Convectors that use gas for operation can hardly be called a popular type of heating equipment. They are used much less frequently than their electric counterparts. However, a gas convector in a wooden house, if used correctly, can become an effective heating option. This is confirmed by numerous reviews from owners of various residential buildings who use this equipment in practice. Of course, it is quite problematic to finally determine which is more convenient, efficient and profitable: a gas convector or an electric boiler, since both options have very serious advantages.

How to heat a country house without mains gas, money and electricity?

The question is both complex and simple. If money is short, then complex and expensive systems that require expensive equipment and hassle-free installation are not suitable for you. Electric convectors are also no longer needed. Although they are inexpensive and easy to install, they are demanding in terms of allocated electrical power. If you have 15 kW, then there are no questions, but if it’s less, or do the lights often turn off? So you can freeze! RuslanM offers a solution.

- Two systems - insurance against accidents and disasters.

- You won't freeze if the power goes out.

- Both options can be installed with your own hands and without spending money on specialists.

- By combining liquefied gas + solid fuel, you increase the overall operating time of the heating system.

For example, during the day, while you are at work, gas convectors work, and in the evening you light the fireplace and get pleasant warmth from a real fire.

Ruslan's house.

Gas convector.

Cast iron fireplace stove with ceramic chimney.

Looking ahead, we will say that Ruslan also installed an original homemade gravity heating system in the house, a “warm baseboard” with a “heart” in the form of a cheap solid fuel boiler. We will talk about it at the end of the article, and now, about the first two options. Go!

What is a gas convector

It should be noted right away that a convector is not a type of boiler; it works not only on a different principle (it heats not the coolant, but the air in a certain room), but also has a slightly different area of application. Most often, gas heaters are used in small houses where there is no need for constant heating. They can only heat the room where they are installed.

What does a convector consist of?

The design of the device is not too complicated, it includes:

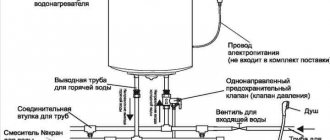

Diagram of a standard gas convector with a fan for forced convection.

- a heat exchanger that heats the air;

- programmer – a device for controlling and maintaining room temperature;

- control panel, which contains various indicators;

- gas valve to control gas supply;

- a fan supplying air to the valve and heat exchanger;

- a fan that provides forced supply of warm air into the room.

Gas convector - operating principle

As you can see from the diagram, everything is quite simple. The convector plays the role of a gas burner; cold air enters from below under the influence of convection, heats up and exits through the hole at the top.

The device works quite simply: the operating principle is based on the phenomenon of convection - warm air rises when heated and cold air falls. Gas models can operate using either natural or forced convection. In the latter case, a special fan is used to supply air.

Advantages and disadvantages

The quality of the device itself, as well as its performance, depend on the price. By choosing a cheap model, you will not save money, since the device may last you less than a year. Repairs in the current situation will not be cost-effective. Therefore, we will consider the advantages and disadvantages based only on high-quality devices. So, the pros:

- efficiency and quick heating of the room;

- easy installation of a gas convector with your own hands;

- there is no need to make a heating system (water);

- low price;

- unlike electric analogues, gas models do not burn oxygen;

- completely autonomous operation mode;

- not connected to electricity (except for convectors with forced circulation);

- It is possible to connect the heater to a gas cylinder.

But gas convectors are not without their disadvantages:

- if gas is used from a centralized system, then it is necessary to obtain permission to connect the device;

- it is necessary to punch holes in the wall outward where the heater will be mounted;

- considerable dimensions;

- if you decide to install several convectors, then gas will have to be supplied to each of them, and only from outside the building.

Choose models with a built-in fan. They are more efficient than their fanless counterparts.

Types of convectors

Devices can be classified by their power, as well as by design. If everything is clear with power: choose the one that can heat the room, then with the types of performance things are a little more complicated.

There are two types of heaters:

Wall-mounted models can fit very well into the interior.

- Floor-standing – devices are installed on the floor and do not require special installation skills. Such a convector can heat a fairly large room (even an industrial one), but it is heavy and requires a special base.

- Wall-mounted are more compact models that fit well into the interior of the house. Often the devices are mounted under the window to create a thermal curtain from cold air passing through the glass. Convectors of this type have low power, so they are only suitable for heating rooms in houses up to 100 square meters.

There is another subtype of heaters - built-in. They can be installed in the floor or wall, and not only do not spoil the interior, but also decorate it. In terms of parameters, such models do not differ from wall-mounted ones. But installing them is more difficult, since it is necessary to prepare a niche for the device in advance.

When choosing a convector, you should also pay attention to the material of the heat exchanger. The latter can be made of steel, cast iron or copper

Nowadays, models with a steel heat exchanger are more common, but cast iron ones have greater efficiency due to the properties of the alloy, and are also able to last longer. Their only drawback is their heavy weight. Copper analogues are effective and durable, but expensive.

All convectors under consideration are closed. Open ones also exist, but they take the air necessary for gas combustion from the room, and the waste enters the general ventilation. Due to these properties, it is highly not recommended to install open-type heaters in residential premises.

Device design and operating principle

Let's start with the definition of a gas convector. This heating device is not an analogue of a gas boiler. It works on a completely different principle - it heats not the coolant, but the air. Gas convectors are installed in relatively small rooms, as they heat the air locally.

