Arranging an autonomous heating system requires a careful approach to the selection of all equipment. If the pipes are incorrectly selected, the coolant may circulate at an abnormal speed; a lack or excess of radiators will lead to poor heating or wasteful consumption of thermal energy. It is equally important to choose the right heating unit. If there is a gas main, the best choice is a gas parapet boiler. The model is distinguished by its small dimensions, ease of installation, ease of operation, maintainability and other advantages. Let's look at the features and characteristics of the product.

Design and operating principle

A distinctive feature of this type of gas equipment is a closed combustion chamber. The convenience of this design is obvious:

- There is no need to arrange well-functioning ventilation. This will be especially true in old buildings.

- There is no need to take care of the chimney, which must be taken outside the roof of the house. In this case, a coaxial type chimney is used. In order to install it, a hole is made in the wall to match the diameter of the coaxial pipe. By the way, it will not be visible from the side of the room, because the output is made behind the boiler in a horizontal direction. Experts recommend installing a parapet boiler near a window so that it is possible to inspect and repair the chimney.

- The design of the heating device contains convection holes. With their help, the heating of the room where the boiler is installed is carried out. That is, it turns out that the unit works both as a device for a water heating system, heating the coolant, and as a regular oven or convector.

If we talk about technical characteristics, it should be noted that parapet boilers operating on gas are produced with a fairly large power range, where 7 kW is the minimum, and 40 kW is the maximum. True, today manufacturers have also offered more powerful units that can be used to heat a very large multi-story building. But statistics show that the most popular are boilers with a power of 7-15 kW. Such units are most often installed in small cottages and city apartments.

Device and design

Let's add to all of the above that this type of heating units includes both single-circuit and double-circuit options. All manufacturers, without exception, in the second type use heat exchangers made of 3 mm thick stainless steel or copper to heat the coolant. The second option is more effective, this must be taken into account when choosing.

Possible problems with gas equipment of this type

Ice formation on the chimney.

Parapet gas boilers for heating can create several problems for their owners. First, their sealed chamber consists of two structural elements that are connected to each other by a porous, thermally resistant polymer-based material. If boiler maintenance is not carried out on time, you may not notice how the thermoplastic will lose its tightness. Carbon monoxide and other toxic components of exhaust gas can enter the living space and cause poisoning. That is why timely maintenance of parapet boilers is mandatory.

Secondly, the coaxial chimney in inexpensive models is made of standard steel grades. At the same time, the operating rules for gas equipment require the use of only stainless steel when creating chimneys. Otherwise, soot and condensation accumulating on the chimney walls can form a chemically active environment.

It eats through steel walls. Carbon monoxide from the inner pipe enters the air flow going to the gas burner. As a result, there is not enough oxygen in the gas chamber for complete combustion of the energy carrier. Equipment performance decreases. Soot forms on the boiler walls, which accelerates corrosion processes.

Thirdly, with a coaxial chimney there is always the danger of the burner flame being blown out by strong gusts of wind. That is why, when installing the device, it is mandatory to install protection against the wind.

Boiler structure

The structure of the products is quite simple:

- durable body covered with heat-resistant enamel;

- closed combustion chamber;

- gas-burner;

- wick;

- heat exchangers (coils made of copper or brass);

- chimney with wind protection.

The entire boiler structure can be divided into the main components:

heat exchanger, a unit in which energy from gas combustion is converted into heat. Heat exchangers are small tanks made in a rectangular shape of two halves, which are connected by welding. The requirements for heat exchangers consist of two main conditions: accessibility to the seams during repairs, efficiency and complete homogeneity of the material;

“turbine” to accelerate the flow of heat, gas and water through process pipelines. The “turbine” can be driven by gas flows, having a construction made of light alloys for fast movement, or it can be turned on forcibly;

combustion chamber in which the combustion of liquid gas occurs. The gas enters the boiler through the communication line, where it is condensed and compressed in the reducer, after which the gas is supplied to the nozzles. Injection occurs through the nozzles and subsequent ignition occurs using piezoelectric elements in the combustion chamber. The combustion chamber has non-linear perforations, that is, perforations that connect to the heat exchanger, this is done in order to discharge the pressure arising from the combustion of fuel;

automatic relays that allow the boiler to turn off and on in automatic mode, maintaining a constant flow and temperature;

gas and water communication pipelines serve to supply fuel to the boiler and return heated water to heating systems and pipelines;

The entire design of the boiler and all its components is a box measuring approximately half a meter by 30 by 30. The small dimensions, however, do not speak unfavorably to the boiler.

