Buying a high-quality cabin is not a problem. Manufacturers offer a large number of models of various purposes, sizes and performance levels. This can be a simple structure to store materials or a small building that is fully prepared for habitation. However, the cost of such cabins is very high.

The ability to handle tools, plumbing and construction skills will allow you to make a change house with your own hands, and its cost will ultimately be several times lower than the options offered on the market. The frame is assembled from profiled metal; the outer cladding is best made from sheet metal or wood boards.

After completing the assembly of the load-bearing structure and securing the external cladding, it is necessary to carry out work on insulating the cabin premises. This will allow the room to be used for living in winter, and in summer the presence of insulation can protect against heat.

General rules for thermal insulation

To properly insulate a wooden outbuilding, certain rules are followed.

- First, we prevent heat loss through the roof - we cover the structure with a special film. Only after this can the roof be laid in the form of corrugated sheets or ondulin.

- To increase heat resistance, MDF panels are used, installed on special profiles. We fill the free space with a heat insulator of your choice.

Change houses made of metal are highly resistant to mechanical and other influences. The metal frame is completely protected from moisture by a special covering. But the roof of an outbuilding is often susceptible to corrosion processes. To prevent corrosion, it should be treated with a polymer-based coating or paint and varnish products.

Wall structures are sheathed with clapboard, block house or plastic panels. Thermal insulators are mineral wool or polyurethane foam. To prevent heat loss, cracks and joints are sealed with tongue and groove boards. Combined outbuildings are insulated in the same way.

Where to start insulating a cabin

If you are just planning to purchase a cabin for winter living, then first of all you need to pay attention to the material from which the structure is made. There are three main types of cabins: metal, wood and combined.

- The metal structure is a frame covered with profiled galvanized iron. The design is resistant to moisture penetration and therefore exhibits better heat retention ability.

- A wooden change house is very vulnerable to the penetration of cold and moisture into the room, and therefore requires more careful thermal insulation.

- A combined cabin is a structure made from several materials. Insulation must be carried out taking into account the material of the cabin in its individual areas.

Characteristics and types

The flexible hose for connecting plumbing is a hose of different lengths made of non-toxic synthetic rubber. Thanks to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, there is an upper reinforcing layer in the form of a braid, which is made from the following materials:

- Aluminum. Such models can withstand no more than +80 °C and retain functionality for 3 years. At high humidity, aluminum braiding is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water line is at least 10 years, and the maximum temperature of the transported medium is +95 °C.

- Nylon. This braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 °C and are designed for intensive use for 15 years.

The fasteners used are nut-nut and nut-fitting pairs, which are made of brass or stainless steel. Devices with different permissible temperatures differ in the color of the braid. Blue ones are used to connect to a pipeline with cold water, and red ones for hot water.

When choosing a water line, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that prevents the rubber from releasing toxic components during operation.

What types of cabins are there?

To install a wooden cabin, you do not need a foundation.

The cabins, insulated for the dacha, differ both in the material used and in their design. They are united by one feature - the absence of a foundation. In some cases, contractors offer to install the shed on a pile foundation, but often they are placed on low pads. The main thing is that there are no distortions; everything should be done according to the water level.

Wooden cabins, insulated for dachas, are:

- panel;

- frame;

- from timber;

- from a log.

Insulated dacha cabins made of metal are either a container or a trailer; there are even cabins from old buses. Sometimes the possibilities are limited only by your imagination. Such mini-rooms are needed to store equipment, change clothes and keep warm. Often, cabins are equipped with heating. Electric heaters, stoves and potbelly stoves, gas or liquid fuel heaters are suitable for this purpose.

An insulated change house with a stove can be used in the winter without any problems.

It is an integral part of any construction site. Workers not only change clothes and have lunch in it while on business trips, they live there. Of course, the lack of water, sewerage and a bathroom cannot but create inconvenience, but in the absence of an alternative, an insulated winter cabin is quite suitable for temporary living. If the size allows, it can be divided into several rooms in which it is quite possible to create minimal amenities.

What can it contain?

Externally, the change house resembles a small house with different layouts. The premises contain oversized furniture for relaxation and cooking. If you properly distribute the usable area, you can equip a bathroom. Often the building is placed next to the main cottage, turning it into guest apartments.

Arrangement of a change houseSource nikasdom.ru

Comfortable parameters of residential premises - 18 square meters. The dimensions of the modules can vary from 6*3 m to 7*3 m, height - from 2 m. The standard layout includes two rooms, a bathroom and a kitchen. Between the zones there is often a small dressing room-corridor.

