Here you will learn:

Traditional solid fuel boilers are not capable of providing long-term combustion of up to one or two days or more.

And even impressive combustion chambers do not adequately solve this problem. Its solution will be the Stropuva boiler - equipment from a Lithuanian brand. The principle of surface combustion is used here, ensuring long-term operation from a single load of fuel. In this review we will look at:

- Construction of Stropuwa boilers.

- The principle of their work.

- Technical characteristics of the equipment.

- Popular models.

At the end of the article, user reviews will be given.

How do Stropuva boilers work?

Let's see how it is customary to start a traditional solid fuel boiler. First, we ignite small chips, and when they take up the flame, we begin to throw full-fledged firewood into the firebox. Our heat source is located below, under the wood stack. This is where the combustion spreads. As a result, the firewood burns out in a matter of hours, and a lot of thermal energy often flies away into the chimney.

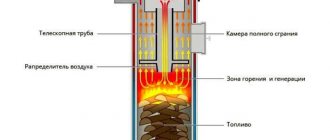

Stropuwa boilers are built on the top combustion principle. In this way they are similar to Bubafonya wood stoves - here the wood is lit from above, not from below. The prototype of these furnaces were Stropuva boilers, which have a similar operating principle. Depending on the power of the selected unit, the combustion duration can be up to several days.

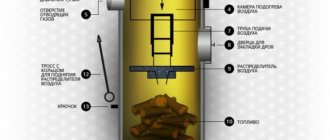

The Stropuwa boiler consists of the following elements:

- Combustion chamber – starts from the very bottom of the equipment.

- Heat exchanger – here a “jacket” of the “pipe-in-pipe” type is used. The coolant flowing through it ensures efficient heat intake and transfer to the heating system.

- Air distributor - it is located above the combustion zone and supplies air to it.

- Draft regulator – allows you to adjust the heating temperature of the coolant.

- Air heating chamber - it is responsible for heating the air masses supplied to the combustion zone. This design ensures efficient combustion of wood.

Air is taken in through a damper, combustion products are removed through a pipe in the rear (the chimney is connected to it). There are two doors in the front part - for loading fuel and removing ash.

The Stropuva solid fuel boiler has a long burning time. On one load it can work for up to several days - it all depends on the heated area, the current operating mode and the thermal power of the unit. Dried firewood, pellets, fuel briquettes or coal are used as fuel. According to the manufacturer, the burning time on coal is up to 5 days.

What to heat with?

The heat consumption for an insulated house with an area of 100 m2 (±5%) for the middle zone is 12500-25000 kW/h (depending on the “softness” of winter and the geographical location of the house). Table 1 shows the estimated costs of various types of fuel.

Firebox of the Stropuva furnace

Table 3. Calculation of fuel volume for 150 days of heating a house with an area of 100 m2

| Type of fuel | Heat released by 1 kg of fuel, kW/h | Firebox capacity, kg | Required for a season (≈150 days), tons | ||||

| S7 | S10 | S20 | S40 | min. | Max. | ||

| Firewood | 3 | 15 | 25 | 45 | 65 | 5 | 10 |

| Sawdust briquettes | 3,5 | 30-33 | 50-55 | 100 | 170-175 | 3,6 | 7,2 |

| Peat briquettes (high peat) | 2,26 | – | 55 | 110 | 175 | 5.5 | 11 |

| Peat briquettes (lowland and middle peat layers) | 2,36 | – | 90 | 119 | 190 | 5,3 | 10,5 |

| Coal DPK (large lump, energy) | 4,85 | – | 65 | 140 | 210 | 1,2 | 2,3 |

| Coal SSOM (energetic, low-caking) | 5,59 | – | 70 | 145 | 230 | 1 | 1,9 |

| Anthracite coal (fist, nut, seed) | 5,68 | – | 85 | 170-175 | 270-280 | 2,2 | 4,4 |

Main models

You can buy a Stropuva boiler in specialized stores that are dealers of the manufacturer, as well as in online stores. The minimum price is 60 thousand rubles for the minimum power model. Let's continue the review with a description of the models being produced.

Stropuva Mini S8

Before us is the smallest wood-burning boiler with a power of 8 kW, designed to heat rooms up to 80 square meters. m. It works on wood briquettes and firewood, is equipped with a safety valve and a thermometer. The heating temperature of the coolant is from +60 to +95 degrees. The maximum pressure in the circuit is up to 1.5 Bar. The efficiency of the model is 85% - a pretty good result for solid fuel equipment. The estimated cost of this boiler is 61 thousand rubles.

