When building a house, the planner will definitely be faced with the issue of providing heating. Within the city limits or in large populated areas, gas equipment is widely used, as this is facilitated by the close location of the main line and the relatively low cost of the fuel itself. An alternative to such a system can be electricity or the energy of burning wood and coal.

Using electricity to heat a room is not always justified due to its final cost, and frequent power outages can lead to unpleasant time spent in a cold room.

Based on similar reasoning, in houses located far from large populated areas, or in country houses, good old stove heating is used. But modern stoves are completely different from those we remember from our childhood. They have gone through several stages of modernization and are distinguished by high performance. In this matter, we are not considering brick stoves, since their use is not always appropriate, construction is accompanied by the expenditure of effort, money and time; there are devices that are more efficient for heating.

Modern home heating device

Ready-made metal stoves are devices that combine the functions of a fireplace, hob, oven and, directly, the stove itself. They are so efficient that they can act as the only heater in the house. A distinctive feature is that a metal fireplace stove occupies a small area and does not require pouring a foundation. The wealth of choice of different methods of external decoration will allow you to choose a model for any interior that provides a single harmonious picture.

Air loop system

The main idea of an efficient heating device is that convection in a fireplace allows air flows to be used as a coolant and distributed in several directions, which helps to warm up several rooms at once. It should be noted that a traditional fireplace gave off only a small fraction of energy in the form of radiation, and warm air escaped through the chimney.

An important element in the structure of such a fireplace is the body and air ducts. The housing allows you to localize warm air, playing the role of a kind of storage device, and air ducts are needed to transport it to the right rooms. In this way, the entire house is heated, and not just the room where the fireplace is located.

When wood burns, the wall of the firebox becomes very hot. The air, passing through the labyrinths and coming into contact with the surface of the walls, also increases its temperature. The heat capacity of air is low, so it manages to heat up to the desired state in a short time.

Placement of a fireplace in the bedroom

When constructing a wood-burning fireplace yourself, one nuance should be taken into account. In order for the air to heat up more efficiently, it needs to increase the contact area, that is, using a system of labyrinths, it will force it to travel a greater distance while inside the fireplace body. But such a number of bends will interfere with the natural convection that occurs due to the buoyant force. You will have to install special fans that are capable of pumping cold air into the firebox, displacing hot air.

Good to know: Brick barbecue fireplace, subtleties of self-construction

In order not to experience unnecessary noise from operating fans and to achieve a natural upward movement of masses, the layout of the labyrinths is significantly simplified. In any case, the heating fireplace is based on constant displacement by incoming air flows. Cold masses, falling down, push the air of the lower layers inside the fireplace body, and rising masses push warm air upward.

To ensure heating of the house with a fireplace, all that remains is to supplement the convection system with a distributor with air ducts. If all equipment installation work is carried out correctly, then the fireplace can become a full-fledged device for heating a country house.

Choosing a location

When choosing a place to install a fireplace, it is important to take into account not only the aesthetic and functional aspects of the issue, but also the design features.

When installing a chimney, which must be led outside through the ceiling and roof, you should avoid contact with floor beams or rafters.

In order for a fireplace to effectively heat a room, it is necessary to choose a location that creates a kind of curtain in the path of the flow of cold air.

You should not place the structure opposite a window, as this increases the likelihood of creating drafts.

In any case, you must remember that it is impossible to heat the entire house with a fireplace. It is used as additional heating to create a microclimate in the room for comfortable living.

After choosing the optimal location for the fireplace, the dimensions of the future building are calculated. Based on them, a design drawing is drawn up, and the dimensions of the base are transferred to the installation site. This stage when solving the problem of how to make a fireplace at home is considered very important, as it allows you to clearly determine the dimensions of the building and the degree of its protrusion towards the room.

Advantages of a convection fireplace

To make a fireplace for your dacha with your own hands, you need to clearly understand its positive distinctive advantages in order to concentrate your attention on them.

Air circulation in the system

- The intensity of combustion, as well as the temperature, depend not only on the amount of fuel, but also on the amount of oxygen. High-quality air supply allows you to save firewood.

- The convector forces air to circulate throughout the system even some time after the combustion has completely stopped. Ordinary fireplaces cool down immediately.

- Air ducts can be arranged in such a way that an additional share of energy will be transferred to the air from hot smoke.

- The fireplace body is involved in three methods of heat transfer at once.

Russian stove on the street

Both the construction of a Russian stove outside the home and its operation have their own peculiarities. They are caused by more aggressive effects of atmospheric phenomena during the combustion process and during long winter downtimes. A stove left in the cold for at least a few days without use will warm up unevenly from the sun's rays. And masonry joints are saturated with atmospheric moisture.

When melting for the first time after a break, you need to use a small amount of wood chips. The gases coming out of the pipe should become transparent, which takes an average of one and a half to two hours. After this, you can lay regular firewood.

With barbecue

The primitive design of a stationary outdoor barbecue involves an open brick box on one side with a chimney tapering upward. This option is closer not to a Russian stove, but to an English fireplace.

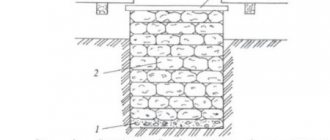

To build a more labor-intensive but effective Russian-style outdoor fireplace, you will need much more brick. The diagram for laying a Russian stove on the street with your own hands is shown in the figure:

Layout of a Russian stove on the street with your own hands

This device performs the functions of an ordinary hearth structure equipped with a grill for cooking over coals.

In the gazebo under the canopy

For the construction of a stove in non-permanent wooden buildings (verandas, gazebos, covered terraces), fire safety requirements become relevant. A non-combustible belt must be created around the masonry: at least 30 cm from the walls and 60 cm from the door. A heat-resistant material is suitable for this - sheet asbestos cardboard with a thickness of over 4 mm. The top should be sheathed with roofing iron.

Bread baking oven

The construction of a wood-burning baking oven can have a simplified design. Many of the requirements for a traditional hearth are optional for this type of stove.

The most important requirements:

- the combustion chamber is large enough to fit a tray with molds inside;

- a pronounced spherical arch so that thermal radiation is focused in the center of the furnace and maintains the desired temperature.

Placing a bread oven outside allows you to not lay out the outlet channels very carefully. After all, the threat of carbon monoxide poisoning in the fresh air is much less than indoors.

How to build outdoors

The main feature of designing an outdoor stove is the need to provide protection from atmospheric moisture. You will need to build a reliable canopy. A rafter structure is erected for it on wooden or metal poles. You can arrange a power system by welding metal. The main requirement: the ability of the canopy to support both its own weight in windy weather and the snow load in winter.

