Ecoover insulation has become a popular thermal insulation material. This is a reliable product created based on basalt raw materials. It is manufactured using modern technologies in the form of special plates, which allows it to be used in many construction industries.

Insulation production lines are characterized by a high degree of localization, and basalt raw material processing plants are located in close proximity to mining sites. In combination with the use of the most modern equipment in the manufacture of insulation, the reduction in costs of transporting raw materials makes thermal insulation economically accessible to a wide range of consumers.

Insulation manufacturers, due to an increased level of automation, are able to process raw materials - solid basalt - into the final product, a lightweight fibrous insulating material. At the exit, the goods are packaged for subsequent transportation.

The insulation manufacturing process is a procedure of melting mineral raw materials with the parallel addition of synthetic additives. At the same time, stretching the raw material mass using advanced technologies and specialized equipment gives the composition a fibrous structure. Production lines are equipped with filtration units that process production waste, protecting the environment from harmful emissions.

The technology has been awarded international quality assessment. Finished products have all the necessary certificates of quality and compliance.

Advantages and disadvantages

Basalt-based thermal insulation is a modern and sought-after product, although it has pros and cons.

- Compared to other mineral thermal insulation, ecoover basalt insulation is highly durable.

- The plates cope with the task of protecting premises from energy loss.

- High sound insulation rates make it possible to use the product as a soundproof barrier.

- Thanks to the introduction of modern technologies into the production line, the Ecover plant has achieved the ability to produce insulation that does not absorb moisture, which is unusual for many mineral insulation materials. This is achieved by treating the basalt mineral raw material with a water repellent. When saturated with moisture, the insulation loses its properties, negating the effect of all the work done.

- Having zero flammability, the material is able to protect the coatings insulated by it from the destructive effects of fire during emergencies.

- The environmental safety of the product is also considered an important quality.

- Among the products of various manufacturers, this basalt insulation is distinguished by its ability to maintain the original geometric and physical parameters. During production at the enterprise, the Ecoover plant uses technologies that ensure the safe operation of products in the long term. Resistance to shrinkage allows the product to be used for insulating sloped or vertical surfaces.

- The products of the factories are adapted to the standards of building structures. The product line is provided on the markets in such a way that it is possible to select insulation boards for the specific geometric dimensions of the elements of the insulated surface. This will avoid unnecessary waste during work. Different widths will allow, if necessary, to achieve maximum thermal insulation effect.

The thermal insulator is resistant to the spread of fungi and mold. Rodents and insects do not harm it. It has no unpleasant odors and does not emit harmful substances during operation. The insulation has vapor barrier characteristics that provide the necessary air circulation.

It is widely used when working on:

- insulation of floors and walls;

- thermal insulation of attics, foundations and roofs;

- finishing of slab joints and window openings;

- soundproofing rooms;

- waterproofing floors, foundations and walls;

- vapor barrier of masonry walls.

Mineral thermal insulation is used in rooms with aggressive environments at high temperatures. It is applicable in industrial buildings for insulation of ventilation or heating equipment, tanks and sewers for water and air.

Material advantages

The wide range of applicability of Ecover suggests the presence of positive characteristics:

- safety of technical indicators to temperature changes;

- resistance to the formation of fungi and mold;

- protection from ultraviolet rays;

- ease of installation;

- long period of operation (more than 50 years);

- reasonable cost;

- absence of foreign odors;

- wide choice of standard sizes.

Ecover light packaging

Ecover light is the optimal choice and practical solution for every home.

Specifications

Mineral insulation is made from basalt raw materials, mined by a manufacturer of thermal insulation materials at the Bazhenov deposit in gabbro rocks. Ecoover is endowed with its characteristics and features by adding water repellents and modified additives to the main raw materials. Its thermal conductivity is not inferior to other popular products on the market among insulating products for construction purposes. 50 mm of insulation has properties equal to almost 200 mm of wood or 300 mm of masonry made of gas or foam concrete.

The characteristics of Ecover basalt fibers give the material a special feature: it is highly resistant to heavy loads.

One square meter of surface can withstand pressure of 8 tons.

Ecoover mineral wool melts at temperatures above 1000 degrees Celsius, which makes it a practically fire-resistant product. The density of insulation in the product line of this brand reaches 150 kilograms per cubic meter. The ecoover light station wagon has a reduced density, in which it is less than 30 kg per square meter. meter. The compressibility of insulation varies from 5 to 25 percent depending on the type of material. When partially immersed in liquid, thermal insulation is characterized by an absorption rate of no more than one kilogram per square meter. At the same time, it allows water to pass through itself without absorbing it. Depending on the operating conditions, the thermal conductivity coefficient of the insulation changes. On average it is 0.035-0.040 W/m*K. The characteristics allow the insulation to be used as a soundproofing product; among the entire line of products, Ecoover Acoustics is the most suitable for these purposes. It is suitable for use in non-load-bearing structures such as frame house partitions, timber floor frames, etc. Has high vapor permeability. The composition contains no more than 3% organic additives.

Manufacturer information

Ecover thermal insulation is produced at a modern Russian plant in the Sverdlovsk region. The choice of location was based on proximity to deposits of the gabbro-basalt group of rocks. Thanks to advanced technical equipment, the production of high-quality products is achieved that can solve issues of improving the energy efficiency and environmental friendliness of buildings.

The insulation composition includes: mineral wool created on the basis of rock and a binding component of synthetic origin. At the same time, it complies with all current standards of GOST 9573-2012.

Geometric dimensions

The dimensions of ecover insulation are selected specifically for ease of use. The slabs are sold in standard sizes of 1 meter by 60 centimeters. The company creates products with a thickness of 30 to 250 mm, which will make it possible to produce thermal insulation where large insulation costs are not required, or in places where there is practically no thermal insulation layer. In this case, it does not matter which brand is used: standard or ecoover acoustic, since the consumer selects the required insulation thickness. In the product line, the thickness change step in the assortment is 10 mm.

Main disadvantages

If you want to choose the insulation described, you should familiarize yourself with its main disadvantages in advance. Among them, we should highlight the need for additional protection of the material from contact with moisture. Despite the fact that cotton wool almost does not absorb water, this does not mean that it does not require protection. You will have to wear special clothing to lay the material; in addition, it is unsuitable for places that are exposed to moisture.

Ecover insulation, the characteristics of which should be considered before purchase, is not produced using resins. The latter may include formaldehyde and phenol, which are used to bond other materials into individual mats. Contrary to the opinion of some consumers, such harmful substances are not contained in the material described.

Facade insulation

The development of technology and the experience of builders when working on insulating walls of building facades raised the question before developers about the need to create a material suitable for thermal insulation of walls. This is how the basalt insulation of the ecover façade became. Traditionally possessing high resistance to external factors, the new product began to be used for insulating external walls and in ventilated facade systems.

Ecover vent facade 80 is also applicable for single-layer insulation of wall surfaces as the main thermal insulation material. It is also used as a surface layer with an air gap in ventilated systems on top of other heat insulators.

For thermal and sound insulation of wall surfaces in façade systems, eco-facade eco-cover is suitable for plastering with a thin layer. It has greater strength compared to other products. Due to its technical characteristics, eco-facade eco-facade is suitable for use in finishing works on buildings of any number of floors. Ecover vent facade has less water absorption than insulation for interior work.

There are several types of insulation for facade use, among which are the following brands:

- Facade decor;

- Façade decor optima;

- Sandwich;

- Sandwich K.

Features of the production of basalt mineral wool

The composition of the raw materials, as well as the production technology of Ecover mineral wool insulation, determine their performance properties. The starting material is gabbro rock . Sometimes during mining it is deoxidized using limestone or dolomite. Before becoming high-quality thermal insulation, this composition goes through the following production stages:

- Melting of raw materials in a special unit at a temperature of 1,500°C.

- Formation of fibers in a centrifuge.

- The entry of raw materials into the chamber where fiber deposition occurs.

- Impregnation of fibers with hydrophobic and modifying compounds to improve the performance properties of the finished material.

- Formation of a mineral wool carpet with uniform density.

- Compressing the carpet under a special corrugated press.

- Polymerization under high temperatures.

- Sawing mineral wool carpet into slabs of specified sizes.

- Sealed packaging of the finished material.

Please note: the Ecover company produces basalt insulation only in slabs .

Internal insulation

For interior work, the following brands of insulation are distinguished:

- light;

- standard;

- roof;

- acoustic.

Brand Light

Ecover mineral wool belongs to the class of light basalt slabs. The main purpose is thermal and sound insulation of non-load-bearing building structures in buildings of any type and class. In addition to being used in partitions of frame walls, attic roofs, attic floors and floors, it can be used in the construction of three-layer, layered (well) masonry. Ecover light universal is used for insulation of various tanks, pipelines, air ducts and other industrial utilities that require thermal insulation. The Light and Ecover light universal brands are suitable for installation as the first layer in ventilated facades.

Thermal insulation parameters:

- Density from 25 to 45 kilograms per cubic meter.

- Compression resistance ranges from 8 to 20%.

- Water absorption 0.75 kg per m2.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.039 W/m*K.

- Included in the class of non-combustible materials.

Application of insulation

This material is used for all types of structures to provide a durable and reliable layer of sound and heat insulation. Basically, Ecover is intended for installation on:

- frame walls;

- attics;

- attics;

- internal partitions;

- floors;

- facades.

Thermal insulation has high thermal protection and physical and mechanical properties, which guarantees the creation of an optimal microclimate in the room and durability.

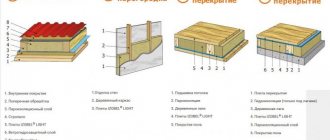

Roof insulation using Ecover light

*

Brand Roofing

Ecover roofing is a thermal insulation product used as a single-layer roof insulation. Ecover has the necessary characteristics for installing roof insulation both without cement and with cement screed. Ecover roofing is suitable for insulating attic and interfloor ceilings, as a thermal insulation layer between the first floor and an unheated basement.

Thermal insulation parameters:

- Density 135 or 150 kg per m3 (indicated in the name).

- Compression resistance 45 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.036 to 0.038 W/m*K.

- Incombustible.

Roof top

Ecover roofing top is a type of rigid mineral insulation for installing two-layer thermal insulation of a flat roof. It is used as a top layer on top of roofing bottom insulation.

Roof insulation parameters:

- Density from 160 to 190 kg per m3.

- Compression resistance from 65 to 120 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.037 to 0.04 W/m*K.

- Included in the non-flammable class.

Roof bottom

Ecover roofing bottom belongs to the class of rigid insulation materials used for roofing thermal insulation work. It is suitable for installing single-layer thermal insulation of a roof, as the first layer in combination with the Roof Top subtype or extruded polystyrene foam, as a fire insulation layer.

Roof insulation parameters:

- Density from 100 to 120 kilograms per m3.

- Compression resistance from 25 to 40 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.038 W/m*K.

- Non-flammable

Parameters Ecover Standard

| Meaning | Measurement |

| Nominal Density | 45 kg per cubic meter |

| Thermal conductivity | 0.035-0.036 W per mK |

| Amount of organic matter | 3% by weight |

| Moisture absorption | No more than 1 kg per sq.m. |

The presented types are mounted mainly on loggias and joists.

