The manufacturer's recommendation for this fault code is brief: contact a professional. In practice, knowing the reasons that trigger the failure of a Baxi gas boiler with error E35 gives the user the opportunity to deal with the problem on their own. The article explains what to do.

Error E35 on the control panel of the Baxi boiler

Installation of Baxi gas boilers

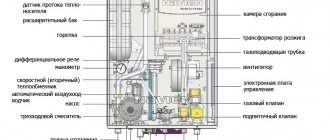

Almost all gas boilers have the same basic design: natural gas flows through the gas valve to the burner nozzle block, then is ignited by an electric spark through the electrode. Using a heat exchanger, the heat from combustion is then transferred to the heat carrier. The heat exchanger is located above the burner.

Gas boilers differ in the presence of a second flow-through heat exchanger, which is necessary for preparing water, as well as in functionality.

The most common options are:

- 1 heat exchanger and indirect heating boiler.

- Two separate heat exchangers. 1 – for preparing water, 2 – for the heating circuit.

- Combined heat exchanger for heating and water preparation.

Gas boilers can be divided into turbocharged, atmospheric, and also with an open and closed combustion chamber. Equipment with an open chamber takes air from the combustion room. All safety standards and regulations must be observed in the premises. In some countries it is prohibited to use this type of gas boiler.

A turbocharged boiler does not require a chimney, unlike an atmospheric one. In the first option, combustion products are forced out of the combustion chamber by a fan through a coaxial chimney. This gas boiler is suitable for installation in an apartment.

The following processes occur in a gas boiler: switching the flow of hot water, heating water, removing combustion products and monitoring safety.

An electronic board is necessary to control and monitor the safety of all equipment. The electronics operate according to the set values and, in the event of failures, stop the operation of the gas boiler.

Additional errors

Other messages may appear on the LCD display of your boiler, which should also not be ignored:

- Flashing "!" signals operation at the lowest power. The reasons for this may be abnormal gas pressure at the inlet, problems with electronics, clogged chimney and/or air duct, problems with the gas valve.

- The flashing sign St means that the boiler has automatically switched to defrosting mode. Once this function is completed, the message should disappear from the screen. Otherwise, a failure occurs.

- The radiator and mixer symbols are flashing - this indicates scale deposits or problems with the temperature sensor attached to the DHW circuit.

All these malfunctions must also be eliminated by specialists of the relevant profile who have the necessary competencies

Why is it necessary to ground a gas boiler?

The safe operation of a Baxi gas boiler is only possible if the device is properly grounded. It is necessary to organize grounding taking into account the current PUE standards.

Before starting the gas boiler, you should check that the connection is correct. The operating instructions state the following: if the requirements are not met, the gas boiler will be void of warranty.

When installing the equipment, the inspection company must check the quality of the grounding. Most often, in apartment buildings, residents buy an apartment with a working gas boiler and do not think about the quality of its connection. Problems may arise over time due to improper grounding. Therefore, it is recommended to check the quality of grounding and installation of the gas boiler before starting use.

Do not forget that this equipment is a gas installation and a high-risk unit. There are times when a fire occurs due to negligence in safety.

It is worth paying special attention to the boiler control electronics. Almost all models are equipped with a security and control system. An electronic board that includes various components is responsible for this. This element has the highest cost and accounts for about 30% of the total cost of a gas boiler. If there is no grounding, the board may break and error e35 may appear.

The operation of the gas boiler is controlled using automation. It includes actuators and various sensors. If the connection to the network is incorrect, a failure and emergency stop of the equipment may occur. In some models, the polarity of the connection must be observed.

Using a tester, the grounding is checked: there should be no potential between the neutral wire and the phase, and the operating voltage between the ground and phase terminals should be 220-230 V. In addition, to check the grounding of metal parts of the equipment, you can use a special indicator screwdriver.

