The history of the creation of a parapet gas boiler

The floor-mounted turbocharged boiler has a closed combustion chamber, therefore it is safe and does not require a separate room.

The product was created in the early nineties of the last century, when mass private construction began and people abandoned central heating. The universal stoves used at that time could operate on any fuel, but they had an open-type burner installed. Since domestic enterprises were closing en masse, and foreign products were unavailable, it was decided to develop and put into production a boiler of our own production that meets all power and safety requirements.

The work was carried out in Ukraine and Luch Russia. In 1996, the first two-circuit samples went on sale, with a compact design, a power of 10 kW, an efficiency of 0.92 and a closed combustion chamber. These boilers became the prototypes of units that are still manufactured today.

Boiler structure

The heating device is small in size, which makes it possible to install it in the kitchen, bathroom or basement level. The presence of convection openings in the body allows the unit to be used as an oven, which makes it possible to avoid installing piping and batteries indoors.

The structure of the products is quite simple:

- durable body covered with heat-resistant enamel;

- closed combustion chamber;

- gas-burner;

- wick;

- heat exchangers (coils made of copper or brass);

- chimney with wind protection.

The product includes automatic control and monitoring devices. These include a thermocouple, an air draft sensor and a thermometer.

Combined models

In addition to traditional heating equipment, it produces 3 combined series of boilers:

- Electric gas heat generators KS-G-SN / KE with a heat output of 10-12 kW.

- Units "Zhytomyr-9" burning coal and natural gas. Designation - KS-G-SN / AOTV, power - 10, 12 and 15 kW.

- Heating and hot water installation “two in one” KS-G-SN, otherwise – “Zhitomir-10”. The range of models covers the range of 7…30 kW.

The line of gas-electric boilers is built on the basis of Zhytomyr-3 units and does not differ in appearance from conventional floor-standing units. The design is complemented by a control unit and an electric heater placed inside the water jacket. 2 types of heating elements are installed - with a power of 4.5 and 9 kW. Important feature: both heating methods can be turned on one by one or simultaneously.

The coal-gas heat generator “Zhytomyr-9” has the following parameters:

- on the left side of the body there is a firebox with a volume of 47 or 70 liters for storing anthracite or firewood;

- to the right of the solid fuel chamber there is a gas firebox with a Polidoro burner and an SIT 630 automation unit, a common heat exchanger, and separate smoke exhausts;

- efficiency on gas – 92%, solid fuel – 78%, operating water pressure – 1 Bar (Max 1.5 Bar);

- work in a closed system is allowed, condition - installation of a safety group with a 1.5 bar safety valve;

- duration of 1 coal combustion cycle – 6…8 hours;

- There are modifications with a DHW water circuit.

The operating algorithm is simple: while the coolant is heated by coal, the gas burner does not ignite. When the sensor detects a drop in temperature, the gas supply will open and the right side of the heat generator will start working. The main thing is that the pilot light is lit.

The gas installation “Zhytomyr-10” consists of two separate sections - a boiler furnace and an instantaneous water heater. Burners, safety devices and heat exchangers are completely separated. In fact, the gas water heater and the boiler are combined in one housing. The goal is to increase water consumption for hot water supply to a comfortable level without compromising heating efficiency.

Main differences and characteristics

Parapet boilers can have 1 or 2 circuits - for heating and hot water.

Various models are made in floor and wall-mounted, left-hand and right-hand versions. Depending on the purpose, they are equipped with one circuit - only for heating or two - to additionally heat water for domestic purposes. Depending on the level of control, devices can be automatic or manual. For automation to work, electricity is required. If it disappears, the boiler turns off. Manually controlled products are practically independent of external conditions and can even be operated from a gas cylinder. The burner is turned on and off by a thermocouple and a constantly burning wick.

How a Lemax floor-standing boiler should work

Lemax company presents a large number of models of floor equipment. For stable operation, Italian SIT automation is used.

The principle of operation of the boiler is as follows. A gas burner is built into the housing, heating the heat exchanger, with a built-in DHW and heating system coil. Coolant circulation is carried out naturally (non-volatile) or forced.