The design of this heating device is relatively simple. The gas convector consists of the following parts:

- heat exchanger in which air is heated,

- programmer - a device responsible for maintaining a certain temperature in the room,

- control panel, on which indicators are displayed,

- gas valve that controls the gas supply,

- fan No. 1, responsible for supplying air to the heat exchanger and valve,

- fan No. 2, which disperses heated air throughout the room.

How does a gas convector work? Everything is quite simple: it operates on the principle of a gas burner. Cold air from the outside, obeying the laws of physics, enters from below, heats up and exits through the hole at the top of the device. Note that gas models can function due to natural or forced convection. In the second case, air is pumped by fan No. 1.

Gas heating options

There are two options for those who are planning to install gas heating in a wooden house.

The first option is a traditional gas boiler. A centralized boiler heats the coolant by burning gas. The gas begins to circulate through the pipes, giving off heat to radiators, which heat the air in the rooms. If there is a gas main in your area, gas heating of the dacha will not be difficult.

Such things as heating design and gas heating scheme for a two-story house should be carried out by specialists with experience in this field.

Gas parapet boiler

Typically, owners prefer convection-type boilers. Condensing systems are more economical; they require a very low return temperature, which is poorly maintained in the house when radiators are used. Therefore, the best option would be a scheme that follows from the type of boiler - single-pipe and barracks type. So, a thick pipe will encircle the entire house along the perimeter, the radiators will not break it, but cut in parallel.

They do not require a constant pilot flame and therefore provide even greater safety. And if the area experiences frequent power surges and outages, you can purchase an uninterruptible power supply.

The second option for gas heating of a residential building involves a gas convector. If there is no main line in the area, and it is only possible to use imported gas in cylinders, then convectors will be a convenient solution to the problem. Gas convectors do not require distributing a heat carrier throughout the house - the convector is placed under the window, the cylinder is placed in the same or an adjacent room. There is an air intake from the street, where combustion products are discharged through a coaxial pipe. The only caveat in this case is that the convector provides heat only in the room in which it is located. Therefore, if there are several rooms in the house, you will have to install a convector in each. The main advantage of a gas convector is cost.

Gas convector

Advantages and disadvantages

Such convectors have both their advantages and disadvantages, which the reviews clearly show.

Among the advantages are the following:

- Heating a dacha with a gas converter is suitable for virtually any type of premises, since there are no space restrictions for equipment.

- They have a compact size and excellent design. Thanks to this, they can fit into any type of interior.

- To install such devices, there is no need to take into account the location of the heating system pipes. There is also no need to take into account their slope or the dependence of heating devices on each other. Installation of such convectors is not difficult.

- Heating a country house with gas convectors does not depend on adjacent premises.

- Gas convectors are highly resistant to freezing.

- In terms of efficiency, some gas convectors are superior even to the latest generation gas boilers.

However, gas convectors also have some disadvantages, among which are the following:

- A gas convector can only heat one room.

- Heating with gas convectors cannot be used to heat water.

- They have rather limited thermal conductivity. Most gas convectors have a power of 2 to 7 kW.

- Gas convectors are not as compact as water convectors, so it is quite difficult to disguise them.

- In residential areas, hot water was always needed. Double-circuit gas boilers will be able to fully satisfy this need for residents, but gas convector heating will not.

- Gas convectors have a rather beautiful design, but thanks to gas boilers you can use compact radiators or a heated floor system that is completely hidden from view.

- The efficiency of gas convectors is approximately at the same level as that of gas boilers.

Radiators for water heating

First, we will examine radiators designed for operation in central and autonomous heating circuits.

Register

The simplest and most affordable homemade heating radiators are made from pipes of large (100 - 250 mm) diameter, capped at the ends and connected by jumpers. These devices - the so-called registers - have a large internal volume and, accordingly, significant thermal inertia, which makes them an ideal solution for systems with solid fuel boilers.

How to make a simple horizontal register?

- Pipes are cut into sections of 1.5 - 4 meters

(depending on the expected length of the register). - Holes for jumpers are drilled or burned with a gas cutter

. An important point: the configuration of the jumpers should create a closed circuit inside the device, eliminating stagnation of the coolant in dead-end areas. - The pipes are connected by jumpers

- pipes of sizes DN20 - DN32. - Parallel to the jumpers, pipe sections of the same length are welded, but already welded to the blank walls

. They will add rigidity to the structure. - The ends are capped with bottoms cut from a steel sheet 4 - 5 mm thick

. - Nozzles are welded into the lower and upper sections

, which will subsequently connect the register to the supply line.

In most cases, a regular round water and gas pipe is used as register sections. It is attractive due to its low price per linear meter and maximum tensile strength with minimal wall thickness, which is ensured by a circular cross-section.

However, sometimes you can find homemade heating radiators made from a profile pipe - square or rectangular. Its advantages are the relative compactness of the register and a slightly larger surface area for the same cross-sectional area.

Convector

The simplest convector is a coil of pipe with plates pressed onto it, increasing the notorious heat transfer surface. The most accessible material is steel. New buildings often serve as sources of ready-made convectors for garage owners: apartment owners in them en masse replace the heating devices installed by the builders with sectional radiators that are more attractive in appearance and have greater heat output.

However, steel has a serious drawback - low thermal conductivity. In order not to be unfounded, we will present the thermal conductivity values for three metals that are most often used in the manufacture of heating devices.