Decoding

Parasitic flame - this is how the malfunction is described in the instructions for the boiler. Error E35 is not typical for Baksi, it is rare, and even experts find it difficult to accurately diagnose the equipment. On thematic forums, the emphasis is on the failure of the Baksi board, although failures are mainly caused by external factors: instability of power supply parameters, improper grounding, interference, and a number of others. The cost of the control unit reaches 30% of the price of the Baxi boiler, and if error E35 occurs, you do not need to immediately purchase a new board - the reason for the unit stopping is not necessarily its malfunction.

Baxi boiler control board

Flame ionization electrode

A flame sensor is installed on the burner of a gas boiler and is necessary to monitor the presence of a flame. The electrode on the control board is connected to the connector. The flame sensor in some boilers can be combined with an igniter.

There is an air gap between the burner and the electrode, which prevents the passage of current when the boiler is not working. When gas burns, the control board records the flow of microcurrents through the flame. The value should be in the range of 0.5-5 µA.

Incorrect operation of the electronics may be caused due to the presence of various parasitic interferences and potentials on the parts.

Advantages of Baxi electric heating boilers

There are many advantages of heating devices. These include affordable prices and excellent work opportunities. But that's not all. Baksi heating units are almost completely autonomous, which allows owners not to worry about their operation.

Positive technical characteristics of heating boilers:

- There are equipment protection systems that eliminate all possibilities of an accident.

- The Baxi boiler supplies fuel and air for heating automatically, so human intervention is not required. And if you also connect climate control equipment, then the units can themselves select the heating temperature on the sensor. This will be especially convenient for those people who have country houses. It is, of course, advisable to connect a generator so that the electric boiler operates in the desired mode without obstacles.

- A wide range of operation modes on the sensor allows you to save money on utilities, as well as ensure comfortable operation of the heating system.

- The Baxi heating boiler is made from environmentally friendly raw materials, so you don’t have to worry about the environment. These electric boilers use fuel efficiently. Some models have an efficiency of about 95 percent. This technological progress makes emissions of harmful gases minimal.

- The Baxi boiler is considered a safe unit as it has a flame control system. If the fire goes out, the gas supply stops. This protection prevents gas leakage.

- Modern Baxi units already have a system that prevents overheating. If the coolant stops circulating, then the heating system will automatically turn off. But if you do not need this function of an electric boiler, then you can buy a simpler unit, especially since it costs less.

Almost every Baxi boiler can be connected to climate control or other control equipment, and there is also a system that prevents the condensation effect.

Among the characteristics we can also name: the presence of a sensor that shows the temperature; the presence of a condensation system that prevents the formation of liquids from steam or gas; An electric ignition system is present in both floor-mounted and wall-mounted electric boilers.

What to do if error e35 remains?

If no methods help resolve the error, you may need to replace the board. Some models of Baxi gas boilers have installed boards that are sensitive to external interference and power supply standards. In the picture below you can see the features of the boards that work correctly.

The cause of error e35 on Honeywell boards may be increased sensitivity to humidity. Due to accumulated dust, this error may appear. For Bertelli boards, simply rinse the surface with isopropyl alcohol.

Gas boiler Baxi mainfour 240f error e35

In this series of gas boilers there are 2 types of control board: 1 different and 2 interchangeable. Visually, you can distinguish the type of board by the color of the display panel. In mainfour 240f gas boilers, the board does not have a flame modulation control circuit and also has a gray panel.

Gas boiler Baxi ecofour 24 error e35

The most versatile gas boilers are the Baxi Mainfor and Ecofor series. The difference is the secondary plate heat exchanger for heating water. Mainfor boilers have 1 heat exchanger for heating water and heating. Most often, the cause of error e35 is improper grounding of the equipment, so the recommendations for elimination are almost the same.

Many manufacturers include universal boards in their equipment, so different boilers have interconnected boards and can be installed on different series. In order to make the correct installation, you need to configure the board to work on a specific boiler using the configuration menu.

