TA Select 4 – program for hydraulic calculations of heating and cooling systems

TA Select is a software program that helps you manage your hydraulic system from the design stage through to the end of the building's life.

Together with our TA SCOPE TA balancing tool, TA Select will help you achieve:

Most economical hydraulic design

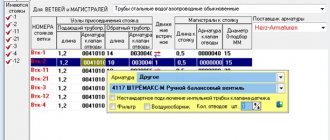

TA Select 4 makes it easy to select the correct valve sizes, preset values, and the most cost-effective system design. To do this, you just need to enter in TA Select:

- Pipe lengths

- Estimated flow rate at terminal devices

- Pressure drops

At the output you get:

- Required pump pressure

- Detailed list of optimally sized components, such as control and balancing valves

- Design of the installation (hydraulic network) for loading into balancing programs

- Total lengths of pipelines by diameters

- Volume of water in the pipeline

Checking that the installation is working as expected...

TA Select 4 interfaces with our new TA SCOPE balancing tool and allows you to easily upload and download system information to and from the TA SCOPE software. This speeds up the balancing process and makes it possible to verify that the system complies with the original design upon commissioning. Then you load the installation design (hydraulic network) designed in TA Select into TA-SCOPE and perform balancing. After balancing the installation, the measured data is loaded into TA Select. Flow, pressure drop, 2 temperatures, pressure drop and power are checked. As a result, you receive a document in the form of a printed report.

...and throughout the entire life of the system

We want the hydraulic system to perform as expected for its entire service life. With TA SCOPE and TA Select you can easily check whether the system is working correctly.

Flow, pressure drop, 2 temperatures, temperature drop and power are entered into TA SCOPE. To analyze this measured data, it is loaded into TA Select.

Enter your email to receive information about new programs

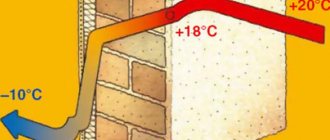

After collecting the initial data, determining the heat losses of the house and the power of the radiators, all that remains is to perform a hydraulic calculation of the heating system. Done correctly, it guarantees correct, silent, stable and reliable operation of the heating system. Moreover, it is a way to avoid unnecessary investment and energy costs.

Calculation of the number of radiators for water heating

Calculation formula

In creating a cozy atmosphere in the house with a water heating system, radiators are an essential element. The calculation takes into account the total volume of the house, the structure of the building, the material of the walls, the type of batteries and other factors.

We make the calculation as follows:

- determine the type of room and select the type of radiators;

- multiply the area of the house by the specified heat flow;

- divide the resulting number by the heat flow rate of one element (section) of the radiator and round the result up.

Radiator characteristics

Radiator type

| Radiator type | Section power | Corrosive effects of oxygen | Ph restrictions | Corrosive effects of stray currents | Working/test pressure | Warranty service life (years) |

| Cast iron | 110 | — | 6.5 — 9.0 | — | 6−9 /12−15 | 10 |

| Aluminum | 175−199 | — | 7— 8 | + | 10−20 / 15−30 | 3−10 |

| Tubular Steel | 85 | + | 6.5 — 9.0 | + | 6−12 / 9−18.27 | 1 |

| Bimetallic | 199 | + | 6.5 — 9.0 | + | 35 / 57 | 3−10 |

By correctly calculating and installing high-quality components, you will provide your home with a reliable, efficient and durable individual heating system.

Calculations and work that need to be done in advance

Hydraulic calculation is the most time-consuming and complex design stage.

Therefore, before calculating the heating in the house, you need to perform a number of calculations.

- Firstly, the balance of heated rooms and premises is determined.

- Secondly, it is necessary to select the type of heat exchangers or heating devices, and also arrange them on the house plan.

- Thirdly, calculating the heating of a private house assumes that a choice has already been made regarding the configuration of the system, types of pipelines and fittings (control and shut-off).

- Fourthly, a drawing of the heating system must be made. It is best if it is an axonometric diagram. It should indicate numbers, length of calculation sections and thermal loads.