It is obvious that when creating a convector it is advantageous to use non-ferrous metals: their thermal conductivity will sharply increase heat transfer, making the heating of the fins more uniform.

Homemade copper heating radiators come in all sorts of designs based on copper and aluminum plates. Aluminum fins are much more affordable compared to copper; some difference in heat transfer is compensated by its increased area.

To assemble the convector, solder intended for copper water pipes is most often used; somewhat rarer plates.

Wall backing material

The main requirement in finishing walls, floors and ceilings is fire protection. For this purpose, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process and protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. A layer with a thickness of 50 mm or more is installed on a rigid base (metal sheet). The density of wool is maximum.

- Basalt fireproof sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is prohibited to use polymeric materials – polypropylene, polystyrene foam

For floor-standing models, special attention is paid to preparing the floor surface. It is leveled, fire-resistant material is installed

In this case, basalt wool is not recommended, as it will shrink under the weight of the boiler. The solution is to install basalt sheets.

Fire safety

What should you pay special attention to when installing gas heating in a wooden house?

What do the fire safety instructions require?

The boiler is mounted exclusively on a fire-protected surface. A typical solution is a sheet of galvanized steel with an asbestos backing. At the same time, both the stand for the floor-standing boiler and the substrate for the wall-mounted one must overlap its dimensions by at least 10 cm in all directions.

Galvanization protects a wooden wall from excessive heat.

- The minimum horizontal distance from the boiler or gas convector to other gas or electrical appliances is at least 30 cm. Installation of wiring or any electrical appliances above a gas convector is extremely undesirable: hot air will inevitably render the insulation unusable over time.

- The chimney of a gas boiler must have a diameter no less than the pipe on the boiler, and no more than three bends. The cross-section is only round. The best material is stainless steel.

- A larger opening is made in the wall or roof for the chimney. Gas combustion products leave the boiler relatively cold, but additional insulation from the walls with asbestos or a piece of asbestos-cement pipe is needed. The same applies to coaxial pipes of a gas convector.

- A separate room with an area of at least 4 m2 with a door at least 80 cm wide and a window is allocated for a gas boiler.

- The chimney must be at least half a meter higher than the roof.

Combustion products will not heat the roof leaving the chimney

Choosing a boiler

If the source is gas, then it is best to choose an automatic wall-mounted gas boiler. This generator is equipped with a pump and protection. If a chimney is not provided, then you need to opt for a boiler with a closed combustion chamber. And to exhaust air in such a boiler, you can use a coaxial pipe. This will save money on pipe installation.

Wall-mounted boilers already have full automation, but if the water volume is more than 100 liters, install an additional expansion tank, even if there is a built-in one. It will make it possible to compensate for the expansion of water when heated. Otherwise, the pressure in the boiler will increase greatly as the temperature rises, and the automation will often turn off.

If the choice fell on an electric boiler, then it is best to choose a fully automatic boiler, with a built-in pump and expansion tank. This option will be more convenient to install and will avoid many mistakes.

If the fuel is of a hard nature, then such a boiler can be installed by yourself, only if you know how to weld. And they are able to weld heating pipes with their own hands. The outlet temperature of this type of boiler can reach 100 degrees and it will be difficult to install any pipes other than iron ones without the help of professionals.

When the boiler is selected, you need to select the right pipes and radiators. Various materials are used for pipes today. But when installing it yourself, it is best to use plastic. It is easy to install. The quality of metal pipes today has deteriorated greatly. So from the proposed option, choose metal-plastic or polypropylene.

The material has been selected, all that remains is to draw a diagram and choose a project for your home. The project will depend on the type of heating you choose.

Radiators are chosen depending on what kind of heat transfer you want to get and which ones suit your interior. The larger the radiator sections, the warmer the house will be. The calculation is 1 section per 1.5 square meters.

The appearance of radiators should not spoil the overall appearance. You will make the right choice by watching the video:

Calculation of materials is carried out after drawing up a detailed diagram of the heating system of your home.

Which brand of electric heating boiler is better?

Good inexpensive electric boiler RusNIT 209M

Photo: www.teplosila.ru

Rating: 9.9 out of 10.

Average price: RUB 16,279

A compact, lightweight, domestically produced electric boiler can be called the best among inexpensive ones. The total power of the boiler is small, 9 kW, but this is enough to heat rooms with a total area of 70-90 m2 (living area of a medium-sized house or cottage, country house). At the same time, the quality and range of functions are no worse than those of expensive imported models: the work is fully automated, you can configure all the main indicators (power in three stages, air temperature, coolant temperature).

From reviews of the electric boiler RusNIT 209M:

“I’ve had an electric RusNIT in my dacha for 2 years now. Never let me down yet. The house still warms up perfectly. The good thing about it is that when you turn it on, it doesn’t immediately load the system; it distributes the load evenly across each phase. This means that, including other devices, you don’t have to worry about them burning out.

It is only important that the boiler is installed by specialists, and maintenance must be carried out on time.”

- low price

- easy installation

- smooth power adjustment

- precise temperature adjustment (+/- 0.5 °C)

- air heating within 5-30 °C

- overheat protection

- coolant presence sensor

- The housing is splash resistant.

Disadvantages of the model:

not suitable for a large house.

The best electric mini-boiler EVAN Warmos QX-18

Photo: warmos.ru

Rating: 9.8 out of 10.