How to install it yourself?

Unlike ordinary stone fireplaces, installing a fireplace stove does not require special knowledge in construction or lengthy preparation. Installation of the heating device is carried out in several steps:

- The location for installation is selected. The distance to flammable objects must be maintained in accordance with the instructions.

- is made in the ceiling above the stove to ensure fireproofing of the area.

- A double-circuit pipe with an adapter is installed in the hole . Such a pipe can withstand strong thermal loads.

- Using a single-circuit pipe, the double-circuit pipe is connected to the stove .

- A roof trim is installed on the roof to protect against leakage.

- A special chimney with an umbrella to prevent rain and snow from getting into the fireplace.

- Aesthetic preparation of the fireplace by painting with heat-resistant paint.

The whole process is quite simple and takes from one to four days . If you have basic knowledge in construction, installing a fireplace yourself will not take much effort and time.

Tools

To install a heating device you will need a standard set of tools. The following may be useful for installation :

- hammer;

- screwdriver;

- perforator;

- Bulgarian;

- putty knife;

- adjustable wrench;

- scissors;

- hydraulic level;

- container for solutions.

These tools are essential for a quick and efficient installation.

In addition to tools, it is necessary to prepare in advance the building materials that will be needed for installation. Basic building materials :

- heat-resistant sealant;

- self-tapping screws;

- mineral or plasterboard sheets with fiber filling;

- ceramic tile;

- metal profiles;

- foiled mineral wool;

- heat-resistant mixture.

When purchasing materials for installation, you should not save money . High-quality materials will ensure the reliability and longevity of your design.

Which location should I choose for the stove?

Proper placement of the fireplace stove guarantees good heating of the entire room. During combustion, the device heats up to 400-600 degrees , and thanks to the metal structure it provides strong heat transfer.

This property requires the absence of masonry or other screens between the stove and the room.

For the correct location of the heating device, it is recommended to draw a plan showing the location of doors and windows.

This will help to approximately calculate the movement of the draft during ventilation. To retain heat, the stove should be located in a place least affected by cold air flows.

What to do before installation

Before installation, it is necessary to completely clear the area and prepare the floor covering on which the device will be installed.

Important! One of the advantages of a fireplace stove over a stone stove is the low installation cost. Most models do not exceed a weight of 200 kg - this allows you to install the stove without additional brickwork.

To ensure the protection of the floor covering, it is enough to use liner sheet , which is made of non-combustible materials and provides heat resistance. ceramic tiles are laid on top of the sheet , which provides protection from fallen embers and warm air flows, and also adds aesthetics to the appearance of the fireplace.

Step-by-step description of the process

To obtain a reliable and safe design, it is necessary to perform all installation steps sequentially.

Installation of the device proceeds as follows :

- Calculations . It is necessary to study all the dimensions of the stove and chimney, and plan in advance the location and possibility of caring for the fireplace.

- Preparing the installation site. The distance between the stove and flammable objects must be at least 1 m. The distance can be reduced if the surface of the walls is protected with gypsum or metal sheets.

- Cutting a hole in the ceiling for the chimney. To improve the aesthetics of the appearance, you can install a decorative plate that will bridge the gaps between the chimney and the opening.

- Installation of thermal insulation . Metal profiles are attached, onto which a plasterboard or mineral sheet is mounted. A layer of foiled mineral wool is placed between the sheet and the wall.

Photo 2. The stove installation process is in full swing: the outlet hole has been cut, the installation of thermal insulation is being completed.

- Arranging a passage opening . It is also lined with foil wool or other heat-resistant material.

- In accordance with the instructions, all pipe elements are assembled and fastened . The distance to the combustible structure when passing through the ceiling must be at least 10 cm.

- Decorative decoration . Insulated sheets and the floor can be decorated with decorative stone or ceramic tiles, and lighting can be added to the ceiling, which will enhance the atmosphere of coziness and comfort.

Laying a fireplace with a cast iron firebox and a metal chimney

To simplify the design, you can use a steel chimney made of sandwich pipes, which are quite suitable for exiting through the wall - and this gives greater freedom when choosing a site for installing a fireplace.

Before you make a fireplace from a pipe with your own hands, you need to stock up on the following materials:

- Cast iron firebox with heat-resistant glass;

- Required number of sandwich pipes;

- Silicone based sealant;

- Tee and set of clamps;

- Elbow with a bend angle corresponding to the design;

- Bracket for installing a chimney;

- Mineral wool required for thermal insulation of the chimney at the point of passage through the ceiling;

- Umbrella for the top of the chimney.

A do-it-yourself fireplace in a private house using these materials is installed using the following technology:

- First of all, the foundation is poured. Filling is carried out exactly the same as in the example described above.

- Protection of walls from temperature effects. Since the fireplace cannot be installed in close proximity to the wall, there must be a layer of super-insulated or sand-lime brick between them. Of course, in the latter case, the support for the brick wall should be the foundation of the fireplace, and not the main building.

- Laying the base. The base is laid out in two rows of ordinary brick.

- Creation of a pedestal. Four rows of bricks are laid out in a U-shape. For masonry, a solution of cement and clay is used. The presence of a pedestal allows you to increase the efficiency of the fireplace - cold air will be taken from the floor and gradually warmed up. On the fourth row of bricks, using a file, grooves are created into which metal corners are installed. The fifth row will be the base for the firebox, so it needs to be covered with heat-resistant mastic.

- Installation of the ash pit.

- Installation of a cast iron firebox. The fuel chamber is installed in its place so that there is a gap of 5 cm between it and the wall. The firebox must be positioned strictly horizontally - this point must be checked and corrected before the mastic hardens.

- Chimney installation. Sandwich pipes are installed in accordance with the project.

- Laying bricks around the firebox. When the combustion chamber is connected to the chimney, it can be lined with bricks. The order in this case does not matter much - the brick structure is laid around the finished firebox.

- Lining the chimney with plasterboard. From the outside, the chimney pipe is covered with a metal profile structure to which sheets of plasterboard are attached. A non-flammable heat-insulating material is attached to the outside of this box.

- Fireplace finishing. To decorate the fireplace, you can use any facing materials - from decorative stone or tiles to ordinary plaster, so there is complete freedom of creativity here. After finishing, the floor covering is laid around the fireplace. It must be remembered that flammable materials should not be placed closer than 80 cm to the fireplace.

- Drying the fireplace and lighting it for the first time. Once assembled and prepared for commissioning, the fireplace must be dried and tested, after which it can be safely used at any time.

