In our country, the average outdoor temperature during the cold season does not exceed 8°C. Consequently, all residential premises in private and apartment buildings must be heated. In most regions, the heating season lasts about 150 days or more. Therefore, the heating system must be reliable and not pose a threat of a possible accident during frosts outside.

The most important element of supplying heat to rooms are heating devices, which, based on the type of material, are divided into:

- steel;

- cast iron;

- bimetallic;

- aluminum.

In addition, you can sometimes find heating convectors made of finned copper pipes, which are most often used for hidden installation in floors.

Radiators with bottom connection

You can hide bulky pipes by making heating with a bottom connection. Of course, standard systems are more familiar to understand, when the coolant enters from the top or side and exits downwards. But such a system is rather unaesthetic, and it is difficult to cover it with a screen or somehow improve it.

Bottom connection principle

The scheme with a bottom connection of heating pipes is not familiar and widespread, as it is less efficient.

than standard connections. But in some cases, this is a winning option. For multi-apartment apartments, such piping is not used. Most often, this type of connection can be found in private homes where aluminum and bimetallic heating radiators are used. With a bottom connection, the main part of the pipes is hidden under the floor covering, sometimes causing difficulties during seasonal inspection or preventative repairs. But there are also advantages - there is a minimum of complex bends or joints, which reduces the risk of leaks or accidents.

The connection diagram for heating radiators with a lower type is simple - the return and coolant supply pipes are located nearby, in the lower corner of the radiator. It is also possible to connect pipes from different sides of the radiator. The upper holes (if any) are screwed in with a plug.

The radiator installation kit is identical to the standard one:

For the bottom connection, it is best to use bimetallic radiators. they are strong, durable, and have excellent heat transfer due to heating, radiation and convection. Even when using a lower connection, heat loss will not be more than 15 percent. Thanks to the supply of hot coolant from below, the bottom of the battery heats up and warms up the top by convection.

Selection and installation of radiators

Bimetallic heating radiators are recommended for bottom connections; they are easy to assemble, install and repair. Radiator sections can be removed, added, or replaced if damaged.

When purchasing, it is better to give preference to domestic manufacturers; it is important to check the integrity of the battery and packaging. Documentation must be clear and written in Russian

Before installation you need to make markings. it is done with a pencil on the wall. In this case, the points where the brackets will be installed are marked. The bottom of the radiator should be at least 7 cm from the floor and 10 cm from the window (if located under the window). Distances are maintained so that the air in the room circulates freely. The distance to the wall should be about 5 cm.

For more efficient coolant circulation, heating radiators are installed with a slight slope. This also eliminates the accumulation of air in the heating system.

When connecting, it is important to follow the markings and not confuse the return and supply. If connected incorrectly, the radiator can be damaged and its efficiency reduced by more than 60 percent

The following types of bottom connection are distinguished:

- one-sided supply - pipes come out from the corner below and are located side by side, heat loss can be about 20 percent;

- versatile supply – pipes are connected from different sides. such a system has more advantages, since the length of the supply and return lines is shorter, and circulation can occur from different sides, heat loss is up to 12 percent;

A top-down connection is also used. but in this case, it will not be possible to hide all the heating pipes, since the coolant will be supplied in the upper corner, and the outlet will be from the opposite lower corner. If the heating radiator is a short-circuit one, then the return flow will be discharged from the same side, but from the lower corner. In this case, heat loss is reduced to 2 percent.

If you plan to connect heating radiators yourself, it is important to follow installation and safety precautions. The coolant must be drained during installation or repair, the batteries are cold

If in doubt, it is better to call a specialist or use a training video lesson, since with a lower connection it will be difficult to repair areas. It is better to plan a heating system with bottom heating together with the layout of the house.

Heating system connection options

In addition to choosing the radiator itself, during installation you will also need to decide how to connect it to the centralized network. There are several different options available to you, each of which has its own scope of use:

- Diagonal connection. This scheme is the best choice for long multi-section heating batteries. It is distinguished by the fact that the water supply pipe is attached to the pipe from above on one edge of the radiator, and the outlet pipe is attached to the lower pipe on the other side. Among the disadvantages of such a system are difficult repairs in case of problems: the scheme does not imply removing the battery without completely turning off the heating.

Radiator connection options

Important! When supplying water from below, you will lose about 10% of the possible heat. . Bottom connection

This wiring diagram looks the most inconspicuous. It is used if pipes are located inside the floor or hidden under baseboards. The supply and outlet pipes are directed perpendicular to the floor surface. The main disadvantage is that this system involves the greatest possible amount of heat loss. Lateral one-way connection. It is the most common and effective. Maximum heat transfer is ensured by connecting the inlet pipe from above, and the outlet pipe from below on the same side of the battery. When inverted, the heating power is significantly reduced, so it is not recommended to swap pipes.

- Bottom connection. This wiring diagram looks the most inconspicuous. It is used if pipes are located inside the floor or hidden under baseboards. The supply and outlet pipes are directed perpendicular to the floor surface. The main disadvantage is that this system involves the greatest possible amount of heat loss.

- Lateral one-way connection. It is the most common and effective. Maximum heat transfer is ensured by connecting the inlet pipe from above, and the outlet pipe from below on the same side of the battery. When inverted, the heating power is significantly reduced, so it is not recommended to swap pipes.

Important! If the distant sections of the battery are not warmed up enough, a water flow extension is used.

- Parallel connection. It occurs through a heat pipe built into the heating system. The withdrawal is implemented in the same way. This system allows you to replace batteries without turning off the central heating, but the main disadvantage is that if there is insufficient pressure in the system, the batteries do not warm up well.

Important! Connecting a heating radiator with your own hands in this way is quite difficult; it would be better to entrust this work to experienced installers.