Average price: 31,400 rub.

The best among powerful Russian-made electric boilers. It can safely be called a mini-boiler room: heating elements (material - stainless steel), a membrane expansion tank, and a circulation pump are assembled in one housing - all this allows you to save space during installation and reduce time. The LCD display is located at the bottom of the case. The convenient control panel is hidden behind a special door. The operation is regulated by a microprocessor, the control is fully automatic, but you can switch the device to manual mode and adjust all the parameters to your taste and needs. It works stably even with voltage fluctuations, but it is still better to connect the boiler through a stabilizer. Versatile. Suitable for heating residential premises (houses, apartments) and industrial facilities (warehouses, shops, etc.)

From reviews of the electric boiler EVAN Warmos QX-18:

“I bought Varmos and installed it at the dacha parallel to the old solid fuel one. Installation is elementary. It has been working for 5 years, no problems"

- works quietly

- built-in expansion tank 12 l

- 3 stages of power adjustment

- microprocessor control

- smooth power adjustment

- control panel at the bottom of the case

- thermostat (air temperature adjustment for 7 days)

- manual adjustment mode available

- built-in pump

- overheat protection, short circuit protection

- coolant level sensor

- pressure meter

- indication of emergency condition (light, sound).

Disadvantages of the model:

- bulky and heavy

- weak point - capacitor

- It is necessary to install a voltage stabilizer

When choosing heating equipment today, it is easy to get confused, since there is a very wide selection of models on the market. There are both simple boilers for apartments and more complex equipment designed for installation in a large country house or country house. They all differ in power, additional features, and connection technologies.

In order not to make a mistake with your choice, you need to pay attention to the rating, which clearly demonstrates which equipment is optimal in certain conditions

To choose the right boiler, you need to pay attention to the rating, which demonstrates all the advantages or disadvantages of the equipment. Choosing a gas boiler will be much easier if you know exactly what functions are needed, what estimated power can satisfy all the needs for heating and hot water supply. The rating will help you understand all the intricacies of such installations

The rating will help you understand all the intricacies of such installations

Choosing a gas boiler will be much easier if you know exactly what functions are needed, what estimated power can satisfy all the needs for heating and hot water supply. The rating will help you understand all the intricacies of such installations.

Permits

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. Connection to the gas main should only be carried out by certified specialists, but installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining technical conditions. It indicates the requirements for connecting to the gas main. It is necessary to provide a house plan with its characteristics.

- Drawing up a gasification project. This work is performed by specialized licensed organizations.

- Based on the project, permission is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, representatives of the gas service must check the building and the main line for compliance with the technical conditions and the agreed project. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of Gorgaz subsidiaries. Their representatives know the nuances of design and the latest changes in requirements for premises and equipment.

Premises requirements

Gas service requirements for premises:

Ceilings should be no lower than two and a half meters, which is important, because many wooden houses are built with low ceilings, and this is with the least powerful equipment; The diameter of the ventilation duct must be equal to or exceed 100 mm, the material from which it is made must comply with SNIP, and the lower part of the ventilation duct must be at least 200 mm below the ceiling; Bottom gaps on interior doors must be at least 25 mm; Each room should have windows to ventilate the room; The boiler room must be equipped with a door to the adjacent non-residential premises, and when installing a boiler with a power of over 150 kW, a separate entrance door; The internal space of the boiler room must have at least 7.5 m3 in volume; for new houses this requirement has been doubled; The chimney must be equipped with two walls, its diameter must be greater than or equal to the incoming pipe of the equipment; Lighting in the boiler room must be safe; for this purpose, open light bulbs without shades are not allowed; In the case of external electrical wiring, it must be placed in specialized cable channels; The indoor gas control system should be installed in a wooden house if the boiler is located in the basement.

Types of heating systems

First of all, the house can be heated using an autonomous structure with forced or gravitational (natural) coolant circulation. Each of these methods has its own advantages and disadvantages. In addition, there are situations when it is better to use one or another variety.

Advantages and disadvantages of natural circulation

Gravity pumping is entirely based on the laws of physics. More precisely, the coolant moves through the pipeline due to the difference in weight between cooled and heated water.

A hot liquid has a much larger volume, but much less mass. Accordingly, it rises up the riser, moves further through pipes that are laid at an angle, and is pumped into heating radiators, where it is cooled.

Before making a final choice in favor of a certain type of fluid circulation in the system, you need to consider the pros and cons of each heating option

The list of advantages of such a solution should include ease of installation. A system with natural circulation lasts much longer and is stable. At the same time, the absence of a pump allows you to get rid of excess noise and ensure independence from the availability of electricity.

As for the disadvantages, this kind of solution can only be used when heating a small house. In addition, the system requires laying large-diameter pipes, which significantly increases the cost of organizing a home heating system.

When choosing natural circulation, you need to take a responsible approach to installation - errors will lead to a serious decrease in the speed of pumping the coolant

Distinctive features of pumping systems

To make water move faster through the pipes, a circulation pump is installed into the heating system. With its help, you can move the media with virtually no loss of temperature. As a result, a wooden building warms up much faster, which saves a considerable amount of fuel.

The main advantage of forced circulation is that the area of the heated house can be practically unlimited. At the same time, the owner is given the opportunity to control the amount of heat and the speed of the pump. The disadvantages of this solution are the dependence of the system on the availability of electricity and the high noise level of the equipment.

