To grow vegetables year-round, heating is required in a greenhouse.

Heating a greenhouse can be done in several different ways. Let's talk about each of them in more detail.

Boilers for heating greenhouses

When choosing a boiler, you should listen to the recommendations:

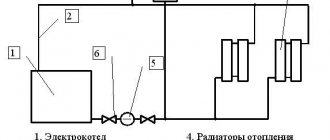

- electric _ The most accessible and practical are heating elements. Electrode ones are cheaper, but place high demands on the coolant. Induction is unreasonably expensive;

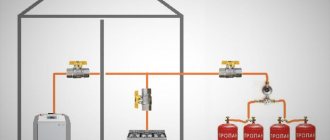

- gas . A model with a closed combustion chamber (air for the firebox is taken from the street) would be preferable. It can be installed in a greenhouse rather than in a vestibule, which eliminates heat loss. Condensing boilers have the highest efficiency. But they only work with low-temperature systems, so you will have to arrange heating according to the “warm floor” scheme (pipes are laid in a “snake” in the ground);

- solid fuel. It is advisable to purchase units that operate for a long time on one load of fuel.

Solid fuel boilers are:

- pyrolysis. Other advantages: high efficiency and clean exhaust;

- top combustion boilers;

- boilers with forced air supply (able to operate in start-stop mode without user intervention);

- pellet boilers. They work on granules pressed from cake or sawdust. They are fed into the firebox automatically by a screw feeder, so the user only needs to fill the hopper from time to time.

Stove for greenhouse

It is not recommended to purchase boilers designed for operation in smoldering mode (Buleryan, etc.), although they also operate on one charge for a relatively long time. Such heaters have extremely low efficiency. And in addition, a large amount of very toxic condensate forms in their chimney.

If it accidentally gets into the soil, it will make the vegetables poisonous. Such boilers can only be used in greenhouses where ornamental plants are grown, not edible ones.

Common Mistakes

The most important mistake when heating a greenhouse with your own hands is flaws in preliminary planning. It is necessary to think through all the details in advance, calculate the costs of materials and time.

If heating work in a greenhouse is carried out in a hurry, the risk of errors increases. This leads to heat loss, malfunctions and equipment breakdowns.

There is also a risk of making mistakes in calculations and choosing the wrong boiler power for the area you plan to heat. As a result: the inability to achieve the required air temperature in the cold season. Therefore, it is recommended to consult a specialist before carrying out work.

Can I use infrared heating?

IR radiation does not pose any danger. Such rays come from any heated body - the sun, stove, heating radiator. The advantage of IR heating is the absence of an intermediary, which is air in other systems: plants receive heat directly.

Heat loss, accordingly, is reduced (in other systems, heat is carried away by air to the ceiling), so IR heating can be considered the most economical.

Do-it-yourself potbelly stove

such heating for a greenhouse yourself. To do this you will need the following materials and tools:

- heat-resistant metal sheets;

- pipes of the same diameter made of cast iron, steel or ceramics;

- metal rods and corners;

- tape measure and plumb line;

- grinder or metal scissors;

- welding machine;

- bolts and couplings;

- baked brick;

- clay and lime mortars.

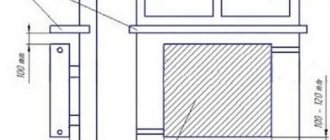

Structure, its location and foundation

One potbelly stove can heat a space of 15 m2 . There must be at least 30 cm between the heated structural elements and the walls of the greenhouse.

If the greenhouse is made of a material that can easily be melted (polycarbonate, polyethylene), then this distance must be doubled.

The heating structure consists of:

- fireboxes;

- chimney;

- chimney.

Fuel burning in the firebox emits warm smoke . It is distributed throughout the greenhouse using a chimney, heating the air, and then goes outside through the chimney.

Do-it-yourself heating of a greenhouse with a potbelly stove:

To do this kind of heating of a greenhouse in winter with your own hands, you first need to make a foundation . Thanks to it, the stove will not warp, its legs will not fall into the ground, and the risk of fire will be minimized.

- For the foundation, you need to prepare a pit 0.5 m deep. Its area depends on the size of the stove. If you plan to cover the finished stove with brickwork, this must be taken into account when digging a pit.

- A mixture of sand, small crushed stone and brick fragments must be poured into the finished pit. A layer of 15–20 cm will be enough.

- Now you can install wooden formwork : the boards need to be placed around the perimeter of the pit, and the gaps between them and the walls of the pit should be filled with sand.