To achieve a good visual effect, the fireplace should be complemented with a good woodpile. Knowing how to make a beautiful fireplace will allow you to maximize the potential of this design as an interior design object.

Conclusion

A fireplace is not only a heating device, but also an excellent addition to the interior, allowing you to create an atmosphere of comfort and coziness in your home. Knowing how to properly make a fireplace in a house will allow you to do this work independently and competently, and the created structure will effectively perform all the tasks assigned to it - both functional and decorative.

Types of foundations for a stove in a wooden house

There are several types of foundations used for furnace equipment, each of which has its own characteristics, design and operation features.

When choosing a suitable foundation, consider the following:

- Installation cost – the price of building materials, installation and preparatory work is taken into account.

- Characteristics of the foundation and soil characteristics - the choice is based on the total weight of the structure, the type of soil (clayey, sandy, black soil, stone).

- Dimensions of the foundation for the stove in the house - depending on the area occupied by the stove equipment, the total weight of the structure, the required type of foundation is calculated.

Additionally, several other factors are taken into account. The choice of foundation is influenced by the time of manufacture of the foundation (in an already finished building or simultaneously with the construction of the house), the qualifications of the craftsman, weather conditions, speed of work, etc.

All existing foundations are usually classified into several groups:

- On stilts and pillars.

- Concrete bases.

The stove, subject to certain conditions, can be installed directly on the floor.

Foundations on piles and pillars

Pillar foundations were first used in areas with a high probability of flooding and the absence of shallow dense soil. Piles are widely used in the construction of multi-storey buildings. Pile foundations in their design are somewhat reminiscent of a table with legs.

The base is made in three ways:

- Screw piles are a method that requires material investments. The advantage of using screw piles is the speed of installation. During installation, a worker drives a steel screw into the ground. The steel pillar will be the basis of the future foundation. The piles are tied together, after which a concrete pad is poured on top. The work only takes 1-2 days. You can even put a heavy cast-iron stove lined with brick on a screw foundation. The only drawback is the limited service life. The steel base rots after 50-60 years of use.

- Bored piles - in this case, holes of sufficient depth and diameter are drilled with a drill. The resulting cavity is reinforced with a mesh to prevent soil from falling out. Knit a reinforcing structure. After reinforcement, the pillars are filled with concrete mixture.

- Columnar piles - the process of installing the foundation is the same as in the case of using bored structures. The difference is that ready-made concrete or wooden pillars are used. Massive structures with a large weight load are installed on a columnar foundation. This is the design that is used in the construction of multi-storey buildings.

If you want to make a foundation for a stove in a wooden house with your own hands, without involving outside help, it is better to choose a pile structure, which is easy to install and does not require (with the exception of a screw device) serious material investments.

During installation, the foundation is insulated, thereby preventing the appearance of condensation on the walls of the furnace or cladding. Pillars without insulation will be “cold bridges,” which will negatively affect the operation of furnace equipment.

Concrete bases

The most common type of foundation used for furnace installations is a monolithic foundation made of concrete with mandatory reinforcement.

Advantages of the device: ability to withstand heavy loads of strength, possibility of self-production, relatively low financial costs. Cons: time required for installation and excavation work.

Concrete foundations are made in two ways:

- Strip foundation - a trench is dug along the perimeter of the structure below the freezing point. A metal frame made of reinforcement is installed. The structure is poured with concrete. The strip foundation of the stove cannot be connected to the foundation of the house. The foundation of the building is squeezed out of the ground in winter. The intensity of the “walking” of the walls, the rise from the ground varies, reaching 20-30 cm. If you make a common foundation, this will lead to the destruction of the brick cladding, and often to the deformation of a steel stove decorated like a brick. In any case, SNiP imposes a strict ban on making a common foundation for a stove and a residential building.

- Concrete slab is another popular solution. The slab is poured with a thickness of 15-20 cm. If installed correctly, the result is a monolithic base that can withstand almost any load. To level and evenly distribute the weight, you will need to make a gravel-sand cushion under the foundation. The layer is thoroughly compacted with plenty of water. After filling, a layer of waterproofing is laid, beacons are placed, along which a concrete screed is poured. To prevent the slab from cracking, freshly poured concrete is covered with oilcloth. The base is watered for 2 weeks.

The foundation gains strength gradually. Installation of a metal furnace and lining it with stone begins no earlier than 28-30 days after pouring the concrete.

Floor placement (floor installation)

Installing a steel stove or installing a cast iron stove in a wooden house with your own hands can do without the need to make a foundation, provided that the total weight of the heater with cladding does not exceed 750 kg.

Existing building codes for installing a home heating stove in a wooden house allow the installation of equipment that does not have cladding directly on a wooden floor. When installing on the second floor, you will need to strengthen the logs with metal corners and channels.

To prevent fire, the tree is protected with a metal sheet or a clay-brick layer. Otherwise, installing a wood-burning stove in a wooden house yourself is not difficult.

Manufacturers of heating equipment must provide detailed installation instructions. By following the recommendations and the step-by-step installation plan specified in the technical documentation, you can independently install the stove and connect it to the chimney.

Furnace piping

In rare cases, a room is heated by a stove due to convection currents. The very status of the device implies the most efficient use of released energy. Therefore, the heating system is supplied with a coolant, which can be water circulating through pipes or air moving under the influence of forced convection. Connecting the coolant channels to the furnace is called piping.

Some problems associated with the installation of a fireplace stove are concentrated in the incorrect installation of the main line. With water heating, circulation is provided by a pump or it is carried out due to natural convection. In the second case, it is important to maintain a certain slope of the line, since a reverse slope will lead to stagnation of liquid. In a closed heating system (case 1), the slope does not matter, but the system has strict requirements for tightness. Even a small amount of trapped air will stop circulation.

The water circuit with which the fireplace stove is equipped has an inlet and an outlet for connection to the main line. If they are not specifically marked, then you must remember that the hot water outlet is located below the cold water inlet.

Heating circuit connection diagram

Piping the air duct is not difficult, but laying the line under the panels or covering it with plasterboard is a labor-intensive process. A furnace that uses air as a coolant is equipped with a fan system that drives air through the main line. By adjusting the supply dampers, you can direct heat selectively to different rooms.