When installing a heating pump, you can use pipes of small diameter. This allows you to save on the purchase of plumbing fixtures

EVAN S1 18

Russian single-circuit high-power boiler. This model allows you to maintain a comfortable temperature in large areas. The retail price of the boiler ranges from 21,000 to 25,000 rubles.

Specifications

The main equipment indicators include:

- base power – 18 kW;

- required voltage – 380 V;

- Efficiency at 93%;

- maximum coolant temperature – 85 0С;

- minimum temperature in the system – 30 0С;

- heating area – 180 m2;

- maximum operating pressure in the system is 0.3 MPa;

- circuit pipeline cross-section - 1 ¼ inches;

- there is no expansion tank;

- weight no more than 24 kg;

- body dimensions – 645x250x180 mm.

Model features

This boiler is characterized by its simplicity of design and ease of operation and maintenance. It does not have an automation system, but the developers took care of the possibility of connecting its elements. Thus, the boiler circuit has built-in connectors and sockets for connecting a circulation pump and an air temperature sensor, which are necessary to automatically maintain a given temperature level in the room.

The small dimensions of the model allow it to fit into any existing circuit as an additional heating element, and also to be used as an independent heat source. One circuit provides space heating, so a storage boiler must be installed to supply hot water.

All boiler elements are made of materials that are not subject to corrosion, which significantly increases the service life of the equipment. Protection systems against power surges and pressure surges ensure trouble-free operation of the model.

Boiler installation

Installation of this model does not require special skills due to the simplicity of the design. But taking into account the network voltage requirements, an autonomous heating project should be drawn up and agreed upon with the electricity distribution organization.

The pipe supply must be carried out in such a way as to ensure natural circulation of the coolant. This connection reduces the pump load and contributes to more economical operation of the equipment. The maximum coolant level in the pipeline should not exceed 30 m; with a higher value, the boiler pump will not be able to circulate it. The best option for working with developed pipeline systems is the additional installation of a circulation pump.

It is also necessary to install an expansion tank to allow the excess volume of coolant or steam to be discharged. It is not allowed to install shut-off valves at the junction of the circuit and the expansion tank. Ball valves are installed at the inlet and outlet of the circuit from the boiler for repair and dismantling work.

Clearances from obstacles are left along all sides of the body of at least 5 cm on the side edges, at least 50 cm from the floor and ceiling, as well as the front surface of the boiler with the control unit.

Flaws

The biggest inconvenience in working with this model is the need to install a large amount of additional equipment. As a result, the total cost of the system increases by 20–35%.

Selecting a convector

How to choose a gas convector? First of all, attention is drawn to the technical characteristics of the unit. The best option is a device with a closed combustion chamber and a cast iron heat exchanger. The presence of a programmable control unit is considered important

Let's look at other factors that you should pay attention to when choosing a household gas convector

The presence of a programmable control unit is considered important

Let's look at other factors that you should pay attention to when choosing a household gas convector

Device power

Since heating occurs due to air circulation, the units operate effectively in only one room. Therefore, each room will require the installation of a separate unit. Power is determined from the calculation: 100 W are required per 1 m 2 of area.

Heat exchanger material

Since gas heating convectors operate on gas, which burns in a special chamber, the heat exchanger is exposed to strong temperature effects. If it burns out after some time, the device fails. Therefore, the material of this part must be resistant to high temperatures. The leader among heat exchanger materials is cast iron. This metal is resistant to thermal stress; in addition, it cools very slowly and distributes heat evenly. Gas convectors with a cast iron heat exchanger can last up to 50 years. The main disadvantages of such devices are the high price and large mass of the unit. A heater with a steel heat exchanger is cheaper and lighter

But when choosing a unit, you should pay attention to the quality of the steel. Steel heat exchangers can last at least 20 years

Combustion chamber type

Heaters may differ in design based on the type of combustion chambers:

- Open

combustion chamber. Installation of a unit with such a chamber requires the installation of a chimney with access to the roof. In addition, when the unit is operating, air will be taken from the room to maintain the combustion process. Therefore, good ventilation of the room is required. - Closed

combustion chamber. Such models are more popular because they do not require a pipe outlet through the roof (a coaxial pipe is installed opposite the device). And another advantage is that the oxygen in the room is not burned, since the air is taken from outside the building.

Availability of a fan

A gas convector with a fan quickly and evenly heats the entire room. Due to the forced air supply to the heat exchanger, the latter is cooled better. And since overheating is prevented, the service life of the heat exchanger is significantly increased.

Room type

If you want to install a convector in an apartment

, then the best choice would be a device with a closed combustion chamber and a chimney with a coaxial pipe. This type of device does not burn oxygen in the room. In private buildings

you can install any. But when using a device with an open combustion chamber, the room must have fresh ventilation.

Type of fuel

The use of liquefied gas is prohibited in apartment buildings. Therefore, the device is connected only to the main line

. In private homes, use a gas convector using bottled gas

possible, provided that the cylinder is installed outdoors in a special metal cabinet.

Amount of fuel consumed

Fuel consumption in gas heating equipment is considered economical. To calculate gas consumption, the following basic parameters are accepted:

- 1 kW of power will require 0.11 m 3 of gas from the main;

- 1 kW of power will require 0.09 m 3 of liquefied gas.