- Serial connection. In this case, heat transfer through the system occurs due to air pressure in it. Excess air is drained using a Mayevsky tap. The main disadvantage of such a system is also the impossibility of repairs without shutting down the entire heating system.

The problem of choosing radiators

There is no universal solution today. Different problems require different solutions.

For example, using aluminum radiators in apartments designed for centralized heating is a bad idea:

- Aluminum is a soft metal and may simply not withstand large differences in coolant pressure.

- The steel from which the pipes are made for passing coolant through them to the batteries gradually reacts with hot water under high pressure. The resulting salt solution interacts intensely with aluminum.

- Aluminum itself is not an inert material at all. At the point of contact with steel, noticeable corrosion reactions occur. The fact is that aluminum and unalloyed steel make up a so-called galvanic couple, that is, damage at the point of contact of these two metals is only a matter of time.

Bimetallic batteries are free from all of the following disadvantages:

- Their strength is such that radiators are guaranteed to withstand five times the coolant pressure of 10 atmospheres typical for centralized networks.

- Excellent appearance and a wide variety of shapes and sizes.

- Mounting bimetallic radiators will be more difficult than aluminum ones, but not much - with comparable dimensions, a bimetallic radiator will be about one and a half times heavier than a pure aluminum one.

Today, bimetallic radiators are used, made using two technologies:

- Steel frame - the coolant circulates through steel pipes and does not come into contact with aluminum. The “aviation” metal only covers the steel pipes to improve convection and the appearance of the batteries.

- Reinforced channels - uses the principle of reinforced concrete (two materials complement and reinforce each other). Using this technology, aluminum pipes are reinforced with steel inserts in critical areas. You should be aware that if installed incorrectly, these inserts can block the lumen of the pipe.

A peculiarity of the operation of bimetallic radiators is the characteristic tapping sound when heating and cooling the batteries (read: “Bimetallic heating radiators: which ones are better to choose”). The fact is that aluminum and steel expand differently, so there are stresses at the point of contact.

Kinds

Bimetallic heating radiators are of four types:

- of steel,

- made of cast iron,

- aluminum,

- from several types of metal.

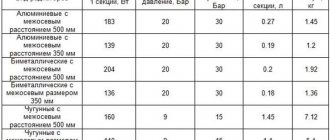

Radiator comparison

Which radiator is best to choose for heating an apartment is a rather difficult question. If traditional heating is carried out, then it is not recommended to install an aluminum radiator, due to high pressure, which requires more durable products. In terms of warranty service life, steel devices are less durable. They are only guaranteed for a year. According to the power parameters of the radiators, bimetallic and aluminum batteries stand out, one hundred and ninety-nine watts.

If you need to purchase more durable devices, you should choose the first ones. They will withstand higher levels of pressure during operation. It is difficult to distinguish them by appearance; they differ in their weight. The second one is much easier than the first one.

Bimetallic batteries for heating systems are divided into types, according to their production technology:

- products equipped with reinforced channels;

- products made on the basis of a steel frame.

The latter are distinguished by the fact that the liquid inside does not come into contact with the aluminum surface. Therefore, they are not subject to corrosion and have a longer service life. When choosing this type of radiator, you must evaluate its cost and weight.

What is needed for installation

Installation of heating radiators of any type requires devices and consumables. The set of necessary materials is almost the same, but for cast iron batteries, for example, the plugs are large, and they do not install a Mayevsky valve, but instead, somewhere at the highest point of the system, they install an automatic air vent. But the installation of aluminum and bimetallic heating radiators is absolutely the same.

Steel panel ones also have some differences, but only in terms of hanging - they come with brackets, and on the back panel there are special arms cast from metal, with which the heater clings to the hooks of the brackets.

Mayevsky crane or automatic air vent

This is a small device for releasing air that may accumulate in the radiator. Placed on the free upper outlet (collector). It must be on every heating device when installing aluminum and bimetallic radiators. The size of this device is significantly smaller than the diameter of the manifold, so you will also need an adapter, but Mayevsky taps usually come complete with adapters, you just need to know the diameter of the manifold (connection dimensions).

In addition to the Mayevsky crane, there are also automatic air vents. They can also be installed on radiators, but they are slightly larger in size and for some reason are only available in a brass or nickel-plated case. Not in white enamel. In general, the picture is unattractive and, although they deflate automatically, they are rarely installed.

Stub

The side-connected radiator has four outputs. Two of them are occupied by the supply and return pipelines, on the third they install a Mayevsky valve. The fourth entrance is closed with a plug. It, like most modern batteries, is most often painted with white enamel and does not spoil the appearance at all.

Shut-off valves

You will need two more ball valves or shut-off valves that can be adjusted. They are placed on each battery at the input and output. If these are ordinary ball valves, they are needed so that, if necessary, you can turn off the radiator and remove it (emergency repairs, replacement during the heating season). In this case, even if something happens to the radiator, you will cut it off, and the rest of the system will work. The advantage of this solution is the low price of ball valves, the disadvantage is the impossibility of adjusting heat transfer.

Almost the same tasks, but with the ability to change the intensity of the coolant flow, are performed by shut-off control valves. They are more expensive, but they also allow you to adjust the heat transfer (make it less), and they look better externally; they are available in straight and angular versions, so the piping itself is more accurate.

If desired, you can install a thermostat on the coolant supply after the ball valve. This is a relatively small device that allows you to change the heat output of a heating device. If the radiator does not heat well, you cannot install them - it will be even worse, since they can only reduce the flow. There are different thermostats for batteries - automatic electronic ones, but more often they use the simplest one - mechanical.

Related materials and tools

You will also need hooks or brackets for hanging on walls. Their number depends on the size of the batteries:

- if there are no more than 8 sections or the length of the radiator is no more than 1.2 m, two mounting points on top and one on the bottom are sufficient;

- For every next 50 cm or 5-6 sections, add one fastener at the top and bottom.