Good to know: Long-burning wood stoves with a water circuit

Brick laying process

To obtain even rows, stretch the thread from one edge to the other; you can also control the brick row with a long level. Clay or special stove mortar is placed using a trowel, although some experienced stove makers carry out a similar operation simply with their hands. The mortar is taken with the right hand, a wet brick is held in the left hand, and the area prepared for the brick is smeared with the mortar. The brick itself is also completely covered with mortar, except for the top “bed”. The mortar is also applied to the edge of the adjacent brick, and the inserted brick is pressed into the masonry with the right hand. Excess mortar can be trimmed with a trowel. (See also: What is the temperature in the oven)

Laboratory and practical work

The stove making training program includes laying models of stoves, fireplaces and barbecues according to the drawings attached to this manual. When laying exact copies of furnaces, knowledge of the entire complex of furnace work is acquired. The models of all furnaces being studied for correspondence education must be folded several times according to the drawing, until it becomes possible to fold them without a drawing in several options - with a change in the location of the firebox, cooking floor, pipe channel, etc. During the period of learning the stove business, one masters such a number of different types of stoves and fireplaces that it will take many years for novice stove makers and practitioners, inevitably making various kinds of mistakes, often leading to reworking their work.

| Layout of the model according to project No. 155 Fireplace stove - 3000 | Laying a fireplace stove according to project No. 155 |

| Layout of the model according to project No. 226(A) BBQ fireplace | Laying a barbecue fireplace according to project No. 226(A) |

| Layout of the model according to project No. 202 POV - 2200 barbecue | Furnace laying according to project No. 202 |

Gas outlet options

Smoke removal depends on the fireplace insert in combination with the flue storage system. The following versions exist: Fireplace insert with cast dome. Recommended for connection to an air storage system with an internal diameter of 180 mm. Fireplace inserts with heat exchanger. Recommended for direct connection to pipes with an internal diameter of 200 mm. Fireplace insert with 45° heat exchanger. Recommended for direct connection to pipes with an internal diameter of 200 mm. Fireplace insert with a heat exchanger with a vertical outlet. Recommended for connection to a storage air duct system or for direct connection to a chimney. Fireplace insert for connecting accumulative rings. Recommended for connection to storage rings with an outer diameter of 440 mm. Fireplace insert with cast iron smoke collector. Recommended for direct connection to pipes with an internal diameter of 200 mm. The fireplace insert is right-handed. Recommended for lateral connections with pipes with an internal diameter of 200 mm. The fireplace insert is left-handed. Recommended for lateral connections with pipes with an internal diameter of 200 mm.

Preparation of tools and materials

To make your own fireplace, you need the following set of tools:

- Master OK;

- Mason's hammer or rubber mallet;

- Notched and regular spatula;

- Buckets for mixing the solution;

- Hammer;

- Screwdriver;

- Construction mixer or drill with an appropriate attachment;

- Building level;

- Water level;

- Plumb;

- Roulette;

- Pencil or marker;

- Bulgarian;

- Device for cutting tiles.

The list of required materials is as follows:

- Red stove brick brand M-200;

- Facing brick;

- Steel corners with a section of 50x50 mm;

- Steel strips measuring 50x5 mm;

- Self-tapping screws with wide washers;

- Plastic dowels for self-tapping screws;

- Heat-resistant masonry mixture;

- Heat-resistant mastic;

- M500 grade cement and sand;

- Thermal insulating foil material in the form of plates;

- Minirite slab (required for installing a fireplace in a wooden building);

- Ceramic tiles or porcelain stoneware;

- UD and CD profiles for drywall;

- Drywall sheets;

- Set of decorative grilles for ventilation windows;

- Heat-resistant sealant.

Selection and types of devices

A stove in a wooden house not only performs a heating function, but it can also be used for cooking, heating water and food.

The first is a heating option, and the second is a cooking option. Depending on what goal you are pursuing, you can choose between a fireplace or a stove. The fireplace wins from an aesthetic point of view, but practicality is the main feature of a traditional stove. A fireplace cannot replace a stove, as it ventilates rather than heats the room. But a clear advantage is the ability to observe long-term combustion and the type of flame. A difficult decision in choosing the type of heating is the combination of a fireplace and stove. True, it will be more difficult to make such a system correctly with your own hands. Installing stove appliances will require care and precision, especially at the junctions of the stove and oven. You can also use the services of a stove maker at your dacha if you discuss the details with him in advance so that you don’t have to wait a long time.

The stove in a wooden house can be either a purchased metal potbelly stove or a brick one. When choosing among them, consider the disadvantages and advantages of each type.

A metal stove has the following advantages:

- long service life;

- quickly heats the room;

- unit of reliable design;

- any fuel is suitable for heating a potbelly stove;

- the temperature can be controlled by installing oven devices;

- reasonable price for potbelly stoves.

The fact is that rapid cooling is directly proportional to heating, and this is one of the disadvantages of metal structures. They need to be looked after. For a large room this type of heating is not economical. It will be more difficult to use it for cooking purposes if there is no stove.

It is more appropriate to install a brick oven at the dacha because of its undeniable advantages:

- If the stove is installed correctly, it will heat any area.

- Fire safety is higher compared to its metal counterpart, even with prolonged burning.

- The heat is retained for a long time.

- Additional protection of walls and ceilings is not required.

Fireplace stove: inspiration for interiors

The dream of a large fireplace in the interior can often be unrealistic due to the labor-intensive reconstruction of the room. The idea of using a fireplace stove can be found in almost any interior. The ease and speed of installation of such a heating device makes it the most preferred source of heat in homes.

Fireplace stoves are available in an unlimited range of colors, shapes and decorations. The most versatile, combining with both classic and modern interiors, are black designs with a simple cylindrical shape. Potbelly stoves in the more classic version, rectangular and trapezoidal, have stylized legs. They also come in very rich colors: from classic black, brown to bottled green, purple, wine, shades of cream and off-white.

Installation requirements: safe installation of the fireplace

Before deciding how to install a classic fireplace in a wooden house, you need to make sure that all installation safety requirements can be met. An open hearth should be a source of heat, not problems.

There are special requirements for the installation of fire hazardous appliances in wooden houses.

General safety rules for installing fireplaces in wooden houses

Those who decide to build a real brick fireplace will have to check the project’s compliance with 10 basic requirements for fireplaces in a wooden house:

- At least 12 months must pass from the date of construction of the house.

- The optimal interval between the completion of construction and the installation of a stove or fireplace is 36 months - this is how much time should pass for wooden structures to become stable and natural shrinkage to complete.

- Installation of open fireboxes on upper floors and attics is prohibited.

- The structure cannot be installed on a wooden floor.

- The foundation for the fireplace must be poured in isolation from the foundation of the house.

- Construction of a chimney is mandatory.

- All wooden surfaces located near the stove or fireplace must be insulated from overheating and sparks.

- You cannot install fireboxes near windows with curtains or drapes, or place upholstered furniture or textile decor near the fireplace.

- The firebox must be equipped with a removable screen.