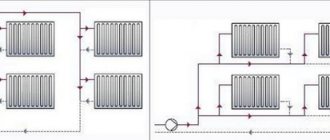

- Fifth, the main circulation ring is installed. This is a closed loop that includes successive sections of pipeline directed to the instrument riser (when considering a single-pipe system) or to the most distant heating device (if there is a two-pipe system) and back to the heat source.

Heating calculations in a wooden house are carried out according to the same scheme as in a brick or any other country cottage.

Single-pipe heating system

Only one main line is installed in the house, under or above the floor, with batteries connected in series. In such a heating circuit there is no distribution between the supply pipe and the return pipe.

Along the perimeter of a one-story building, only one round pipe with a diameter of at least 32 mm is installed, which is conventionally divided in half. The half leaving the heat generator is called the supply, and the second part of the line is called the return. Radiators/convectors are mounted into the loop using a welded or seamless pipe of small diameter.

Organizing a heating system with natural circulation involves installing a supply pipeline with a slope of 4-5 mm every 2 m

The single-pipe circuit includes the following functional elements:

- heat supply source (boiler);

- heating radiators;

- expansion tank;

- pipe routing elements.

The heated liquid flows alternately into the heating radiators, each time giving off part of its heat. After this, it is already cooled and returned to the boiler for the next heating cycle. Each battery loses heat and the last element in the chain remains the coldest in comparison with the others.

There are several ways to optimize the operation of a single-pipe system. You can additionally install special thermostatic valves for heat exchangers, balancing valves with adjustable hydraulic resistance or compact ball valves. Such equipment helps normalize the heat supply to the batteries.

Installed valves make it possible to regulate the amount of heat entering each individual radiator

Another way is to increase the number of sections of each subsequent radiator in the heating circuit. You can also install a circulation pump. The pumping device is connected at the end of the return line - the place where the working fluid has the lowest temperature.

The single-pipe heating option is easy to install and put into operation. Heat loss is minimized, since absolutely all communications are located inside the living rooms of a private house.

Such a scheme can be organized in the form of a system with horizontal wiring and forced movement of the coolant or a vertical heating network with natural, forced or combined movement of the working fluid.

We also recommend reading our other material, where we examined in detail a single-pipe heating system for a private home.

Horizontal wiring method

Installation of the supply pipe in a horizontal plane is carried out with the required slope in the direction of movement of the heated water. In this case, all batteries around the perimeter of the house must be installed at the same level. To bleed air from radiators, Mayevsky taps or automatic air vent devices are used.

The Mayevsky tap is a special device for removing accumulated air from batteries. The shut-off valve is turned until a hissing sound is clearly audible. When the mixture of gases is removed, water will flow from the tap.

The horizontal line can be installed in the floor structure itself or mounted above it. To avoid heat loss, in the first case it is necessary to insulate the pipes.

Vertical wiring option

In such a system, the transportation of the coolant liquid is ensured by a natural circulation mode, and therefore there is no need to install an additional pump. Energy independence is the main advantage of a single-pipe vertical home heating system.

With this method of wiring, the working fluid, heated to a given temperature, moves up the riser, after which it enters the batteries through distribution pipes. The operating efficiency of a vertically located single-pipe system is achieved by installing the main line at a slope, as well as by installing large-diameter pipes.

Of course, a massive pipeline will not decorate the interior of living rooms. But this obvious drawback can be avoided by installing circulation equipment in the system.

Date: September 25, 2020Calculation procedure

Hydraulic calculation of the heating system involves solving the following problems:

- determination of pipeline diameters at various sections (economically feasible and recommended coolant flow rates are taken into account);

- calculation of hydraulic pressure losses in different areas;

- hydraulic linkage of all branches of the system (hydraulic instrumentation and others). It involves the use of control valves, which allows for dynamic balancing under non-stationary hydraulic and thermal operating conditions of the heating system;

- coolant flow and pressure loss calculation.

What is the essence of such a calculation?

The main difference between modern systems is a special mechanism that provides hydraulic mode. Modern developments and high-quality materials that are used today in heating systems make it possible to respond in a timely manner to the slightest temperature fluctuation. It would seem that this is very profitable: energy is saved, and therefore our heating costs are minimized. But on the other hand, such equipment requires special knowledge regarding the use of high-tech control valves, as well as other elements when arranging the system.