Stropuva Mini SP8

This boiler differs from the previous model by supporting operation with pellets. In this mode, it needs to be connected to an electrical network with a voltage of 220 Volts - the electricity is used to operate the fan used in the fuel ignition system. When working with wood and briquettes, the boiler operates in autonomous mode. The remaining parameters are almost 100% similar.

Stropuva S20

One of the most popular models. It allows you to heat residential buildings up to 200 square meters. m. The boiler is built according to an energy-independent scheme; briquettes and ordinary firewood are used as fuel. Burning time is up to 31 hours. If you want to forget about adding fuel for several days, we recommend purchasing the Stropuva S20U modification - it can run on coal, providing up to 120 hours of continuous combustion. The Stropuva S20P model can work on pellets for up to three hours.

Stropuva S40

Before us is the most powerful boiler in the entire line. Its thermal power is 40 kW, combustion duration is up to 31 hours, heated area is up to 400 sq. m. The device is equipped with a rather impressive heat exchanger jacket that holds 58 liters of water. The maximum pressure in the system is up to 2 atmospheres at an average temperature of up to +75 degrees. Over 90 kg of firewood is placed in the combustion chamber of the device. Modifications for working on pellets and coal are also available.

Other models and manufactured modifications

Also on sale are solid fuel boilers from the Stropuva company with a capacity of 15 and 30 kW. They are designed for areas up to 150 and 300 square meters. m. All models discussed in the review are available in three modifications:

- The main one is that the equipment runs only on wood and fuel briquettes (euro firewood).

- With index P – the possibility of working on pellets is provided, burning up to 72 hours.

- With index U - units with the ability to operate on coal, burning time up to 120 hours.

conclusions

- Stropuva boilers are a good option for heating residential buildings, buildings and premises of service industry enterprises, cafes, and small production workshops. The reliability of the design is confirmed by the long service life of these boilers. No completely negative reviews on the Internet about the brand’s products were found.

- Price categories: in terms of cost, solid fuel boilers of this brand correspond to gas analogues in the middle segment. The difference in price between Stropuva models is almost twofold: a minimum power stove can be found from 50 thousand rubles, a 40 kW boiler costs up to 100 thousand rubles.

Stropuva stove piping

- The optimal types of fuel are coal and firewood. No reviews were found on the use of peat briquettes and other types of fuel.

- Installation of the boiler is simple and can be done with your own hands. Given the large height dimensions, make sure you have an assistant. It is important to remember that this boiler must be installed on a foundation 10-15 cm high.

- The fire safety of the equipment and safe operation, in general, completely satisfy the owners of this equipment.

- In terms of price/quality/heating and operating costs, you can safely rate it 4+ on a five-point system.

- The manufacturer provides a 5-year warranty on all components and assemblies of the boiler.

Feedback on the operation of the Stropuva boiler

What else to read:

How to start a Stropuva boiler

First, you need to purchase a piping kit to connect the equipment to the heating system. We recommend purchasing a kit with the ability to connect an indirect heating boiler. It includes a set of pipes, a safety group, an expansion tank and a circulation pump. Also on sale are kits for connecting underfloor heating.

It is not recommended to use damp firewood - this will interfere with the normal operation of the boiler.

Ignition is carried out in the following way - here are brief instructions for use:

- We load the wood combustion chamber full with the air distributor raised.

- We fill the finished masonry with sawdust.

- Open the flap for switching to wood.

- Open the air damper 3-5 cm.

- We light the top layer, close the loading door, leaving a gap 3-5 cm wide.

- We wait for reliable combustion, close the loading door and immediately lower the air distributor.

Please note that the cleaning door must be closed.

A new portion of firewood can be added to the Stropuv boiler at any time, but doing this with coal is dangerous. In any case, the manufacturer recommends that you always wait until the fuel burns out completely before adding a new portion.