- There must be a working fire extinguisher in the room at all times.

Can't meet all the requirements? Give preference to safe electric fireplaces, especially if you plan to install them in the attic, on the second floor of a house with a wooden floor.

Beautiful and safe: an alternative to standard stoves

Surface insulation: how to protect wood from fire

Those who decide to build a classic brick fireplace will have to take care of protecting wooden surfaces. The main tasks are to prevent heating of the walls and ceilings, to protect the floor and walls from sparks that could fly out of the firebox.

Wall insulation scheme

Basic insulating materials for wooden walls:

Basalt wool.

Plates of different thicknesses

Mineral sheet insulation with a heat-reflecting screen - sold in sheets.

Rolled non-flammable insulation.

Heat-resistant synthetic foil insulation

Brickwork: instead of sheathing with sheets, you can lay out part of the wall with half-brick masonry.

You can protect the floor made of parquet or deck boards with steel sheets or stainless steel, or line the area in front of the stove with porcelain stoneware, ceramic tiles or facing stones.

The chimney passing through the ceiling is insulated with rolled fire-resistant wool with foil film.

Combination of materials

Quite an interesting result can be obtained by combining different finishing materials.

This technique allows you not only to create a unique appearance, but also saves on materials. You will be able to use cheaper finishing options for parts of the stove that are subject to less wear. This question interests home craftsmen who decide to lay a stove or fireplace. It is also very relevant for everyone who has stove heating in their home. Finishing the hearth with simple plaster is not highly aesthetic and after ten years of use requires replacement.

Of course, cracks and peeling of the finishing layer can be repaired. However, after such a procedure, the stove does not look its best and after a short time begins to crack again.

We will tell you how to cover a stove or fireplace so that it looks great, gives off heat well and does not require repairs for a long time.

Installation of stove and chimney

The installation of a metal stove itself is not difficult. The main thing is to strictly follow the recommendations in the instructions supplied with the equipment, and also to align the structure at a horizontal level. In this case, the minimum distance specified above must be observed from the wall.

Advice!

Before installing the device in the house, it is recommended to carry out the first firing in the yard so that the thermal paint that covers the stove outside and inside is firmly fixed and loses its specific smell.

After installing the stove, the chimney is connected. The most successful option for a wooden house is a sandwich chimney. There is a heat insulator between the two layers of steel that it is made of, so the outer surface does not get too hot. Other advantages of chimneys of this type include the fact that they are not prone to condensation and less soot accumulates in them.

If the pipe is made of stainless galvanized steel, then it must be insulated with non-combustible material. But, despite the presence of insulation, the chimney, according to safety regulations, must, like the stove itself, be located no closer than 38 cm from the wall.

The rules for installing a chimney are as follows:

- In order to make chimney passages through the ceiling, a factory-made cutting (special box) is used. This type of cutting is called interfloor or attic.

- The box should be selected so that the diameter of its hole matches the outer diameter of the pipe.

- A square hole should be cut between the beams, the size of which should correspond to the square part of the cutting. You can make this hole a little larger so that you can metal it with two layers of basalt wool.

- After this, the assembly of the chimney begins. A pipe must be connected to the chimney outlet, which is located on the top or rear surface of the housing. A slide valve is mounted above, which is designed to regulate draft.

- To create hermetic connections, special heat-resistant compounds are used. If it is necessary to create a connection between pipes of different diameters, special adapters (so-called glasses) are installed. You should not make a chimney with a large number of turns - fuel combustion products will accumulate in them.

- Next, the chimney is passed through a box in the ceiling, and the space between the cutting walls and the pipe is filled with basalt fiber.

Foundation for a fireplace - main stages of construction

If you plan to build a brick heating device of one type or another in the designed house, a permanent foundation for them must be provided in advance. It is best to first determine the location and size of the foundation for the fireplace. Otherwise, you will have to perform this work in an already built house, which cannot be done without dismantling the finished floors.

Work on making a foundation for the fireplace should begin by marking its location. The dimensions of the base itself must exceed the dimensions of the fireplace in plan by 10 cm on each side. Based on the calculated parameters, the future recess for filling is marked.

The depth of the foundation for the fireplace can be different and varies from 0.5-0.7 meters to 1.5 meters or more. This parameter depends on the level at which groundwater is located and the depth to which soils freeze in a given area. In the case of permanent rather than temporary use of a brick heating device - a stove or fireplace, the last parameter is usually not taken into account.

According to the markings on the soil, made using corner pegs and cords stretched between them, remove the top turf layer of soil and dig a hole with smooth horizontal walls. The bottom of the recess is carefully leveled in a horizontal plane, I control its required position by level.

Concreting the foundation

A special feature of building a foundation for a fireplace with your own hands is the layer-by-layer filling of the hole dug in the wound with a concrete mixture of various compositions. For work you should prepare the following materials:

- Finely seeded river or quarry sand without foreign impurities in the form of roots, grass, aquatic vegetation;

- Cement is the main type of binder when performing concrete work. To obtain a high-quality fireplace foundation, you must choose this building material correctly - it must have a uniform, loose consistency and not be crumpled or expired. The grade of cement should be chosen not lower than M400.

- Crushed stone is a medium-sized crushed natural stone. In construction, granite and limestone gravel are most common. The first type has the best frost resistance, the second has the lowest price among analogues.

- Rubble stone is a natural stone, which is larger pieces of rock, reaching linear dimensions of 0.5 meters and a mass of 50 kg.

The first layer of the foundation for the fireplace is a concrete pour made of sand-cement mortar and filler - medium or fine crushed stone. A little bit of this mixture is required. The thickness of the first layer should be about 0.25 meters. After the concrete has partially set, the next layer is poured. It is based on a larger stone. The technology for pouring a rubble foundation is as follows:

- First, a layer of large pieces of rock of one type or another is laid;

- Next, to compact the backfill, the gaps between the rubble stones are filled with medium-sized crushed stone;

- The next stage is pouring the stone backfill with a cement-sand mortar of medium thickness.

The rubble foundation is raised to the ground level. Regardless of the floor level of the first floor, the base of the fireplace must be raised to a level approximately 10-15 cm below this value. To do this, it is necessary to install formwork.

Production and installation of formwork

The foundation formwork for the fireplace is a hollow structure made of durable wooden, plastic or steel panels. For making it yourself, the first type is best suited. To make it, you will need edged boards of an inch thickness or sheet materials - plywood, OSB, lined with chipboard.

Installation of formwork for a fireplace

Shields are knocked together from boards using nails or connected with self-tapping screws, without recessing their heads deep into the wood. When assembling, you must try to minimize the gap between the lumber to avoid rapid removal of moisture from the concrete solution. Formwork made of sheet materials is more preferable in this case.