- cement into the hole limited by the boards , and then lay a layer of roofing felt . This will provide additional waterproofing and the foundation will last longer.

- The final touch is laying the bricks . They are placed on roofing felt in two layers, secured with a clay-sand mortar.

Advice! To ensure that the structure is level, you need to check the plumb line after each step.

Designs:

There are different designs of potbelly stoves , but the simplest is the ordinary rectangular stove . It is better to install it so that the combustion hole goes outside. This will make the combustion process easier, and the possibility of smoke in the greenhouse will be reduced.

- The size of the stove will depend on the size of the greenhouse. Average parameters: width – 30 cm, length – 40 cm, height – 45–50 cm. Such a stove can heat 10–15 m2 of space. Taking these features into account, you need to draw a diagram of the future design.

- The firebox is made of any heat-resistant metal . You need to mark the sheets and cut out the structural elements (bottom, walls and roof) with a grinder or metal scissors.

- Now you should weld the bottom and three walls. inside, to a height of ¼ from the bottom . A lattice is placed on them.

- You can buy a grate in a store or make it yourself from metal rods. The rods are welded together in such a way as to form a lattice with holes of 1–4 cm2 . The size of the holes will depend on the future fuel. The grate will hold the fuel, and the combustion products - soot and ash - will pass down into the ash box.

- In the future roof of the stove you need to cut a hole for the chimney with a diameter of 13–15 cm . The roof can then be welded to the structure.

Important! If the chimney is placed underground, the hole can be made not in the roof, but at the bottom or in one of the walls.

- two holes on the front wall of the stove : fuel will be placed through one, and the second will be used as a blower. Through it you can clean the stove from ash. The doors for the holes must be cut out of a metal sheet and attached to the wall using hinges. Handles should be attached to the doors.

- Now you can weld the front part to the stove. If you intend to place the combustion hole outside, it must be covered with heat-insulating material . Otherwise, the heated metal in contact with the greenhouse parts will melt them.

- A short section of pipe needs to be welded to the hole in the roof, to which the chimney .

- Metal legs need to be welded to the bottom or ends of the stove and secured with a jumper. This will add stability .

- To reduce the risk of fire and increase heat transfer time, you can line the stove with brickwork . This material retains heat longer: thanks to it, the stove will have to be fired up less often.

Chimney

The chimney can be made either from a single pipe or from sections of pipes of equal diameter. If the greenhouse is small and air heating is sufficient, the chimney can be laid above the ground. If soil heating is required, an underground structure is suitable.

- The pipe sections for the chimney must be fastened together. To do this, you can use a welding machine or special couplings (clamps). In the latter case, the joints between the pipes under the couplings are coated with clay.

- The chimney must be connected to the stove using the same couplings or welding.

- If you plan to place the chimney underground, then you need to dig shallow trenches (25–40 cm) and lay parallel pipes in them. The distance between the pipes should be from 60 to 100 cm. The pipes are covered with expanded clay or small crushed stone, and their ends are brought outside the greenhouse. This design will be an ideal replacement for “warm floors” .

- If the chimney is above ground, it must be supported by supports. It is best to place it at a slight angle so that the end adjacent to the chimney is slightly raised. This will increase cravings.

- The above-ground chimney must be covered with lime or chalk. Any deformation or rust stains will be visible on the white surface. This will help you easily monitor the condition of the structure.

Chimney

This part of the structure will allow smoke to be removed outside the greenhouse.

- The pipe must be welded to the chimney and covered with heat-insulating material so that when it comes into contact with the roof of the greenhouse, the latter does not melt.

- a spark arrester on top of the pipe . You can buy it in a store or make it yourself.

To do this, you will need a piece of flexible metal grate or a regular tin can.

You need to make a lot of small holes in the jar, and simply twist the lattice into a cylinder.

- To prevent debris and sediment from getting into the pipe, it must be covered with a metal cone .

It can be made from a piece of tin or bought in a store. This structure can be secured to the pipe with thick wire.

- To regulate the draft, a metal damper . It is welded to a piece of thick wire. The ends of the wire are brought out from both sides of the pipe. By turning the ends of the wire, you can change the position of the damper and adjust the draft.

Advice! The damper can only be closed after the fuel has completely burned out. Otherwise, carbon monoxide may enter the greenhouse.