Important information! The combination of hydraulic calculations and control valves is the key to the efficiency and performance of modern heating systems.

There are certain circumstances due to which we must comply with the above conditions.

- The coolant must be supplied to the heating devices in the proper quantity - this way you will achieve a balance of heat, provided that you set the temperature in the building, and the temperature outside will change.

- No noise, durability and stability of the heating system.

- Minimum operating costs, in particular, electricity, which would be used to overcome the hydraulic resistance of the pipeline.

- The costs of installing the system should be kept to a minimum, which largely depends on the diameter of the pipeline.

Video instruction

Are there free calculation programs?

To simplify the calculation of the heating system of a private house, you can use special programs. Of course, there are not as many of them as graphic editors, but there is still a choice. Some are distributed free of charge, others in demo versions. In any case, it will be possible to make the necessary calculations once or twice without any material investments.

Oventrop CO software

The free software "Oventrop CO" is designed to perform hydraulic calculations for heating a country house.

Oventrop CO was created to provide graphical assistance during the heating design phase. It allows you to perform hydraulic calculations for both one-pipe and two-pipe systems. Working in it is simple and convenient: there are ready-made blocks, error control is provided, and a huge catalog of materials

Based on preliminary settings and selection of heating devices, pipelines and fittings, new systems can be designed. In addition, it is possible to adjust the existing circuit. It is carried out by selecting the power of existing equipment in accordance with the needs of heated rooms and premises.

Both of these options can be combined in this program, allowing you to adjust existing fragments and design new ones. For any calculation option, Oventrop CO selects the valve settings. In terms of performing hydraulic calculations, this program has wide capabilities: from selecting pipeline diameters to analyzing water flow in equipment. All results (tables, diagrams, drawings) can be printed or transferred to the Windows environment.

Software "Instal-Therm HCR"

The "Instal-Therm HCR" program allows you to calculate radiator and surface heating systems.

It comes with the InstalSystem TECE kit, which includes three more programs: Instal-San T (for designing cold and hot water supply), Instal-Heat&Energy (for calculating heat losses) and Instal-Scan (for scanning drawings).

The “Instal-Therm HCR” program is equipped with expanded catalogs of materials (pipes, water consumers, fittings, radiators, thermal insulation and shut-off and control valves). The calculation results are presented in the form of specifications for the materials and products offered by the program. The only drawback of the trial version is that it cannot be printed.

Computing capabilities of "Instal-Therm HCR": - selection by diameter of pipes and fittings, as well as tees, fittings, distributors, bushings and pipeline thermal insulation; — determination of the lifting height of pumps located in the mixers of the system or on the site; — hydraulic and thermal calculations of heating surfaces, automatic determination of the optimal inlet (supply) temperature; — selection of radiators taking into account cooling in the pipelines of the working fluid.

The trial version is free to use, but it has a number of limitations. Firstly, as with most shareware programs, the results cannot be printed, nor can they be exported. Secondly, only three projects can be created in each application of the package. True, you can change them as much as you like. Thirdly, the created project is saved in a modified format. Files with this extension will not be read by any other trial or even standard version.

Software "HERZ CO"

The HERZ CO program is freely distributed. With its help, you can make a hydraulic calculation of both one-pipe and two-pipe heating systems. An important difference from others is the ability to perform calculations in new or reconstructed buildings, where a glycol mixture acts as a coolant. This software has a certificate of conformity from CSPS LLC.

"HERZ CO" provides the user with the following options: selection of pipes by diameter, settings of pressure difference regulators (branching, base of drains); analysis of water flow and determination of pressure losses in equipment; calculation of hydraulic resistance of circulation rings; taking into account the necessary authorities of thermostatic valves; reduction of excess pressure in circulation rings by selecting valve settings. For user convenience, graphical data entry is organized. The calculation results are displayed in the form of diagrams and floor plans.