Installation of the foundation formwork under the fireplace should provide the future foundation with the correct geometric shape. To fix the panels, spacers made of wooden slats, ties made of boards or bars are used. After installing the formwork, it is recommended to coat all seams between the slabs with bitumen mastic.

Protective cladding for walls and ceilings

The walls directly adjacent to the stove, as well as part of the ceiling along the passage of the chimney, are subject to significant thermal loads.

Therefore, before installing a stove in a wooden house, you need to fulfill a number of prerequisites:

- The ceiling lining is made of non-combustible material. Wooden or plastic panels are not used. It is best to purchase gypsum fiber boards treated with gypsum putty for painting.

- The walls must be protected with a layer of basalt cardboard and covered with a sheet of steel. As an option, you can use ready-made decorative stainless steel screens. These products are able to provide safety and are distinguished by external beauty. In addition, the walls can be plastered with a layer of 3 cm or more, and also lined with brick (read: “How to line a metal stove with brick in a house - a step-by-step guide”).

Fire safety rules for installing iron stoves in wooden houses are described in more detail in SNiP 05/31/2003 and SP 118.13330.2012.

Adjacent to the wall at one of the ends

Such models are recommended for fairly large or medium-sized rooms. By making a similar fireplace in your home with your own hands, you can zone the room or reduce the size of the passage between separate rooms.

A special feature of this option is the possibility of installing a through metal firebox with two-sided or three-sided finishing with heat-resistant glass. In addition, you can make a firebox on one side and decorate the back with natural stone.

In small rooms, you can also build a fireplace with your own hands, adjacent to the wall at the end. In this case, it allows you to divide one room into two functional zones, making your stay more comfortable.

Treatment of wood against fire

Additional means of protecting wooden structures located in the immediate vicinity of an iron stove are fire-retardant impregnations and mastics. Beams, load-bearing structures, floors and walls adjacent to the furnace are subjected to this treatment. Mastic has a higher level of fire protection, and the impregnation is almost colorless.

Fire retardant treatment can be carried out by both representatives of the Ministry of Emergency Situations and the owners of a wooden house. In the latter case, before starting to operate the stove, it will be necessary to obtain a certificate from the inspector of the Ministry of Emergency Situations about the compliance of its installation with the requirements of the safety regulations.

All leading European and Russian manufacturers of solid fuel stoves describe in detail the rules for installing equipment and fire safety requirements in their technical documentation.

Wall fireplace with podium

The peculiarity of this fireplace is the absence of an ash pan and a straight chimney of a simple shape. At the bottom of the fireplace there is a forward semicircular podium. It serves not only for decorative purposes, but also for safety: the firebox of this fireplace is shallow, and sparking is possible; the firebox is lined with refractory bricks.

The narrowing of the firebox in the rear part forms a protrusion - a gas tooth. The mantelpiece is made of wood and rests on a semicircular log. The simple shape of this fireplace will fit perfectly into a hunting-style house.

Sample of a wall-mounted fireplace with a podium

As can be seen from the article, it is not at all difficult to install stoves and fireplaces with your own hands; drawings and diagrams will help you understand the intricacies of the stove craft. You can also learn how to properly make a foundation for a fireplace, mix masonry mortar and lay bricks from the article on laying a fireplace with your own hands.

Throughout time, the main place in the house was given to the hearth. Recently, fireplaces in houses and cottages have become very popular, and the question of how to build a fireplace with your own hands is quite relevant.

Any stove or fireplace must meet the following requirements:

- No smoke. Room heating. Beautiful appearance.

To achieve these goals, all stages of construction must be followed.

Construction of a ceramic smoke channel

The most reliable and safe option for installing a chimney in a wooden house is a construction made of ceramic blocks. Its outer side practically does not heat up, which means there will be no problems with passage through the ceilings.

Let's consider the sequence of assembling a smoke channel from components of the German brand Schiedel Rondo Plus:

Let’s immediately make a reservation that the main one is constructed from ceramic modules, i.e. a separate pipe for which a separate foundation is arranged.

All technological holes are cut out along the construction site. Cutting is done with a regular grinder with a diamond blade.

To make geometrically accurate holes, the ceramic chimney kit includes a template. Further:

The ceramic chimney is assembled in a standard manner: modules are built up one after another

However, it is worth paying attention to the specifics of passages through the attic floor and through the roof

In our example, the chimney and ventilation riser are located next to each other, which is why we had to slightly trim the rafters:

We also have another article on our website containing step-by-step instructions on how to build a ceramic chimney, attach it and decorate the outside.

Where can you see a Russian stove?

We will answer all your questions step by step. In our country, a huge part of the population lives far from civilization. In the 90s, there was a tendency for villages to die out. Young people left their parents' homes and went to the city in search of a better life. Many buildings remained simply abandoned.

Most village houses were equipped with stove heating. In order to dismantle the stove, it is necessary to re-lay the floor covering and seal the hole in the roof under the chimney. Not everyone had the desire and opportunity for this, so the symbols of warmth and comfort in the home, sung in Russian fairy tales, still stand to this day.

Massive brick building

Gasification made it possible to install a burner in the stove and give the structure a second life. But the modern approach to reconstruction implies that it will be converted into a functional, stylish fireplace.

Tips for installing a fireplace chimney

Chimneys for a fireplace are easier to install than chimneys for stoves. Typically, this is an almost straight vertical pipe that runs from the fireplace insert to the roof. If you need to make a branch or tie-in into a common chimney, then the elbow is mounted at an angle of no more than 45º.

The diagrams of all fireplace chimneys are similar, since the system works on the same principle.

Brick chimneys are not practical, since more soot settles on these chimneys and the draft is worse.

At the moment, stainless steel sandwich pipes with a thermal insulation layer are used to install the chimney. Installing a chimney from such pipes is much cheaper, plus any home craftsman can do it.

The basalt layer in sandwich pipes protects the chimney channel from condensation.

A sector of a regular (not insulated) pipe is installed directly above the fireplace insert; in advanced models, this sector can be equipped with an adjustable smoke damper. An insulated pipe is already installed on top of it.

A draft regulator is necessary in any chimney.

To connect the insulated and non-insulated parts of the chimney, a special adapter is used; it prevents the basalt layer from “sliding” down and ensures the tightness of the system.

It is impossible to assemble an insulated chimney without a transition washer.

Remember - all joints and connections in the chimney must be coated with heat-resistant sealants, and where this is provided, the pipe is also secured with a metal clamp.

All connections in the chimney must be sealed.