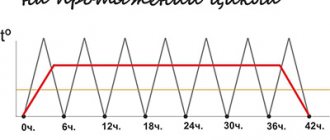

Reservation of work

The Stropuva boiler will delight you with long-lasting fuel combustion. But even in this case, you can miss the moment of the next bookmark. As a result, the temperature of the coolant in the heating circuit will begin to fall. To prevent this from happening, we recommend installing a backup electric boiler in the circuit. If it detects a temperature drop below the set limit, it will turn on and maintain the set temperature.

Electricity consumption will be small if you don’t forget to add firewood for 2-3 days. The vast majority of the time the boiler will burn, providing heat to consumers. Therefore, you should not expect huge expenses. In addition, the auxiliary boiler does not have to be as powerful as the main one - a model with a power 2-3 times lower is quite enough so as not to make your teeth chatter in the morning. We also recommend working on insulating your home so that it retains the accumulated heat longer.

Reviews from real owners

While manufacturers do their best to praise their equipment, real owners work with it. They are the ones who can tell how the equipment behaves under constant operating conditions. Reviews from Stropuvo boiler owners will definitely be useful to you when choosing heating equipment for your home.

Tired of traffic jams and noise, I moved with my wife and child outside the city, to a small village. It is quiet and comfortable here, there is no city noise. And there is no gas here. I had to buy a wood-burning boiler from the Lithuanian company Stropuva, since I didn’t want to bother with constantly throwing in new bundles of firewood. The choice turned out to be successful - for a house of 65 square meters. m of the selected boiler turned out to be more than enough. I load the logs once a day, after removing the coals and ash. Hot water is heated in an 80 liter electric boiler. The Stropuva boiler heats just fine, but in reality it still doesn’t last up to 30 hours.

I went to specialized forums to get reviews about these boilers. Some people praise them, while others complain about their low reliability. I made my choice quickly, but in the end I was wrong. It’s really better to spend more money and buy a boiler with a pellet burner and automatic pellet supply. Stropuva also knows how to work with pellets, but automation is difficult. It would be much easier with a bunker for bulk fuel. And the temperature control on Stropuv is not the best. Cleaning away ash is inconvenient. In general, the expensive purchase did not justify itself. It would be better if I took a universal boiler with a pellet burner, which could later be converted to gas.

As with everything, it has its drawbacks. When you start cleaning, smoke pours out in all directions from the still burning coals, since there is no grate here. I can’t understand how anyone could even think of doing without an ash pan. I fixed the problem, but spending almost 100 thousand rubles to fix the manufacturer’s defects yourself is an incredibly interesting activity. Secondly, reloading firewood is very inconvenient, the heat radiates into your face. Moreover, it is not recommended to do this, they say, it is necessary for the firewood to burn out completely. But in the evening there is no time to think about it - I want to sleep, and not wait for the logs to burn out. What I liked is that it heats up quickly, literally after an hour of operation the rooms become warm. Stropuva burns for a long time, at least a day. In cold weather, the burning time is reduced, but this is not so critical. For hot water, I installed a boiler in the system; in the summer it will work from the built-in heating element.

Patented combustion scheme ↑

The long-burning solid fuel boiler under the Stropuva brand is well-deservedly popular in the country due to its certain fuel versatility and affordable price.

Heating boilers using solid fuels are widely used when there is no possibility of connecting to a gas main or in places where there are problems with the electricity supply. In such cases, wood, coke or coal can be used as fuel. Also, these devices are in demand as a backup (additional) heat source.

The manufacturer of Stropuva products is a Russian-Lithuanian company that produces solid fuel boilers, the operating principle of which is based on a patented top-down combustion scheme. The long period of fuel combustion ensures continuous operation of the boiler for up to several days.

Stropuvo boilers offer such advantages on the heating market as a unique (up to 5 days!) combustion duration on one load of solid fuel, as well as energy independence and simplicity of design

Adjusting the temperature of a solid fuel boiler

The efficiency of a heating system depends on a uniform temperature supply. And if in gas and liquid fuel boilers this issue is resolved by continuous fuel supply, then in solid fuel boilers there is no such possibility. And the solid fuel itself, when burned, releases its temperature unevenly: at the beginning and end of combustion, the portions of firewood are smaller, in the middle of the process – more.

A system for regulating the intensity of fuel combustion, that is, the supply of air necessary for combustion, helps to partially solve this problem.

Thermostatic draft regulator

The boiler doors have seals, so air enters under the grates through the lower damper. The amount of opening of this blower flap is controlled by a thermostatic draft regulator .

