Having a portable stove on hand in an unfinished home or garage is a big deal. You can finish the work put off since the fall without haste. True, such a stove is very expensive, and it weighs almost a hundred kilograms, so how mobile is it? But even in such situations, there is a way out - to make a stove yourself, for example, from old gas cylinders. Moreover, such creativity will cost much less than buying a cast iron potbelly stove, because all the work can be done independently, and the materials can be collected at any metal collection point for almost nothing.

How the device works

A potbelly stove made from a gas cylinder using wood or exhaust is the simplest design that works like a regular stove and is reliable. The body is an old cylinder; due to the large thickness of the walls, it provides good heat transfer and lasts much longer than versions made of sheet metal.

The principle of operation is extremely simple - fuel is placed in the main chamber, due to its combustion, heat is transferred through the walls into the room and quickly heats the space. Efficiency directly depends on the size of the stove, so you should not use small cylinders.

To make it easier to remove combustion products, grates are usually installed and a compartment is made at the bottom to collect ash. And the smoke is discharged through a pipe on top, which is welded or secured in another suitable way. The design is very simple, so it is well suited for garages, boxes and other work areas.

Will a small bottle suffice?

You can also work with a small balloon. It is made according to the same plan as a horizontal stove.

- But in this version, instead of drilled holes in the bottom of the stove, a cast iron grate is installed. A window of the required size was cut out for it.

Installation of a cast iron grate

- The blower in combination with the grate is welded as follows.

Ash pan made from a piece of channel

- Next, the legs are welded onto the ash pan box, the structure is turned over and the chimney pipe is installed on top and secured by welding.

- After completing work on the potbelly stove, it is installed in a permanent place and the chimney is taken out into the street.

Which cylinder to choose for a potbelly stove

For a system to work effectively, it must be of a certain size. Therefore, options with a capacity of 5 or 12 liters are not suitable, since they are very small. If you need to heat a small space, you can use a variety with a capacity of 27 liters.

To make a potbelly stove from a gas cylinder using long-burning wood, it is best to use 40 or 50 liter products. They are ideal for such purposes and have the necessary dimensions for convenient use.

By the way!

In order not to spoil a good cylinder, you can buy an old or broken one from a supply organization; it will not cost much.

Any options are suitable for work, the condition does not really matter. The main thing is that there is no serious damage or deformation. The most important thing is the size so that it is convenient to lay firewood.

Furnace modernization

Improving the operating parameters of the furnace is associated with an increase in its heat transfer. For this purpose, additional heat exchange surfaces are used on the furnace body. Such parts can be made from various metal profiles, including strips, angles, and profile pipes. The choice of material depends on what is available from leftovers.

Additional heat exchangers made of metal profiles increase the efficiency of the device

Additional heating surfaces can be installed not only on the outer surface, but also inside the firebox, which allows you to intensively heat the air in the room. A negative result of such a solution will be oxygen burnout at high temperatures.

What are the doors made of?

This is an important part of the design, since the ease of use and safety of the potbelly stove directly depends on it. There are no special requirements; most often, one of two varieties is used, since they are the ones that are suitable for a stove made from a gas cylinder.

The first option is pieces of metal remaining after cutting openings in the walls of the workpiece. This solution is convenient because the elements fit perfectly in size and have the same properties as the body, which means they will not be deformed. But there are also difficulties - you need to select and weld hinges of the appropriate size and make a latch for locking.

The second option is ready-made doors made of cast iron - a wear-resistant solution that is not afraid of any temperature and lasts a long time. The main thing is to choose a product of the appropriate size and accurately cut the opening for it. For fastening, a metal corner is welded to the edges of the cutout, in which holes for the bolts are drilled.

The main thing is to accurately fit the parts so that there are no large gaps and the doors close tightly. It is important that they lock securely, and that the hinges ensure easy opening and do not sag over time.

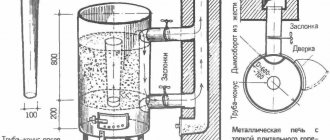

Horizontal potbelly stove

Horizontal potbelly stove from a cylinder

- Another version of a stove made from a cylinder, which is placed horizontally, also has its advantage - you can install a large hob on it, which will be able to not only warm tea, but also cook lunch.

- In order for the structure of the potbelly stove to stand steadily, a reliable stand is welded for it from a corner, and after completion of the work, the finished stove is secured to it using spot welding.

- Work on the cylinder also begins with markings, after which a square hole is cut for installing the door and a round one for installing a chimney pipe. You may have to work with a round hole if you don't have a cutter. The “grinder” is not an assistant here, so first, drill holes around the circumference, then work with a chisel and hammer, and then final finishing with a file.

- Holes are drilled in the bottom of the future furnace, which will play the role of a grate, and under it a box is welded from a sheet of metal into which the ash will be poured.