Parapet boiler - photo

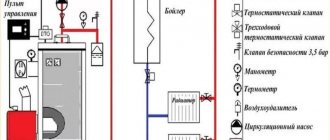

although the boiler can be installed in any accessible place near communications, it is still necessary to adhere to fire safety measures: it is advisable to attach the boiler to a fireproof wall at a distance of 15 to 25 centimeters from flammable objects; It is also necessary to remember that gas boilers and water heaters require at least rare supervision and caution when using. Diagnostics and some “maintenance” are also necessary. since the fuel for the boiler is gas, it is necessary to remember the ventilation system and the tightness of the entire structure; Parapet boiler connection diagram

since the fuel for the boiler is gas, it is necessary to remember the ventilation system and the tightness of the entire structure; Parapet boiler connection diagram

The combustion products that may arise during the setup of the boiler or its malfunction, or the “active phase of heat,” are removed through a coaxial pipe - a pipe that has several diameters. Therefore, it must be remembered that the chimney should not be discharged through balconies or loggias, but should be placed inside walls or masonry on the leeward side.

These rules are basic and are a typical minimum that must be taken into account before installation.

Installation process

The entire procedure can be summarized in several sequential steps.

Well, of course we buy the boiler, unpack it, read the instructions and proceed as follows:

First, you need to decide on the location of the gas and water communications in the house or lay communications with the calculation of the installation of the boiler. After this, next to the approximate installation location, we lay grooves for the chimney of the coaxial pipe and the terminals of the “active phase of heat” - the products of unburnt gas outside; Parapet boiler structure

What is typical for parapet boilers is the presence of ball shut-off valves for all communications, which means that it is necessary to take care of tightness. This is the first safety issue. To seal all threaded connections, you can use liquid sealant, Tangit tape or Fuma tape, which perfectly seals the connections when screwing;

The boiler must be installed on special beams, which fix the boiler to the wall. Boiler installation rules

Installation

You can do some work yourself using prepared parts and appropriate equipment.

The remaining stages (installation of chimney pipes and first start-up) require the involvement of a specialist in order to avoid failures in the subsequent operation of the equipment:

- The pipe outlet channel is made;

- The first pipe is installed and fixed together with the installation of the water supply section;

- To secure the boiler, studs are attached;

- The chimney section is installed at an inclined angle, this makes it easier to remove condensate;

- Protection is installed after connecting the pipe and the chimney section;

- Pipes with radiators and an expansion tank are connected;

- After inspection by gas service specialists, the equipment is put into operation.

Maintenance work can only be entrusted to those who are already familiar with the design and operating rules.

Varieties in design and material

At the moment, there are various models. Externally, they are not particularly different, except in size and installation method: wall-mounted and floor-mounted. To know which one to choose, you need to understand the filling.

Single and double circuit

There are single-circuit and double-circuit devices. The difference is that the single-circuit heats water only for heating the house; in order to have warm water for domestic use, an additional water heater is installed.

A double-circuit boiler immediately heats water for batteries and household use. This smart device responds to the actions of its owners. While water is needed only for heating, he takes care of it. As soon as you open the tap to wash dishes or take a shower, water begins to flow into the tap using a special valve.

It is necessary to provide the required power of the device. The more people will take a bath or shower, the more powerful the device needed to heat it.

Typically, consumers choose double-circuit boilers. They are more functional, you do not need to buy an additional boiler, but they are also more expensive than single-circuit ones.

Floor and wall mounted

The next difference is the method of installing the boilers. There can be two of them: floor-mounted and wall-mounted.

Mounted ones are more compact, the requirements for their installation are less extensive. They do not need a separate chimney; such elements are installed even in the kitchen; it is enough to simply ensure safety during operation.

Floor-standing ones have large volumes, high power and weight. A separate room must be allocated for them; they require a lot of free space around. It will be necessary to build a separate chimney for a floor-standing boiler, since they produce noise, unlike wall-mounted ones.

For a small house or apartment, a wall-mounted heater will be sufficient. When heating a large house, you need to look after a floor-standing unit. Such models are dependent on constant voltage in the electrical network, so during surges the equipment may fail.

Combustion chamber view

The combustion chambers in these boilers are of open and closed types. The former take oxygen for combustion from the room in which they are located, so they require ventilation. But at the same time, they have a simple design, are more reliable, easier to install and cheaper.

