Home » Classification of gas boilers » Operating principles » Features of ignition of different models of gas boilers

After purchasing and installing a new gas unit, inexperienced users may have a question about how to light a gas boiler. Please note that the first start-up should only be carried out by a gas service specialist. He can also give some recommendations on how to turn on and subsequently operate the unit.

…

- 1 Preliminary work

- 2 The process of igniting a gas boiler

- 3 Features of ignition of different models of gas boilers

- 4 Problems when igniting a gas boiler

Preliminary work

Before lighting a gas boiler, you need to check it for leaks - perform a pressure test. This can be done in two ways: by filling the system with water or using an air compressor. The process consists of the following steps:

- open the tap, which is responsible for filling the system with coolant;

- slowly fill the radiators with water until the pressure in the system reaches 2 atmospheres;

- close the tap and wait about an hour;

- if the pressure remains at the same level, then everything is normal; if the reading on the pressure gauge has decreased, there is a leak - you need to find it and fix it.

Checking the air heating system is advisable if you do not intend to use it in the near future.

This will eliminate the need to drain water from the system. If, after pressure testing, you plan to put the gas boiler into operation, it is better to immediately fill the radiators with coolant. Note! Checking the tightness of the heating system can only be carried out if the room temperature is above zero.

Before lighting an old gas boiler that has not been used for a long time, you should thoroughly rinse its heat exchangers, clean the burner device, and also wipe the body.

The heating system is flushed using pressurized water. It is advisable to rinse not only the old, but also the new heating system, since during the installation process debris often gets inside the radiators.

…

Find out here how to reduce gas consumption in a gas boiler?

Why doesn't the gas boiler light up?

Gas boiler does not reach temperature - causes and methods of eliminating them

Premises requirements

The room in which gas equipment is to be installed should be equipped with fresh ventilation.

Moreover, door and window openings cannot be classified as such if they do not have devices that ensure constant air flow - fans, holes in the door leaf, etc. When the heater is put into operation, it is prohibited to carry out construction work in the room that could change the ventilation design, thereby affecting the volume of incoming oxygen. In the boiler room it is prohibited:

- Store flammable substances and materials.

- Store chemically active substances - chlorine, ammonia, acids, etc.

- Place heating devices and air conditioners near the boiler.

- Install equipment near stairs, in wall openings, near windows and emergency exits.

The process of igniting a gas boiler

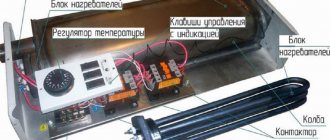

When the preparatory activities are completed, they proceed to starting the gas unit. Manipulations for igniting a gas boiler depend on what type of ignition is installed on it: piezo or automatic.

Most modern gas boilers, for example, such as Beretta, Ferroli, Bosch, are equipped with automatic ignition and can be easily ignited by pressing one “Start” button. Before doing this, do not forget to turn on the unit to the electrical network and open the gas valve. Temperature adjustment is usually done using the “+” and “-” buttons. The unit does not always turn on instantly; sometimes you need to wait a few seconds for it to light up.

Piezo ignition is a little more difficult to implement: you will need to press the flame regulator and hold it for a while, and then activate the piezo button. Many domestically produced units are ignited in this way: ZhMZ, Lemax, AOGV, etc.

…

If a gas boiler is controlled using a remote control, then it always has a “Start” button, when pressed, the unit will ignite.

Note! Do not light a gas boiler if you smell gas in the room.

System flushing and pressure testing

This process is not mandatory. However, it is extremely important to carry it out, because it can show flaws or leaks in the system at the stage of preparing the boiler for startup.

To carry out crimping, you need to call a specialist and special equipment. Because of this, many people neglect it. However, it’s scary to imagine what could happen if the system fails in cold weather.

The procedure is important to carry out on new systems, as well as on those that have been in service for a long time.

System flushing and pressure testing

Construction companies announce a price tag of 3 thousand rubles for the pressure testing procedure. Some companies also include a site visit service. For comparison, a portable pressure testing pump can be purchased for 6 thousand rubles.

Features of ignition of different models of gas boilers

Different models have their own ignition features. For example, before lighting a gas boiler Aton or Danko, you should set the regulator to the icon with an asterisk and hold it there for 5-10 seconds. After this, you need to press the button next to it.

How to light a gas boiler AOGV? When the boiler is turned off, the control knob is in the “dot” position. To ignite, it is switched to the “spark” mode and held in the pressed position until it stops. At the same time, activate the piezo ignition button until the burner ignites. If necessary, press the piezo several times. After the flame appears in the burner, hold the handle for about 10 seconds until the thermocouple warms up.

Another option is how to light a Lemax gas boiler. It has a main burner and a pilot burner. Initially, the handle is in the “dot” position. To light the boiler, turn the handle to the “spark” position and hold it for 10-60 seconds. At the same time, press the piezo ignition button until fire appears in the pilot burner. If after releasing the handle the flame goes out, you should repeat the manipulations again, but hold the handle longer. To immediately turn on the main burner of the Lemax boiler, you need to turn the knob to position 1.