You also need fum tape or linen winding and plumbing paste to seal the joints. You will also need a drill with drills, a level (preferably a level, but a regular bubble one will do), and a number of dowels. You will also need equipment for connecting pipes and fittings, but it depends on the type of pipes. That's all.

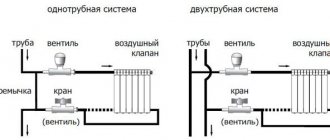

Heating system type

Single pipe systems can be routed vertically or horizontally. The latter option is most suitable for low-rise dwellings: usually we are talking about one- or two-story houses. Three-story buildings are rarely equipped with horizontal wiring. Vertical wiring is usually used in high-rise buildings. This scheme consists of a pipe coming out of the flow, going to the radiator, and then to the floor. This picture can be observed in all (or almost all) rooms. Sometimes there are cases where two radiators are powered from one riser at once. However, it is not at all necessary that they be in the same room.

The strengths of this scheme are the low installation costs and stability of operation (it is quite difficult to unbalance it). However, if significant changes in the parameters of batteries and pipes occur, this can significantly affect the hydraulic resistance. As a result, only the first two sections turn out to be warm, and the rest of the device remains cold.

Single-pipe wiring is characterized by a gradual decrease in the temperature of the coolant as it moves away from the boiler. The efficiency of heating the battery of the neighbor above (with top supply) is inversely proportional to the heating of the radiator on the floor below. To avoid such situations, a law on common ownership of the heating system was adopted. Now, in order to replace a pipe or heating device, you need to obtain the appropriate permits. High-rise buildings are not so often equipped with two-pipe wiring. This is explained by the large consumption of pipes for its organization. In addition, the large dimensions complicate the balancing of the circuit.

A two-pipe system in a multi-story building has the following diagram:

- Two pipes are brought into the room.

- The hotter part serves to supply coolant to the battery.

- The second removes the coolant that has cooled down after the radiator further.

Thanks to this scheme, the temperature of the coolant supplied to all heating devices is identical. It is important to remember that if there is a change in hydraulic resistance in just one radiator, the entire system can be completely unbalanced. A very small resistance will provoke the passage of almost the entire volume of coolant through this section. Therefore, in the presence of such wiring, installation of control valves is mandatory. Most often these are manual control valves or thermostats.

Installation of bimetallic batteries

It clearly describes the procedure for connecting bimetallic heating radiators for a specific model. It should be noted that the installation of all system elements is carried out in plastic packaging of the radiator. And this packaging cannot be removed until the entire installation process is completed.

Let's look at how to connect a bimetallic heating radiator yourself. When carrying out installation work, the following nuances must be taken into account:

- It is better to place the battery in the center of the window;

- equipment is installed only in a horizontal position;

- heating parts must be installed at the same level within the room;

- the distance from the wall to the battery should be from 3 to 5 cm. If the heating system is located too close to the wall, the thermal energy will be distributed irrationally;

- a distance of 8-12 cm must be maintained from the window sill. If the gap is too small, the heat flow from the battery will decrease;

- the distance between the radiator and the floor should be 10 cm. If you install the device lower, the efficiency of heat transfer will decrease. It will also be inconvenient to clean the floor under the radiator. But if the heating unit is located too high, the temperature readings at the bottom and top of the room will be very different.

The installation algorithm for a bimetallic radiator is as follows:

- the location for installation of brackets on the wall is marked;

- fixing the brackets. If the wall is brick or reinforced concrete, then the brackets are secured with dowels and cement mortar. If you are dealing with a plasterboard partition, then fixation is carried out using double-sided fastening;

- The battery is placed on the brackets;

- the radiator is connected to the pipes;

- a thermostatic valve or faucet is installed;

- An air valve is placed at the top of the battery.

Below are some recommendations regarding self-installation of a bimetallic heating device:

- Before starting installation, the flow of coolant into the system at the outlet and inlet should be shut off. There should be no liquid in the pipeline;

- Before installation, you must check that the battery is complete. The radiator must be assembled. Otherwise, you need to assemble the unit according to the manufacturer's instructions;

- It is prohibited to use abrasive materials during assembly. Because the battery design must be sealed. And abrasive substances can destroy the material of the device;

- bimetallic radiators use both right-handed and left-handed threads. This must be kept in mind when tightening fasteners;

- When connecting sanitary fittings, the correct choice of material plays an important role. As a rule, flax with a heat-resistant sealant is used. Tangit threads or FUM tape are used;

- Before starting installation, you must have a clearly planned radiator connection diagram. It should be noted here that the connection diagram for bimetallic heating radiators can be bottom, diagonal or side;

- When the installation is completed, the device is turned on: all the valves of the unit, which previously blocked the path of the coolant, smoothly open. If you open the taps abruptly, you can cause clogging of the internal pipe section or cause a water hammer. After the valves are open, excess air should be released using an air vent;

- You should not cover bimetallic batteries with screens or install them in wall niches. This will cause the heat output of the device to sharply decrease.

Nuances of equipment installation

An example of installing a radiator depending on external factors.

The assembly of bimetallic batteries begins with turning off the heating system. It is necessary to drain the water and rinse the communication system with non-alkaline solutions. To avoid coolant leakage, it is strictly forbidden to clean the contact surfaces of connections with abrasive materials.

On the eve of work, it is worth carefully considering the diagram according to which the radiators should be connected. A properly installed pipe should bypass the radiator. That is, during installation of one battery, the functioning of the others must be maintained. One of the best ways to connect is the diagonal method. It provides hot water supply through the top hole of the radiator. The return flow of coolant is carried out in the lower part of the radiator.