Thermostatic draft regulator. Photo from cotlix.com

The required temperature is set on it, and the regulator itself is mechanically (by a chain) connected to the blower door. If the temperature is insufficient, the regulator slightly opens the blower door; if it is too high, it closes it.

You need to understand that a solid fuel boiler is a very inert device, and the draft regulator controls the combustion process with a large error. Therefore, the entire heating system must be designed taking this feature into account.

Fan and controller

A smoother adjustment of the combustion process is possible using a fan that pumps a specified amount of air into the firebox. The number of revolutions of the device blades is regulated by a controller that takes into account the readings of the temperature sensor and the value of the temperature set by the user.

Shiber

A damper is a damper on a chimney, otherwise called a throttle. The damper is installed after the boiler and blocks the chimney channel. Whether it needs to be installed or not depends on the equipment model. Some types of boilers are equipped with a damper as standard; in other cases, manufacturers may recommend installing an additional damper in the chimney.

The damper allows you to increase the efficiency of the heating device by partially blocking the chimney and reducing the rate of removal of heated combustion products. How much to open or close the damper can only be determined experimentally, because it depends on the outside air temperature, humidity, atmospheric pressure, wind direction and strength.

Properly selected heating equipment, and most importantly, its effective use, will bring warmth into the house, and the owners will only need to supplement it with home comfort.

Among all the models of solid fuel boilers, long-burning boilers are those that use the principle of upper combustion and have occupied a significant market niche. Stropuva, SWaG, Buran are the most famous. In addition to them, there are also a lot of small manufacturers on the market and simply clones of famous brands. For reference: the principle of top combustion itself was patented in Lithuania by the manufacturer of solid fuel boilers Stropuva. A lot has been written on the Internet about the advantages of these boilers. You can easily go to the website of any online store and read about all the advantages of this type of combustion and about the boilers themselves, but there is another side to the coin - the disadvantages of long-burning solid fuel boilers.

The easiest path that the average person takes when choosing a solid fuel boiler is typing: long-burning solid fuel boiler reviews, in the browser and, of course, the first thing they do is run into the manufacturers’ websites. (A low bow to the team of those who support these sites and monitor their positions). Next come forums where happy owners of solid fuel boilers communicate, discuss, complain, boast, swear, and generally create a certain information background, which forms an opinion, based on which the consumer will decide whether to buy a long-burning boiler or not. In principle, this is the correct approach, but it is worth considering that this is information from the lips of non-professionals, and their conclusions are made on the basis of one single boiler - which is in their home.

And that is why, for those who are going to buy a long-burning solid fuel boiler, I have collected in one place the most complete description of all its shortcomings.

There is information on the manufacturers' websites: A long-burning boiler provides burning time on one load: firewood - up to 36 hours, briquettes - up to 2 days, coal - up to 5 days.

Technical characteristics and features ↑

The Stropuva boiler consists of two cylinders, between which the coolant passes. Access to the combustion zone is through the upper and lower doors. Heated air from a special chamber enters the top layer of fuel; as the wood or coal burns out, the air distributor moves down and is always located in the combustion area. A draft regulator is used to regulate the water temperature and the amount of air required.

Stropuva long-burning boilers are available in two types: universal and wood-burning . On universal varieties there is a forced air flow to increase combustion intensity. The optimal operating mode is achieved within 2-3 hours and is maintained evenly throughout the combustion time of one portion of fuel.

Different Stropuv models make it easy to select a boiler for each room, based on the following technical characteristics:

- Power – from 7 to 40 kW

- Heating area – 50-400 sq.m.

- Burning duration – from 6 to 130 hours

- Volume of fuel placed – 150-320 cubic dm

- Equipment weights – from 180 to 330 kg

All boilers have high efficiency (86.3-86.8%) and an operating coolant temperature of about 85°C.

The duration of operation of the boiler at one load, and therefore its performance, depends on the fulfillment of certain conditions:

- The degree of insulation of the room and the correct choice of device power.

- The quality of fuel, determined by such parameters as its humidity, ash content and composition.

- Proper organization of the heating system as a whole.

- Optimal draft in the chimney.

- Professional installation.

Advantages and disadvantages ↑

Sectional diagram of the Stropuva boiler

It is worth briefly listing the main advantages of Stropuva boilers:

- Cost-effectiveness and convenience - their installation does not require an expensive gas supply, and the long duration of work on a one-time fuel supply saves money and time.

- Energy independence - there are no electronics in the design, so wood-burning boilers, when used in a gravity heating system, do not require electricity.

- Safety and reliability - one of the advantages is control using a bimetallic valve - a simple and trouble-free draft regulator.

- Aesthetics along with simplicity - STROPUVA boilers differ from similar types of devices in their elegant appearance and compact placement. The clear design of the unit eliminates any difficulties during operation.

Among the disadvantages, the following can be noted: their performance is greatly affected by the humidity of the loaded fuel. But this is rather a minus of all solid fuel boilers, and not of a specific brand in particular. The solution here is simple - keep firewood or coal in a dry place.

Reliability and safety

Stropuva pellet boilers are not equipped with complex, malfunctioning automation. The boiler is controlled by a fairly simple in design and non-volatile bimetallic draft regulator. This solution gives the boiler high reliability and stability in operation.

The boiler is designed in such a way that, unlike diesel, electric or gas boilers, if the load is repeatedly exceeded, it will not explode, but will shrink inward. The manufacturer is confident in the quality of the equipment produced and provides a factory warranty of up to 5 years.

Consumer reviews ↑

We were able to collect several reviews from conversations with users of Stropuva boilers in Russia.

Vasily Nikolaevich Nazarov: Before last season, I bought an S20U boiler for my woodworking workshop. Once every 5-6 days you fill a full bunker with coal - and that’s it, no problems. With pieces of wood, of course, there is more hassle, but I still need to put them somewhere.

Oleg Vladimirovich Serov: The main thing is to correctly determine the required power. There is no point in taking based on the principle: the more, the better. Each model will be effective where it is designed, and the price will be higher - why overpay?

Andrey P.: I have a dacha, there’s not even light there always. At first I tried to heat it with gas from cylinders, it was a hassle and too expensive. Now I have installed a small wood-burning unit with ten kilowatts, the car has enough firewood for the winter. I heat it 2-3 times a week, the house is 6x12 meters plus massandra, I haven’t seen any shortcomings yet.

For using wood materials as fuel and heating buildings up to 100 square meters. meters, it is enough to purchase a Stropuva S10 boiler (power 10 kW) costing about 80 thousand rubles. A universal solid fuel unit model S40U, capable of heating a room of at least 200 square meters. meters will cost the buyer more - about 120,000 rubles.

Checking the boiler after assembly

Checking the boiler after assembly

Before accepting a homemade Stropuv boiler for permanent use, be sure to ensure that it is in good working order and reliable. Don't ignore this step. The safety of further operation of the heating unit directly depends on a correctly performed check.

Fill the barrel with wood to about a third of the height. Add some kerosene and throw a lit match into the container. Ideally, the wood will ignite almost immediately. At the same time, you should not notice the presence of smoke, or any draft, or any kind of uncharacteristic odors.

STROPUVA

If any of the above symptoms are present, do not use the boiler. Such equipment is very likely to soon fail and harm its owners. But if you assembled the unit in strict accordance with the instructions above, there will be no problems.

The amount of firewood given earlier will be enough for approximately daily heating of a small room. If the room is medium sized, double the loading volume.

Thus, you can assemble an excellent sling boiler for heating a variety of small and medium-sized rooms with your own hands. Now you don’t have to spend a lot of money on buying expensive equipment. You just need to follow the instructions in everything and your home will always be warm and cozy.

Good luck!

Operating instructions for boilers Stropuva ↑

- First of all, you will need to adjust the bimetallic valve. To do this, before the first kindling, use the adjusting screw to set a gap of 3-4 cm between the heating chamber and the damper. Next, the boiler is ignited and when it reaches 70°C (if wood) or 85°C (if coal), the damper is lowered with the same screw, stopping the further increase in water temperature.

- Firewood is laid horizontally until the firebox is fully loaded, and a layer of wood chips and sawdust is poured on top. You can use kindling liquids for stoves. It is possible to replenish fuel during operation, but this reduces combustion efficiency for a short time.

- To use coal, the boiler must be equipped with an air supply manifold. The coal is ignited using firewood weighing about 5 kg, loaded on top. When the boiler is operating, the fuel is never mixed - this can lead to combustion failure.