Error E35 on a Baxi boiler, how to fix it

Reboot the boiler. On the Baksi panel, the Reset (R) button: after pressing and holding for 2 seconds, the false error E35 will disappear. If the code appears again, the following procedure is recommended.

Restart the boiler Baxi boiler

Check what

Presence of condensate

Dampness is the cause of error E35 in a gas boiler. If Baksi is in an unheated room, after a long period of inactivity, the appearance of code 35 is expected: you need to evaluate the condition of the ionization sensor. In conditions of high humidity, it gives a false signal of the presence of a flame, even when the valve on the pipe is closed. Located in the chamber, it serves to record the current between the metal of the boiler burner and the sensor electrode; in some models Baksi is combined with an ignition device. When the unit is not working, in damp conditions, it produces a parasitic signal on the board, which generates error e35.

Baxi boiler ionization sensor

Solution to the problem:

- dry the combustion chamber with a stream of warm air (hair dryer, heater or the like);

- if the Baxi boiler is installed in the kitchen, organize an effective exhaust hood. The cause of error E35 is increased humidity.

Electrical parameters

Deviation from the value specified in the instructions for Baxi (~230V) initiates malfunctions in the electronics and causes the boiler to stop with an error.

Tips . If there is a power line near the object, another source of powerful EM radiation, an error in the Baxi E35 boiler is not uncommon. Under such conditions, the operating algorithm of the electronic board is disrupted and a false fault code is generated. Incorrect functioning of the external stabilizer also causes code 35.

Recommendation . One way to get rid of error E35 is to install a cut-off fitting (dielectric coupling) on the gas pipe between the boiler and the tap. It will prevent the influence of stray currents and interference on Baksi electronics. Sources of interference include power lines, tram lines, electrified railway tracks, and the like during accidental breakdowns. Electricity “dumped” into the ground, passing to the metal of the gas main, affects the “brain” of the boiler, causing error E35.

one dielectric coupling

Connecting a dialectical coupling

Connection diagram to the dielectric coupling

Grounding

This is faced by users who are piping the Baksi boiler on their own, and by owners of apartments in high-rise buildings. The connection must be checked when the unit is put into operation for the first time. It is not without reason that violation of the grounding procedure, its non-compliance with the requirements of the PUE, is the basis for removing the heating installation from the factory warranty.

Grounding the baxi boiler

This is specifically stated in the manufacturer’s instructions, which, unfortunately, not everyone carefully studies. Poor connection of the Baksi boiler to the circuit causes malfunctions in the control board, an emergency stop and the display of error E35. At home, the reliability and effectiveness of grounding can be easily determined using an indicator screwdriver by the absence of glow when the probe touches metal parts, components, or the body of the Baksi boiler.

Gas valve

Its leakage is the cause of error E35. If the solenoid valves do not completely block the gas path after removing the opening command, the Baksi boiler ionization sensor detects the burner flame. Its repair is a separate topic, but it is more rational to replace it: the defect is associated with the depletion of the resource.

Electronic board

If error E35 is present, after taking measures, you need to check this unit. Baksi boilers (depending on the year of manufacture, series) are equipped with different boards. While functioning identically, they differ in their response to external factors (power supply, interference, grounding). Honeywell boards are the most “sensitive” to moisture.

How to proceed

- Rinse the surface . To remove dust, which when moistened becomes a conductive layer, isopropyl alcohol and a brush (with medium-hard bristles) are used; in laboratory conditions, an ultrasonic bath is used. After removing contamination from the electronic board and drying it, error E35 will disappear.

- Install a new unit into the boiler . You should consult a professional on this issue - not all boards are interchangeable. The product specification (numbers, letters) is indicated on the panel. When ordering (selecting) an electronic unit, you need to take this code into account - there will be no errors. Owners of Baksi mainfour should know that these boilers are equipped with boards of 3 options: one has a different circuit and is not interchangeable.

On a note! After installing the new electronic board, you need to go to the menu and configure it to work with this Baxi boiler model (adapt).

