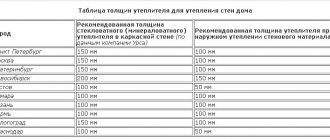

A wet façade is a more complex technology for exterior wall finishing when compared to ordinary siding. This technology for processing construction projects implies the need to install insulating materials, which are most often used polystyrene foam or mineral wool. This finishing method got its name because in the process of cladding a building one has to deal with a variety of mixtures and solutions. The facing surface is ordinary plaster, which can have a different relief and be painted in any color.

What is a wet façade?

The name of this device does not at all mean that water will constantly flow down such a facade. On the contrary, it is precisely from moisture that it should protect the building. It was called wet because of the installation features - it uses several types of compounds that need time to dry.

The technology for installing a wet facade involves multi-layering. Each layer is responsible for a certain quality - thermal insulation , structural strength, fastening to the wall, protection from moisture, decorative function. An important role is played by insulation and moisture protection - the design of the facade is such that it allows moisture to pass through from inside the building, but does not allow it to pass through from the outside. is carried out incorrectly , this property may be lost, and moisture will begin to condense in the insulation .

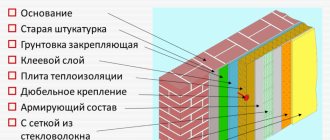

Figure 1. Installation of a wet facade

A properly made wet façade requires the following features:

- Tight fixation to the wall, as well as strong connection of all layers to each other;

- Reduced vapor permeability from the inside out;

- Structural strength;

- Light weight that does not create additional load on the foundation;

- Possibility of using any decorative solution;

- Ease of use in houses of any size and purpose - private, multi-apartment, offices.

In a private house, you can do the work of installing a wet facade yourself if you carefully read the instructions for the products used. But it is better to enlist the help of professionals who have the necessary knowledge for installation. Not any time of year is suitable for work; you need to wait for suitable weather and protect the walls from the adverse effects of the external environment. Materials are selected based on the characteristics of the walls.

What is the difference between insulation materials?

If this material is so good, then why is mineral wool used? The high elasticity index makes it possible to cover internal and external curves on surfaces. Mineral wool will always be in close contact with the wall. The high sound insulation rate makes it possible to install a wet façade with such insulation on a building located close to a noisy highway. Mineral wool allows more steam to pass through it than polystyrene foam.

When a wet facade is designed, the size of the insulating layer is selected in such a way that moisture does not collect in the walls and the house remains warm. All efforts will be in vain if water vapor penetrates the wall from inside the building. Wet structures will always freeze strongly and such finishing will not last long in the future. To make the correct calculation of the material when designing a wet facade, you need to contact specialists, and it is first recommended to obtain the necessary data yourself, using one of the online calculators.

Advantages and disadvantages

The installation of a wet facade is considered the best choice that can be made, combining low price, ease of work and the desired quality. An alternative is wall-mounted structures, which create the same effects due to a sealed air cushion between the wall and the outer layer. Compared to them, wet technology has both advantages and disadvantages.

The advantages of a wet facade, in addition to simplicity and low cost:

- Reliable heat and moisture insulation. The insulation layer completely eliminates the problem of heat leakage from the building, and also prevents the formation of condensation in the room and inside the walls;

- Noise insulation – insulation dampens sounds from the street well, which is important for residents of private houses and the first floors of apartment buildings;

- Correction of defects in external walls - if the walls are uneven, a wet façade can correct this;

- No load on the foundation - unlike suspended structures, a wet facade has virtually no effect on the weight of the building, and there is no need to additionally strengthen the foundation for its application;

- The work can be performed at any stage of the house’s operation, unless the property has become dilapidated.

Serious disadvantages of wet facades include the demanding conditions in which the work is carried out. They are only possible in summer, in good weather, using protection from wind, sun and rain. Violation of technology at any stage will lead not to improvement, but to deterioration of conditions in the house, the appearance of mold inside the walls and in the building, high humidity, and destruction of insulation. It is also impossible to install a wet facade in dilapidated housing, and hanging devices can extend the life of such houses.

Mineral wool or polystyrene foam?

Many different nuances can affect the choice of material for wall insulation. It cannot be stated unequivocally that mineral wool or polystyrene foam is best suited for installing a wet facade.

Expanded polystyrene weighs much less, performs excellently during building operation, does not allow condensation to pass through, is used almost everywhere and is more affordable. However, all positive properties will be minimized if there are mice in the building. In the external walls of houses, the insulation of which was carried out with special facade foam, the level of contained vapors will be slightly higher. This feature causes them to become moisturized. The fire resistance level of polystyrene foam is the lowest possible.

The area of use of mineral wool is also very wide. The material is used in the household, shipbuilding, manufacturing, automotive industries, as well as in agriculture. At the same time, mineral wool is less resistant to moisture, and also has relatively high thermal conductivity and fire resistance. For external insulation of wet facades, it is necessary to use high-density basalt-based material.

It is impossible to say unequivocally which material is better suited to replace insulation when designing wet facades. The choice will always be determined by the area in which certain components will be used, as well as many different nuances that should always be taken into account when designing. It is best to entrust this task to real professionals, whose highly specialized activities include determining the necessary materials. Each homeowner can always do an independent calculation if he is confident in his knowledge, but he will also have to be responsible for the result himself.

Source

Kinds

Figure 2. Installed insulation for a wet facade

Wet facades are divided into several types depending on the insulation used, on which the plaster for the external coating depends. Main types of insulation:

- Expanded polystyrene in combination with acrylic or silicone plaster;

- Mineral wool in combination with mineral or silicate finishes;

- Combined insulation with a mineral composition.

Each type has its own advantages and disadvantages.

Expanded polystyrene (foam)

The density of this insulation is the highest; it effectively protects the wall from moisture and heat loss. Significantly reduces heating costs in winter and air conditioning in summer, maintaining a stable temperature inside the house. Used on facades made of dense heavy materials - brick, concrete, cinder blocks. This technology is suitable for multi-storey buildings, the walls of which are made of such materials.

The wet facade uses several layers of foam with different vapor permeability to effectively remove moisture from the walls. The installation of foam plastic insulation in houses with walls made of porous types of concrete will lead to the opposite effect - water will accumulate in the pores of the concrete, gradually destroying the walls.

The main disadvantage of a foam-based device is its flammability. In addition to the actual ignition of the walls, when such a wet facade burns, extremely toxic smoke is released. To solve the problem, special impregnations are used to make the insulation resistant to fire.

For decorative purposes, two types of plaster are combined with polystyrene foam - acrylic and silicone. Acrylic resin is an organic substance with great plasticity. The plaster is produced in the form of a water-dispersion composition, the permeability to steam is average.

Silicone resin, which is part of silicone plaster, makes it extremely durable, resistant to any weather conditions, and does not allow or absorb water. It definitely requires preliminary priming with a special composition, preferably of the same brand as the plaster itself, otherwise all its useful qualities are nullified.

Mineral wool

This is a lightweight material with high vapor permeability, best suited to porous walls made of lightweight concrete. Not any mineral wool is suitable for a wet facade, but only basalt wool of increased strength. made from basalt has another important property - it does not burn at all. The bottom layer can be softer to compensate for uneven walls. The rule of reducing vapor permeability from the inside to the surface remains the same.

Plasters that are used in conjunction with mineral wool have high vapor permeability. This is a cement-based mineral plaster that easily allows steam to pass through and does not burn; a more expensive option is silicate plaster (not to be confused with silicone). It requires special primer, is expensive, but has an excellent appearance and is very durable.

Combined materials

This is a combination of foam and mineral wool in the wet facade. Two types of insulation make it possible to provide good insulation and protect the finished façade from fire. Only mineral plaster is used with them; other solutions are rarely used. It is distinguished by high reliability, but also by the same high cost of work.

Description of materials

Today, not a single building renovation project is complete without external cladding.

There are a huge number of different types of insulation materials available on the market. A wide range of possible varieties allows finishing of a wide variety of construction projects. When cladding residential buildings in our country, a wet facade is often used, and foam plastic or mineral wool is used as insulation. Knowledge of the composition and technology of these materials helps every homeowner make the right choice.

Polystyrene foam is produced by heating polystyrene granules. The material is given a certain density during manufacturing. After this, the foam is cut into separate blocks of standard thicknesses of 20, 30, 50 and 100 mm. The size is determined by specialists when designing each specific construction project.

Each individual granule contains air inside, which increases the moisture resistance and vapor permeability of the substance.

The main advantage of a material such as foam is its lightness. The stove is almost 98% air. This feature has a very favorable effect on the thermal insulation properties. Extruded foam differs only in the manufacturing principle. This is a solid homogeneous plate, endowed with identical properties, but at the same time has a higher elasticity index. A wet facade cannot be installed with such insulation. Extruded foam plastic is often used in floor thermal insulation systems due to its resistance to various influences, elasticity, and moisture resistance. The high cost of such material is justified by its quality.

Mineral wool consists of fibers of basalt minerals on synthetic connecting components. According to its characteristics, the material resembles ordinary asbestos, but at the same time it is absolutely safe. Mineral wool does not support combustion processes at all and has a very impressive moisture resistance indicator. These features make it possible to use the material not only as a means of absorbing noise, insulation, but also as a heat insulator. Mineral wool is also often used in the design and installation of chimneys, sauna stoves, and fireplaces. Areas of use:

What layers does a wet façade consist of?

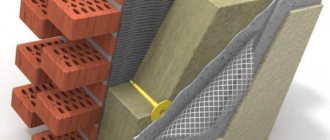

Figure 3. Installation of insulation for a wet facade

The wet facade is applied in several layers, each of which has its own function. Main elements of the device:

- The first adhesive layer is applied directly to the wall and is needed to secure the entire device. There should not be any unreliable parts under it - remnants of paint, plaster, etc.;

- Insulation under a wet facade is the main part of the device;

- Base adhesive layer - provides a connection between the insulation and the reinforcing mesh;

- Reinforcing mesh - necessary for the strength of a wet facade;

- Finishing adhesive layer – fixes external decorative elements;

- Plaster – creates the necessary texture of the wall;

- Primer – ensures uniform application of paint;

- Paint – completes the appearance of the facade.

Each layer takes time to dry, so the work takes several weeks in total.

Wet façade installation technology

Everything is important when installing a wet façade. If the house has just been built, then external work is one of the final elements of the work; if repairs are taking place, it is important to make sure that everything necessary has been done in the remaining parts of the house, namely:

- The foundation is isolated from water;

- Roofing installed;

- Engineering communications are connected and working properly;

- Work on windows and doors has been completed;

- Floor screed completed;

- Interior finishing work has been completed.

Those. When renovating and building a house, the installation of the facade occurs last. For work, you need to choose a warm time of year - the temperature outside should not fall below +5˚. The ideal period is mid or late summer, when dry and warm weather has firmly established itself. Before you begin installing a wet facade, you need to provide protection from wind, direct sunlight and sudden rain. Construction film is used for this purpose.

Installation and installation of a wet facade with insulation in rainy weather is contraindicated. This way you can achieve a result that is exactly the opposite of what you expected.

Stages of work

Main stages of work:

- Preparatory stage. Scaffolding is installed there, as well as a thorough inspection and cleaning of the wall surface. It is necessary to completely remove construction debris, dust, dirt, and when renovating a house - traces of the old decorative coating to the state of a bare wall. If there are cracks, they need to be repaired.

- Installation of the base profile - metal structures that will hold the wet facade and be used as guides for its application.

- Installation of insulation. The wall is treated with an adhesive composition, then blocks of the selected material are placed on its surface. You need to start from the bottom edge - so the lower blocks will rest on the base profile, and each row above will rest on the underlying rows.

- Fixation and reinforcement. Occurs 1-3 days after installing the insulation (the time depends on the composition of the glue). The wet facade slabs are additionally fixed with dowels, then a plaster solution (base adhesive layer) is applied, and the reinforcing mesh is embedded in it.

- Finishing work. Carry out after the base adhesive layer has dried. The wall is treated with plaster, primer, and paint to create the desired aesthetic solution.

Artificial stone or decorative panels can be used as external finishing - this will give the wet facade additional strength. A prerequisite is that the finishing must be light, otherwise the structure will not last long.

Plastering insulation

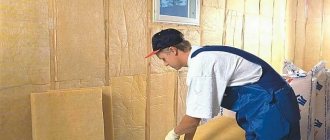

Figure 4. Plastering a wet facade

Plaster on a wet facade performs two functions - an additional moisture-proof layer and a decorative design. Its choice depends on the type of insulation, expected weather conditions and the desired effect. The most durable plasters are silicone (used with foam plastic) and silicate, also known as liquid glass (used with mineral wool).

With the help of plaster, you can create a smooth surface that is convenient to paint, and when used, it can be kept in order; dust and dirt will not settle on it.

Various types of decorative plaster can create a surface that imitates wood, stone or any other uneven texture. This will make the appearance of the house beautiful and unusual. Requires special tools for application and subsequent painting. Dirt may become clogged in uneven walls; such a façade will need to be cleaned occasionally.

Colored plaster gives an additional shade of color and allows you to use transparent materials instead of paint. Can create both smooth and decorative surfaces. It has the same advantages and disadvantages as colorless plaster for a wet facade.

Installing a wet facade is a great way to make your home warm in winter and cool in summer, and show your design talent in decorating walls. Having assessed the advantages and disadvantages of the design, you can choose the most suitable insulation and plaster and begin installation.