The box for the chimney pipe, which we mounted directly above the firebox, is not only made for beauty; with the help of this thermally insulated chamber, you can easily redirect the flow of warm air to neighboring rooms or to the general ventilation system.

Scheme of heat redistribution in the fireplace.

In order to ensure good draft in the chimney, the pipe must be correctly mounted on the roof. The higher the chimney, the better the draft, but it is not always possible to install a high pipe; for such cases there are minimum requirements, which are reflected in the diagram below, the data is indicated in millimeters.

To ensure good draft, the chimney on the roof is installed according to certain rules.

Firebox selection

If you decide to use a metal firebox, then the chimney pipe must be selected according to the diameter of the pipe already on it.

Easy to install ready-made firebox

In specialized stores today you can purchase a firebox of any configuration - open and closed, through and one-sided, as well as with a built-in heat exchanger for the water circuit. Its design can be clearly seen in the diagram, where a similar firebox is shown in section.

Fireplace insert with built-in heat exchanger

The traditional brick firebox is lined with white fireclay bricks placed on the end side. It is heat-resistant, so it can easily withstand high temperatures. This work requires extreme care, since the surfaces of the fireplace must be as smooth as possible. Therefore, the process of its installation will take quite a lot of time. If you have no experience in the art of bricklaying, then it is better to choose a ready-made metal firebox. It will fit perfectly into the modern interior of rooms.

Before installation

Before installation, it is recommended to inspect the product to ensure that the original packaging is intact and that there are no defects, chips or breakages. Each heater must be accompanied by detailed instructions and a technical passport from the manufacturer, a diagram and description of the complete package. Based on the information from the technical data sheet of the product, you should study the conformity of the product with the stated configuration. If you find that the package is incomplete, broken or defective, you must contact the manufacturer or sales representative to replace the product.

Thermal screens

How to install a stove in a bathhouse on a wooden floor and protect wooden partitions from high temperatures? For steel and cast iron units, the following types of screens are used:

Fire protection will protect the tree from fire and charring. The material is mounted on the wall surface, in some cases through thermal insulation inserts. They lay out a brick covering or line it with natural stone or ceramic tiles. Another option is to install iron sheets on the partitions and ceiling. It is recommended to use stainless steel, which is attached to the boards with a heat-resistant gasket, or basalt cardboard can be laid on top of the layer.

Brick barriers can be laid on the sides of the stoveSource bg.decoratex.biz

Protective types protect users from various burns of contact and remote origin. In this option, the firebox itself is lined, with the obligatory arrangement of an air gap of 3-7 cm. The thickness of the finishing material is half a brick, but some builders make masonry using a quarter of a whole brick. When installing the stove, the iron screen is also attached at a certain distance from the body.

A wooden wall and floor can be protected by metal shields Source banya-ili-sauna.ru

A floor heat shield made of steel sheet will protect boards located near the heating device. It is recommended to use a sheet measuring 70x50 cm; it is attached along the front part of the firebox, while a layer of heat-insulating building material is laid between the wooden floor and the metal. Basalt or asbestos cardboard is suitable.

In addition to its protective qualities, the screen will give the furnace unit a complete appearance.

How to protect a country house from fire when installing a stove

Fire regulations require protection of walls and floors made of combustible materials when using solid fuel heating equipment. Fire prevention measures include:

- Use of thermal insulation materials with a high degree of fire resistance to protect walls and ceilings at the installation site.

- Application of fire protection: impregnations and mastics.

Safe installation of the furnace and the use of fire prevention products are a mandatory requirement for the operation of furnace equipment.

How to cover the walls and ceiling when installing an iron stove

The part of the ceiling located above the stove and at the point where the chimney passes, as well as the adjacent walls, experience severe thermal stress. The following fire safety conditions and measures are considered mandatory:

- The ceiling is made of non-combustible materials. The use of wooden and plastic panels is not allowed. It is optimal to use gypsum fiber boards treated with gypsum putty for painting.

- The walls are protected with basalt cardboard followed by sheathing with steel sheets. For convenience, we use ready-made protective decorative wall screens made of stainless steel, which have a beautiful appearance and provide a high degree of safety. The walls are protected with plaster with a thickness of at least 3 cm, as well as brickwork.

Fire safety requirements for installing a metal stove in a wooden house are described in detail in SNiP 31-05-2003 and SP 118.13330.2012.

Fire retardant treatment of wooden structures

Where the stove is installed, wooden walls are protected using fire retardants: mastics and impregnations. Load-bearing structures and beams must be processed. Fire retardants are applied to the walls and floors where the furnace equipment is installed.

Mastics and impregnations have been developed for protection. The former provide better fire protection, the latter are almost colorless.

The order of installation regarding fire safety measures specified by the manufacturer is specified in the technical documentation. Fire protection work is carried out by representatives of the Ministry of Emergency Situations. You can take measures to prevent fire yourself, but before putting the stove into operation, you will need to obtain a certificate from the inspector of the Ministry of Emergency Situations about the fulfillment of all requirements of the safety regulations.

Detailed parameters for installing a solid fuel heating country stove are described in the technical documentation attached to the heaters of leading European and Russian factories. Compliance with the described rules is mandatory.

Small brick stoves without a foundation are great for country houses or temporary buildings, especially if the building is already ready, and there is no way to build a foundation for the stove in it. You can install a small stove on a regular floor, even a wooden one, as long as it is made of thick enough boards. Being equipped with a cast iron hob, it can be used not only for heating, but also for cooking. At the same time, this unit is more convenient to use than steel stoves, since it emits heat softly and can accumulate it in sufficient quantities (you have to add firewood less often).

It is not always possible to allocate space for a stove foundation, but there are stove options where a foundation is not required.

Many owners of already built country houses do not dare to build such a unit due to reluctance or lack of opportunity to build a foundation for the stove. In such a situation, you can build a miniature brick oven without a foundation.

Installation stage No. 4: connecting the device to the chimney and utility networks of the house

The final stage of installation consists of connecting the stove to the smoke duct. To do this, a piece of pipe without insulation of the required diameter, which is indicated by the manufacturer in the product passport, is connected to the chimney outlet pipe in the furnace body. Next, a single-wall pipe section is connected to the main thread of the chimney. The joints between the stove and the chimney should be as tight as possible. If the equipment is equipped with hot air or coolant distribution systems, air ducts and pipelines are connected to the unit.

Wall cladding with tiled tiles for stoves

When installing a fireplace or stove in country houses, you will have to take care of thermal insulation of the nearest walls.