The second type is more modern. These boilers are parapet, they provide safety, but are more expensive and more difficult to install. It is worth considering that these boilers, if properly installed and equipped with an air duct, do not pose a risk of poisoning to residents in the event of a malfunction, which cannot be said about units with an open chamber.

The choice in this case depends on the equipment room. A closed-type boiler is safer and more convenient, but only if it is possible to equip an air duct. If there is a power outage and the ventilation does not work, the heating will also turn off.

About heating water for DHW

As stated in the recommendations above, double-circuit wall-mounted and floor-standing boilers with flow-through heat exchangers are effective at low water consumption (1-2 consumers). In addition, to heat water they are completely disconnected from the heating system, since this function is a priority for the controller.

In a cottage with two bathrooms, a laundry room and a kitchen, a “wall unit” with a flow-through heat exchanger will not be enough. There are 2 options here:

- Mounted or floor heater with built-in storage tank with a capacity of 45 to 100 l.

- Floor-standing single-circuit unit operating in conjunction with an indirect heating boiler. You can also use a wall-mounted modification with one heating circuit.

The latter option is suitable for providing any water flow for hot water supply. Only this wish should be taken into account at the stage of purchasing a gas boiler, choosing it with a power reserve of 1.5-2 times the heat requirement. If you do not take into account the additional power for hot water supply, then the generated thermal energy will not be enough to heat your home.

Choosing a place to install a parapet-type boiler

Parapet-type boilers are installed only in non-residential and non-service premises, i.e. they cannot be installed in living rooms and offices, but they may well be located in kitchens, halls, corridors and other utility rooms. Gas boilers of this type do not require constant monitoring.

Parapet gas boilers are installed only on the outer wall of the building in such a way that there are no combustible structural elements near their installation site. If the wall includes combustible elements, then the distance from the pipe to such elements must be at least 20 cm, and these elements themselves must be protected with fire-resistant material on the side of the pipe and the gas boiler. On the facade itself there should be no combustible elements closer than 30 cm from the pipe. If such elements exist, they are either removed or protected with fireproof material.

The pipe should not go into the loggia, onto the balcony, under the canopy, and especially into the entrance or arch. You should immediately make sure that the pipe does not disturb passers-by if the boiler is installed at a low height relative to the ground, and does not throw combustion products out the window to neighbors.

Figure 3. Diagram of a parapet boiler.

For boilers with a power of up to 7 kW, it is allowed to place the pipe 25 cm from the window in any direction and 50 cm to the sides if the boiler power is higher. If the boiler is located on the ground floor, then the installation height of the pipe above the ground should not be less than 0.5 m, if there is no passage of people at the pipe outlet, but if there is passage of people, and the boiler power exceeds 7 kW, the height of the pipe should not be less than 2.2 m. Also, the pipe should not go under the supply vent closer than 2.5 m or next to it closer than 0.6 m for boilers with a power of 7 kW and no closer than 1.5 m - if the power of the gas boiler is over 7 kW. Under balconies and other elements protruding more than 0.4 m, it is allowed to place a parapet-type boiler pipe no closer than 2 m (if the power of a gas boiler is over 7 kW - 3 m), cornices and other elements protruding less than 0.4 m - no closer than 0.3 m (if the power of the gas boiler is over 7 kW - 1.5 m).

Since the coaxial pipe requires periodic monitoring and maintenance, the installation location of the gas boiler should be chosen in such a way that it is possible to organize access to the pipe.

There should be no flammable interior elements (curtains, curtains, draperies) near the gas boiler indoors; furniture and electrical appliances should not be installed close to it or closer than 30 cm.

The controls of the gas boiler itself, the control and shut-off valves of the pipelines connected to the boiler must be accessible for inspection and control, for which there must be a passage at least 1 m wide in front of the front panel.

Go to table of contents

Prices: summary table

Rating of the most popular models of parapet gas boilers:

| Model name | DHW, l/min | power, kWt | Efficiency, % | Flow, m3/h | price, rub. |

| LEMAX Patriot-12.5 | —— | 12,5 | 87 | 0,75 | 18 500 |

| ATON Compact-12.5EB | 5–6 | 12,5 | 90 | 1,53 | 25 000 |

| TERMO MAX C-12E | —— | 12,0 | 90 | 1,39 | 18 000 |

| Hephaestus VPR KSG-10S | —— | 10,0 | 92 | 0,60 | 21 500 |

Strengths of parapet heating boilers

Parapet gas boilers have the following advantages:

- Compact sizes. This allows you to easily solve the problem of how to install a parapet gas boiler inside a small apartment, the owners of which have decided to acquire an individual heating system. Equipment of this type can even be installed under the kitchen table or in a niche near the window. The main thing is that the gas pipes reach there.