Based on these indicators, you can make a calculation. For example, a 4 kW heater (designed for 40 m 2 of area) will consume 0.44 m 3 of gas per hour of operation, and 10.56 m 3 per day. But, since the device does not work constantly, this figure will be significantly less.

Types of gas convectors

To choose a suitable convector, you should learn about the main differences between existing equipment, the pros and cons of modifications.

By what criteria can heaters be classified?

- Installation method - there are wall and floor models. The former take up less space, are lightweight and efficient, and are limited in performance (maximum power 10 kW). For heating a garage or large premises, it is better to choose a floor-standing model. The heaters are heavy due to the enlarged heat exchanger. The performance of floor convectors reaches several mW (industrial versions).

Exhaust gas removal. A conventional convector has an open gas combustion chamber. The operating principle of the device is somewhat reminiscent of a simple wood stove. The design has several disadvantages - it burns oxygen, requires good ventilation of the room, as well as the manufacture of a complex smoke removal system. New generation convectors use a closed combustion chamber. Instead of a chimney, a coaxial pipe is used. Air is taken from the street, so the oxygen in the room is not burned during operation. Systems with a closed combustion chamber have only one drawback - the cost is 30-50% more than classic models.

Heat exchanger material. The operating principle of the convector is associated with constant thermal exposure. One of the common causes of heater failure is burnout of the chamber walls. The heat exchanger is made of steel or cast iron. The crystalline structure of the latter metal ensures a long service life (about 50 years) and high heat transfer. A steel camera will last about 10-15 years.

Fan. High power convectors are equipped with a forced air circulation system. Budget household models may not have a fan.

Type of gas. The models are designed to operate on any type of “blue” fuel. A gas convector running on natural gas can also operate on propane. For conversion you will need a special adapter kit.

Automatic control. Budget models are equipped with conventional thermostats. A programmable control unit allows you to control the room temperature and set the required heating mode.

The cost of a gas convector depends on the material of the heat exchanger, the availability of an adapter kit, as well as the characteristics of the control unit.

Features of organizing gas heating in a wooden house

Before purchasing a gas boiler for installation in a wooden cottage, you need to think about what fire safety measures will need to be taken.

Note! Before installing gas heating, the house should be well insulated, otherwise the gas consumption will be too high. A lot of heat escapes through the roof, floor, door and window openings

Therefore, special attention should be paid to these areas.

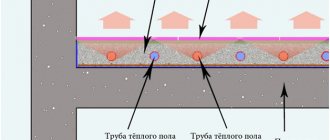

If you want to install a “warm floor” system in your home, then you can say goodbye to this thought if the floor in the house is made of boards, plywood or OSB. The fact is that these types of bases are too mobile, and for the installation of “warm floors” a cement screed is needed.

There are two options for gas heating for a wooden house:

- boiler;

- convector

Each of them has its own characteristics.

A gas boiler

A heating system with a gas boiler works on the following principle: the coolant is heated in the heat exchanger of the unit and then moves into the heating system. As the liquid passes through the radiators, it cools and returns to the boiler. The maximum heating of the coolant reaches 80-85ºC.

Heating a wooden house with a gas boiler has the following features:

- The unit can be installed in a wooden house if there is mains gas, since a system running on bottled fuel will be too flammable.

- It is recommended to choose a convection type boiler, since condensing boilers operate at low temperatures. They will not be able to provide enough heat to maintain optimal heating levels.

- It is advisable to purchase a single-circuit model so that more power is used for heating.

- Units equipped with a closed combustion chamber are considered more fireproof. The flame burns inside the firebox, and the coaxial pipe has fairly compact dimensions.

- You should purchase a boiler equipped with electric ignition. Such a unit does not need to constantly maintain combustion, so it is safer.

Note! If the power supply is often cut off in your region, then to ensure uninterrupted operation of the boiler you will have to purchase an uninterruptible power supply

Convector

Heating with a gas convector is beneficial if there is no central main line nearby, and the fuel source will be gas cylinders. Then the convector is installed under the window, and the cylinder is placed behind the wall of the house in a metal container.

The disadvantage of such heating is that its power is only enough for a small room - usually only the room where it is located. If you place a convector in each room, you will have to provide each of them with a gas cylinder and a coaxial chimney. Also, convectors are not as multifunctional as gas boilers, which can not only heat a room, but also heat water.

A significant advantage of the convector heating system is its low cost, especially when compared with the price of radiators and a gas boiler.

Gas heater. Flaws in work

Next, you should deal with the disadvantages of convectors. The main disadvantage of such a device is that you have to break through the wall to complete the installation. Moreover, a hole is needed here for the coaxial gas outlet, which is a special tube in the pipe through which exhaust gases exit. The fresh air required for combustion is supplied to the convector thanks to an external pipe. It can be assumed that the hole in the wall may be located in a certain area where the convector itself will be placed. If they are located under every window of every room, then there will be a lot of holes in the walls, and they cannot be hidden or placed in one area. In addition, additional space must be made in the wall for the gas supply.

Gas convector installation diagram.

If a standard heating system is used in a living room with an area of 30 square meters with two windows, almost under each window it would be worth installing one convector. However, with gas convectors this option is unacceptable. Here you should install one convector with increased power in a certain area on the outer wall of the room (where there are the most optimal conditions for supplying gas and creating a discharge for exhaust gases). This installation does not imply creating a temperature balance in the room. One corner will be quite hot, and the other will be cold. To create proper comfort, one low-power convector should be placed under each window. However, here the question of price arises, which will double, although the aesthetics of the room will increase. Hence the conclusion - the installation of this heating option will be in many ways inferior to a standard water heating system.

The gas convector includes low inertia. In other words, it heats up quite quickly and cools down at a similar interval. This feature can be attributed to both pros and cons. It all depends on how the device is used. Using it in a residential area can negatively affect the comfort of the temperature regime, but installing it in a garage, barn or workshop will undoubtedly give positive results.

Another nuance in the operation of a gas convector, which can also be considered a plus and a minus, is the presence of a combustion chamber, where the gas heats the chamber, which subsequently heats the air. For the durability of the convector, its design must contain steel that is resistant to fading. It’s good if the device is equipped with just this type of specialized steel (however, the price of the device will double). If the convector uses cheap steel, then it runs the risk of failing very quickly due to corrosion, burnout and other factors. If the combustion chamber in the convector is created using 10 mm cast iron, then the service of the device will be durable.

How to install a gas convector

After you have chosen and purchased the heater, you can proceed to preparing the installation. Make sure you have the following tools and materials:

Tools necessary for installing a gas convector.

- drill and set of drills;

- pipe cutter;

- a set of wrenches and an adjustable wrench;

- shoulder blade;

- perforator;

- screwdrivers;

- sanitary and high temperature silicone;

- dowels and screws;

- gas tap.

When everything is ready, you need to choose the location of the convector. For the correct selection, use GOST. The latter requires mandatory installation of the heater under the window. Don’t be lazy in the process to try on the device to the chosen place, and also make markings after that. The next stage is preparing the premises. The room must be covered, as during work a large amount of dust will appear.

Installation

Technical requirements for installation of a gas convector.

Installation is carried out according to the following plan:

- Determine the hole for the gas pipe inlet. Do not forget to leave a distance for connecting this very pipe and fitting.

- According to the diameter of the exhaust pipe, you need to drill a through hole in the wall using a hammer drill. This is the most difficult stage, since the hole is large, so the work will take a long time (depending on the wall and the hammer drill), and a lot of dust will also appear.

- The next step is to drill holes for mounting the heater itself and hammer dowels into them.

- Now we connect the exhaust pipe to the convector and make a joint with silicone (capable of withstanding high temperatures).

- The heater itself is fixed to the wall with self-tapping screws. Outside help will be useful here, since the weight of the device is considerable.

Be sure to seal all holes with foam to prevent cold air from entering the room.

Gas connection

Take this stage extremely seriously. If you doubt your skills, it is better to entrust the connection to specialists.

Carry out installation according to the following scheme:

In accordance with GOST, the pipe must be installed from the street.

- If there is a special threaded outlet on the gas pipe, this will make life easier. You just need to screw the gas valve onto the pipe. But if there is no withdrawal, then it must be made.

- Next, bring the pipe to the convector. It is better to use metal-plastic. The connection of the fittings must be perfect.

- When laying a pipe every meter, it must be secured with special clips. To do this you also need to drill holes.

- To check the connections, you must call a gas service employee.

Remember to lubricate the fittings and pipe with silicone to ensure maximum sealing of the system.

Functionality check

Before turning on the device, be sure to call the gas service to check the connections for gas leaks.

After completing the installation work, you need to do a test run:

- First of all, open the gas tap, listen to all joints for possible leaks (you can use soapy water or a special device). If leaks are found, close the tap and fix them.

- After checking all joints, start the convector. During startup, hold down the button for a minute to allow gas to enter the combustion chamber.

- After the burner lights, adjust the operation of the device.

Installing a gas convector in a wooden house is no different from installing it in any other building. Fire hazardous elements are located inside the convector.

Advantages and disadvantages

A convector cannot become a complete replacement for a gas heating boiler. Only in a limited number of cases is its use justified. The advantage of a convector is that there is no need to install water heating pipes throughout the house, but instead you will have to lay gas pipes, which is associated with great risk.

One or two gas convectors will cost less than a gas boiler, so in this aspect they may be preferable for a small house. The costs for laying pipes are approximately the same, but you do not need to spend money on heating radiators.

The main advantage is quick heating of the room and easy start of the heater, even if the temperature in the room was initially negative.

Important features of gas convectors should be taken into account:

- The high temperature of the heat exchanger causes dust to decompose in the air, which requires constant ventilation so that the well-being of the residents does not deteriorate.

- An active convection flow covers the entire volume of the room.

- Since the convector is installed alone per room, a noticeable temperature difference inevitably occurs directly near the heater and away from it.

- To install a convector, you need to drill a hole in the wall for the chimney and gas pipe, which affects the appearance of the building and is not always possible.

The convector is best located under the window opening. In this place it is easier to drill into the wall to install a chimney, and the heat from the heater will form a thermal curtain for the window. It is advisable to make the distance from the extreme points of the opening at least 30 cm, the rise above the floor at least 15 cm.

The instructions indicate the dimensions, as well as a plan for the distribution of the chimney and the connection of the gas pipe. However, it is better to remove the heater’s protective casing on site and record the actual values and transfer them to the installation site. Two/four heater mounts will be required. From them the position of the through hole for the chimney is already measured.