Before installing new radiators, you should remove the old battery from its hinges, having first cut it off from the system. Metal pipes must be cut at equal distances. Next, they are threaded for the fastening nuts. It should be borne in mind that the thread used on modern radiators can be left-handed or right-handed. This feature sometimes confuses residential owners who decide to carry out such work themselves. The next stage involves marking the mounting location of the brackets for bimetallic radiators. The brackets are fastened with dowels (the use of cement mortar is also possible). They must be installed in such a way that the horizontal sections of the heads in the sections lie directly on the brackets.

http:

Bimetallic radiators are installed at a distance of 5 cm from the wall. To improve convection, a gap of 15-20 cm is made between the floor and the radiator, and the gap to the window sill should be at least 12 cm. The existing protective film is removed only upon completion of the installation work. In this way, damage to the surface of the installed equipment is prevented.

A special role during installation work should be given to connecting sections. The assembly of threaded connections is carried out very carefully. All of them must be extremely tightened (but in no case overtightened). Plumbing fittings are used to seal connections. A heat-resistant sealant or a special Tangit thread must be used.

Installation of the radiator is accompanied by the adjustment of an automatic or manual valve, which is designed to eliminate air accumulated in the system. The valve can be adjusted using multi-start threads. The tightening force should not exceed 12 kg. To protect the valve working area from contamination, special filters should be installed on the supply risers of the system.

http:

The installation of heating batteries ends with their trial connection. Plumbing taps should open as smoothly as possible. Otherwise, the flowing internal section of the pipes may become clogged from the old system. In addition, sudden opening of taps can cause water hammer.

Radiator connection diagrams

How well the radiators will heat depends on how the coolant is supplied to them. There are more and less effective options.

Radiators with bottom connection

All heating radiators have two types of connection - side and bottom. There can be no discrepancies with the bottom connection. There are only two pipes - inlet and outlet. Accordingly, coolant is supplied to the radiator on one side and removed from the other.

Bottom connection of heating radiators for single-pipe and two-pipe heating systems

Specifically, where to connect the supply and where the return is connected is written in the installation instructions, which must be available.

Heating radiators with side connection

With a lateral connection, there are many more options: here the supply and return pipelines can be connected into two pipes, respectively, there are four options.

Option #1. Diagonal connection

This connection of heating radiators is considered the most effective, it is taken as a standard and this is how manufacturers test their heating devices and the data in the thermal power passport for such a connection. All other connection types transfer heat less efficiently.

Diagonal diagram for connecting heating radiators with a two-pipe and one-pipe system

This is because when the batteries are connected diagonally, the hot coolant is supplied to the upper inlet on one side, passes through the entire radiator and exits from the opposite, lower side.

Option #2. Unilateral

As the name implies, pipelines are connected on one side - supply from above, return from below. This option is convenient when the riser runs on the side of the heating device, which often happens in apartments, because this type of connection usually predominates. When the coolant is supplied from below, this scheme is used infrequently - it is not very convenient to position the pipes.

Lateral connection for two-pipe and one-pipe systems

With this connection of radiators, the heating efficiency is only slightly lower - by 2%. But this is only if there are few sections in the radiators - no more than 10. With a longer battery, its farthest edge will not heat up well or will remain cold at all. In panel radiators, to solve the problem, flow extenders are installed - tubes that bring the coolant a little further than the middle. The same devices can be installed in aluminum or bimetallic radiators, thereby improving heat transfer.

Option #3. Bottom or saddle connection

Of all the options, saddle connections for heating radiators are the least effective. Losses are approximately 12-14%. But this option is the most inconspicuous - pipes are usually laid on the floor or under it, and this method is the most optimal from an aesthetic point of view. And so that losses do not affect the temperature in the room, you can take a radiator a little more powerful than required.

Saddle connection of heating radiators

In systems with natural circulation, this type of connection should not be made, but if there is a pump, it works well. In some cases, it’s not even worse than the side one. It’s just that at a certain speed of movement of the coolant, vortex flows arise, the entire surface heats up, and heat transfer increases. These phenomena have not yet been fully studied, therefore it is not yet possible to predict the behavior of the coolant.

Dismantling old cast iron radiators

If you are building a new home, then, naturally, the issue of dismantling will not arise before you.

But many apartment and house owners, when installing bimetallic radiators, inevitably face the problem of dismantling old cast iron or metal batteries. It would seem that “breaking does not build,” but you want to do all this as carefully as possible, without causing significant damage to the walls of your home. Dismantling old cast iron batteries using a grinder

You need to start this whole process by draining the water from the heating system. Owners of private houses and cottages are more fortunate in this matter, as they will be able to complete this stage of work on their own, without contacting the housing office. But for residents living in apartment buildings, this is much more difficult to do, since they need to look for a mechanic, negotiate with him on a certain day, quietly pay money for draining each riser, etc. And it is quite clear that work to replace radiators is needed produce outside the heating season, because no one will drain water in winter. For your information, in the summer, the entire heating system in the house is also filled with water and contact with a plumber cannot be avoided.

After draining the water, you can proceed directly to dismantling the old batteries, where you cannot do without a cutting power tool, which is a cylindrical grinder, or, simply put, an angle grinder. In theory, all connections of metal pipes and radiators should be disconnected using gas wrenches, but over time and water in the heating system in many places, the connections have become so “akin” to corrosion and scale that it is impossible to do without the use of an angle grinder.

You need to start disassembling the old system from the upper sections, gradually moving downwards. In this case, all operations must be carried out slowly, trying not to damage the walls, ceiling and floor, which will then add extra work to your restoration. It would be rational to remove the dismantled sections of the system from the premises and store them somewhere in the corridor or on the street so as not to create rubbish. Subsequently, the results of dismantling the old heating system can be handed over to the nearest metal collection point and thereby compensate for part of your costs for dismantling the old batteries.

Bimetallic battery design

As practice in recent years has shown, of the listed series of radiators, the most effective and reliable are bimetallic models. They have a clear advantage over other materials, which are:

- high corrosion resistance;

- wide range of operating temperatures and pressures;

- simple ability to change the heat transfer of the device by changing the number of assembled sections;

- low inertia during heating and cooling;

- a small amount of coolant required for filling;

- low weight, facilitating installation;

- affordable for most people.

It should also be noted that bimetallic radiators are easy to install. Thanks to the presence of standard fasteners, this process will not cause structural damage and will ensure high-quality fixation of heating equipment.

The design of bimetallic batteries consists of a set of sections. When assembled, such a package consists of two horizontal pipes connected by vertical hollow ribs through which the coolant circulates.

To increase the heat transfer of the heating device, the outer surface of the fins and pipes is increased due to additional planes. The sections are connected to each other using hollow nipples with double-sided threads, provided that a sealing gasket is installed.

Core.

To protect against corrosion, the inner surface of the sections is covered with a protective layer of aluminum alloy. The outer metal surface is painted using the technology of thermal application of polymer powder paints. This gives the products a beautiful appearance and ensures their durability.

Before installing a bimetallic heating radiator with your own hands, you need to purchase a set of 4 special plugs. Two of them have a ½-inch internal thread, the third should be without a hole, and another one has an air release device installed

When purchasing a kit, you should pay attention to the direction of the threads - there should be two right and two left

What kind of fittings are needed

To connect a sectional bimetallic radiator, you will need a standard connection kit.

We are talking about the following elements:

- Plugs.

- Manual air vent valve (Maevsky faucet) and the key to it.

- Pair of adapters (with right-hand and left-hand threads).

Adapters are supplied to the right and left sides of the radiator. You can connect fittings or pipes to them. Their diameter (½ or ¾ inch) directly affects the diameter of the fittings and liner.

Features of bimetal radiators

Installation of a heating system involving bimetallic radiators requires knowledge of their design and internal structure.

Design

A bimetallic heating radiator consists of two layers of metal - an aluminum body and a core made of steel or copper. There are two modifications of this device:

- Absolutely bimetallic devices, in which the core is tubes through which coolant flows without contact with the body material,

- Semi-bimetallic, the internal channels of which are simply reinforced with plates of another metal.

Different designs result in differences in the properties of the device itself. Fully bimetallic heating radiators are much stronger, more resistant to sudden changes in operating conditions and, therefore, more durable.

Bimetal heating device design

Calculation of the number of sections

Correct installation of bimetallic batteries requires an accurate calculation of their quantity. It is best to entrust this matter to specialists. But if you plan to install the heating yourself, then you will have to do all the calculations yourself. To do this, you will only need two quantities - the power of the heating element you have chosen and the area of the room:

- First, divide the area by 10 to calculate 1 kW per 10 m2.

- Then we divide the resulting number by the radiator power stated in the device passport.

- Rounding the resulting number up to whole numbers gives the required amount.

Installation of bimetallic radiators

Calculation of the required number of sections

The number of sections of heating devices is determined depending on the heat losses through the building envelope. An accurate calculation can only be performed by a specialist with the appropriate education.

But enlarged standard indicators for standard buildings have long been determined, which take the required heat consumption at the rate of 1 kW of thermal energy per 10 m2 of room . This figure provides a guaranteed reserve power reserve of the device by 10-15%.

The heat output of sections of bimetallic radiators in Watts is indicated in the product passport, which is included in each package. Therefore, to determine the number of sections required to heat a room, it is necessary to multiply its area in m2 by 100 and divide by the heat transfer of one section in W.

The resulting result is rounded up to the nearest whole number. A rough check is made from the condition that on average one section heats 1.2-1.4 m2. Performing calculations allows you to avoid purchasing unnecessary items and save money.

Recommendations for installing the battery yourself

- Before starting work, you need to shut off the flow of coolant in the heating system at the inlet and outlet or make sure that there is no liquid in the pipeline.

- Even before installation, you need to check that the radiator is complete. It must be assembled. If this is not the case, take a radiator key and assemble the battery according to the manufacturer's instructions.

The structure must be absolutely sealed, so abrasive materials cannot be used during assembly, as they destroy the material of the device. When tightening fasteners, do not forget that bimetallic devices use both left-handed and right-handed threads. When connecting sanitary fittings, it is extremely important to choose the right material. Typically, flax is used together with a heat-resistant sealant, FUM tape (fluoroplastic sealing material) or Tangit threads. Before starting installation work, you need to carefully plan the connection diagram

Batteries can be connected diagonally, sideways or downwards. It is rational to install a bypass in a single-pipe system, that is, a pipe that will allow the system to function normally when the batteries are connected in series. After installation is complete, the system is turned on. This must be done by smoothly opening all the valves that previously blocked the path of the coolant. Opening the taps too sharply leads to clogging of the internal pipe section or hydrodynamic shocks. After opening the valves, it is necessary to bleed off excess air through an air vent (for example, a Mayevsky valve).

Note! Do not cover batteries with screens or place them in wall niches. This will sharply reduce the heat transfer of the equipment

Correctly installed bimetallic heating radiators are the key to their long and trouble-free operation. If you have any doubts about your ability to install them yourself, it is better to contact a specialist.

Functionality check

Upon completion of installation work, the functionality of the system is checked. Having opened the Mayevsky tap, they begin to fill the radiator through the return line. To do this, open the ball valve on the lower manifold. When all the air is out of the battery, water flows out of Mayevsky’s tap, it is turned off. Open the second ball valve on the upper manifold.

In order for the battery to warm up, all the air must be vented while filling it with coolant.

If there is no air left in the sections, the circulating coolant will begin to warm them up. The presence of cold spots indicates air pockets. The bleeding procedure through the Mayevsky tap is repeated until a positive result is achieved.

How to install correctly

Now about how to hang the radiator. It is very desirable that the wall behind the radiator is level - this makes it easier to work. Mark the middle of the opening on the wall, draw a horizontal line 10-12 cm below the window sill line. This is the line along which the top edge of the heating device is leveled. The brackets must be installed so that the top edge coincides with the drawn line, that is, it is horizontal. This arrangement is suitable for heating systems with forced circulation (with a pump) or for apartments. For systems with natural circulation, a slight slope is made - 1-1.5% - along the flow of the coolant. You can’t do more - there will be stagnation.

Wall mount

This must be taken into account when installing hooks or brackets for heating radiators. Hooks are installed like dowels - a hole of a suitable diameter is drilled in the wall, a plastic dowel is installed in it, and the hook is screwed into it. The distance from the wall to the heating device is easily adjusted by screwing in and unscrewing the hook body.

When installing hooks under heating radiators, keep in mind that the main load falls on the upper fasteners. The lower one serves only to fix it in a given position relative to the wall and is installed 1-1.5 cm lower than the lower collector. Otherwise, you simply will not be able to hang the radiator.

When installing the brackets, they are applied to the wall in the place where they will be mounted. To do this, first attach the battery to the installation location, see where the bracket “fits,” and mark the location on the wall. After placing the battery, you can attach the bracket to the wall and mark the location of the fasteners on it. In these places, holes are drilled, dowels are inserted, and the bracket is screwed. Having installed all the fasteners, hang the heating device on them.

Floor fixing

Not all walls can support even lightweight aluminum batteries. If the walls are made of lightweight concrete or covered with plasterboard, floor installation is required. Some types of cast iron and steel radiators come directly with legs, but not everyone is satisfied with their appearance or characteristics.

Floor installation of heating radiators made of aluminum and bimetallic is possible. There are special brackets for them. They are attached to the floor, then the heating device is installed, and the lower collector is secured with an arc to the installed legs. Similar legs are available with adjustable height and some with a fixed height. The method of fastening to the floor is standard - with nails or dowels, depending on the material.

Purpose and selection of bypass

When installing a bimetallic radiator in a single-pipe system, it is imperative to use a bypass. This is the name given to the jumper between the supply and return pipes. It allows excess coolant to bypass the battery. This scheme allows you to avoid blocking the drain and subsequent troubles with the management campaign. Most often, the bypass is made offset: its optimal location is between the radiator and the riser. If you insert a tap into the jumper, this will make it possible to adjust the temperature of the radiator. However, in this case there is a possibility of blocking the riser.

A more effective solution is to use an unregulated bypass, equipping the radiator directly with control valves. This is mainly done in cases where the room is very hot. If there is no such problem, then it is better not to reduce the efficiency of radiators, which inevitably happens when installing regulators.

The automatic fittings are designed for a pressure of 10 atm. Therefore, when the testing pressure drops below 15 atmospheres, operation does not encounter any difficulties. Exceeding this limit will most likely lead to device failure. If it is absolutely impossible to do without a thermostat, and the test pressure is very high, it is better to dismantle the device before starting the circuit and replace it with a drain. Upon completion of the pressure testing, the device is mounted back, which makes it possible to clean the valve at the same time.

Which radiator is better to install?

The modern market offers a wide selection of bimetallic radiators of different brands from different manufacturers. There are domestic and imported options. Among foreign models, Italian or German bimetallic heating radiators are popular.

Popular German-made batteries include radiators from Tenrad. All products of this company are distinguished by reliability and high performance parameters. The fins are three-row, which ensures good heat transfer performance.

Among the Italian products, it is worth considering the Italian bimetallic heating radiators Global STYLE PLUS 500. To connect such a unit, a side circuit is used. The device is mounted on the wall. Thanks to its excellent technical characteristics and attractive appearance, the bimetallic radiator Global STYLE PLUS 500 receives only positive reviews. Most often, users note efficient operation and durability. The heat output is 185 W. And the coolant temperature can reach a maximum of 110 degrees. There are numerous reviews of Global heating radiators.

The Italian company Radena also specializes in the production of bimetallic batteries. Only high carbon steel is used for production. The working pressure is 25 atmospheres. And the ambient temperature reaches 100 degrees. There are batteries with standard side and bottom connections. Reviews for Raden heating radiators are positive. Durability, good design, and the possibility of use in one-pipe and two-pipe heating systems with horizontal and vertical placement of heat pipes are noted.

Let's consider domestically produced models. For example, Russian bimetallic heating radiators Rifar Monolit. Although the Rifar brand appeared on the market quite recently, the products of this company have already managed to displace the products of famous German and Italian manufacturers. Rifar radiators are used in residential and administrative buildings. They have excellent characteristics. Bimetallic radiators also fully comply with GOST 31311 2005, TU. Rifar monolith is available in two sizes: 350 and 500 mm. Radiators with a center distance of 500 mm are most often used. There are no joints between sections. Therefore, if you decide to install such a battery, you must immediately select the required length. For bimetallic heating radiators Rifar Monolit 500, the price is optimally combined with functionality and quality. Installation of such batteries is quick and easy. Does not require the use of adapters.

Not long ago, Russian-made Termohit radiators also went on sale. This equipment belongs to the budget class. It has not yet become widespread, so there are not too many reviews of Thermohit heating radiators. The technical characteristics are high. But still the quality is inferior to more expensive models.

There are also Chinese-made batteries on the domestic market. Here it is worth noting the Oasis radiators. The products have international certification and have good technical characteristics. Reviews for bimetallic heating radiators Oasis are mostly positive. Users highlight such advantages of these units as high technical performance, long factory warranty and affordable price.