- It is not recommended to use too fine fractions - both wood and anthracite or coal. After the bookmark burns out, it is necessary to remove the remaining ash.

Bubafonya stove with water jacket

Pyrolysis furnace Bubafonya from a gas cylinder with a water jacket.

Finally, we got to the domestic analogue of the Stropuva boiler, which is much simpler to implement, since it has a non-folding pipe for supplying air to the firebox. There are already so many instructions on how to make a Bubafonya stove with your own hands that only a blind person would not have seen them, unless, of course, they were interested in this topic. And why all? Yes, because the process is so simple and if you take the matter seriously, you can get a finished product from scratch in a day. What is the Bubafonya stove made from with your own hands:

- from a gas cylinder;

- from a barrel;

- from pipes

It can be either round or square. Let’s not repeat the same thing, just read the article: “Bubafonya stove from a gas cylinder” - and everything will become clear to you. Today we will consider a version of the product with a water circuit, as if we will try to repeat the principle of operation of the Stropuva boiler. All that is required is to make a simple Bubafonya and insert it into a pipe of a larger diameter. Thus, we obtain a gap in which the coolant will be heated.

Naturally, this space above and below is sealed so that various debris does not get there. What is important when making a Bubafonya stove with a water jacket with your own hands:

- use of heat-resistant steel;

- wall thickness of at least 4 mm;

- the presence of a tap for draining and replenishing water.

Immediately provide a hole in the upper part through the outer and inner walls for installing a chimney into it. There should also be enough space for water. The distance from the outer to the inner wall is about 10 cm. When connecting, do not confuse the supply and return pipes (supply from above).

Wood-fired boilers Stropuvo

The design and arrangement of all Stropuva solid fuel equipment is based on the principle of top combustion. Thanks to this, the boiler can operate for up to 30 hours from one fill. At the same time, the efficiency reaches 86.3%.

The Stropuva long-burning solid fuel wood boiler is designed for heating small houses and cottages with a maximum area of up to 400 m². The line includes five models with performance from 8 to 40 kW.

It is prohibited to burn long-burning wood-burning boilers at Stropuva with coal, as this may lead to loss of integrity of the heat exchanger. It is better to burn coal using combined universal models.

A small disadvantage of top-burning wood-burning boilers is that you can load wood into the firebox only before kindling; it is impossible to refuel during the combustion process.

Top combustion boiler

In the post-Soviet space, these heat generators are known in two varieties:

- Baltic units (Stropuva) and their derivatives from other manufacturers.

- Wood-burning stoves of the “Bubafonya” type.

It is not known which of the heaters appeared first, but the Bubafonya stove has gained wide popularity as a heater for cottages, garages and other buildings with low requirements for the aesthetics of the product. The same cannot be said about top-burning boilers, although many for some reason consider them to be the only possible version of continuous-burning solid fuel heat generators. In fact, their only trump card is still the same - a large firebox.

The principle of operation of such boilers is to burn fuel, pressed down by a load, in a direction from top to bottom. Moreover, air is supplied to the combustion zone from above, through a telescopic pipe connected to the load. The operating diagram of the unit is shown in the figure:

Original boiler diagram, taken from the website stropuva.ru

During the operation of Stropuva boilers, many shortcomings appeared, as evidenced by reviews from owners on the forums:

- You cannot add logs to the firebox until the previous one has burned out. Physically this is possible, but then the principle of top combustion will be violated, the flame will engulf all layers of fuel.

- When working on fresh sawdust and other small debris, fuel residues “hang” on the walls.

- The efficiency of a TT boiler is not very high because it does not have a heat exchanger. Due to the air heating chamber and the large firebox, there was no room left for the heat exchanger.

The heat generator has no other critical shortcomings, and some things in the homemade version can be corrected according to your own understanding. For example, install a bottom and grates, organizing an ash chamber. You can also get rid of the problem with additional loading if you install an additional door between the loading and ash opening. This idea of upgrading a top combustion boiler belongs to another of our experts, Vladimir Sukhorukov, which he talks about in his video:

Preparation of materials

A round body creates some inconveniences in manufacturing, but you can’t make it square either - the fuel will “hang” in the corners. There is also a problem with assembling the telescopic pipe with a load, so it is better to take this part from the Bubafonya stove. A drawing of a long-burning boiler, comparable in size to the classic version, looks like this:

Before making a boiler, we select materials according to the drawing:

- pipe DN 400 with a wall of 5 mm - for the firebox;

- the same, DN 50 – for air supply and water pipes;

- the same, DN 100 – for the chimney;

- a round blank made of 10 mm thick sheet with a diameter of 38 cm;

- strip 40 x 4 mm – for air distributors;

- reinforcement with a diameter of 16-20 mm of a periodic profile - on grates;

- basalt wool 3 cm thick and density 100 kg/m³;

- thin sheet metal with polymer coating.