It is customary to distinguish several types of stationary equipment according to the following technical characteristics:

- Number of circuits - the Lemax steel single-circuit floor-mounted gas heating boiler works with virtually no complaints. It is non-volatile. Provides maximum performance. Used to heat the home heating system. It has low gas consumption. The Lemax floor-standing household double-circuit gas boiler operates in two modes: heating the coolant and water for hot water supply. The advantage of the model is its high efficiency (there is practically no difference in gas consumption compared to Valliant and other boilers). There are certain shortcomings associated with the operation of the secondary circuit. Mainly associated with errors made when piping the boiler. Lemax steel floor heating 2-circuit gas boilers are an economical and optimal option for a large private house.

Heat exchanger design - there are two modifications that differ in the material used in the production of the boiler. Russian non-volatile single-circuit gas heating boilers Lemax with a cast iron heat exchanger have the best technical characteristics among the entire model range of the manufacturer. The cast iron firebox is resistant to aggressive substances and overheating, thickness 4 mm. The sectional heat exchanger is manufactured at the VIADRUS plant (Czech Republic). It has anti-corrosion properties. The steel heat exchanger is sensitive to the quality of the coolant. A water treatment system is required for operation. The thickness of the steel heat exchanger is 2 mm.

Download: Lemax Clever - user manual.pdfDownload: Lemax KSG - technical data sheet.pdfDownload: Lemax Wise - user manual.pdfDownload: Lemax Leader - technical manual.pdfDownload: Lemax Premium - instructions.pdfDownload: Lemax Premium 50 60 70 80 90 100 - instructions.pdfDownload: Lemax Gazovik.pdfDownload: Lemax Premier.pdfDownload: Lemax Comfort - turbo nozzle for a gas boiler.pdf

Floor-standing versions are non-volatile. To ignite the boiler, a manual ignition system using a piezoelectric element is used. After the flame dies out, you will need to start the combustion process yourself.

Advantages and disadvantages

The main advantages of parapet boilers:

- high performance;

- closed combustion chamber ensuring complete safety;

- compactness;

- functionality;

- versatility;

- ease of use and maintenance.

The disadvantages include the need to drill a hole in the wall for the pipe, which negatively affects the supporting structures. If installing a gas boiler in a private house is not a problem, then equipping a city apartment with it is almost impossible, due to the current moratorium on such events. We should not forget about the high cost of equipment and installation work.

Why does the device go out?

There may be several reasons for the burner to go out:

- Stopping the gas supply. Turn off the boiler and wait until the supply is restored.

- Unstable or absent voltage in the power supply network (for volatile Lemax boilers).

- Failure or activation of the traction sensor. We need to check whether it is there and whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts have oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive draft. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most common in non-volatile installations, where the stability of the unit’s operation depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of the flame on the burner exploding, which will provoke the supply of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency event, leading to the boiler stopping.

Criteria for choosing a parapet gas boiler

Since a gas boiler is purchased for decades, its choice must be taken as responsibly as possible.

For single-circuit boilers it is necessary to install a hot water boiler

When purchasing, you should pay attention to the following criteria:

- Heat exchanger steel thickness. It should not be less than 3 mm, preferably made of non-ferrous metal or stainless steel.

- Product design and effectiveness. To save money, it is better to take dual-circuit devices with an efficiency of 0.92 and higher.

- Dimensions and dimensions. If the space of the room allows, it is advisable to choose a floor-standing option. This type of boiler is more reliable and unpretentious.

- Location of connectors for connection. Depending on the installation location, a type of product with side or rear connection is selected.

- Power. You should purchase a unit at the rate of 1 kW per 10 m² of total area of the house with a reserve of 15% for extremely cold periods.

- Chimney material. The pipe must be made of thick stainless steel, resistant to high temperatures and the formation of soot inside the channel.

- Ease of installation. The cost, duration and labor intensity of the installation of a heating system depends on this.

- Functionality. A single-circuit boiler is smaller and cheaper, but does not solve the DHW problem.

You can get information about which parapet boiler is best to choose for your home in a specialized store that sells certified products.