Convenient change houseSource freelance.ru

The dimensions of technical buildings are from 6 to 14 m2. Traditionally, a block contains one room, which can be divided by partitions or ordered with ready-made walls. Multi-room models have an entrance and window for each area. Standard height is 2.5 m.

A separate cabin will become a convenient bathhouse. The minimum size of the “trailer” is 12 squares. A boiler is needed to heat the liquid, and a sewer system is needed to remove dirty moisture. Wooden benches and containers for cold and hot water are installed in the washing department. In the room you can put a massage bed and a shower. Depending on the size, the steam room can accommodate 2-3 people.

It’s easy to set up a summer kitchen in a change house. A separate 10 m2 “trailer” will accommodate a full-fledged work area with an “island” and a set of furniture. Electricity, water and sewerage are supplied to the structure. To keep the room from getting hot, you need forced exhaust.

Medium-sized modules (11-12 squares) are equipped as a utility block. The design is convenient for storing garden tools. To increase capacity, ceiling racks are needed. The premises are often converted into a food warehouse. Perishable food requires a refrigerator and an electricity supply.

Change house with bedroom and kitchenSource yandex.ua

Compact buildings of 2*3 m will become a full-fledged bathroom. In the premises you can place a bath (shower stall), a sink, and a toilet behind the partition. If the family is large, then the toilet should be equipped with a separate one. Each zone has a separate entrance. The boiler is installed next to the washbasin or in the corner.

Insulation materials

A change house without insulation will not perform all the functions and tasks for which it is intended. Therefore, you should carefully consider and select the insulation technology, as well as select a suitable insulator.

The modern market provides a variety of thermal insulation materials. Let's look at the most common ones in detail.

Styrofoam

This type of heat insulator is mainly used to insulate the walls of outbuildings. Foam insulation is beneficial when finishing wooden cabins. The material is resistant to moisture, simple and easy to install. Foam insulation has disadvantages: short service life and large volume for good insulation, and with low-quality products - significant heat loss. Several layers of polystyrene foam will reduce the area of the room, and improper use of the structure will lead to a fire.

Mineral wool and fiberglass

The advantages of the materials are fire safety and excellent thermal insulation characteristics, subject to all the requirements of the technological process. If you install several layers of heat insulation, the acoustic properties of the rooms will increase. Disadvantages - the components are harmful to health.

Basalt slabs

Such fibers are produced through careful processing of basalt rocks. On the construction market, a common form of material is slabs, which can be easily cut to size and laid. The heat insulator is completely resistant to fire and does not undergo deformation processes for a long time. The easy-to-use material will not take up much free space, so the area of the shed will remain almost the same. The disadvantage is the many seams that remain after installing thermal insulation.

Cotton thermal insulator

This substance is the safest for today. It is high quality and environmentally friendly. Can be used to insulate walls inside a trailer and does not require special installation skills. It is often used for thermal insulation of cabins in which it is planned to live. The downside is that the product is difficult to cut.

Polyurethane foam

This thermal insulation material is the most common and effective for insulating commercial buildings. There are 2 types: liquid and hard. Experts recommend using the second option to increase the heat capacity of the building’s exterior. It is excellent for strengthening roofing systems and exterior walls. Using the unique structure of polyurethane foam, it is possible to mask possible defects in the roofing system and increase the temperature in the structure.

Requirements

The main function of the material is to make the room temperature comfortable for year-round living. Accordingly, certain requirements are imposed on it. Even at high temperatures, it is necessary to exclude the possibility that the insulation will catch fire with an open flame. It must be compatible with the frame. The wear-resistant qualities of the material must be at a high level to ensure a long service life.

In addition, if it is planned that the premises will be intended for permanent housing, the products must be completely safe for people, their life and health.

Step-by-step instructions for insulating a cabin

Work can be carried out both inside the trailer and outside. These methods have both positive and negative aspects. Insulating the cabin from the outside will preserve its internal volume . This will also protect the walls of the building from the effects of external negative factors, which will extend the life of the trailer. The downside of insulating the cabin from the outside is that it will then have to be finished with decorative material to make it look attractive.

To carry out work inside, it is important to use non-toxic and environmentally friendly materials that do not burn. An excellent option would be to use mineral wool. The installation process consists of the following stages:

- A frame is installed on the wall.

