands, you should carry out a number of activities. It is necessary to wipe the walls of the house from dust, mold, moss, old build-up, and also remove all unnecessary objects from them. Remove old plaster that doesn't adhere well. Remove temporary drainage systems until the end of installation. Remove air conditioners, etc.

Metal fittings and nails protruding from the walls, if not removed, will rust over time as a result of temperature fluctuations, which will lead to the formation of unsightly red stains.

It should be noted that if you plan to insulate the facade with mineral wool and then cover it with siding, then you can allow some errors in the installation with slabs, but if you were planning on gluing it using the wet method with further plastering yourself, you should first practice a little on the back walls.

Wall marking

It is necessary to drive a piece of reinforcement into a previously prepared hole in the upper part of the wall, and then in the lower part. Reinforcing pieces should not be strengthened too securely, because later they will have to be removed. Set the distance from the wall surface equal to the width of the insulation plus 1 cm, and pull the nylon cord. Subsequent sagging should be done at a distance of 80-90 cm from each other.

Horizontal sags must be made at least two pieces, one placed on top and the second on the bottom of the layout map. For a complete picture, you can make two more diagonal sags.

The technology of work is such that measurements taken with a tape measure from the beginning to the extreme point of the cord should be entered in a notebook with a sag map for further comparison. Measurements should be taken every half meter to identify depressions and bulges. If the fluctuations are 0.5-1.0 cm, then we can say that the wall is perfectly flat and will be easy to work with. If large depressions are found, they should be primed.

Primer

If traces of mold or mildew are found on the walls of the house, then an antifungal agent should be applied to its surface. For reliability, coat the areas adjacent to the base with Aquastop primer for good waterproofing and adhesion. To treat the walls, a deeply penetrating primer is used, it is applied with a brush.

Installation of the starting base profile

To install a guide profile that provides support for the first row of mineral wool, you need to prepare:

To correctly install the profile, you should determine the zero point using a water level. Next, mark a line along the length of the wall using a tapping cord. The mesh starts 10 cm above the line and is glued using mineral wool glue. Holes are made with a puncher and the profile is secured with a dowel.

Bonding insulation

The insulation of the façade with mineral wool is done using a special adhesive for cotton wool slabs . In a 15-20 liter container it is diluted with water to a puree consistency. You should let it sit for a few minutes, then stir thoroughly to improve its properties. The glue will be usable for about 2 hours.

Correct application of glue to mineral wool - the entire surface is completely covered

The adhesive solution must be applied to the entire surface of the slab and distributed using a comb spatula. This will create additional strength for the surface of the slab and prevent its deformation. Attaching the slab in a pointwise manner will have disastrous results. If covering the entire surface of the slab with mortar gives it rigidity and the ability to retain its shape for a long time, then a spot coating will not even allow the slab to fully adhere to the surface of the wall.

The insulation coated with a layer of glue is installed on the base strip and leveled vertically using a level. When installing the next sheet, make sure that the seams at the joints do not exceed 5 mm.

If you don’t control and align everything from the very beginning, then it will be much more difficult to do so. Large cracks are sealed with strips of insulation, and uneven areas are wiped off with a foam grater.

Safety precautions when working with mineral wool

When working with basalt slabs, you need to protect your body, and especially your face and hands, with special clothing. Goggles are put on the eyes, and the nose and mouth are covered with a respirator. When contacted with the body or eyes, microdust causes itching and redness of the mucous membranes and skin.

Mechanical fastening of insulation

Insulating walls from the outside with mineral wool is done not only with glue. To ensure greater reliability, the slabs are reinforced with disc-shaped dowels. This ensures that the slab will not slip and will last a long time. This is quite simple to do, so everyone can easily fix the material with their own hands.

For 1 square meter of mineral wool slab, 5-7 dowels should be used. Location of dowels: at the corners of the slab and in the center. After finishing the work, the recesses should be sealed with an adhesive solution.

Reinforcement and finishing coating

When the insulation of the facade is completed, they proceed to covering the wall with a layer of decorative plaster. This can be done no earlier than two days after completion of the insulation work to allow the rough plaster to dry.

If you want to insulate under the siding, no question!