The choice of water jacket material depends on the method of its installation, because a home craftsman is unlikely to have rollers in stock that can give 3 mm thick metal a cylinder shape. The options are (shown in the diagram below):

- Scheme No. 1. Take a thin-walled pipe of larger diameter, although it is not easy to find one, and a regular one will make the boiler much heavier.

- Scheme No. 2. Bend two sheets of metal in 2 places at an angle of 60°, and then weld the two halves together. You will need a sheet press.

- Scheme No. 2 in a different design. Cook a shirt from 6 sheets - segments on clips.

- Scheme No. 3. Weld a rectangular box, which will increase the volume of the boiler tank.

Scheme No. 2 can be implemented in two ways - welded from 2 bent halves or 6 flat sheets.

You will also need 3 mm sheet metal for the frame of the doors, the bottom with a lid and the air damper.

Manufacturing of heat generator

The work begins with cutting out blanks and openings in the pipe wall according to the dimensions in the drawing. Doors are made from the cut out parts, and awnings and purchased handles are attached to them. The grate shown in the photo is made from the reinforcement:

In general, the algorithm for assembling a top combustion boiler looks like this:

- Cut a hole in a round blank for the load, insert a pipe into it and weld it.

- Weld 6 curved strips to the bottom of the load to serve as air distributors.

- Attach the bottom to the firebox and install grates inside.

- After cutting a hole in the center of the cover for the air pipe, attach it to the firebox. Before this, you need to put the pipe with the load in place.

- Weld the chimney pipe.

- Install the water jacket according to the chosen scheme, seal all joints.

- Make connections for coolant pipes.

- Perform insulation and casing of the boiler, install doors.

- Place a damper on the top of the air pipe.

Six distribution strips are sufficient to distribute air.

It is difficult to install automation and pressurization on a long-term top-burning boiler, since you cannot attach a fan to a moving pipe. It is necessary to make a flexible hose, and provide a submersible sleeve for the temperature sensor. It cannot be placed under the insulation, because the combustion zone in this type of heater is constantly moving downward.

It is better, of course, to test the boiler outside

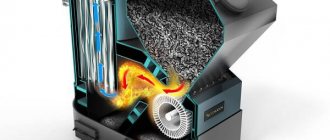

Stropuva pellet boilers

Stropuva solid fuel pellet boilers can operate in two modes.

- Designed for burning wood in long-term burning mode. At the same time, autonomous combustion from one stack of firewood is ensured for 30 hours, with minimal load.

- The operating mode is associated with the ability to burn with pellets. Burning from one bookmark to 72 hours.

Dual-fuel boilers have almost identical technical characteristics as equipment that runs exclusively on wood.

Pellets are burned using a special burner, which gradually goes down as the pellets burn out. This design of the Stropuva solid fuel pellet boiler allows you to increase efficiency and reduce heat loss. Due to the fact that the coolant circulates around the entire heat exchanger, its rapid and uniform heating is ensured.

Advantages and disadvantages

Reviews from owners indicate that heating boilers from this company have many advantages. Stropuva is better than its counterparts in many ways. The main advantage, of course, is continuous combustion and the ability to use one bookmark for a long time. For example, if you choose coal as fuel, then one load will last for almost a week, and briquettes will last for two days. If you have to heat the room with wood, then the stash will last for thirty hours. Standard models can function on one tab for no more than eight hours. According to users, the device is very easy to use and there are no loading issues with it.

Stropuva boilers are also quite economical. They themselves are relatively inexpensive, as well as the fuel used, which can be ordinary wood, coal, wood chips or other common materials. If we compare Stropuva products, which are solid fuel devices, with a conventional pellet boiler, the benefits will be obvious. There will be no unnecessary fuel consumption - only as much as needed. You can change the mode depending on changing conditions and thereby extend the burning hours of one bookmark. For example, if it gets warmer outside, less energy will be required, which means the boiler will run on fuel longer. When switching to Stropuva, heating costs are reduced by approximately half.