In the role of a grate - rows of drilled holes

- The same chamber will be a blower, so an adjustable door is installed on it so that the air flow can be reduced or increased to establish the desired draft.

You can make the door yourself...

- You can make the door for this stove yourself by scalding a part cut out of a cylinder, or you can install a ready-made cast iron part that already has a frame. The second option will be easier to install, and it is already equipped with a latch to securely close the firebox.

...or buy ready-made ones in the store

- After installing the door, the potbelly stove is fixed on the stand or legs of the required height are welded to it.

- Then a pipe is welded onto which the chimney pipe will be installed. It can also be discharged through a wall or roof.

How to improve heat transfer

Before you make a potbelly stove from a gas cylinder using waste or wood, it’s worth figuring out how to increase its efficiency. It is better to study this point in advance, since due to it you can significantly improve heating and reduce fuel consumption:

- Welding two cylinders. The horizontal part is welded to the vertical firebox, thereby increasing the heat transfer area.

- Adding bends to the chimney. Due to this, hot air leaves much more slowly, which increases heating efficiency. The main thing is to choose the number of bends so as not to worsen traction.

- You can figure out how to make a long-burning potbelly stove from a gas cylinder. It is distinguished by the presence of an afterburning chamber, due to which the consumption of firewood is reduced and efficiency is increased. But the design is much more complex.

- Often pipes or a U-shaped profile are welded to the edges, which increases heat transfer.

- Another option is to install a mesh frame and fill the space around the stove with stones.

Advice!

You can cover a horizontal potbelly stove with bricks and you will get an improvised stove.

There are other options - constructing a metal frame that is welded to the outside of the cylinder. The easiest way is to decorate the surface of the wall near which the potbelly stove stands with tin or reflective material to direct heat into the room.

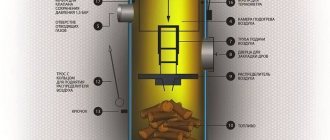

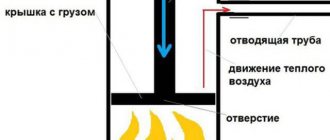

Slow burning pyrolysis furnace “Bubafonya”

It is impossible to describe or simply list all the designs of stoves that can be made from cylinders, but it is advisable to consider in detail the “bubafonya” design. This model can be made at home with your own hands.

Safety

Before describing the design of the furnace and its manufacturing technology, let us pay attention to safety issues. We will talk about preparing the cylinder itself for processing. Despite its dense structure, the inner surface of the metal is riddled with a network of microscopic cracks. During long-term operation of the container for its intended purpose, a considerable amount of gas condensate and its sediment accumulates inside these defects. Such a substance may be explosive and is in no way beneficial to health. Before you start working with the cylinder, you need to fill it with water and let it sit for 2-3 days. It is better to perform the operation away from home. When the liquid is drained, the reasons for this recommendation will become clear - it has an extremely unpleasant and strong odor.

Video: how to safely disassemble a gas cylinder

Tools and materials for making the Bubafonya stove

To make such a heating unit with your own hands, you will need:

Table: required materials and tools

| Name | Purpose | Notes |

| Cylinder for furnace body | Manufacturing of the main product | boo |

| Steel rod with a diameter of 10 mm | Making handles for the oven lid and body | From waste |

| Angles 45x45, any profile, pipe cuttings | For support legs | From waste |

| Bulgarian | Cutting blank parts, cutting the cylinder during the manufacture of the body | |

| Steel sheet 6–10 millimeters thick | Making a pancake | |

| Steel strip 40x4 millimeters | Manufacturing of support ribs | |

| Cement, sand, gravel and fireclay bricks | Making the furnace support base | |

| Reinforcing bars | Foundation reinforcement | |

| Trowel, shovel, container for mixing the solution | Pouring the foundation | |

| Welding machine for working with ferrous metals and electrodes for it | Making welded joints when assembling the furnace | Possible to rent |

| Electric drill no less than 0.7 kW, set of metal drills | Drilling holes | |

| Measuring tool | Taking measurements and marking | |

| Locksmith's corner | Positioning of parts during assembly, quality control | |

| Kerner | Hole marking | |

| Files flat and semicircular | Removing sharp edges and burrs, adjusting dimensions | |

| Marker black | Marking production | |

| Individual protection means | Goggles, welder's mask, face shield, mittens, gloves, special shoes, rags. |

How to make a potbelly stove from a gas cylinder with your own hands

If you understand how to make a potbelly stove with your own hands from a gas cylinder during mining, first find the drawings. The configuration of the furnace is different there, since it will require a container for processing and an injector in the form of a pipe with holes for efficient combustion. This variety is difficult to implement; the easiest way is to make a classic wood-burning stove.