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Source

Preparing the wall plane

Move to top

This is the first stage of starting work on facade insulation. The main task of preparing the wall before gluing the insulation is to clean it from residual mortar, paint, whitewash, and remove the old plaster layer. If the wall contains cracks, they must first be sealed with mortar or filled with foam.

The second stage of wall preparation is applying a deep penetration primer. The most common are Kreisel 301, Ceresit ST 17, Pana Farb.

Laying insulation according to the current SP 71.13330.2017 (SNiP)

Correct installation of the thermal insulation layer is standardized in section 5.3 of the current SP 71.13330.2017 “Insulating and finishing coatings. Updated version of SNiP 3.04.01-87.”

These requirements must be observed during the production and acceptance of insulation work when installing insulating layers of roofs, insulating coatings of equipment and pipelines, and interiors of buildings and structures.

Let us highlight the most important points of these requirements that need to be monitored during the production and acceptance of thermal insulation work.

5.3.1 Thermal insulation boards should be laid close to each other in the “toward” direction along the surface of the pre-laid vapor barrier layer.

5.3.2 The use of slabs of different thicknesses in thermal insulation layers is not allowed.

5.3.3 During the process of thermal insulation work, the surface of the laid thermal insulation boards should be protected from the effects of precipitation by covering with a tarpaulin or plastic film.

5.3.4 It is allowed to combine the laying of thermal insulation boards with the laying of a vapor barrier layer, provided that the requirements for laying the vapor barrier layer material set out in 5.2.1 are met.

5.3.5 In cases where the base for laying heat-insulating boards is a profiled flooring, the laying of heat-insulating boards should be carried out with the long side across its corrugations.

5.3.6 The minimum surface area for supporting heat-insulating boards on the top flanges of the profiled flooring should be 30%.

5.3.7 Filling the corrugations of the profiled sheet should be done with shaped elements made of factory-produced mineral wool or cut locally (the use of bulk heat-insulating materials is not allowed).

5.3.8 Mechanical fastening of heat-insulating boards to the profiled decking must be carried out separately from the fastening of the roofing carpet and only for the top layer of heat-insulating boards, and at least two fasteners must be installed on one heat-insulating board.

5.3.9 The distance from the edge of the heat-insulating boards to the fastening element must be at least 200 mm. In this case, when laying heat-insulating slabs in one layer, mechanical fastening should be carried out along the center line of the slab along the long side, and when laying in two layers or more - in the corner areas.

5.3.10 Thermal insulation boards are laid in one or several layers close to each other.

5.3.11 When laying thermal insulation boards in two layers or more, it is necessary to avoid movement on the underlying layers of thermal insulation, and if movement is necessary, it is necessary to arrange walking bridges (roof ladders).

5.3.12 Thermal insulation boards, when laid in two layers or more in thickness, should be placed staggered with a tight fit to each other.

5.3.13 When laying thermal insulation boards, it is necessary to ensure that the seams of adjacent rows are offset by a distance of at least 150 mm. When laying thermal insulation boards in two or more layers, the displacement of the joints of each subsequent layer relative to the previous one must be at least 200 mm.

5.3.14 For the passage of engineering equipment through the heat-insulating layer, it is necessary to provide special sleeves, the height of which above the roof surface must be at least 350 mm.

5.3.15 The gluing of heat-insulating boards to the base and to each other (with a thickness of two layers or more) should be carried out in accordance with the requirements of the design and working documentation using adhesives, cold and hot bitumen mastics, dotted or striped.

Note - When using blocks or foam glass slabs as the material for the thermal insulation layer, the bottom plane and two adjacent faces should be coated with bitumen mastic before laying them. After installation, you should monitor the filling of all joints of the slabs (blocks) with bitumen mastic.

5.3.16 For a building height of up to 75 m, spot or strip gluing must be uniform and constitute from 25% to 35% of the bonded surfaces.

5.3.17 If the building height is more than 75 m, the thermal insulation boards must be glued to the base in a continuous layer.