Method for finding a breakdown

First of all, you need to start checking the gas sensor. It is the weakest element of the gas boiler automation system. Due to the fact that the sensor is not protected by a casing, after about a year it becomes covered with a thick layer of dust. As a result, the bimetallic plate oxidizes and thus the contact deteriorates.

Dust can be removed with a soft brush. Next, you need to pull the plate away from the contact and clean it with fine sandpaper. But it is worth remembering that you need to clean the contact. After the contact and plate have been cleaned, a thin layer of liquid lubricant must be applied.

Then it is necessary to check the serviceability of the thermocouple. The service life of this element is much shorter than others, since it is in the pilot flame and is exposed to high temperatures. The main failure of a thermocouple is burnout of the housing. When burnout occurs, the contact resistance at the junction increases. And the bimetallic plate will become lower than the required value and the electromagnet will no longer be able to fix the rod.

Problems when igniting a gas boiler

In some cases, when igniting, the operation of the gas boiler is blocked. You can unlock the device by pressing the “Restart” button.

Often the cause of blockage is excessive accumulation of air masses in the heating system.

In this case, it is necessary to remove excess air from the radiators. To do this, a Mayevsky tap or automatic valve is installed in the upper fitting of each of them. In the first case, you will need to place a basin under the tap and open it - air hissing along with a small amount of coolant will come out of the battery. Carrying out similar manipulations with each radiator will allow you to release excess air from the entire system. In the second case, the automation itself will release excess oxygen. Note! The release of air masses is accompanied by a drop in pressure in the system.

Sometimes the ignition of a gas boiler is blocked due to problems with the circulation pump - a corresponding error is displayed on the screen. Sometimes air accumulates in it, as a result of which the blades do not rotate freely and become jammed. Then you need to turn them manually. To do this, remove the lid of the gas boiler, find the central bolt and unscrew it, then turn the shaft in the direction indicated by the arrow. There should be an air vent above the pump. Its lid is pulled up and the air is allowed to escape.

Ignition may be blocked due to the fact that sufficient gas is not supplied to the burner. In this case, check whether the gas valve is open, whether the gas pipe is clogged with anything, and whether there is gas in the line.

After the first start-up, the heating system may make gurgling sounds for some time. They are produced by air bubbles, since it is impossible to get rid of all the excess oxygen immediately. This is not a malfunction, the air will gradually leave the system and the sounds will disappear. Further operation of the gas boiler is described in the attached instructions.

The flame does not ignite (general faults)

Pipe burnout

To organize the safe operation of the chimney, a steel pipe is used. However, it can overheat when interacting with combustion products and burn out. To avoid this problem, it is recommended to use a sandwich pipe, which will protect against overheated gases.

Chimney problems

There may be several problems associated with the chimney design. So, fallen leaves, snow can get into it, and the mouth can freeze over (in this case, the frequency of occurrence depends on the deflector, umbrella or other end). This requires cleaning the chimney or reshaping its fungus to allow smoke to escape unhindered. Below in the picture are options for “fungi” deflectors.

In addition, if the chimney is poorly insulated, the gases in it can form an air lock, since the cooled, cold gas is more dense and does not allow hotter gases to escape freely.

If the chimney is not insulated, strong condensation may settle inside it and freeze up during the cold season. Insulating the chimney will help solve the problem.

If foreign objects (house, tree) interfere with the mouth of the chimney, you will need to increase its height, cut off interfering branches, or otherwise remove the obstacle to the exit of smoke.

Weak supply ventilation

Organizing normal supply ventilation is very important for the proper operation of gas equipment. Thus, combustion requires oxygen, and combustion of 1 m3 of gas uses 10 m3 of air. If this air is not enough, then backdraft may form in the chimney, and ventilation will not be enough. The exhaust hood in the kitchen also contributes to weak supply ventilation if the boiler is installed in this room. Also, due to plastic windows there may not be enough air. The problem needs to be solved by proper installation of gas equipment and proper ventilation.

Installation

Before installing the device, you should make sure that it runs on natural gas. If you plan to use liquefied gas, you need to readjust the heater - this should be done by a specialist. A power supply with parameters of 220 V/50 Hz must be supplied to the installation site of volatile models. Deviation of parameters from the norm leads to decreased performance and reduced service life.

It is prohibited to connect other electrical appliances to the boiler power source. It is also prohibited to use extension cords and adapters when connecting. Violation of safety standards may result in a fire.

Solutions to Question 1

The boiler has a self-diagnosis system and fault signals appear on the display. Errors marked with the symbol A cause the boiler to block. In this case, the user must manually reset the boiler by pressing the RESET button. Errors marked with the symbol F cause a temporary shutdown of the boiler with automatic activation after the value that caused the error returns to normal values.

Accordingly, errors A01.

Corestar boiler error codes - troubleshooting instructions

Did the Corestar boiler show errors on the display? This means that the self-diagnosis system “detected” a malfunction. All modern heating equipment is equipped with automation - sensors that monitor the operation of each unit. Sometimes the user does not even need to contact the service center. It is enough to determine the meaning of the code and find the problem.