The hole should be drilled at a slight angle, sloping down and towards the street. This will protect the device from rainwater flowing in. The slope is maintained at an angle of approximately 15 degrees.

Once the hole is prepared, the coaxial chimney is inserted and foamed. If the walls of the house are made of fire-hazardous material, a larger hole is prepared and fire-resistant heat-insulating material is laid around the chimney. Basalt wool is perfect.

The installation of the gas pipe and the connection of the convector is carried out only by gas workers. These works require increased attention and appropriate permission. It is enough to bring the pipe to the convector at a distance of no more than half a meter and install a shut-off valve. It is easier to form the remaining section with a flexible hose. This will allow you to remove the heater if necessary.

Sandwich chimney device

For a wooden building, this system is an ideal option. Such a chimney consists of two pipes of different diameters located one inside the other. A heat insulator is placed between their walls. Such a chimney installed in a wooden house differs from a traditional brick one in a lot of advantages. Watch the video about the sandwich pipe:

The roof structure, made of wooden materials, even when dried well, seems to play a little over time. Displacements invisible to the eye and seemingly insignificant can lead to the destruction of a brick chimney, even the hardest one. But the sandwich, thanks to its design features, is not afraid of these threats.

And it is not surprising that the chimney in a wooden private house is increasingly being made in exactly this way. All its many advantages include the excellent fire safety of the pipe compared to a brick pipe.

Stove heating device in a private house: design of modern stoves

The main structural elements in a stove heating device for a private house are: foundation, trenches, ash chamber, firebox, smoke channels (smoke circuits), chimneys.

The foundation is the base of the stove, which takes on the loads from the stove and chimneys. This structural element must be reliable, since the safety of the structure in use depends on its strength. Correct placement of the stove foundation requires its location to be separate from the foundation of the house. The minimum gap between them is 3 cm, which is filled with sand.

First of all, they dig a well, which is then filled with small fragments of stone or baked brick, after which everything is carefully compacted. In this way, a pillow is prepared for the foundation. Then liquid cement mortar is poured into the pit. Laying a brick or stone foundation is done with bandaging of the seams. The last layer of cement mortar is carefully leveled.

After erecting the foundation, they begin to construct such a structural element of the furnace as shale. They are rows of brickwork that raise the oven on top of the foundation. To install the slates, two or three rows of brickwork are made. The bottom of the furnace is thus also involved in heat transfer.

An element of the design of heating furnaces, such as a blower, or ash chamber, serves to supply air to the firebox and to accumulate the ash coming from it. A special grate in the form of cast iron or steel rods is installed between the firebox and the ash chamber. While the stove is operating, the chamber door should be open, and at the end of the fire it should be closed to avoid rapid cooling of the air inside the stove.

The firebox in heating stoves is a furnace chamber in which fuel is burned - wood and coal. A special hole is installed in the upper part of the firebox to remove flue gas. The dimensions of the chamber are selected in such a way that it is possible to load into the furnace the amount of fuel necessary to heat the furnace.

At the bottom of the firebox, slopes to the grate are arranged, ensuring the free movement of ash into the ash pit. To prevent coals and ash from falling out of the combustion chamber, its door is installed above the grate by one row of brickwork. You can extend the life of the firebox by lining it with refractory bricks.

The operating principle of a stove heating system in a private home is based on heat intake through smoke channels, or smoke circulations. They can be positioned both vertically and horizontally, as well as rise and fall. How efficiently a stove operates depends on the size of the smoke ducts and their location.

The flue gas, passing through the channel, gives off energy in the form of heat to the walls, which heat the furnace. In order to increase heat transfer, smoke channels are designed in such a way that they are long and often change direction.

The smoke ducts of a modern stove heating of a private house can have a cross-section of 13 x 13, 13 x 26, 26 x 26 cm, their walls are made smooth (they are not plastered, since if the plaster is destroyed, the channels may become clogged). Access to the smoke circuits for cleaning them from soot is provided through special doors.

To obtain draft that helps remove gases from burned fuel, a chimney is installed, which is placed outside the house - on the roof. Most often it is made with a round cross-section, since gas movement in pipes with corners is somewhat difficult. In addition, round pipes are easier to clean. Ceramic or asbestos-cement pipes are used as the material for their manufacture.

Methods of water circulation in heating systems

The efficiency of water heating depends on the constant circulation of coolant through the pipelines. There are two ways to move hot water in a closed heating circuit:

- Natural way of circulation. The principle of moving hot water through pipes is based on the natural gravity of the warm coolant moving up and flowing down as it cools. In order for natural circulation to be good, it is necessary to install the pipework with a slope (for every 1 linear meter, the pipe should be lowered by 10 mm).

- Forced coolant circulation. In modern individual heating lines, the constant movement of hot water through the pipes is ensured by a circulation pump. This electromechanical device increases the speed of coolant movement, which leads to improved heat transfer.

Launch

Boiler installation

Before the first start-up, gas technicians check the entire system for leaks, the visually normal condition of the device and the correct connection of communications. The heating system is then filled with water. A special system replenishment unit is already built into modern gas appliances, so the procedure does not require additional effort.

Stop filling when the pressure gauge reads 2 atmospheres. Then the accumulated air is released from the main components, circulation pump and radiators. As soon as air stops coming out of the system and water starts flowing, the equipment is ready to start at full power.