5.3.18 The requirements for the thermal insulation layer are given in Table 5.2.

Table 5.2 - Requirements for the thermal insulation layer

1 Deviation of the plane of the heat-insulating layer from the slope specified in the design (over the entire area)

Measuring, using a certified measuring inclinometer. At least five measurements for every 50-70 m2 of surface or on a smaller area in places determined by visual inspection

2 Deviation of the plane of the heat-insulating layer:

Measuring, using a wooden or metal (aluminum) rod with dimensions of at least 2000x20x50 mm and a metal ruler in accordance with GOST 427. At least five measurements for every 50-70 m2 of surface or on a smaller area in places determined by visual inspection

3 Humidity of the thermal insulation layer material

Measuring, using a cylindrical probe method according to GOST 30256. At least five measurements for every 50-70 m2 of surface or on a smaller area in places determined by visual inspection

4 Width of joints between thermal insulation boards made of mineral wool

Measuring, using a caliper in accordance with GOST 166 and a metal ruler in accordance with GOST 427. At least five measurements for every 50-70 m2 of surface or on a smaller area in places determined by visual inspection

5.3.19 When using slabs based on foamed polystyrene, extruded foamed polystyrene, polyisocyanurate foam, etc. as a material for the thermal insulation layer. For gluing them, cold mastics or special adhesive compositions that do not contain organic solvents should be used.

5.3.20 Bulk thermal insulation bulk materials must be sorted into fractions before installation. Thermal insulation must be arranged along the lighthouse slats in strips 2-4 m wide. The installation of the second and subsequent (if necessary) layers is carried out after compaction of the first (previous): loose insulation of a finer fraction is placed in each subsequent layer.

5.3.21 Layers should be laid with a thickness of no more than 60 mm and compacted. The compaction coefficient should be taken in accordance with the requirements of the design documentation. The deviation of the compaction coefficient should be no more than 5%.

5.3.22 The use of bulk heat-insulating materials as a base for a waterproofing layer without installing a leveling screed on it is not allowed.

5.3.23 The installation of a thermal insulation layer in pitched roof structures should begin from the underlying areas.

5.3.24 The laying of thermal insulation boards in pitched roof structures should be carried out between the rafters (beams, purlins) or additional bars.

5.3.25 When using thermal insulation materials made of mineral wool, they should be cut with allowances of 5 mm on each side to ensure a tight fit.

Source

Variety of thermal insulation materials

Insulation of house facades involves the use of various thermal materials. They are attached to load-bearing walls, plastered and covered with decorative panels and other materials.

the following insulation options for insulating external walls

- Styrofoam;

- expanded polystyrene and extruded polystyrene variants;

- mineral wool in various designs;

- panels made of foam concrete and aerated concrete;

- thermal panels.

Foam panels

The polystyrene foam material has long been known to builders and over the years of its existence has acquired both supporters and opponents. Polystyrene foam is made from polystyrene, the granules of which are subjected to air heat treatment. They increase in size and stick together, forming a cellular structure.

The method used to create the material has its positive and negative qualities, which the homeowner must remember. The positive side of using polystyrene foam:

- the material is quite light;

- the work of installing panels on the wall is done quickly, the material does not require special equipment and is easy to cut to obtain parts of the required size and shape;

- polystyrene foam does not conduct heat well; this quality will help retain heat inside the house.

Negative qualities of polystyrene foam:

- The structure of polystyrene foam is porous, so the material is quite fragile, and rodents love to chew on granules;

- Foam plastic has a certain service life. After the expiration of the period, the material crumbles into granules, and not locally in individual parts, but over the entire used area;

- Polystyrene foam has low vapor conductivity and gas permeability;

- The material burns and is capable of supporting an open fire.

The low cost of polystyrene foam makes it attractive for façade insulation.

Extruded polystyrene and its variations

Unlike polystyrene foam, expanded polystyrene has a denser structure. It depends on the method of manufacturing the material. The foam is heated, it melts, and high pressure with heating causes the granules to foam. As they cool, they form a dense structure where the cells are filled with air.

Arguments in favor of using polystyrene foam:

- expanded polystyrene has greater strength than polystyrene foam;

- the material is capable of conducting steam and gas and is considered a breathable material;

- elastic polystyrene foam sheets;

- Foamed foam has good quality heat and sound insulation.