Pipes

When replacing radiators in a high-rise building, it is necessary to use the same pipes and with the same diameter. This is not just a whim. The fact is that multi-storey buildings use systems with certain parameters. The main ones are hydraulic resistance and operating pressure. A test (pressure test) pressure used during system startup is specially organized for them. As a rule, it is an order of magnitude higher than the working one.

The use of polypropylene and metal-plastic pipes to connect bimetallic radiators, despite all their advantages, is not recommended in such conditions. Their external attractiveness does not in any way contribute to increasing the service life in conditions of centralized systems, which is fraught with the appearance of leaks with all the ensuing consequences.

The same applies to the diameter of the pipes. When changing the diameter of the liner, the hydraulic resistance of the entire circuit changes greatly. And no one can guarantee that this will have beneficial consequences. Therefore, when using half-inch pipes in a system, there is no need to experiment with other diameters. The same goes for fittings and battery adapters.

Technical features of installing bimetallic heating devices

An increasing number of owners today prefer heating mechanisms such as bimetallic heating radiators, which are not particularly complicated and at the same time have a number of advantages.

These devices today have become much more popular compared to traditional aluminum or cast iron radiators, which is explained by their resistance to pressure drops inside the heating system and high performance (for more details: “Which is better: aluminum or bimetallic radiators - comparative characteristics”). These products can rightfully be called an alternative option between standard devices made of cast iron and aluminum.

Before connecting bimetallic heating radiators, it is extremely important to make sure that all materials required for the work are available. The main list of equipment includes a set of direct radiator components, as well as brackets designed for mounting bimetallic heating radiators on them

It is important to remember that connecting bimetallic batteries of one type or another should only be done with equipment suitable for its purpose. Many owners, when carrying out repair work, prefer to save some money and fix the batteries with old brackets, but in this case it is extremely important to make sure that these parts are not damaged by corrosion and are able to tightly hold the entire system.

When installing a bimetallic radiator with a bottom connection or another installation method, you need to have additional parts available if you plan to replace the heating pipes (read: “How to connect a heating radiator - methods and options”). As a rule, today an alternative to steel pipes are reinforced polypropylene samples. Experts do not recommend using metal-plastic pipes equipped with collet clamps

It is important that high-quality and reliable cranes are used during the installation process; here you should not focus on the low cost of these elements

To monitor any changes in temperature in the radiator, you should use a device specially designed for this - a thermostat.

So, in order to understand how to properly connect a bimetallic radiator, you should first of all have the following equipment available:

- directly bimetallic heater;

- installation kit for connecting a heating battery;

- additional functional parts for connecting the system.

What coolant to use

The type of coolant used has a significant impact on the service life of the devices and the efficiency of the heating system. The internal structure of bimetallic heaters allows the use of liquids that have lower quality and purity standards. Such coolants are used in centralized heating systems.

The use of low-quality water containing chemically active elements negatively affects all elements of the heating system. Calcium and magnesium salts dissolved in the coolant are harmful to radiators, causing the appearance of scale and insoluble deposits on the inner surface.

Corrosion can occur under the influence of the following factors:

- increased water hardness;

- the value of the pH degree that does not meet the operating requirements;

- a large number of organic particles contained in water;

- oxygen entering the device.

To avoid negative effects on batteries, the manufacturer warns about the need to use water in accordance with clause 4.8. SO 153–34.20.501 - 2003.

For bimetallic radiators, it is permissible to use water and antifreeze with a pH level in the range of 6.5–9.5 as a coolant.

The use of antifreeze in heating systems has its own characteristics:

- It is recommended to use it in private homes where heating may be turned off due to electrical problems to prevent the coolant from freezing.

- The use has a beneficial effect on the condition of seals and gaskets, extending their service life.

- An environmentally friendly product does not have a negative impact on human health.

- If all rules of use are followed, the service life can reach 10 years.

- Since this liquid has a higher viscosity compared to water, you need to think about purchasing a more powerful circulation pump for your heating system.

- The use of antifreeze in heating systems where zinc pipes are installed is not recommended in order to prevent the occurrence of a chemical reaction leading to a decrease in the performance of the equipment.

- Constant monitoring of coolant acidity is required. Exceeding the pH level recommended for radiators increases the likelihood of corrosion.

- Antifreeze has a high fluidity, so it is necessary to use high-quality intersectional paronite and silicone gaskets.

Installation of bimetallic radiators

Installation of bimetallic radiators is a responsible undertaking that will help ensure warmth and comfort in your home.

Bimetallic radiators are not inferior in power to cast iron ones, but they are lighter.

The very name of these heating devices indicates that they are made of two different types of metals, namely aluminum and steel. The frame of the radiators is made of aluminum, and the pipes are made of steel. Bimetal provides a combination of properties such as high strength and good thermal conductivity.

Like the installation of sectional radiators, this type of work involves the use of both standard right-hand and left-hand threads. This specific type of work is often the most problematic aspect when installing bimetallic batteries if you plan to do it yourself. This feature often leads to components being twisted in the wrong direction. This can lead to leaks in the future.

Before installation begins, it is necessary to assemble them. As a rule, bimetallic radiators are assembled immediately at the manufacturing plant or at points of sale, but in some cases customers have to assemble the radiators themselves, directly at the installation site. This work is carried out using a special radiator key, which can be used to connect all sections together. To perform this assembly, some experience in plumbing work is required. Moreover, it is almost impossible to assemble radiators alone. If you are faced with the need to assemble sections, it is best to contact specialists in this field.

Requirements for devices

First, bimetallic heating batteries must be efficient and practical to use.

Secondly, the appearance of bimetallic radiators should attract the buyer and not spoil the living space itself. They should fit into the room and become a pleasant addition to it.

The third requirement for this heating device is strength. This technical requirement is considered the main one when choosing a bimetallic battery. If the strength of such a device is good, it means that it will withstand high pressure in heating during operation.

According to the passport data of the heating radiator, it is able to withstand pressure of twenty to forty atmospheres. In apartment buildings, heating pressure does not exceed the level of ten atmospheres. However, an extra margin of safety will not hurt. Bimetallic heating radiators are made of two types of metal, therefore, they have the best qualities of one and the other.

If you look at this device in section, then under the outer aluminum layer you can see the internal steel collector, and the vertical channels that conduct heat are steel.

Bimetallic battery in section

How to cook at home

To make fresh juice at home, it is best to take varieties of pink and red potatoes.

You will need:

- Fresh or farm vegetable.

- Brush.

- A knife to remove the eyes.

- Gauze or juicer.

- Cup.

Wash thoroughly with a brush and pass through a juicer along with the peel. Another method of preparation: grate, then squeeze the mixture through cheesecloth. Let sit for 1 minute. This is necessary so that the starch settles to the bottom.

Carefully drain and drink immediately. You can improve the taste by simply adding a teaspoon of honey.

Important! Many may have a question: how to drink potato juice? It is worth remembering that it is recommended to drink the solution in small sips or through a straw for a maximum of 10 minutes, until it darkens and loses its beneficial qualities.

Variety of heating radiators

The most traditional are cast iron models of heating radiators, which are familiar to everyone. Today, these units are used extremely rarely due to their large weight and the impossibility of installation in heating systems that operate automatically. However, these devices also have their own advantages, which distinguish them from batteries made from other materials.

First of all, the design of the heating radiator made of cast iron allows it to withstand severe pressure drops

In addition, such batteries are resistant to the appearance of corrosive deposits on them and withstand the effects of harmful impurities in the coolant, which is also important

The design of a panel-type heating radiator is somewhat different. First of all, these devices are significantly lighter than cast iron batteries. In addition, their walls are less thick, which reduces their inertia. The operating principle of a panel-type steel heating radiator is based on greater heat transfer compared to other models. In addition, the appearance of these devices is much more modern. Many consumers appreciate aluminum heating radiators. These radiators are also very light in weight, their heat dissipation is quite acceptable, and the design can be very different.

Sometimes you can find heating devices where aluminum is not the only material included in the product. In inexpensive devices, silicon is added as an addition, preventing rupture of the structure in the event of serious changes in pressure and temperature.

And those devices that are more expensive may contain zinc and titanium, since these substances are designed to provide the structure with increased resistance to various types of mechanical damage and protection against corrosion.

Water heating devices

The following can serve as heating elements for rooms:

- traditional radiators installed under window openings and near cold walls, for example, on the north side of the building;

- pipe underfloor heating circuits, otherwise heated floors;

- baseboard heaters;

- in-floor convectors.

Water radiator heating is the most reliable and cheapest option among those listed. It is quite possible to install and connect batteries yourself; the main thing is to correctly select the number of sections according to power. Disadvantages are poor heating of the lower zone of the room and the placement of appliances in plain sight, which is not always consistent with the interior design.

All commercially available radiators are divided into 4 groups according to the material of manufacture:

- Aluminum - sectional and monolithic. In fact, they are cast from silumin, an alloy of aluminum and silicon, and are the most efficient in terms of heating speed.

- Bimetallic. A complete analogue of aluminum batteries, only the frame is made of steel pipes inside. Scope of application: multi-apartment high-rise buildings with central heating, where the coolant is supplied at a pressure of over 10 bar.

- Steel panel. Relatively cheap monolithic radiators made from sheets of stamped metal plus additional fins.

- Cast iron sectional. Heavy, heat-intensive and expensive devices with an original design. Due to their considerable weight, some models are equipped with legs - it is unrealistic to hang such an “accordion” on the wall.

In terms of demand, steel appliances occupy a leading position - they are inexpensive, and from the point of view of heat transfer, thin metal is not much inferior to silumin. Next come aluminum, bimetallic and cast iron heaters. Choose which ones you like best.

Construction of heated floors

The underfloor heating system consists of the following elements:

- heating circuits made of metal-plastic or polyethylene pipes, filled with cement screed or laid between joists (in a wooden house);

- distribution manifold with flow meters and thermostatic valves to regulate water flow in each loop;

- mixing unit - a circulation pump plus a valve (two- or three-way) that maintains the coolant temperature in the range of 35...55 °C.

The mixing unit and the manifold are connected to the boiler by two lines - supply and return. Water heated to 60...80 degrees is mixed in portions by valve into the circuits as the circulating coolant cools.

Warm floors are the most comfortable and economical heating method, although installation costs are 2-3 times higher than installing a radiator network. The optimal heating option is shown in the photo - floor water circuits + batteries, controlled by thermal heads.

Warm floors at the installation stage - laying out pipes on top of the insulation, attaching a damper strip for subsequent filling with cement-sand mortar

Skirting and in-floor convectors

Both types of heaters are similar in the design of the water heat exchanger - a copper coil with thin plates mounted on it - ribs. In the floor-standing version, the heating part is covered with a decorative casing that looks like a plinth; gaps are left at the top and bottom for the passage of air.

The heat exchanger of the in-floor convector is installed in a housing located below the level of the finished floor. Some models are equipped with low-noise fans that increase the heater's performance. The coolant is supplied through pipes laid hidden under the screed.

The described devices fit well into the design of the room, and underfloor convectors are indispensable near transparent external walls made entirely of glass. But ordinary homeowners are in no hurry to purchase these devices because:

- copper-aluminum convector radiators are not a cheap pleasure;

- to fully heat a cottage located in the middle zone, you will have to install heaters around the perimeter of all rooms;

- in-floor heat exchangers without fans are ineffective;

- the same products with fans emit a quiet monotonous hum.

Baseboard heating device (pictured left) and in-floor convector (right)