Important!

Before starting work, be sure to clean the cylinder of any remaining gas and get rid of the fragrance odor. To do this, first take the element outside and open the valve all the way so that the contents escape. Next, the condensate is drained, it is this that gives the pungent odor. After this, it is advisable to fill the container to the top with water to remove the remaining solution and displace the gas. After draining it, you can start working.

Horizontal potbelly stove

This option takes up more space, but can be an excellent solution for saving firewood. They can be laid in several rows so that combustion occurs gradually. At the same time, the horizontal version can create a risk of burns, since the surface becomes very hot during operation. It should be collected like this:

- The easiest way to make a door is at the top end. The valve can be left to regulate the air supply or a special fitting can be installed instead. If a finished door is installed, make an opening for it by welding a corner for the frame around the perimeter.

- Make a hole for the chimney on the side opposite the door with an indentation of about 20 cm from the edge. In order not to cut it exactly to fit the pipe, you can make an opening and weld it with a metal ring, to which the chimney is also welded.

- To make it more convenient to remove ash, it is advisable to place grates inside. The easiest way is to take two corners that are grabbed at the desired level. A home-made element made from reinforcement or a ready-made cast iron grate is then placed on them, if a suitable size can be found.

- Weld supports or legs at the bottom. Make the distance to the ground such that the floor does not overheat, and the entire surface of the cylinder transfers heat into the room. There are no special requirements, the main thing is that the stove is stable and safe.

By the way!

To seal the door junction in other places where necessary, use asbestos cord.

Before you make a horizontal potbelly stove from a gas cylinder in the garage, be sure to make sure that there is enough space for it. The fact is that you will have to leave at least a meter of space around the structure, and this is difficult to do in small garages.

Vertical stove made from a gas cylinder

This solution is much more compact and takes up minimal space, so it is used more often. It is most convenient to place such a stove in a corner to create less interference with movement. The manufacturing instructions look like this:

- At the bottom, make supports or weld a platform larger than the diameter of the cylinder. This will ensure the stability of the structure. If the floor in the room is uneven, you can make adjustable legs to position the potbelly stove perfectly.

- Remove the valve and make a hole around its installation site according to the diameter of the future chimney. Usually a pipe of 10 cm or slightly larger is used. To make it easier to attach it around the perimeter of the hole, weld the gate from a metal strip.

- Step back about 10 cm from the bottom of the cylinder and cut a door for the blower; it usually has a small height. Remember that ash will be removed through this opening; it should not be too small. Secure the door with 2 hinges so that it moves smoothly and does not warp.

- Above the ash pit, make a door for storing firewood. It is much larger in size, the lower part should be about 10 cm from the top edge of the first opening. It is very important to fasten this element securely. Consider which valve will provide simple locking and easy opening. Remember that the surface becomes very hot during operation.

- Approximately in the middle between the two openings, weld several pieces of corner to create a support for the future grate. Weld it from fittings according to the size of the cylinder, use rods of large diameter, since thin rods will quickly burn out and will have to be replaced.

Advice!

Cook several grates at once and you won’t have to make them later.

When assembling a vertical potbelly stove from a wood-burning gas cylinder for the garage with your own hands, you should pay special attention to the strong fastening of the doors and the high-quality connection of the body to the chimney. If there are cracks there, they should be sealed with asbestos-cement cord.

It is not difficult to assemble a heating stove from a gas cylinder. The main thing is to prepare it correctly in order to get rid of residual gas and odorants, and follow the instructions for carrying out the work. It is important to accurately match the elements to each other and place the potbelly stove in a safe place. The easiest way is to watch the video to understand the process even better.

Selection of cylinder and materials

So, if you have a suitable old natural gas cylinder on hand, you can safely get to work. Well, if there is none, then it’s worth thinking about what kind of cylinder is needed for the potbelly stove. In total, several standard sizes of cylinders are used for transportation and storage of liquefied petroleum gas - the most common capacity is 50 liters - height 85 cm, diameter 30. There are even smaller sizes, for example 27 liters and 10 liters, there are tourist ones or, as they are also called, country houses options are 5 liters each, and there are very tiny ones of 2 and 1 liter. The prospect of using small containers is very illusory - there is a lot of hassle and little heat. Well, maybe use it to heat a tent for winter fishing or on a camping trip. The average size would seem to have more volume and look more solid, but what is 10 liters? How much firewood will fit in it? That's right, not much, which means the room should be no more than a closet, 2x2 meters with a low ceiling.

Another thing is a full-size 50 liter container. Here you can cut out a place for an ash pan and weld a pipe like a human. By the way, about the pipe, one of the reasons why it is not recommended for novice welders to use small cylinders is the thickness of the metal. 1-2 millimeters of metal wall thickness is not the best option for learning to work with electric welding on your own. Another thing is the large capacity, here there is enough metal for a week of work and you can get to any point.

But, understanding the thirst for creativity of craftsmen, I would like to warn against the mistakes that are often made when choosing the type of cylinder for work.

It is not recommended, under any circumstances, to use cylinders of carbon dioxide, oxygen, acetylene, and even other gases and liquids as the main material. The reason is simple - the material of these types of containers is difficult to cut and even worse to weld.

So it’s better to use what others have done well and not look for your own untrodden paths. As for the rest, with regard to the selection of materials for assembly, everything will be used - steel pipes with a diameter of 100, 120 and even 150 mm, and a steel angle of even 25 mm, and a steel strip, and construction fittings with a diameter of 8 mm. Even an old motorcycle chain will find its application in the design of a potbelly stove.

All you need to do is take a sheet of paper and figure out how, what and where will be welded and installed, and how it will all be attached in order of priority.

Features of operation of a pyrolysis furnace

The main difference between pyrolysis furnaces is the ability to use a wide variety of fuels. In solid fuel stoves, it is possible to burn not only traditional flammable substances, but also rubber, plastic and other materials that are strictly not recommended for burning conventional stoves.

This feature is associated with complete decomposition of the fuel and secondary combustion of the resulting gases in a separate chamber. After this, only carbon dioxide and water vapor remain in the smoke emissions. No harmful emissions into the atmosphere occur during pyrolysis.

But when using such fuel at the ignition stage, a persistent smell of burnt rubber remains in the room. Therefore, such heating units must be installed outside residential premises.

Preparatory work before assembling the stove

Preparatory work includes a very important step - removing residual gas from the cylinder. This stage should be considered in detail, since without its correct implementation, further work is extremely dangerous.

First of all, it is necessary to unscrew the cylinder valve to remove the gas under residual pressure in the cylinder. The valve is completely removed from the housing. After the gas has been removed, the cylinder is inverted to remove condensate.

The gas contained in the cylinder contains a certain percentage of moisture content. Moisture accumulates inside it in the form of condensation (liquid).

By turning the container over, we remove moisture naturally. It is better to collect condensate in a disposable unnecessary container. Condensation often has a specific unpleasant odor. Therefore, it is better to immediately throw away the container with the collected condensate.

Next, the cylinder is turned over again and placed in a vertical position. To completely remove gas residues, you need to fill it with water. Water filled to the edges of the cylinder will completely displace the remaining gas from it. After this, the cylinder is emptied of water and it is considered suitable for cutting.

For greater clarity, here is a video of preparing the cylinder for cutting.

The video was taken from the Internet resource Youtube. Used for informational purposes only and does not constitute advertising.

Preparing a gas cylinder for safe handling with power tools: video

Preparing a tool (power tool) includes inspecting it for damage and determining the degree of its suitability for safe operation.

Features of a potbelly stove - pros and cons

A good master can easily make a Bubafonya stove in one day, this is a significant plus. The maximum you have to buy is a cylinder and pipes from scrap metal. Other advantages of a potbelly stove:

- burning duration on 1 load is 6…10 hours;

- omnivory - waste wood, garbage, sawdust, freshly cut branches are placed in the firebox;

- ease of repair, any burnt part can be easily replaced.

Note. It is better to load garbage, small waste and coal mixed. To heat with sawdust alone, you need to weld a metal heel from below to the diffusers, otherwise the shavings will block the path of air. The stove operates mediocrely on pure coal and requires forced pressurization.

On the left in the photo is the manufacture of a boiler jacket from a bent steel sheet, on the right is an assembled boiler. The

disadvantages of Bubafoni are much more unpleasant:

- The stove is difficult to regulate. When working with high-quality dry wood, the damper helps you choose the optimal mode. If you burn with garbage and damp wood, the air duct must be opened completely.

- The potbelly stove's omnivorous nature is a double-edged sword. From burning low-quality fuel, the chimney becomes clogged with soot literally within a day.

- Without good draft, the stove will begin to smoke into the room. Hence the requirement for the height of the chimney - at least 4 m, counting from the grate, pipe turns 90° - no more than two.

- You can’t throw logs “on the go”, unless you pour a handful of sawdust through the air channel. This means we learn to dose the amount of fuel correctly.

- A potbelly stove made from a 200 liter iron barrel is very bulky and inconvenient to use. The piston is too large and heavy, the thin metal quickly burns out. Fortunately, the housing is easy to replace.

Why is “Bubafonya” dangerous: a well-heated firebox cannot be extinguished using a damper. Air seeps through the cracks, and the wood continues to smolder. The heater should not be left unattended or act radically - lift the lid and pour out a bucket of water. Is there a smoke screen in the room?