Prices for all kinds of coolants are growing more and more every year, so alternative heating for a private home is more relevant today than ever. Owners of country and private houses are searching for the most affordable sources of heat. Alternative heating allows you to become completely energy independent, and, perhaps, this is the most optimal and profitable solution for a country house.

Alternative heating is profitable and environmentally friendly Source teko-ua.com

What is alternative heating of a private house

Typically, “alternative heating” refers to all methods of heating a residential building that were not used by consumers a few decades ago. In reality, this term should be interpreted more narrowly.

Alternative types of heating for a private home are space heating, in which:

- Renewable energy sources are used to generate heat and do not require billing from service providers. As an option, their partial use is possible;

- the arrangement of heating systems is carried out at an acceptable cost, incomparable with the cost of a heated house.

Waste into income: biogas plants

All alternative energy sources are of natural origin, but double benefits can only be obtained from biogas plants. They process waste from domestic animals and poultry. The result is a certain volume of gas, which, after purification and drying, can be used for its intended purpose. The remaining processed waste can be sold or used on fields to increase yields - a very effective and safe fertilizer is obtained.

Energy can also be obtained from manure, but not in pure form, but in the form of gas

Briefly about technology

Gas formation occurs during fermentation, and bacteria living in manure are involved in this. The waste of any livestock and poultry is suitable for producing biogas, but cattle manure is optimal. It is even added to the rest of the waste for “ferment” - it contains exactly the bacteria needed for processing.

To create optimal conditions, an anaerobic environment is necessary - fermentation must take place without oxygen. Therefore, effective bioreactors are closed containers. To make the process more active, regular mixing of the mass is necessary. In industrial installations, mixers with electric drives are installed for this purpose; in home-made biogas plants, these are usually mechanical devices - from the simplest stick to mechanical mixers that “work” by hand force.

Schematic diagram of biogas plants

Two types of bacteria are involved in the formation of gas from manure: mesophilic and thermophilic. Mesophilic are active at temperatures from +30°C to +40°C, thermophilic - at +42°C to +53°C. Thermophilic bacteria work more efficiently. Under ideal conditions, gas production from 1 liter of usable area can reach 4-4.5 liters of gas. But maintaining a temperature of 50°C in the installation is very difficult and expensive, although the costs are justified.

A little about designs

The simplest biogas plant is a barrel with a lid and a stirrer. The lid has a terminal for connecting a hose through which gas enters the tank. You won’t get a lot of gas from such a volume, but it’s enough for one or two gas burners.

More serious volumes can be obtained from an underground or above-ground bunker. If we are talking about an underground bunker, then it is made of reinforced concrete. The walls are separated from the ground by a layer of thermal insulation; the container itself can be divided into several compartments in which processing will take place with a time shift. Since mesophilic cultures usually work under such conditions, the entire process takes from 12 to 30 days (thermophilic cultures are processed in 3 days), therefore a time shift is desirable.

Scheme of a bunker biogas plant

Manure enters through the loading hopper; an unloading hatch is made on the opposite side, from where processed raw materials are taken. The bunker is not completely filled with the bio-mixture - about 15-20% of the space remains free - gas accumulates here. To drain it, a tube is built into the lid, the second end of which is lowered into a water seal - a container partially filled with water. In this way, the gas is dried - already purified gas is collected in the upper part, it is removed using another tube and can already be choked to the consumer.

Everyone can use alternative energy sources. It is more difficult for apartment owners to implement this, but in a private house they can at least implement all the ideas. There are even real examples of this. People fully provide for their own needs and for their large households.

Reasons for introducing alternative heating

The main reason why property owners are introducing alternative heating systems for a private home is the constant increase in prices for many types of energy resources, including electricity, natural gas, coal, etc. Despite the fact that currently the heat supply to a private home powered by main gas is the cheapest, this source of thermal energy is becoming more expensive from year to year. Since its supplies are limited, this trend will continue in the future. Alternative heating of a private home is not only economical, it is progressive, since it does not burn fossil fuels and wood.

Adjustment mechanism

Thermostatic mixing valve

A thermostatic mixing valve is also used in radiator-type heating schemes, but convective air circulation (even with balanced ventilation and careful insulation) still leaves the lower layers as the coldest part of the room.

The source of thermal energy can be either a central heating plant or an autonomous boiler. In any case, boilers operate effectively in stable modes and will not provide smooth adjustment of coolant flow in each individual room.

For this purpose, special fittings with selected operating parameters and a specific type of design are included in the system. Installing a mixing valve for underfloor heating gives the following stabilizing result in normalizing the temperature in the house:

Mixing valves perform the task of combining a high-temperature heating circuit with a low-temperature underfloor heating distribution, since the recommended temperature in the pipes under the floor is 40°C, and for the water leaving the boiler 70 - 90°C.

Work principles

If the coolant is too hot, a cold stream is mixed into the water

The three-way valve for heated floors performs its function in the following order:

- the hot coolant from the boiler is directed to the distribution manifold, from which it diverges through the loops of the underfloor heating system;

- a thermo-mixing valve is installed along the path of movement, reacting to the heating temperature of the water;

- when the flow temperature exceeds the set value on the regulator, the latter opens a passage for mixing cooled water from the return pipeline;

- in the tee, two converging flows are mixed and the coolant of the desired temperature is released into the system;

- When balance is achieved, the change in the internal sections of the valve stops.

The valve body is made of brass and consists of 3 channels converging to the adjustment mechanism. The use of 3 different methods of mixing water flows distinguishes 3 types of three-way valve designs.

Three way thermostat

The thermostat mixes hot and cold flow

The set temperature is maintained by a three-way thermostatic valve, which automatically mixes the hot liquid flow from the heater and cooled water from the return pipeline. The need for quantitative changes in flows is determined by the thermostat settings.

This product can be used in underfloor heating systems (especially complex configurations), on radiator wiring and in the internal hot water supply circuit.

Automatic change in the temperature of the outgoing coolant protects a person from elevated temperatures in the event of a pipe rupture. If for some reason the flow of cold water stops, the valve will automatically close the flow of hot pressure from the boiler. The temperature-sensitive unit responds to the amount of heating and, accordingly, changes the cross-section of the inlet holes, achieving the required balance.

The layout of the thermostatic valve for a heated floor looks like this:

A pressure throttle is a device that provides fluid pressure regardless of the pressure difference at the inlet and outlet. Paired with a thermal head for a heated floor, it stabilizes the operation of all system circuits when incoming conditions change.

3-way thermostatic valve

The operation of this valve is not as complicated as a thermostat. Only the incoming hot media is regulated. For more information about the operation of three-way valves, watch this video:

To analyze changes in temperature indicators, the kit includes a thermal head for heated floors, which acts as an executive body based on a signal from an external sensor.

Solar systems

Solar energy can be used to heat residential premises in two ways:

- by converting it into electricity, which will then be used by heating equipment;

- for heating liquid coolant circulating naturally or using a pump through convectors or radiators.

The simplest alternative home heating can be created with your own hands using a solar heating collector, a circulation pump and batteries.

The peculiarity of the use of solar systems is that even in the southern regions, where there are many sunny days a year, no one has canceled cloudy weather and night time. For this reason, we can conclude that they are not suitable as round-the-clock sources of thermal energy. The following options for implementing this type of heat supply are possible:

- A solar heating collector for heating a house operates in parallel with an electric heater. The temperature of the coolant is controlled using special sensors. If the degree of heating drops below a certain value, heating continues with heating elements.

Biofuel

From biomass, which includes organic waste, manure, plants, wastewater, biogas is obtained as a result of decomposition with the help of bacteria. It is advisable to heat low-rise buildings with wood pellet chips, logs, and pressed waste from the woodworking industry. Fuel is supplied to the boilers using various automated supply methods. As for boilers operating on logs, fuel is loaded into them manually.

Alternatives to gas heating also include pallet boilers. They can be with either manual or automatic fuel supply. This ensures that a person does not need to be near the boiler all the time. The automatic control system maintains the temperature at a certain parameter.

This is what biofuel looks like.

Wind energy

You can also use wind energy to generate heat. Industrial relevant equipment is commercially available and is quite affordable. This solution has a special feature - large impeller parameters. In a 4-kilowatt wind generator, this element can reach 10 meters.

The problems associated with accumulating electricity for heating, inherent in solar systems, are similar to those of wind generators. Of course, it makes sense to use alternative methods of heating a private home that use the power of the wind in regions where moderately windy weather is constantly observed, and this is, first of all, the sea coast and steppe areas.

If the collector can use solar energy to heat the coolant directly, then when using a wind generator everything is much more complicated. It is necessary to convert the mechanical energy of rotation of the windmill into electricity, and only then is it possible to heat the air in the room. As a result, the efficiency of the heating system decreases.

Solar collectors

Despite the fact that heating a country house with solar panels is almost impossible in harsh climates, it is impossible not to consider this type of alternative source of energy and heat.

The greatest efficiency can be achieved only with intense solar radiation - only in this case the temperature in the premises will be as comfortable as possible.

Varieties

Solar systems for heating the coolant (in our case it is a water-glycol solution) can be divided into passive and active.

The first ones are combined into one so-called “water heater”, which is located on the roof. The coolant reservoir is located above the collector level, and cold water is supplied to the tank from below.

Scheme of operation of a flat solar collector. Click to enlarge.

The latter have a structural difference from passive solar heating systems: the solar collectors themselves are placed on the roof of the house, and the coolant reservoir is located in the house.

The coolant is water, circulates in the heating system using a pump.

Most often, solar collectors are used for household needs - heating water in storage tanks.

But in this case, in winter you will have to drain all the water from the tank to avoid freezing.

There are two different types of solar collectors: flat plate and vacuum (tube).

A flat-plate collector is a solar absorber with glazing on the top, having a layer of foil-coated thermal insulation on the inside.

Diagram of the operation of a pipe manifold. Click to enlarge.

The absorber is a flat sheet of metal connected to a piping system.

It “collects” solar heat, transferring it to the coolant. The glass should not reflect glare - to achieve maximum effect from light energy.

A tube collector differs from a flat one only in the presence of vacuum glass pipes collected in one bundle.

An absorber made of a sheet of steel is inserted into each tube - it can be rotated inside to even out the sunlight.

Tube solar collectors are more expensive to install and maintain, but they provide a greater effect than flat ones due to longer retention of solar heat.

Both types of heating systems are mounted on the roof of the house - in the inclined part.

Recently, manufacturers have been offering so-called “solar” roofs, in which solar panels are already installed, but this option has not become widespread due to the leakage of the roof covering.

Heat pumps

The most versatile alternative heating systems to central heating are modern equipment called heat pumps, shown in the photo. The principle of their operation is based on the transfer of thermal energy from a low potential source into the building. The operation of all heat pumps, without exception, is based on the same elements that can be observed in any refrigerator: a heat exchanger, an evaporator and a compressor. As for specific implementation options, they can differ significantly and therefore the issue of the cost of the solution adopted lies in a wide range of prices.

Color combinations

Stylists advise taking into account the following nuances:

- direction in the interior;

- combination of shades;

- illumination

It is much easier to choose a palette if the style for the kitchen and living room has already been selected. For example, neoclassicism and Provence have their own combinations. In a classic interior, designers combine pastel colors, pale colors, which are slightly diluted with dark shades. In French country houses you can often see soft blue, pink, and pistachio colors. Art Deco designers make up objects and finishing materials in black and white, sometimes beige and brown or silver and black. The main thing is to choose a shade for the walls. White will become universal, it will expand the space, and later you can paint them with any paint. However, in the cooking area, white ceases to look fresh. Beige or gray shades would be more practical. This background will highlight the other colors. In a monochrome interior, designers recommend gluing wallpaper in an unusual color or with a photo print.

Ground-to-water heat pumps

These devices are the most versatile alternative sources of heating for suburban households in terms of dependence on the climate zone. The principle of their operation is based on the fact that even at a depth of several tens of meters in permafrost areas, the soil temperature exceeds zero degrees.

Heat exchangers designed to extract heat from the ground are probes that are immersed in special wells. It requires the laying of pipelines, the length of which exceeds several dozen meters, and in addition to the high price of the pump, the cost of its installation itself is quite high. Thus, drilling one well costs approximately several thousand rubles per linear meter, but more than one is needed. In addition, you still need to install a pump and immerse probes in the well.

It will cost a little less to install a ground-water pump with a horizontally located collector. Heat exchangers are immersed in trenches below the freezing level.

The disadvantage of such heating is the large area required to install a heat pump. The resulting heat is spent on heating water for domestic needs and transferring thermal energy to heating devices.

conclusions

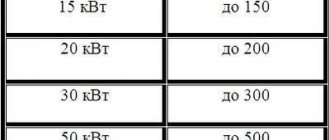

Heating without gas is possible. Some heat sources serve as a complete replacement for a gas boiler, while others can only be used as a supplement. For convenience, let's combine everything into a table:

| Alternative to gas | Addition |

| Ground source heat pump Solid fuel boiler Pellet boiler | Fireplace with water circuit Air fireplace Pellet fireplace Solar collectors Inverter air conditioners Air source heat pump Electric boilers |

There are other alternative ways to heat a building that are not included in the list: stoves, boilers, electric boilers and other heating devices.

And, of course, it is important to remember that installing other heat sources is not the only way to save gas and reduce dependence on it. It is necessary to work to improve the overall energy efficiency of the building: identify and eliminate all heat leaks, use heat more efficiently and minimize heat loss in the building

Water-to-water heat pumps

The presence of flowing groundwater in the area where the building is located allows you to create alternative heating with your own hands, and the cost of implementing such a project will be low. This is explained by the fact that it is easier to remove heat from such an energy source. Also, only one immersed heat exchanger probe is required. A sufficient drilling depth is considered to be 10-15 meters.

Warm floor system

The well-known heating scheme – “warm floor” – is perfect for heating a country house. During installation, no additional redevelopment will be required. You can save significant amounts of money on heating. The system is installed under the floor covering. If you have the necessary knowledge and skills, you can install a heated floor yourself.

The process of installing heated floors.

Air-to-water heat pumps

An air-to-water heat pump uses outdoor air. The heat exchanger is a radiator with a large fin area; it is blown by a low-speed fan. These pumps are affordable and much cheaper to install. But they have the following drawback: when the temperature outside drops, their effectiveness decreases significantly, because it is more difficult to remove heat from cool air.

Coolant and its properties

There is no ideal coolant. Each option has an acceptable temperature range and technical parameters, if violated, the heating system can be damaged. Replacing equipment will be very expensive.

The main characteristics of the coolant that need to be taken into account when choosing:

- temperature regime;

- viscosity;

- anti-corrosion properties;

- toxicity when heated.

The best coolant is purified water and antifreeze.

The main advantages of antifreeze over water are presented in the table. Its use is especially recommended in houses with seasonal or periodic residence.

| Coolant | freezing t, °C | Viscosity, mm²/s at 40°С | Fire hazard, critical temperature, °C |

| Purified water | 0,9 | Yes | |

| Industrial oils | -15 (-18) | 10÷40 | 140÷190 |

| Salt compositions | -55 | 1 | No |

| Alcohol compositions | -40 | 0,7 | Yes |

| Antifreeze | -40 | 3,1 | No |

There is no need to drain it from the system during departure. When you return, simply turn on the boiler. If the temperature drops below the limit, the composition will turn into a viscous liquid - a gel, while its physical characteristics will not change. After the temperature rises to the required level, it will again acquire a liquid form while maintaining its original volume.

Special product for the system - antifreeze antifreeze for heating

Despite all the advantages of antifreeze, many people choose water. It is safe, there are no chemical impurities in it, especially if you have dug your own well. The only negative point is the mineral salts in the composition, which cause corrosion. To prevent it, you can use boiled or melt water. Or alternatively, use a pre-cleaning system.

Filling the heating system with antifreeze

Air-to-air heat pumps

The absolute record holder in terms of the cheapest implementation of a heat supply project is the use of an air-to-air heat pump. An example of such equipment is a conventional split system configured for heating mode.

Warming up a room with an air conditioner will be much more economical than with an electric heater, since electricity is spent not on heating the air, but on operating a compressor that pumps heat from the street. Thus, the best models of inverter air conditioners pump 5 kW of heat into the house per kilowatt of electricity consumed. Inverters from well-known manufacturers cost up to one thousand US dollars including installation services and are capable of operating at outdoor temperatures down to 25 degrees below zero. Detailed video about alternative heating of a private house:

Ventilation

The use of ventilation as a source of heating, at least, sounds interesting, because the purpose of ventilation is to remove from the premises air that contains dust, oxygen deficiency and the presence of unpleasant odors. But some of the heat is also removed with the air. How can this be used? You can also install a heating element into the ventilation system (in its supply part) with your own hands to supply heated air to the house.

The greatest efficiency is in the supply and exhaust ventilation system, with forced circulation and heat recovery.

The systems use warm exhaust air to preheat cold, supply air. The best efficiency and equipment utilization rates are achieved by regulating the air flow according to its actual need.

Wind generator assembly and connection

The second most popular source of alternative energy is wind. Homemade wind generators allow you to provide your home with heat at minimal cost.

First stage. Choose the appropriate type of structure and its power. Beginners are recommended to choose the most popular vertical wind generators. Select power individually. Increasing the power of a wind generator is achieved by increasing the size of the impeller and adding additional blades.

Second phase. Make a foundation for a wind generator. A basic three-point base is enough. Determine the depth and area of the structure individually, taking into account the characteristics of the soil and the climate at the construction site.

Install the mast no earlier than the base has completely hardened, i.e. in about 1.5-2 weeks. Instead of a foundation, you can use guy wires. This is an even simpler option for installing a mast. Dig a small pit approximately 50-60 cm deep, install the wind generator mast in it and securely fasten the structure using ordinary guy wires.

Third stage. Make the blades. At home, a metal barrel is perfect for this.

You need to divide the container into equal parts in an amount equal to the number of selected blades. Make marks first, it is important that the blades have exactly the same size. Cut out the blades of the future wind generator. The grinder will help you with this

If you don’t have a grinder, you can get by with scissors for cutting metal.

Fourth stage. Secure the workpiece to the generator with bolts, and then bend the blades. Many parameters of the wind generator’s operation depend on how far the blades are bent. It is impossible to give any specific recommendations in this regard. You can only determine the appropriate angle through experience.

Fifth stage. Connect the electrical wires to the generator and connect the system elements into a circuit. Fix the generator on the windmill mast, then connect the wires to the mast and connect the generator and battery to the circuit. Apply the load using wires. At this point the wind generator is ready. You can connect it to a water heating system using the same storage tanks.

Thus, the use of alternative energy is a very promising area that definitely deserves attention. Now you too can feel part of the modern world and save significantly on heating costs by assembling a simple wind or solar installation. Follow the instructions and everything will work out.

Video - Do-it-yourself alternative home heating

The rise in price of traditional fuels (gas, firewood, electricity, peat, etc.) forces us to look for cheaper heating methods. Traditional boilers are gradually being replaced by alternative heating of a private home, which allows one to obtain thermal energy and at the same time save money.