Water tank

a water tank next to or on the stove . It will allow you to water your plants with warm water all year round. In addition, water next to the stove will maintain an optimal level of humidity in the room, which will have a beneficial effect on the green residents.

Now you know how to make a heated greenhouse with your own hands. With the help of a warm greenhouse you can get an excellent harvest even in winter. You just need to choose the right heating method . For southern regions, any method is suitable, but residents of the north should give preference to electric heaters.

self-made greenhouse with heating will delight you with a tasty and healthy harvest all year round!

Types of IR heaters

All IR heaters for greenhouses operate on electricity. However, using the same energy carrier, they can have different designs.

Hull

Such devices are also called lamp IR heaters. The emitter is a spiral placed in a quartz tube (protected from dust), fixed in a reflector.

Case IR heater

Cabinet IR heaters are mounted at the top - on the wall or under the ceiling. The minimum distance to plants is 1-1.5 m (depending on power).

Film

Between the two layers of polyester there are tracks of carbon paste. In fact, such devices are not infrared: they heat up to a temperature no higher than +400C (with poor heat dissipation - up to +700C), so they emit even less intense IR radiation than a regular heating radiator.

For comparison: the coil of an IR lamp heater heats up to a temperature of 600C (until a red glow).

A film heater gives off heat by contact, so it is laid in the ground like a heating cable. Using such a heater in a greenhouse is dangerous!

A thin insulating film is easily damaged (the insulation of a heating cable is much thicker), as a result of which, when watering, water can get on conductive elements with subsequent electrical injury to the user.

Tape

These heaters are designed similarly to film heaters, but have a small width, equal to a garden bed. This allows you to save money by placing heating devices only under the plants.

Belt heaters are also installed vertically between rows. In this position, they heat the air like low-temperature radiators of a large area.

Heating the greenhouse with candles. How to heat a small room, tent, greenhouse with one candle?

We all know how much heat it takes to warm a cold house on a winter day. However, modern inventors are constantly coming up with new devices that can significantly save resources and effort. An example of such an invention would be a miniature stove powered by a single candle.

Most likely, such a stove will not be able to heat a large room on a frosty day. Here you will need to organize a full-fledged heating system, for example, think through electric heating schemes. But for heating a tent during a hike or even a greenhouse, the power of this stove will be quite enough.

This amazing device was invented by a Californian named Doyle Doss. It is put on stream and is called “Candle Heater” or in the original “Kandle Heeter”. The heater is quite successfully sold on the American market for $25 apiece. You can do it yourself using the diagram below.

To create such a heater, you will need:

Candle base; Three ceramic flower pots of different diameters; Metal bolt and set of metal washers and nuts; Supports for pots; Candle.

So, the pots need to be placed one inside the other and connected with a metal bolt with washers and nuts threaded onto it as shown in the heater diagram. Place the candle on the stand and secure the finished structure to the supports above the candle. The heater is ready.

Now all the heat from the burning candle will not be wasted, but will serve to heat the room. By heating the metal rod and air in ceramic pots, the candle thus completely transfers its heat to heat the room. In the end, it turns out that there is a lot of it. Probably not enough for a room in a big house. But for a tent, greenhouse, hallway or bathroom - it’s quite enough. An additional bonus will be the absence of soot on the ceiling (it remains in a small pot and can be washed out), as well as the lighting of the room from candle light. A very convenient option during power outages.

Greenhouse heating calculation

The power of the heating system corresponds to heat loss during the coldest period of winter. The amount of heat loss depends on the temperature difference inside and outside the greenhouse, as well as on the thermal conductivity of the enclosing structures - walls and roof.

Formula W = 1.25 * Kt * S * (tin - tout), where:

- W —heat loss power, W;

- 1,25 — coefficient taking into account heat loss from ventilation and blowing;

- Kt - heat transfer coefficient of the enclosing structure, W/sq. m*0С (not to be confused with the thermal conductivity coefficient of the material);

- S —area of the enclosing structure, sq. m;

- Tin - temperature inside the greenhouse, taken equal to +180C;

- Tnar - the lowest temperature of the coldest month, 0C.

Kt values for various designs:

- glass with metal sprockets: 6.4;

- double glazing on metal frames: 3.3;

- polyethylene film: 10;

- polyethylene film with condensation (in greenhouses with high relative humidity): 7.5;

- double film coating with an air gap: 5.8;

- the same with condensate: 4.6;

- concrete plinth 40 cm thick: 2.

There are computer programs and online calculators that perform calculations based on user-entered parameters.