Preparation for installation

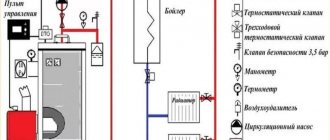

Figure 4. Installation diagram of a parapet boiler: 1 - air duct pipe;

2 — air duct section; 3 - boiler; 4 - seal; 5 — M6 bolt; 6 — clamp; 8 - chimney pipe; 10 — M8 nut; 11 — washer 8; 12 - chimney protection; 13 - eye; 14 — M10 pin; 15 — M10 nut; 16 - washer 10. The very first thing you should start preparing for installation is to read the detailed instructions for installing the device and purchase everything that is necessary to install the boiler and connect it to the heating system: fittings, fittings, fasteners, etc. P.

The next stage of preparation is the selection of tools. To make a hole in a stone wall, you will need at least a hammer drill, or better yet, a hammer drill with a diamond bit that matches the diameter of the air duct pipe (for Aton boilers, the air duct diameter is 240 or 270 mm). If there is no crown, you can get by with a small-diameter drill, the length of which is sufficient to pass through the wall. If you work without a crown, then you will need a spatula, and if you have to work high, where you cannot get to it from the street, then you will need a spatula as long as the thickness of the wall. You will need drills for stone with a diameter corresponding to the fastening elements of the boiler being installed.

You will also need keys (in particular, an adjustable wrench) and screwdrivers in accordance with the fasteners supplied to the boiler and connections to the pipelines.

To remove the coating from the wall, you will need a knife, a spatula, a sponge and a basin if the wall is covered with wallpaper, or another appropriate tool.

The measuring tool you will need is a level and a ruler, most likely you will need a square. You will, of course, need a pencil or marker for marking.

Personal protective equipment: glasses, mask, vibration-proof gloves, possibly knee pads.

The principle of operation of a parapet gas boiler

Layout diagram of the main components of a parapet boiler.

The operating principle of an autonomous boiler is quite simple:

- The wick ignites the burner, which heats the heat exchanger.

- Water moves along the circuit by natural current or under the influence of a pump.

- After heating the working fluid to the set temperature, the thermocouple closes the gas valve and combustion stops.

- When the coolant cools down to the set value, the valve opens and the constantly working wick ignites the gas.

A coaxial chimney is connected to the boiler. It is a structure of two pipes. The internal one removes smoke, and the external one supplies fresh air into the combustion chamber.

Possible faults

No matter how hard the engineers try to prevent possible problems, no matter how attentive the owners themselves are, sooner or later everyone faces failures. If Lemax Premium, for example, goes out (the main burner stops arbitrarily), we can assume the following reasons:

- weak vacuum in the smoke passage;

- gas outlet overflow;

- Incorrect thermostat setting.

First, inspect the channel through which the smoke is removed. If any dirt or blockages are found, they are removed immediately. If this does not help or nothing interfering is detected, you need to configure the regulator.

If a gas leak is detected, you should give up the idea of fixing it yourself. All restoration work may only be carried out by authorized gas service specialists.

Please note: cleaning chimneys and burners can help with excessively elongated flames that take on an orange or even red hue.

If there is no movement of water in the system, it needs to be topped up. When this measure does not help, you will have to redo the entire heating circuit. If the boiler suddenly turns off due to a temporary failure in the gas supply, the inlet valve must be closed. Then very unpleasant consequences will be excluded. If you cannot light the boiler, the problem may be related to the igniter or thermocouple. It is necessary to clean the contacts and replace the thermocouple. You also sometimes need to work on the traction sensor, connecting it not “by crimping”, but according to a more practical scheme.

Important: ignition is strictly not allowed if the fire from the igniter rushes outward, which is almost always due to a lack of draft and poses a great danger

DIY boiler installation

A protective cap is installed on the chimney to prevent the wind from blowing smoke back in.

Installation of the boiler must be carried out by gas industry specialists. The property owner can prepare a base or a place on the wall for it, drill a hole for the chimney and make connections for heating and hot water supply. Fixing the device and connecting communications is carried out by a specialist. Exceptions are cases when the boiler is connected to a gas cylinder.

To prevent the wind from blowing into the boiler, it is necessary to make a protective cap at the end of the chimney at the installation stage, which will dampen turbulence and strong air currents. Periodically, the inner pipe must be cleaned of soot, since internal deposits reduce draft.