In this case, the enclosing corner of the internal OSB partition was lined with super-insulated boards. The material is ugly, so we decided to cover it with tiles for stoves. The walls were made of super-insulated material, lined with tiled tiles, and the fireplace stove was installed in a pre-prepared place.

| They decided to lay the tiles without a reinforcing mesh, and to ensure better adhesion between the tiles and the base, they used “Betokontakt” - an acrylic primer containing small pebbles. For reliability, the surface was coated twice, with a break of a day. Heat-resistant adhesive mastic was used to lay the tiles. Usually it is applied to one of the adhesive surfaces in a layer of 0.5 to 1 mm, but not more than 2 mm. In this case, it was applied directly to the tile - with five dots. |

| The laying began from the bottom from the corner. In this case, there was no need to set the horizontal lines, since the floor tiles were already laid and served as a guide. The thickness of the joints was adjusted using ordinary crosses for laying 1 mm tiles. |

| The tiles and joint thickness were selected in such a way as to avoid undercutting. However, in the upper part of the partition, near the ceiling beam, adjustments were required. To do this, we first prepared a paper pattern. It was used to make cuts on tiles. |

| After 24 hours, the crosses were removed, the seams were moistened with water and filled with grout using a rubber spatula. The mixture was diluted with a special latex additive for cement mixtures, which improves the technical properties of the grout, in particular, increasing its resistance to deformation loads in the form of sudden temperature changes. |

| After 10 minutes, use a damp sponge to thoroughly clean the tiles from traces of grout. To improve the hydration process of the cement contained in the grout mixture, the joints were additionally moistened several hours after grouting. |

| The edges of the tiled masonry and the ends of the wall were edged with wooden corners and plinths, combined with the floor plinth. For this purpose, you can use special plastic or metal strips for tiles, which give a beautiful, smooth edge. |

Dimensions and location of the hearth in the room

When choosing the design and drawings of the fireplace, pay attention to the dimensions of the portal, fuel chamber and chimney. The indicated dimensions are selected according to the area of the heated room and are related to each other by the following ratios:

- cross-sectional area of the chimney pipe - 1/9 of the portal quadrature;

- the depth of the firebox is made 1.5-2 times less than the height of the portal opening;

- the area of the open opening is 1/50 of the square footage of the room.

If you make a large fireplace in a small room, the chimney draft will not have enough air flow. The fireplace will begin to smoke into the room or “suck” air from neighboring rooms, along with the heat. It is permissible to build a small structure in a spacious room, but the heating will be minimal - the fireplace will decorate the living room and play the role of a barbecue.

For the convenience of determining the size of the firebox and smoke exhaust duct, depending on the square footage of the room, there is a ready-made table:

According to their shape, fireplaces are divided into 2 types - wall-mounted and corner. In the publication we provide a description of the first type - it is relatively simple. To build corner-type home fires, you need to gain experience in the stove business. Having decided on the dimensions of the heater, select a place for installation, taking into account our recommendations:

- Place the fireplace in the central part of the interior partition. If a private house is under redevelopment, renovation or construction, the rear wall can be brought into the adjacent room by making an opening inside the partition.

- It is not advisable to build a fireplace near the outer wall - some of the heat will go outside.

- Think about convenience - do not place the structure near interior doors and do not place furniture close to each other.

- Carefully study the design of the ceilings and rafter system so that the chimney pipe does not fall into the load-bearing beam or onto the edge of the reinforced concrete floor slab. The minimum distance from the wall of the flue to the rafters is 10 cm (taking into account fire-resistant furnace cutting).

When choosing a site for a fireplace, do not forget about the foundation. In a residential area, you will have to dismantle the floors, dismantle the screed and dig a pit without affecting the existing foundation of the building. Remember if there are house utilities installed in the selected location - sewerage, water supply or heated floors. The basement under the room is also a problem; not every ceiling can withstand the weight of the masonry.

Experience in installation and installation of heating equipment for more than 20 years

For more than 20 years, it has been providing services for professional installation of heating, smoke exhaust and accompanying equipment of any level of complexity. The company’s specialists are guided by all established rules and standards of fire, technical, and operational safety. Installation of equipment is carried out promptly, taking into account the individual parameters of the Customer’s structure, his needs and the type of heating system. At the end of the work, commissioning of equipment and testing of all systems connected to the heater are carried out. All work is provided with reliable quality guarantees with appropriate documentation.

Varieties

The material of manufacture determines two types of furnace units - brick and metal. The brick oven is made of refractory fireclay bricks and lined with ceramic. The metal structure can be made of different metal alloys.

The most accessible option is to install an iron stove in the bathhouse. The metal warms up quickly with low fuel consumption. The weight of the stove structure varies depending on the dimensions of the firebox and heater, on average 100 – 400 kg. A cast iron stove is characterized by heavy weight and increased heat accumulation.

READ MORE: How to make a wooden floor in the kitchen question

The advantage of such units is obvious:

- economical and fast installation;

- low labor costs during installation;

- compact size and weight;

- the tightness of the structure increases safety and reduces the leakage of carbon monoxide.

The disadvantage of using a metal stove is the rapid cooling and uneven heating of the room. When fuel burns, the metal quickly cools and stops giving off heat.

The stove heats up to 500 degrees, which can lead to burns if touched carelessly

The further the distance, the lower the temperature. Disadvantages can be neutralized by installing a brick case.

Brick furnace structures do not have the negative aspects of metal units. Uniform and long-lasting heat will remain for several hours after heating. But to heat a brick oven, you will need a lot of firewood and at least 2 hours to heat the brick.

The skill of masonry, the preparation of a solid foundation and its impressive size pose a challenge when installing a brick stove.

Depending on the location of fuel loading in the furnace design, there are separate types of heating units:

- Fuel loading is carried out from the steam room. When installing oven equipment in a steam room, proper installation and additional ventilation are required. If the bathhouse is made of timber, then the stove is placed according to fire safety rules. When the firebox is open, oxygen burns out from the room, so you need to ensure high-quality ventilation. The advantage of placing the stove in the steam room is constant control and the ability to quickly regulate heating.

- The furnace firebox is located in the dressing room. This location is relevant for a wood-burning stove. This is optimal from the point of view of cleanliness and ease of fuel loading. In this case, it is planned to erect a frame wall between the steam room and the dressing room.

- Fuel is supplied from the street. This option is suitable for mini-baths or seasonal summer cottage buildings when heating with coal. Fuel is loaded from the street side, which can cause inconvenience when loading and monitoring the stove.

Furnace structures can be of various shapes - cylindrical, rectangular, barrel-shaped, with high or low sides. In addition to the firebox, the design of the stove may include a tank for heating water and a container for the heater.