- Series for facades. It includes slabs with increased density and better thermal insulation properties. The line includes:

- Eco-facade - mounted on walls, under a thin layer of plaster. Withstands up to 40 kPa. The degree of thermal conductivity is 0.035-0.041 VK per mK;

- decor - have a thickness from 2 to 20 cm, peel strength exceeds 80 kPa, thermal conductivity - 0.039-0.043 W per mK. The insulation for the facade is packaged in 6 slabs, measuring 100x60x5 cm. Volume - 3.6 square meters.;

- ventilated façade 80, 90 – used both for exterior finishing and for finishing with plaster with reinforced mesh on the surface. Density varies from 70 to 120 kg per cubic meter. The degree of moisture absorption is 0.75 percent. Packaging – 12 slabs measuring 100x60x5 cm and a volume of 0.36 cubic meters.

Indicators of main characteristics

| Meaning | Measurement indicator | Number |

| Heat conductivity at 10/25 degrees | Watts per mK | does not exceed 0.035 – 0.037 |

| Tensile strength | kPa | not less than 40 |

| Number of organic components | % | no more than 4 by weight |

For the roof. This model range includes slabs with a higher degree of rigidity. Scope of application: used roofs. Density degree – 135 – 150 kg per cubic meter. Not recommended for use in attics and basements. The thickness of the material is 5 – 20 cm. Moisture absorption does not exceed 0.75%. The amount of organic substances in the composition is no more than 4.5%. Ecover for roofing is packed in 8 sheets, each of them has dimensions of 100x60x5 cm. Volume - 0.24 cubic meters.

Characteristics table

| Meaning | What is it measured in? | Type | |

| 135 | 150 | ||

| Nominal density indicator | kg per cubic meter | 135 | 150 |

| Heat conductivity rate at 10/25 degrees | Watts per mK | 0,038 – 0,039 | 0,038 – 0,039 |

| Compression | kPa | not less than 45 | not less than 50 |

| Strength under direct load | N | not less than 600 | not less than 650 |

| Tensile strength limit | kPa | about 10 | about 12 |

For the floor. Here Ecover Step is used with a density of 135 kg per cubic meter. and Step + - 150 kg per cubic meter. Scope of application: installation of floors, basement floors and basements. Additionally, underfloor heating, concrete or cement-sand screed can be laid on the insulation. Ability to withstand loads – 30-35 kPa.

Floor insulation Ecover Light

Technical indicators of the material

| Meaning | Measurement | Quantity |

| Thermal conductivity 10 – 25 degrees | Watts per mK | 0,035 – 0,037 |

| Compression ratio | kPa | not less than 35 |

| Moisture absorption | kg per sq.m. | does not exceed 0.75% |

| Presence of organic matter | % | no more than 4 |

Acoustic

Acoustic eco-cover has become a material that can not only retain heat, but also exhibit a good sound-absorbing effect. It is suitable for creating a sound threshold. Ecover acoustic creates the necessary acoustic effect in cultural premises.

Ecover acoustic has the following characteristics:

- The sound absorption coefficient is 0.95.

- Compression resistance does not exceed 12%.

- Water absorption 1 kg per m2.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.037 W/m*K.

- Non-flammable composition.

In addition, ecoover acoustics are highly effective in apartments when there is a need to protect yourself from neighbors.

Wall insulation options

The only correct option for effective and durable thermal insulation of walls is external thermal insulation. It fully complies with the principle of proper insulation from the point of view of thermal physical processes.

The essence of proper insulation is that the vapor permeability of all wall construction materials in the direction from the room to the street should increase. When insulating from the inside, this proportion is violated, which leads to numerous undesirable effects and significantly reduces the efficiency of using insulation. Therefore, insulating walls from the inside is justified only when, for some reason, external thermal insulation is impossible. And only when using a special additional vapor barrier on the side of the room.

In addition, external thermal insulation avoids the formation of condensation on the walls, which prevents the formation of dampness, which contributes to the spread of microorganisms and the formation of mold. Insulation also helps to neutralize the undesirable effects of strong temperature changes, when the wall “heats” under the scorching sun during the day and cools down greatly on a cool night.