Operating principle of closed CO

A closed (otherwise known as closed) heating system is a network of pipelines and heating devices in which the coolant is completely isolated from the atmosphere and moves forcibly - from a circulation pump. Any SSO necessarily includes the following elements:

- heating unit - gas, solid fuel or electric boiler;

- safety group consisting of a pressure gauge, safety and air valve;

- heating devices - radiators or underfloor heating circuits;

- connecting pipelines;

- a pump that pumps water or non-freezing liquid through pipes and batteries;

- coarse mesh filter (dirt collector);

- closed expansion tank equipped with a membrane (rubber “bulb”);

- shut-off valves, balancing valves.

Typical diagram of a closed heating network for a two-story house

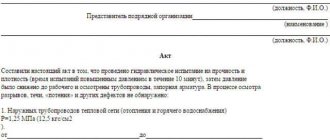

The operating algorithm of a closed type system with forced circulation looks like this:

- After assembly and pressure testing, the pipeline network is filled with water until the pressure gauge shows a minimum pressure of 1 bar.

- The automatic air vent of the safety group releases air from the system during the filling process. He also removes gases that accumulate in pipes during operation.

- The next step is to turn on the pump, start the boiler and warm up the coolant.

- As a result of heating, the pressure inside the ZSO increases to 1.5-2 Bar.

- The increase in the volume of hot water is compensated by a membrane expansion tank.

- If the pressure rises above the critical point (usually 3 Bar), the safety valve will release excess liquid.

- Once every 1-2 years, the system must undergo an emptying and flushing procedure.

The principle of operation of an apartment building's SSS is absolutely identical - the movement of coolant through pipes and radiators is ensured by network pumps located in an industrial boiler room. There are also expansion tanks there; the temperature is regulated by a mixing or elevator unit.

How a closed heating system functions is explained in the video:

ABOK-SOFT

TA Select is a software program that helps you manage your hydraulic system from the design stage through to the end of the building's life.

Link to go to the program website

Together with our TA SCOPE TA balancing tool, TA Select will help you achieve:

Most economical hydraulic design

TA Select 4 makes it easy to select the correct valve sizes, preset values, and the most cost-effective system design. To do this, you just need to enter in TA Select:

- Pipe lengths

- Estimated flow rate at terminal devices

- Pressure drops

At the output you get:

- Required pump pressure

- Detailed list of optimally sized components, such as control and balancing valves

- Design of the installation (hydraulic network) for loading into balancing programs

- Total lengths of pipelines by diameters

- Volume of water in the pipeline

Checking that the installation is working as expected...

TA Select 4 interfaces with our new TA SCOPE balancing tool and allows you to easily upload and download system information to and from the TA SCOPE software. This speeds up the balancing process and makes it possible to verify that the system complies with the original design upon commissioning. Then you load the installation design (hydraulic network) designed in TA Select into TA-SCOPE and perform balancing. After balancing the installation, the measured data is loaded into TA Select. Flow, pressure drop, 2 temperatures, pressure drop and power are checked. As a result, you receive a document in the form of a printed report.

...and throughout the entire life of the system

We want the hydraulic system to perform as expected for its entire service life. With TA SCOPE and TA Select you can easily check whether the system is working correctly.

Flow, pressure drop, 2 temperatures, temperature drop and power are entered into TA SCOPE. To analyze this measured data, it is loaded into TA Select.

Link to go to the program website

Heating design

If the radiators do not work in a new private house, heated floors heat one room better, another worse, and the owner cannot regulate the microclimate in the rooms at will, errors were made in the calculations when designing the heating systems. To prevent this, contact trusted agencies and avoid private freelancers.

Most often, the latter do not have professional software. They use pirated versions of popular developments or their low-quality analogues, which can be downloaded for free on the Internet.

They do not have the opportunity to create a project that will meet not only the requirements and preferences of the customer, but also all technical standards.

In this article you will find a list of well-known software that allows you to carry out large calculations and create complex diagrams. We will tell you about the advantages and disadvantages of each option, offer alternatives to the well-known but expensive AutoCAD and help you make your choice. The material will be useful not only to owners of large organizations, but also to individual entrepreneurs who want to take their activities to a new level with the help of professional technologies.