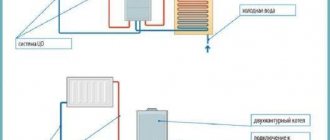

Connection to an existing heating system

Before you do anything, you need to make sure that the boiler can provide the required pressure.

In addition, it makes no sense to connect to an existing system if the greenhouse is located at a distance of more than 10 m from the house.

And since the pipes laid to it must be insulated, it will not cost much. It is also necessary to take into account that the greenhouse needs heating most of all at night. This is when adjustable heating systems can lower the temperature. Here it is important to consider the priority of connection to the greenhouse.

Recommendations

When choosing an IR heater, it is important to pay attention to its power. Devices should be selected taking into account the size of the room. Usually, to heat 10 m2, a device with a power of 1000 W is required, but it is better to purchase units with a reserve

If a wall-mounted heater is selected, it is important to find out the thickness of the foil layer of the emitter. Its indicators must be at least 120 microns. Otherwise, a significant part of the energy will be spent on heating the ceiling

Usually, to heat 10 m2, a device with a power of 1000 W is required, but it is better to purchase units with a reserve

If a wall-mounted heater is selected, it is important to find out the thickness of the foil layer of the emitter. Its indicators must be at least 120 microns

Otherwise, a significant part of the energy will be spent on heating the ceiling.

Manufacturers produce heater models with various functions. You need to think in advance whether they will be used during operation, otherwise there is a high risk of overpaying for something that will not be useful in the future.

Devices may have the following options:

- regulation of temperature parameters;

- automatic shutdown of the device when it is turned over (mobile variations);

- shutdown of equipment in case of possible overheating;

- turning the unit on or off at the right time.

Before purchasing a device, you should carefully inspect its case. It can be made of steel or aluminum. The first options are more durable, the second – stylish design. There should be no traces of mechanical stress or rust on any of the housings. Corrosion can reduce the service life of the device declared by the manufacturer.

Advantages and disadvantages

Every year, an increasing number of plant growers refuse to use outdated systems for heating cold greenhouses. Today, it is rare for anyone to heat their premises using “stove stoves”, fan heaters or boilers using coal or wood fuel. All these methods are becoming a thing of the past, since they have a significant drawback. These systems heat the air, which, according to the laws of physics, tends to rise, leaving the crops being grown cool.

Infrared heaters have been able to solve this and many problems of heating a room once and for all.

Compared to other systems, they have a number of advantages.

- Optimally distributes heat around the entire perimeter. Most types of thermal devices presented on the modern market cannot boast of this effect.

- Quick heating of the room. The spread of heat is felt already in the first minute after turning on the device. The devices operate in a directional manner, making it possible to evenly heat a specific area. Due to this feature, heat-loving plants and crops for which thermal energy is not so important can be grown in one greenhouse.

- Economical consumption of electrical energy. With proper installation of equipment, it is possible to achieve energy savings of up to 40%.

- Elimination of drafts and movement of warm air currents, which not all plants like.

- Silent operation of devices.

- Elimination of “burning” of oxygen in the air. Thanks to this feature, optimal humidity is maintained indoors. This is one of the most important conditions for good growth and fruiting of plants.

- Durability of devices and their uninterrupted operation. The fact is that IR equipment does not include moving mechanisms and rubbing parts that need frequent replacement.

- Small dimensions and weight of the units, making them easy to transport and install.

Unfortunately, no heating equipment is without drawbacks. Infrared heaters also have disadvantages. These include the high cost of organizing an infrared heating system and the low fire safety of some models (mainly mobile units). In addition, there are counterfeits of equipment from well-known brands on the market, which is why the buyer runs the risk of purchasing a low-quality product.

Installation

Installation of a cable electric soil heating system in greenhouses consists of the following steps:

Under the greenhouse it is necessary to remove a layer of earth approximately 40 cm deep; Sprinkle the bottom of the hole with a 5-centimeter layer of sand. Sand needs to be spilled and compacted to make the base stronger; We place a reinforced mesh with cells of approximately 10 cm on the sand and lay out the heating cable on it. The cable should be secured to the mesh with plastic ties so as not to damage the outer sheath. The wire is laid out like a snake with a laying step of approximately 12-15 cm; Between the turns of the heating cable we install a temperature sensor, which it is advisable to place in a corrugated tube; Sprinkle the mesh with the cable with a 5-7 cm layer of sand and again spill and compact it; We put a fine-mesh reinforced mesh on top to protect the cable from mechanical damage with a shovel or other objects; We fill the system with a fertile layer of soil on top; Install the thermostat and connect the cable to it

Attention! It is advisable to install an RCD in front of the thermostat to ensure safety precautions against electric shock.

After completing all installation stages, you can safely plant seedlings and connect the plant root heating system in your new greenhouse.

Owners' opinion

If you look at the reviews of owners of warm beds, you can see a truly rosy picture. A larger number of authors argue that growing seedlings in warm beds, and even in greenhouses, only has a better effect on the harvest. Those who use organic warm beds claim that in any climatic conditions the yield increases several times. They note the ease of formation of such beds, the possibility of early planting of seedlings and, accordingly, earlier harvesting. Many also point to the cost-effectiveness and durability of this method. On any site there will always be the ingredients to create this type of beds. And even a woman can build it with her own hands.

Owners of electric heated beds point to the ease of installation if you follow the instructions exactly, and the durability of such a structure. The only downside is that you can’t find such a system in stores everywhere. Some users order installation kits online. Increased productivity, early fruit ripening and full automation of this method are noted if you install a thermostat.

Many gardeners prefer the water method of heating beds. Among the advantages, in addition to high yield and early ripening, is the possibility of self-assembly of this type of heating. Any man is able to install pipes of the required size and diameter, connect a water pump and install a furnace to heat water. In addition, this method, as the authors note, is more economical than electrically heated beds.

Warm bed in a greenhouse made of polycarbonate, biological method

The biological method of heating beds is made using natural biofuel placed in the subsoil layer. Plant residues, sawdust and manure are used as filler, which is spilled with water for the rotting process. Such beds are the most economical design.

Warm beds running on natural fuel are usually divided according to the type of construction:

- In-depth, when fertile soil is removed, a trench is dug, compost is laid and filled with soil on top so that it is level with the total mass of the earth;

- Raised beds, the top layer of soil is removed from the surface and placed in special wooden boxes, which serve as protection against shedding and washing away of the soil during operation;

- A hilly bed, laid without a box on top of the main platform;

- A combined option, when the lower layers with organic matter are laid at ground level, and the fertile soil layer is fixed with a box.

To make a structure for a combined warm ridge, you need to mark out places for future plantings. Then carefully remove the layer of turf, putting the fertile soil aside. Next, you need to dig a trench up to 60 cm deep. To protect against freezing, foam plastic or closed plastic containers are placed at the bottom of the trench. Next begins the first layer of organic matter, consisting of large branches, wooden chocks, and large plant objects.

This layer will play a drainage role. Then a paper backing consisting of waste paper is laid.

After this comes a layer of finer organic matter, food waste, tree leaves, and small grass stems. Next, add ready-made compost, or semi-rotted manure, to begin the rotting process. We install a pre-prepared box into which we will pour fertile soil. Each laid layer must be thoroughly watered. We cover the last layer with fertile soil. Soil enriched with organic matter is perfect for planting tomatoes, pumpkins and cucumbers. The rotting process can warm the earth for 2 months.

Solar batteries

The principle of operation of a solar battery

Collecting and accumulating the heat given off by the sun's rays will help to get an early harvest in the spring. Heating a greenhouse using solar batteries can also be used as an additional option. For the winter period, the heat received only from them will not be enough.

To accumulate solar energy, the greenhouse must be installed in the most open place and located from east to west. It has been proven that arched polycarbonate structures are capable of “collecting” the maximum number of rays. Plus, the air in the cells of this material will serve as a natural heat insulator.

Solar batteries are divided into:

- water : the heat storage in this case is water containers (barrels or pools); Moreover, several small containers have a higher efficiency than one large one, because water always warms up better closer to the surface; they are distributed evenly throughout the room

- stone : this material is capable of retaining heat for a long time, so it makes sense to line the walls of the greenhouse with stone or cover it with a sufficiently large layer around the perimeter of the structure

- air : are among the most efficient battery devices (see photo); for efficient heating, heat exchangers are positioned perpendicular to the direction of the sun's rays; heated air enters the greenhouse through pipes; cold air is taken in through the second duct

When installing an air heating system in a polycarbonate greenhouse, it is advisable to use fans to ensure rapid air exchange. The inlet pipe of the air duct is located as close to the ground as possible. The pipe through which heated air enters the greenhouse is placed in the upper part of the room.