- The space between the beams is filled with cotton wool.

- A layer of waterproofing is laid.

- Facing.

Preparation

You will need to prepare the following materials and tools:

- Vapor barrier.

- Minvata.

- Beam.

- Mastic for wood processing.

- Hammer.

- Screws.

- Nails.

Floor insulation

How to insulate the base of a cabin with your own hands? For such work you can use:

- Expanded polystyrene.

- Minvatu.

- Styrofoam.

The instructions say that initially you need to lay a timber frame on the floor. The base will first need to be cleaned of dirt. The tree must be treated with antiseptics so that it does not rot and insects do not breed there. The cells in it need to be 50x50cm. They contain insulation. A layer of waterproofing is placed on top. Then the surface is covered with boards.

Roof

How to insulate a trailer for winter living on top? It is recommended to carry out such work outside. To do this, you need to remove the roofing material (slate), lay waterproofing and insulation under it. Then attach the roofing material back.

If it is not possible to do such work from above, then it is necessary to thermally insulate it from the inside. To do this, you need to attach beams to the ceiling. Thermal material is laid between them and chipboard is sewn up. It is worth remembering that this may reduce the height of the room.

Frame installation

The walls must first be treated with antiseptics so that they do not rot or rust. This will also help prevent fungus from forming on the surface. Then wooden slats are attached to them, to which a heat insulator is mounted with a stapler. The distance between the beams should be equal to the width of the heat insulator.

When carrying out work, it is worth leaving vents at the bottom of the walls so that steam does not collect there and condensation does not form. You can also put penofol on top of the insulation, which will create the effect of a thermos in the building.

Window

Windows can be sealed using silicone. To do this, you will have to dismantle the glazing beads and apply a layer of sealant underneath them. Then the glazing beads are fastened into place. This will help retain additional heat in the room. You can, of course, install double-glazed windows.

Insulation of the floor before laying the finishing coating

The best option for floor insulation in a private wooden house is considered to be the creation of a so-called double floor. When a thermal insulation cake is created between the boards of the rough and finished floor, consisting of several layers of different materials.

Such a pie can be installed both at the construction stage and during a major renovation, when the current floor is dismantled to its foundation.

The double floor design is shown in the diagram below:

- Joists or cross beams.

- Skull beam.

- Subfloor boards.

- Waterproofing layer.

- Insulation.

- Vapor barrier layer.

- Finished floor boards.

The following insulation materials are used: expanded clay, expanded polystyrene (also known as polystyrene foam), extruded polystyrene foam Penoplex or mineral wool.

Let's look at each of the materials in more detail.

Expanded clay

Expanded clay is widely used as insulation in the construction of multi-storey buildings. They are used to insulate basements and attics. But expanded clay is also suitable for insulating floors in a private house.

Expanded clay granules are made from clay, have high strength and resistance to mechanical stress and demonstrate high thermal insulation properties.

On a note. To create a dense layer of insulation, it is better to use several different fractions of expanded clay.

Material advantages

Disadvantages of the material

Laying features

Before laying expanded clay, a layer of waterproofing is created on the surface of the subfloor. For example, it could be liquid mastic. After this, a layer of expanded clay with a thickness of at least 10 cm is poured between the joists. The pouring should be done carefully, avoiding damage to the granules. The surface of the expanded clay is leveled.

A layer of vapor barrier, for example Izospan, is laid on top. After this, you can lay the finished floor boards.

Expanded polystyrene

Expanded polystyrene (also known as polystyrene foam), along with expanded clay, is the most affordable option for floor insulation in a private home or country house.

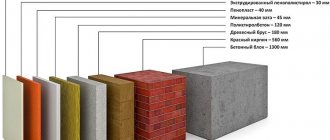

This material consists of 98% air and has high thermal insulation properties. For comparison, 2 cm of polystyrene foam retains heat as well as 40 cm of brickwork.

When used in a country house as floor insulation, it should be remembered that polystyrene foam receives increased attention from rodents.

On a note. For insulation, choose expanded polystyrene with a density of at least 35 kg per sq.m.

Insulating the cabin from the outside

Insulating a structure from the outside can have both pros and cons. The advantage is the preservation of the free space of the room, and the negative is the need to finish the outer part with siding or eurolining.

Polystyrene foam can be used as insulation

, which has a porous structure, light weight and soundproof. It holds heat well and is highly resistant to rotting. You can also use basalt slabs, slag wool, glass wool. To thoroughly seal joints and cracks, polyurethane foam is used, which perfectly seals and retains heat in the room.

Features of insulation of different types of utility rooms

Huge heat losses in metal cabins occur due to cracks in the floor

In general, there are 3 types of cabins: metal, wooden and combined models. Accordingly, taking into account the material used as insulation, the thermal insulation process itself is carried out. Wooden cabins are especially vulnerable to cold, so they must be insulated by following the following rules:

The first thing you should pay attention to is the roof, given that most of the heat loss goes through it. Usually the roof is covered with a polymer-coated film, followed by the use of corrugated sheets. The next stage is walls, the thermal resistance coefficient of which can be increased through the use of MDF panels

Since they are installed on metal profiles, the resulting space is filled with any bulk insulation.

As for metal cabins, they are more resistant to negative influences. This is due, first of all, to the design of the room itself: the metal body, as a rule, is protected from moisture penetration by the flooring. However, there is a possibility that the roof will still be subject to corrosion. To prevent this situation, it is necessary to treat the surface with a polymer coating (or paint). For wall insulation, lining or plastic panels are perfect. The thermal insulation material can be, for example, mineral wool or sprayed polyurethane foam. And since huge heat losses in metal cabins occur due to cracks in the floor, for this purpose it can be additionally reinforced with tongue and groove boards. Thermal insulation of combined cabins is carried out approximately according to the same scheme.

How to insulate a cabin for winter living

Temporary often becomes synonymous with permanent; when purchasing a change house for your dacha, you may assume that it will only be needed for the summer season, but in reality it will also be needed in winter. However, not every house will be cozy during the cold period. That is why how to insulate a cabin for winter living is an important issue that requires consideration. In fact, the correct answer consists of two factors, without each other they will be useless. To live in a cabin during the winter cold, you need not only to take care of insulation, but also to think about heating the structure.

Heating issues

Of course, it is difficult to organize a large stove in a change house, but there are several systems that will help make the house much more comfortable and ensure a comfortable temperature in it. So:

- Electrical systems. First of all, these can be electric furnaces that not only have suitable power, but also have good fire safety, as well as protection from possible burns. In addition, wall heaters, infrared heaters, and electric heat guns are used in cabins;

- Gas systems. This type can operate, for example, on liquefied gas from cylinders;

- Heat guns operating on several types of fuel, using diesel fuel, etc.

Having decided which room heating system to prefer, you can move on to the second part of the process.

Basic properties of thermal insulation materials

The main characteristic of a heat-insulating material is thermal conductivity, which determines the ability of the material to carry out heat exchange, that is, the transfer of thermal energy from a more heated part to a less heated one. A quantitative indicator of thermal conductivity is the thermal conductivity coefficient. Let's imagine two certain environments, the temperature difference of which is 1 K (degree Kelvin). These media are separated by a sample of material of unit thickness and area. The thermal conductivity coefficient of this material is numerically equal to the amount of thermal energy that passes through it per unit time. The coefficient is denoted by the letter λ, and is measured in W/(m K). Thus, the lower the thermal conductivity coefficient, the better the thermal insulation.

Mineral wool insulation. This material is most often used for insulating cabins. The thickness of the insulation is selected 50 or 100 mm depending on the outside temperature. The most reliable is considered to be laying mats 50 mm thick in two layers. Laying is done with overlapping joints in adjacent layers. This technology eliminates freezing through the cracks between individual mats. The use of mineral wool is due to its advantages:

The heat-insulating layer of the cabin walls is laid between the outer and inner cladding. In this case, a layer of rolled non-woven material is placed between the mats and the outer wall to protect from the wind. The insulation is separated from the inner lining by a vapor barrier film that does not allow moisture to pass through from the warm room. For these purposes, roll penofol is sometimes used.

Foam boards have different thicknesses and differ in the grade of material, which determines its density. The lower the density of the material, the higher its thermal insulation properties. On the other hand, looser material has less mechanical strength and can be easily damaged during loading, transportation and storage. Insulation of cabins should be done with foam plastic grade D40 or denser.

Extruded polystyrene foam is produced in slabs with special overlapping locks at the ends, which ensure overlap of the joints.

Positive qualities of polystyrene foam and expanded polystyrene:

It is convenient to install foam plastic boards on a metal or wooden surface using special glue.

Polyurethane foam. The most effective heat insulator of all listed, but also the most expensive. Apply to the surface using a sprayer. When hardened, it forms a dense foam layer with good adhesion to the surface. It is fed into a closed space (for example, between the outer and inner walls), and when hardened it expands, filling it.

Insulation of an iron trailer

Before insulating an iron trailer, you need to secure the wooden sheathing.

Before insulating an iron trailer, the issue of finishing should be resolved. The design of a metal cabin is quite simple - it is a frame made of profiled pipes, sheathed with corrugated sheets or other metal. The finishing needs to be attached to something; you can’t do without lathing. To do this, you need to securely fasten wooden blocks to a frame made of profiled pipes. Foam plastic is laid between the sheathing, since it is the cheapest. The foam is attached to the metal using foam adhesive, which has good adhesion to almost any surface.

Basic methods and their features

There are only three options for insulating such a building - these are:

recommended articles:

- Izospan: a universal insulating material

- Thermal insulation Knauf: application and characteristics of insulation

- applying internal heat insulation;

- installation of external insulation;

- and placing it in the space between the walls (this option is only possible for frame temporary buildings!).

Installation of insulating materials inside the walls is only possible if the change house initially provides for this possibility. It is extremely difficult to change an already finished design.

Internal insulation reduces the usable area of the room. Therefore, this method is not suitable for small buildings. Also, the technical properties of the material do not always allow it to be mounted on the inner surface of the walls. For example, the selected insulation emits harmful substances or is a source of dust.

Insulated cabin

External thermal insulation is the best choice for most cases. This method has a number of advantages, such as:

- significant savings in indoor space;

- providing an additional protective layer on the outside (bad weather has less impact on the integrity and safety of the entire structure);

- reducing the likelihood of walls freezing during the cold season;

- environmental safety - no harmful chemical compounds will end up inside the cabin.

A significant disadvantage is the necessity. The finished insulation layer must be carefully insulated from any external influence. This point is important to ensure long-term operation of the material.

Insulating a building from the inside will be cheaper - here you can use polystyrene foam or polystyrene foam (if no one lives in the shed!). The latter insulation does not have a long service life and is not suitable for permanent buildings that have been used for decades in a row.

Basic requirements for installation

When insulating cabins, it is necessary to strictly observe certain conditions for the correct execution of work:

- all enclosing structures of the room, including the floor and ceiling, are insulated;

- it is necessary to ensure that there are no gaps at joints, in walls and in places where doors and windows are installed;

- the design of the walls must include ventilation holes to remove excess moisture from the insulation;

- when installing a change house in a position raised above the ground, it is necessary to cover the base to protect the lower part from additional heat loss;

- In places where heating equipment and appliances are installed, cover the walls with penofol or other reflective material.

To secure the insulation in the form of slabs and mats, wooden slats are installed, between which mats or slabs are laid. The interior wall can be made of plywood, fiberboard, chipboard or other sheet materials. The procedure for assembling an insulated wall is as follows:

- external cladding made of metal sheets or wooden materials is mounted on the finished frame of the cabin;

- a vapor-permeable, wind- and waterproof membrane is fixed on the inside of the casing;

- vertical wooden slats are installed;

- insulation is laid between the slats and covered with a vapor barrier layer;

- Internal decorative cladding is installed from sheet materials or wooden lining.

A variety of modern finishing materials allows you to create a beautiful, stylish interior inside the cabin.

Video lesson on how to do the job

How many myths are there about insulation?

Foam is chewed by mice. Yes, it's a fact that rodents can actually make holes in this material. They don't eat it, but simply remove the barrier between them and their destination.

Styrofoam burns quickly. This is also true. But, this material has the ability to extinguish itself, and during combustion it emits 7 times less heat than, for example, wood. Therefore, it cannot be called the most flammable.

All mineral wool is the same. This is wrong. Mineral wool, which is not basalt, can be made from various minerals, slags, including glass. It differs in many characteristics. View all construction myths

How to prepare a shed for winter

If properly insulated and provided with heating, a dacha shed may well be suitable for living in the winter.

How to properly prepare your shed for winter:

- Floor insulation on subfloors;

- Insulation of the ceiling base;

- External wall insulation;

- Replacement or improvement of window design.

As practice shows, the weakest link in a cabin is the floor

Therefore, even during construction, it is important to correctly determine the foundation (it is necessary; putting a change house on the ground is bad manners and there is no way to warm it up properly).

To insulate the subfloor, you will need a wooden beam with a cross section of 50x50 mm, mineral wool, a vapor barrier film, a floorboard and a solution against wood insect pests. Initially, the existing floor surface is cleaned of dust and a protective emulsion is applied. Also, in parallel, the entire wooden beam is treated with the solution. When the floor base has dried well, a vapor barrier film is spread on it with the glossy side facing away from you. Next, retreating 10-15 cm from one of the walls of the change house, parallel to the wall, the first beam is mounted on top of the film on self-tapping screws.

Having mounted the first beam, 100-120 cm retreat from it and install the second and all subsequent beams in the same way. At the next stage, the entire space between the beams is filled with slab or rolled mineral wool. On top of the mineral wool, on top of all the beams, a second layer of PVC film is mounted with a stapler. The insulation of the floor of the country house is completed by padding along the existing floorboard beams.

Of course, it is advisable to insulate the ceiling from the outside. That is, sheets of slate or ondulin are dismantled, mineral wool is laid and the roofing material is installed in its place. However, if this operation cannot be performed, the insulation of the ceiling in the cabins is made from nutria. If the ceiling is covered with wooden clapboard on a sheathing made of timber of at least 50x50 mm, then the space in the sheathing can be safely used for filling with insulation. But, if there is no cavity in the ceiling base, the ceiling is insulated in the same way as the floor, followed by finishing with clapboard.

When insulating the walls of a country house, work begins by covering the surfaces of the walls with an antifungal solution. When the walls have dried on their surface, a 50x50 mm beam is mounted vertically at a distance of 100-150 cm from each other. Next, mineral wool is installed between the beams using brackets or by surprise. You can, of course, use polystyrene foam for insulation, but a wooden building “wrapped” in foam plastic can quickly begin to bloom. Polystyrene foam is excellent for insulating any walls except wooden ones. Having installed the mineral wool, a film is placed on top of it and the façade board or wide lining is stuffed.

How to equip it correctly

The arrangement of the cabin depends on the size and layout of the structure. To make your house comfortable, you need to use useful squares wisely. Small-sized one-room modules will become a functional studio. In large rooms, you can install a partition in the bathroom area. A veranda and a small porch will add comfort.

Cabin designSource yandex.by

Options for cabins consisting of two blocks connected by a vestibule are considered convenient. In one zone there is a bedroom, in the second there is a kitchen-dining room and a storage system. Instead of a large bed, you can take a transforming sofa, and instead of a closet, a tall, spacious chest of drawers. A shoe rack and a hanger are installed in the hallway.

Residential change houseSource bytovok-arenda.ru

In small-sized cabins, compact furniture is used. The sleeping place is located on the short side of the rectangular “trailer”. The ramp bed is a convenient design, in the inner drawers of which you can store bed linen and things. Low shelving combines the function of seating.

Tiny change houseSource yandex.ua

For a family with a child, designers recommend using bunk beds in the cabin. The sleeping area is located on the top floor; a storage system or table is installed below. If the building is high (more than 3.5 m), then the bed is placed in the attic. To avoid stuffiness, forced ventilation is installed.

The disadvantage of change houses is low ceilings and limited space. Large windows will help correct this deficiency. Designers recommend enlarging the openings or installing sliding glass door blocks on the entire wall. Natural lighting and the absence of a partition visually make the “trailer” larger.

The kitchen takes up all the free space in the shed. Full-size cabinet furniture, 0.6 m deep, often does not fit into the limited squares of the temporary shed. Instead of a large set, narrow pencil cases are used, which are placed in the corners. Instead of a full-fledged table, a folding model or a bar counter is appropriate, and stools instead of chairs.

If the shed does not have enough space to store items, then purchase 2-in-1 furniture. A narrow sofa (bench) combines functions with a cabinet. Modular options that are easy to move around the room are appropriate. Small items can be hidden in containers. Boxes are often used as chairs.

Miniature houseSource yandex.ua

Convenient change houseSource yandex.ua

When there is a lack of free space, unnecessary interior items add a feeling of clutter to the design. Oversized furniture and options with voluminous decor are contraindicated in the room. It is better to furnish the rooms in a minimalist style. Instead of cabinets, shelving will help to visually unload the space.

Country house designSource 4archive.org

Cozy roomSource yandex.ua

Interior of individual roomsSource yandex.ua

Modules with all amenities are a popular option that is often used on the site. A properly designed temporary shed will turn into a miniature comfortable house. In order for the structure to last for a long time, it is necessary to decide on the layout, external and internal decoration.

Insulation of a wooden cabin for a summer residence

It is better to insulate wooden cabins with mineral wool, as it allows the wood to breathe.

Insulated trailers for dachas are on sale, their price starts from 20 thousand rubles for a room 1.5 by 2 meters, while thermal insulation is paid separately. Naturally, the larger the area, the more expensive. Making it yourself is not so difficult, but insulating it is even more so, so there is no point in overpaying. Regardless of the design, the thermal insulation is installed from the inside, only the technique differs.

Panel and frame structures are insulated according to the same scheme, since in both cases the thermal insulation is placed in the cavities of the frame. Do-it-yourself insulation of the cabin should be done with materials that allow steam to pass through, since this is important for wood. Any thermal insulation that is applicable for insulating frame houses is suitable: . PPU; penoizol; bulk insulation materials; ecowool; polystyrene foam in sheets and crumbs.

- PPU;

- penoizol;

- bulk insulation materials;

- ecowool;

- polystyrene foam in sheets and crumbs.

Those materials that are afraid of moisture need to be protected with special films (vapor barrier and waterproofing). They must be laid in such a way that steam from the room does not enter the thermal insulation layer, and that which does penetrate can leave the walls without hindrance. Moist air always moves from a warm environment to a cold one, and not vice versa. Look carefully at what is written on the film, it indicates which side it should be laid on. Many films are made in the form of membranes and allow air to pass in only one direction. Incorrect installation can result in the opposite result from the use of protective films.

In addition to insulating the walls, work must be carried out to insulate the floor and ceiling; the materials are the same. The only problem that almost all owners of insulated cabins face is mice. There is simply no way I can save you from them, especially in such a small area, so perhaps you should give preference to materials in which rodents do not live. As an option, you can insulate with foam insulation, but not liquid, but in sheets, it will be cheaper.

A lot has been said about how convector heaters work, because this method of heating the air is the fastest.

You can read about what is the most compact room heater.

Features of gas connections

When connecting gas stoves, water heaters and other types of equipment, flexible hoses are also used. Unlike water models, they are yellow and are not tested for environmental safety. For fixation, end steel or aluminum reinforcement is used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- made of synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

The Santekhkomplekt holding offers engineering equipment, fittings, plumbing fixtures and devices for connecting them to communications. The assortment is represented by products and materials from well-known foreign and domestic manufacturers. Discounts apply for bulk purchases, and product quality is confirmed by standard certificates. For information support and assistance, each client is assigned a personal manager. The ability to arrange delivery within Moscow and to other regions of the Russian Federation allows you to quickly receive the purchased goods without unnecessary hassle.

Upon completion of the technological and production tasks associated with the arrangement of a sewer system in an apartment building, industrial building, as well as in a private household, it is necessary to test the involved system using the forced flow method. This task is used to identify possible defects or improper installation of the entire involved sewerage part, and the test report for internal sewerage and drainage systems will be material evidence of the work on acceptance of the facility.

A visual inspection should be accompanied by inclusion in the test report of internal sewerage and drainage systems according to SNIP, which is currently represented by the current regulations of the “D” series appendix, which corresponds to SP 73.13330.2012 “Internal sanitary systems of a building”, recently a new one has been applied updated working edition according to SNiP 3.05.01-85.

The change house belongs to the category of temporary technical structures that are installed at the site of construction work and serve to store various equipment, construction materials, as well as to locate working personnel there. As a rule, construction is carried out during the warm season. Then it may not be insulated. But if construction is delayed and moves into the winter, then it’s worth thinking about insulating the cabin.

After the construction of any objects is completed, the change house is most often dismantled due to its uselessness. But enterprising land owners often adapt it for other purposes.

After a little improvement, it can turn into an excellent bathhouse or a good country house, barn or other utility room. This is where the need for insulation of such a structure arises. Metal and wooden cabins are usually insulated from the outside and from the inside. We will consider these questions in more detail.

Related works

Additional insulation of not only the ceiling, but also, just as important, the floor and walls will help reduce heat loss and, as a result, reduce the cost of heating the cabin. Professional builders also recommend sealing door and window fillings, through which a significant amount of heat is also lost. Only a comprehensive solution to the problem of insulation will lead to the achievement of the necessary energy efficiency and guarantee a positive final result.