Expert opinion

Error e35 in Baxi Eco Four, MAIN four and Fourtech

This error can be described as a stray flame. A combustion signal comes from the ionization sensor until the board sends a signal to open the gas valve.

This error can be caused in a Baxi gas boiler for the following reasons:

- The gas valve is not sealed. After the signal to open the valve is turned off, the presence of a flame is detected.

- Moisture has entered the electronic board of the gas boiler.

Error e35 can occur accidentally in a gas boiler. To solve the problem, you can hold down the “R” button to reboot the equipment. If after this the error does not disappear, then you should look for another cause of the failure.

One of the causes of error e35 may be a malfunction of the electronic board or its incorrect operation.

You can resolve this error as follows:

- Install an isolation transformer.

- Check the network parameters, which must comply with the standards. It is necessary to check the absence of potentials between the ground, zero and pipes.

- Install a special interface device.

Useful tips

- If the boiler error E35 is not eliminated by the measures taken, check household electrical appliances. Perhaps some consumer of electricity negatively affects the parameters of the network (“lowers” the voltage, introduces interference, etc.). It is recommended to turn off all operating equipment one by one at night, leaving only Baksi in operation - based on experience in eliminating the E35 error, this technique helps to find the culprit for the appearance of the fault code.

- When connecting a gas boiler to the mains, professionals recommend using the Teplocom GF device. Referred to as: galvanic isolation, interface device, isolation transformer. The price of 5,350 rubles will not be a burdensome purchase, but the E35 error of the Baksi boiler will not appear due to problems with interference. The instructions for the unit say: for connecting heating installations to networks ~I without grounding. Even if it actually exists, at many sites it does not meet regulatory requirements. Teplocom eliminates parasitic (stray) currents on the line, adapts the heating unit with autonomous sources. If the operation of the Baksi boiler in a house or apartment is systematically blocked with errors, galvanic isolation is the solution to the problem.

Content

- Baxi boiler installation instructions

- What to do

- baxi boiler error codes

- Error E 01

- Common error e03 on a baxi boiler

- Baxi boiler error e35 - problem with the flame control sensor.

- Error E 25

- Error E 26

- Error E 10

- Error E 00

It has already been proven that the safest and most effective heating occurs through the condensation of water vapor generated during the combustion of hydrocarbons. Gas boilers that operate using such a system are called condensers. This is exactly what Baxi belongs to, which is designed for the conditions of post-Soviet countries. In Russia, Ukraine and Belarus, it is important to use energy-saving technologies, which is what the manufacturer of gas boilers Baksi does.

Installation, dismantling, adjustment, assembly, connection and adjustment work

Baxi boilers are modern and high-tech heating equipment that is widely used both in residential buildings and in industrial premises, warehouses and non-residential buildings to create autonomous heating, ensure effective maintenance of set temperatures with minimal energy losses. Installation (installation) of the Baxi boiler

guarantees the user the supply of heat and hot water; this is a complex process that requires the participation of specialists.

To select Baksi boiler systems, as well as domestic and industrial models, kits with a boiler or wall-mounted/floor-mounted boiler units, manufactured in Italy, you need to take into account many parameters, among which the most important are:

• equipment power;

• volume of the heated room;

• energy carrier used to generate heat;

• desired temperature of the heated room;

• climatic conditions.

Since the choice of a specific Baksi heating installation, which allows you to provide the house with heat and hot water, will depend on these factors. Installation is recommended in apartments and country houses due to the highest efficiency, convenient control and excellent design.

At the same time, it should be understood that it is important not only to choose a suitable solution, but also to carry out the installation of Baxi at the highest level, since the efficiency, reliability, durability and cost-effectiveness of the equipment in operation largely depends on how the work is performed. If you want to install heating using high-quality and reliable equipment from Italy, which is appreciated by hundreds of thousands of consumers throughout Russia, and after installation, supply the equipment for service (autonomous heating systems and boiler rooms) based on Baksi gas boilers, we recommend contacting Ajax Thermo

All works published on the site are made by hand. We treat our work with care and meticulousness, therefore we necessarily provide a guarantee for all work. All installation and commissioning specialists, service engineers and repair teams have certificates for installation work. We confidently take on projects of any complexity of installation, maintenance and repair! Our own design department will draw up a design for your heating system, taking into account all your wishes.