Mineral wools and their properties

The most common method of insulating walls is using mineral wool. Cotton wool is made of different compositions, different sizes and provides the opportunity to select the material of the required thickness.

Insulation with mineral wool is carried out using a certain technology. The process is carried out using waterproofing and vapor-moisture-proof materials. If one of the components is missing, condensation will accumulate in the layers of mineral wool. This moisture will not contribute to the formation of mold or fungal growth, but the weight of the insulating layer will increase, and the liquid will moisten the surface of the walls. A wet wall will cause a lot of trouble, even destruction.

Modern versions of basalt materials are made in different densities; they are easily cut with the necessary details. Cotton wool is widely used when insulating facades using the wet method. Basalt wool is plastered.

Mineral wool does not burn and does not support an open flame of fire, and does not smolder. It retains heat well and has a high noise insulation coefficient. It is unattractive to rodents. The service life is up to 40 years.

Foam concrete and aerated concrete

Available in the form of facing slabs. The slabs are laid according to the principle of brickwork, which eliminates the appearance of cold bridges. Foam concrete slabs are glued to load-bearing walls. In turn, the glue acts as an additional layer of waterproofing. To increase the holding properties of the glue, the panels are attached to the wall with umbrella dowels for installing insulation.

Foam concrete and aerated concrete panels do not have much weight due to the method of their manufacture, so they are easy to install. The material is cut into the necessary parts. Installation is completed in a short time. You can do it yourself, without having any special education or skills.

Foam concrete and aerated concrete panels are made with the addition of reagents that foam the concrete mixture, so the material has some disadvantages. If the panels freeze, they lose strength. It is impossible to stop this process and achieve the integrity of the panel, even if you apply waterproofing.

Decorative thermal insulation panels

The sheathing is a set that consists of insulation and a decorative finishing layer. The most popular panels have an insulating layer made of polystyrene foam or expanded polystyrene, and a decorative layer imitates plaster or brickwork. The panels are installed by gluing. A special solution acts as glue.

The positive aspect of using decorative panels is ease of installation and high decorative qualities, the appearance of the wall is beautiful. The panels retain heat well.

Negative qualities include the adhesive ability of the composition to adhere to the wall surface. The panels peel off over time; umbrella dowels will help improve the fastening system, but the walls will lose their aesthetic appearance, and the integrity of the panel will be compromised.

Features of external insulation

Thermal insulation can be installed both inside and outside the building. Moreover, its design necessarily includes a vapor barrier, insulation and waterproofing. The difference in the “pie” is determined by the position of the wall.

With external insulation, the “pie” is almost entirely taken outside. There are 2 options.

Wet facade - insulation is laid on the wall, waterproofing is covered with finishing. A layer of vapor barrier is laid on the inside. In this case, condensation partially forms inside the building. Moisture from outside - rain, snow - does not get inside the “pie”, since the insulation is protected by waterproofing. Excess condensate is removed using well-established ventilation.

A ventilated façade - in this case, the entire “pie” - vapor membrane, insulation and waterproofing - ends up on the outside. The dew point is brought out, but moisture does not enter the insulation, since the air circulating through the ventilation gap between the “pie” and the cladding removes it.

The first option is easier to install and cheaper. The second is safer, but requires more costs, so the “wet” facade is very popular. When externally insulating an apartment in a multi-storey building, this is the only solution.

Advantages of external insulation over internal insulation

Of course, when insulating the outside wall of a house, the question arises: “Why an external insulator and not an internal one?” The answer lies in the regulations that guide most general contractors and private construction organizations. So, with internal insulation, the outside becomes unprotected before the “dew point”. In other words, you reliably insulate the inner surface - heat will not escape through the walls. But then, in this case, the facade remains susceptible to frost, rain, snow and other atmospheric phenomena. Therefore, experts advise installing insulation on the outside of the house in order to reliably protect it from the cold. To put it another way, it is more effective to protect the external surface from the cold than to prevent heat from leaving the room. Conclusion:

- With internal insulation, the “dew point” is located on the inner surface of the wall, which leads to condensation, hence mold, rot, and fungus.

- External insulation of house facades shifts the dew point to the outer surface, which eliminates the above problems.

Requirements for facade thermal insulation

Insulation of facades must first of all comply with SNIP standards, fire safety and energy efficiency requirements. The provisions are described in the relevant documents - DBN V.1.1-7, DBN V.2.6-31 and others.

The facades of private houses are often not plastered, but covered with vinyl, wood siding, and clinker cladding. The vapor permeability of such cladding is low. However, in this case the insulation is additionally waterproofed.

The insulation system should dampen noise, and not create its own due to an incorrectly installed reinforced frame or an overly wide ventilation gap.

Requirements are not always met exactly. The decisive factor is the overall indicator of heat preservation, fire safety and water resistance. This can be achieved in different ways.

How and when is insulation carried out?

When carrying out facade work, it is necessary to take into account many factors of weather conditions. Not only the comfort of insulating the house, but also the strength of the entire structure depends on this:

- the air temperature should be between +10 and +25 degrees Celsius;

- before work there should be no precipitation in the form of rain, thick fog or hail for 10 days;

- at the time of work, the humidity level should not exceed 40%.

So, the optimal time for carrying out facade work is April-May or September-October.

Types of insulation

Insulation of the house from the outside is carried out with materials of organic and inorganic origin. The most important criterion here is the indicator of heat conservation and fire safety. The efficiency of the system and cost depend on the first, and the risk of fire depends on the second.

Mineral wool

The most popular option because it is the cheapest . There are basalt wool, slag wool, and glass wool. Preference is given to the first because it is more effective.

In basalt or diabase material, the length of the fibers is greater than in slag material, for example. This ensures the formation of more air cavities and greater strength of the insulation. In fiberglass, the threads are even longer, but more fragile. In addition, during use, some of the fibers break, and the smallest glass fragments irritate the mucous membranes. You can work with such material only in a respirator and protective clothing.

Mineral wool is usually produced in the form of a roll. It is easily held in the cavities of the sheathing and due to the fastening of the waterproofing.

Styrofoam

The most famous of porous materials, as it is also the cheapest. It is a slab of foamed polymer. With large sizes, the insulation sheet weighs very little.

You can install foam plastic either on dowels or glue. The material is easy to cut and saw.

Extruded polystyrene foam

Or penoplex. It is produced by extrusion, that is, pressing through dies, which causes the formation of cells filled with air. The structure of the material is very uniform, which results in both greater strength and the absence of open external pores.

When laying foam boards, you need to join them very carefully. The seams must be taped to prevent moisture from entering.

Polyurethane foam

The most effective option. For thermal insulation, both liquid and slab are used. In the first case, insulation is applied to the facade using special equipment. The material foams directly on the surface and hardens immediately. An excellent option is used both for a “wet” facade and for a ventilated one.

Installation of double frame

Those who have not yet decided how to insulate the facade from the outside should pay attention to double ventilated frames. The double frame is a suspended structure used to prevent condensation from accumulating inside the structure. Such facades include thermal panels, as well as foam and polystyrene foam materials, for the fastening of which profiles are used. Basalt wool is also often used as insulation for ventilated facades.

Frame insulation for a ventilation facade is a heat-insulating panel protected by a facing slab. A metal substructure is used to fasten the facing slab, and disc dowels are used to fasten the insulating panel. Thus, a ventilated layer is created for the insulation, preventing the accumulation of moisture.

Calculation of insulation thickness

The main task of a heat insulator is to retain heat. To do this, you need to select a suitable material of the required thickness. The calculation algorithm is as follows.

Calculate the heat retention of the wall using the formula Rs=(1/a(b))+R1+ R2+R3+(1/a(h)), where

The minimum thermal resistance then . Formula: Rain=Q/U, where

Compare the results obtained . If Rmin is less than or equal to Rs, then the facade does not need additional thermal insulation. If the difference is in favor of Rmin, you need to subtract it from the larger value and get the value of heat conservation that needs to be added. The thickness of the insulation is selected according to the indicator. The easiest way is to use ready-made tables for this.

How to level out uneven walls for insulation?

Move to top

The technology for leveling walls for gluing insulation depends on the amount of their curvature. For deviations of up to 10-15 mm in one direction or another, the issue is resolved by adding a layer of glue for concave areas and trimming the insulation for convex areas.

If the deviations are large, then use an additional layer of insulation for the concave areas.

For areas with strongly protruding irregularities, it is necessary to initially calculate the plane during hanging based on these irregularities, i.e. actually increase it. In this case, when hanging the facade, it is necessary to take into account the maximum unevenness of the convex part and the ratio of the vertical plumb line to be done according to the formula: glue thickness + insulation thickness + maximum protrusion of the wall unevenness.

This is the only correct approach, since cutting off a large amount of insulation will lead to a loss of its effectiveness in these areas and possible further freezing of the facade.

It is also possible that the plane of the façade is tilted forward or backward. If it is within 10 mm per floor, then you can install the insulation parallel to the plane of the facade; if it is more, then you need to solve the issue of leveling the plane.

Work order

External wall insulation can be used for any type of insulation. This depends on its technical characteristics and the chosen thermal insulation system. The installation algorithm is different.

"Well" insulation

It is carried out during the construction of walls or when facing the facade with clinker or facing bricks. The method is expensive, but very reliable.

This option is only possible when cladding a stone, concrete, or aerated concrete structure.

Option with lathing

This method is used more often, as it is more accessible and can be done by hand.

If the insulation was laid in one layer, it is more rational to take bars for the frame grille with a height sufficient for the ventilation gap to appear automatically. If this is too expensive, sheathing is mounted on the main frame, and then the trim is attached.

If mineral wool is used, there is no need to lay a vapor barrier inside the room. The vapor permeability of the insulation is high, so the dew point will still be brought outside.

Standard number of layers of finishing and insulation for exterior walls of a house

Insulation can be two or three layers. Moreover, in the first case, the external finishing material is not considered a separate layer. That is, its thermal insulation characteristics are not taken into account in the calculations. When choosing how to insulate a house from the outside, you need to immediately understand whether there will be an air gap between the wall and the finish.

| Material | Compound | Density kg/m3 | Thermal conductivity W/m*K | Fire resistance | Vapor permeability | Environmental friendliness | Manufacturability |

| Ecowool CV-1* | wood fiber, borax, boric acid | 30-60 | 0,032-0,041 | flame retardant, non-flammable, combustion products are non-toxic | absorbs excess moisture, maintaining its thermal properties | environmentally friendly material | fills all cracks without leaving voids |

| expanded clay | clay | 250-800 | 0,180-0,099 | does not burn | vapor permeable | There are no components harmful to health | fills all the voids |

| polyurethane foam | polyurethane | 40-50 | 0,022-0,030 | highly flammable | vapor-NOT-permeable | material used in refrigeration technology | fills all the voids |

| expanded polystyrene | polystyrene | 25-35 | 0,030-0,035 | highly flammable | vapor-NOT-permeable | decomposition products during combustion are toxic | possible formation of cracks |

| Rockwool | basalt rock melt | 30-34 | 0,032-0,42 | Max. temperature +650 | vapor permeable, the quality of thermal conductivity is impaired | decomposition products during combustion are toxic | possible formation of cracks |

| URSA | sand, soda, limestone, borax | 24-36 | 0,034-0,046 | Max temperature +400 | vapor permeable, the quality of thermal conductivity is impaired | polymer binders cause irritation | there are seams and voids after installation |

| ISOVER | sand, soda, dolomite | 24-36 | 0,034-0,042 | Max temperature +400 | vapor permeable, the quality of thermal conductivity is impaired | polymer binders cause irritation | there are seams and voids after installation |

Among the recommended insulation options, depending on the wall material, the following solutions should be highlighted:

- frame houses with thin-sheet cladding - three-layer insulation with a heat-insulating layer in the middle, it is possible to use a ventilated facade;

- brick, reinforced concrete, expanded clay concrete - any insulation options are suitable;

- houses made of wood - two- or three-layer insulation with a ventilated air gap;

- cellular concrete - two-layer insulation with brick lining.

In practice, it all comes down to the choice of a ventilated or “wet” façade. In the first case, basalt wool plays the role of insulation. It is also suitable for a “wet” facade, but extruded polystyrene foam has less weight, therefore it is optimal for buildings more than 3 floors high. It is also used when facing walls with brick.