- High-quality smoke removal. This is ensured by the use of coaxial pipes, which can be laid at any convenient angle.

- Easy to install. This is especially true for wall-mounted parapet boilers. Before installing a floor-standing parapet boiler, you will have to equip a separate room (boiler room) in accordance with the recommendations of the gas service. A prerequisite for using floor-standing gas boilers is a chimney pipe and a wide entrance door (from 80 cm). The boiler room must be equipped with a window for regular ventilation. The chimney must be equipped with a series of small ventilation holes. Parapet boilers do not have similar installation requirements

- Possibility of connection on any part of the heating circuit. Some boilers have only a right- or left-hand installation principle, but this restriction does not apply to parapet devices. Thanks to this, the installation of a parapet gas boiler can be carried out in a convenient place.

- Aesthetics. Parapet models are distinguished by their visual appeal. Most often they are tinted in a light color, which allows them to fit harmoniously into any modern design. Very high-quality material is used to paint the devices, which retains its original decorative qualities over a long period of use. Such a surface is not afraid of sunlight and frequent wet cleaning.

- Ease of management. Gas parapet boilers are equipped with a modern control unit. Thanks to the automatic control system, the condition of the coolant is constantly monitored. If its temperature goes beyond the preset parameters, the sensors immediately send a signal to the main control panel, which turns on the heating or cooling system. The pressure level inside the pipes is controlled in a similar way. Thanks to automation, it is possible to select the most optimal mode of operation of the device, which makes it possible to save energy resources.

- Presence of piezoelectric ignition. This allows a single- or double-circuit parapet gas boiler not to depend on the availability of electrical energy in the room. This is especially convenient outside the city, where power outages often occur.

- Full set. The device is already equipped with all the necessary elements, which are compactly located under a beautiful body. A parapet boiler hung on the wall will not be hung on the sides with additional equipment that spoils the overall interior.

- Possibility of conversion to another fuel. When switching to another type of fuel (electricity, liquefied gas), you do not need to buy new boilers: parapet models can be reconfigured and the nozzles in them can be changed.

In the room where a single-circuit gas parapet boiler is located, heating radiators do not need to be installed. The fact is that the body of the device is equipped with many convection holes through which heat enters the room.

Bottom line

A parapet boiler is an excellent opportunity to solve the issue of organizing heating in any home (private house or apartment). When researching the question of which parapet boiler is better, it is necessary to take into account a number of factors. For example, if in addition to heating it is also necessary to provide heating of water for domestic use, imported double-circuit parapet boilers are available for sale. Some of them do not require connecting a chimney pipe at all. In situations where the home already has a single-circuit heater of low power, the organization of a hot water system can be carried out using a boiler

When choosing a heating parapet boiler, it is recommended to pay special attention to its power: the area that the equipment is able to heat directly depends on it.

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile design and no impact on the internal atmosphere of residential premises.

If a conventional atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then parapet models are completely separate and do not disturb the air exchange regime.

Another difference is the ability to independently heat air, making a parapet boiler similar to a stove.

Requirements for the chimney

Chimneys for gas boilers are necessary to remove the results of combustion and neutralize condensate.

Although boilers with an open chimney chamber do not have a chimney, combustion products are still released, so it is better to install it in a separate room.

In the closed type of devices there is forced draft. Since the flow of the air mass depends on the strength of the fan, the cross-section of the pipe does not have to be large; a coaxial pipe of small diameter will be sufficient, or you can install a damper on the chimney.

The air from gas-generating boilers is ventilated directly to the street by a fan; large holes are also not required. Here there is no need for a chimney, but there is a need to regularly clean the entrance from possible debris from the street.

If power is often cut off in the area where the unit is installed, it is better to use a model with natural draft - non-volatile, which does not require a chimney, or install an uninterruptible power supply for a gas boiler.

How are they arranged?

The parapet boiler has a closed combustion chamber. It does not contact the room. The equipment does not emit combustion products into the atmosphere, which is very important for small areas with poor ventilation. Therefore, these devices do not require traditional chimneys. The side two-pipe design is sufficient for operation. The main task of these pipes is the intake of air and the removal of exhaust gases. Due to the presence of a hole in the unit body, additional radiators are not needed. If you correctly perform all the calculations and select the device, then one unit will be enough for a complete heating system.

READ How to install hdri card in 3d max corona

Installation of parapet boilers is carried out according to the principle of convectors. Due to the pipes, the system is connected to the gas main (and water supply in the case of double-circuit boilers). Next, the unit is mounted on the wall using brackets. The chimney for the boiler is of the coaxial type. It has a small diameter. The reader can see what a coaxial type chimney looks like in the photo below.

Installation of a wall-mounted boiler

Installation of gas heating boilers of this type requires care when installing fastening units that are fixed on one of the walls of the room. This boiler is very popular among owners of private or country houses, as it is light in weight and compact in size.

If the house is built from a material such as wood, then the wall on which the boiler will be installed must be covered with a sheet of non-combustible material, such as metal. Often in private homes, a wall-mounted gas boiler is installed in the kitchen. Modern devices have an attractive appearance, so they will fit into any interior and will be combined with kitchen furniture.

A wall-mounted gas boiler does not require a separate boiler room, since it includes all units and components, such as a circulation pump, shut-off equipment, automation, and others. You will need to carry out such a step as installing heating from a gas boiler.

This will help avoid mistakes that could affect the efficiency of the heating system. If you do the installation yourself, you must have certain skills and knowledge, and also take as a basis all the requirements specified by SNiP. Otherwise, the system simply will not be approved by government services and will require repair of gas heating boilers.

Kinds

There are different design options for parapet boilers, which can be divided according to specific characteristics.

By installation method:

- wall-mounted Installed in a hinged manner on an external (load-bearing) wall. According to installation conditions, weight and power are limited;

- floor Installed on the floor. If it is wooden, a non-flammable stand is required. There are no restrictions on weight, dimensions and power.

By power supply method:

- volatile. The design contains components that require the use of electricity - a circulation pump. electronic control board, etc.;

- non-volatile. They work only with mechanical control. A good choice for remote villages and areas with intermittent power supplies.

By set of functions:

- single-circuit. Capable only of providing heating of the coolant;

- double-circuit. In parallel with heating, the heating agents are capable of preparing hot water for domestic needs.

NOTE! Most users prefer single-circuit floor-standing models, which demonstrate the greatest efficiency.

Model overview

If you choose the right manufacturer and model of the boiler, it will be able to effectively heat your home even without the “help” of additional equipment.

Thus, Danko gas boilers have a power of 7 to 15 kilowatts, so they are quite capable of handling a room with an area of up to 140 square meters. All devices from this manufacturer have an automatic gas supply system, micro-torch burners and piezo ignition. The walls of the heat exchanger are 3 millimeters thick.

It is characteristic that the design of this exchanger has been updated, and the right-left connection is ignored in principle. This makes installation easier. The connection in this case is two-way, which significantly saves work space. There is also a special panel that allows you to adjust the operation of the device and visually monitor it.

Video parapet boiler – Model “Danko 7U”

ROSS is one of the largest Russian manufacturers of gas equipment. Boilers from it are known to ordinary users as AOGV and have a power of up to 100 kilowatts.

Parapet boiler Aton Compact

The boilers of the Aton series are no less popular, since considerable funds have been invested in this company in recent years. The boilers are produced using modern equipment, thanks to which excellent external performance of the products is combined with high quality.

Gas parapet boiler Zhitomir

There are also Zhitomir gas boilers, which are perfect for heating a multi-storey building. The fuel combustion chamber in them is absolutely sealed and equipped with automatic process control, a temperature control device, piezo ignition and a built-in gearbox. Each of the boilers has pipes for connection to the heating system on both sides.

The manufacturer guarantees that all products are absolutely safe to use, since they are tested seven times for failure-free operation in emergency conditions. If we talk about efficiency, then it can reach 90 percent.

Video - Advantages of Zhitomir models

Attention! The cost of parapet boilers ranges from 11,250-25,000 rubles, although there are more expensive models. It all depends on the technical parameters and the manufacturer

Basic safety rules

The first and most important point in the safety of using a gas heating structure is strict adherence to the connection and installation diagram of all systems. Several other conditions must be met:

- compliance with indoor humidity requirements;

- maintenance by gas service professionals once a year;

- presence of a filter on the return line;

- mandatory room ventilation;

- the presence of the necessary draft in the air duct pipe.

The boiler is the main component of the entire heating system. Whether normal temperature and humidity in the room will be maintained depends on it. Therefore, you should take the choice of a heating device seriously. The variety of types and models allows you to determine the most optimal option, having first weighed the pros and cons.