The boiler from Stropuva always works in the best mode. A conventional boiler operates until all the fuel is burned, and in a short period of time produces a huge amount of heat. Therefore, you have to either constantly update the bookmark, or supplement the design with a heat accumulator that will store heat. In Stropuva, only a small part of the fuel is burned and no additional devices are required. The efficiency of the boilers reaches 90%, and the boiler itself is non-volatile and can work with almost any solid fuel. Even if there is no electricity in remote areas, Stropuva will still be successfully operated. It is also worth mentioning that the boiler itself is quite compact and does not take up much space, it is very easy to clean, and it can function for up to 5 years.

Boilers of this type are distinguished by their safety for users. The device is made of steel, characterized by increased heat resistance and heat resistance. If there is a fire, the boiler will not explode anyway. In addition, the design is equipped with a special protection valve, which in case of danger activates the extinguishing mode. Stropuva can be easily equipped with radiators and boilers, connected to underfloor heating, as well as any heating system. You can set different temperatures for different connections. For example, the heated floor will maintain a temperature of 33 degrees, and the radiators will maintain a temperature of 55 degrees.

Universal boilers Stropuva

The advantages of the multi-fuel series include the ability to operate the boiler on almost any type of solid fuel:

- Coal.

- Pellets.

- Wood waste.

- Firewood.

The Stropuva universal solid fuel boiler, according to research and consumer reviews, can be classified as one of the most economical types of heating equipment produced by the Stropuva company.

The use of wood waste only is not permitted. With each fire, you will need to add a small amount of high-quality solid fuel. Stropuva universal dual-fuel coal-wood boilers require regular maintenance.

In practice, it has been proven that it is better to use coal for a combination boiler. This type of fuel significantly increases the battery life from one load, as well as the efficiency of heat transfer. In normal mode without extreme loads, the unit can operate for up to 130 hours. Firebox capacity 220 kg. It is not allowed to add coal during combustion.

Installation and operation of Stropuva boilers

When installing and connecting, you must adhere to the basic rules that apply to all solid fuel units. The housing contains two outlets for supply and return of coolant, and connections to the central heating of the house.

It is mandatory to install an overheating protection system. If necessary, install circulation equipment.

A check valve and a coarse filter must be installed in the boiler piping. For the universal and pellet models, you will additionally need to purchase and install an air manifold.

The chimney is located on the rear side of the housing. It is recommended to install the chimney using insulated sandwich pipes.

Cleaning of carbon deposits is necessary after each fuel burnout. This is done through a special hatch located at the bottom of the boiler.

Kindling is carried out as follows:

- The air damper opens and the draft regulator is fixed in the raised position using a cable.

- Firewood is laid in layers. As a rule, large logs are placed in the center of the firebox, small ones at the edges.

- The top layer is filled with sawdust and wood chips. It will not be possible to add firewood until the already stored fuel has burned out, due to the internal structure and operating principle of the unit. Therefore, it is immediately necessary to fill the firebox completely (with the exception of the first kindling).

- The reason for the lack of draft may be the accumulation of soot in the smoke exhaust manifold, as well as insufficient heating of the chimney. Therefore, it is recommended to leave the damper open until the wood burns. This will provide good traction and reduce the formation of condensation.

Hole for cleaning hard-to-reach places

To clean hard-to-reach places, universal versions of boilers have a technological hole in the cover of the air heating chamber. The hole is covered with a plug. To access the hole, it is necessary to remove all boiler attachments in the upper part of the boiler (adjusting flywheel, air damper, roller cable lifting system, coal-wood mode switching comb, manifold with fan).

Before removing the roller system, it is necessary to unfasten the cable from the upper part of the lower segment of the telescopic pipe, through the hole in the pipe covered by the air damper.

Next, you need to remove the cladding cover, having first unscrewed all the fixing elements (screws).

Directly under the lining cover there is a cover for the air heating chamber, in the back of which there is a plug. By unscrewing the fixing elements (screws), access is provided for cleaning hard-to-reach places along the edges of the junction of the chimney with the boiler shell.

Upon completion of cleaning, it is necessary to reassemble the boiler. Reassembly is carried out in the reverse order identical to the disassembly process.