Stock

1. When purchasing equipment and ordering installation, you receive a -10% discount on work! 2. When purchasing equipment, ordering installation, commissioning and concluding a service contract for maintenance, you receive an additional emergency call (24 hours)!

List of boiler installation works and estimated prices

| № | Name of works | Price, rub) |

| Wall boilers | ||

| 1 | Installation of a wall-mounted boiler with connection to an existing system* | 7500 |

| 2 | Installation and installation of a heating system coarse filter (with shut-off valves) | 3000 |

| 3 | Installation and connection of DHW (single point)** | 3800 |

| 4 | Installation and connection of sewerage (one point)** | 2800 |

| 5 | Installation, assembly and connection of one manifold cabinet** | 5600 |

| 6 | Installation and connection of the heating system (one point)** | 4300 |

| 7 | Installation of boiler room power supply** | 4000 |

| 8 | Installation of a coaxial chimney with hole punching | 3000 |

| 9 | Installation of stainless smoke exhaust pipes with a diameter of up to 160 mm in the existing chimney up to 2 lm | 2000 |

| Gas water heaters | ||

| 1 | Installation of a gas water heater | 4000 |

| 2 | Supervised installation of a gas water heater | 3000 |

| Floor standing boilers with atmospheric burner | ||

| 1 | Installation of a floor-standing boiler up to 40 kW | 11 500 |

| 2 | Installation of a floor-standing boiler up to 60 kW | 14 800 |

| 3 | Installation of a floor-standing boiler up to 100 kW | 20 000 |

| 4 | Installation of a floor-standing boiler up to 150 kW** | negotiable |

| 5 | Installing a boiler safety group | 2000 |

| 6 | Installation and connection of the pump unit | 4500 |

| 7 | Installation and connection of a boiler up to 400 l | 8500 |

| 8 | Installation and installation of an expansion tank for domestic hot water | 3500 |

| 9 | Installation of a safety group for a boiler and recirculation pump | 2500 |

| 10 | Wall chipping 1 working day* | 10 000 |

| Floor standing boilers with inflatable burner | ||

| 1 | Installation of a floor-standing boiler up to 100 kW | 25 000 |

| Electric boilers | ||

| 1 | Installation of an electric boiler with connection to existing pipes and electrical network | 7500 |

| Equipment dismantling | ||

| 1 | Easy boiler dismantling (polypropylene/metallic piping) | 5000 |

| 2 | Difficult dismantling (steel strapping) | 10 000 |

* The price for installing a wall-mounted boiler is given on the basis of its simple installation to existing pipelines, a chimney, without the need to replace or install a chimney, fittings and other equipment necessary for the operation of the boiler.

**Prices are given as a guide; the exact cost of installing a boiler room is determined after an inspection of the facility, taking into account the individual wishes of the customer.

Advantages and disadvantages

The Baksi company occupies a leading position in the heating equipment market.

The boiler is very easy to operate and maintain

The following advantages of this manufacturer’s equipment can be highlighted:

- environmental friendliness and safety;

- ease of operation and flexible adjustable settings;

- reliable protection against freezing;

- automatic diagnostic function;

- efficiency;

- a wide range of models, the ability to select a unit to suit any requirements;

- stylish, thoughtful design.

Of course, any equipment has its drawbacks, and Baxi products are no exception. The disadvantages are:

- Sensitivity of equipment to voltage changes. For the device to work reliably, you need to connect it through a stabilizer.

- Installation is quite complicated, so it is best to entrust it to a professional.

- High price compared to models from other manufacturers.

In this video you will learn about the main malfunctions of Baksi boilers: