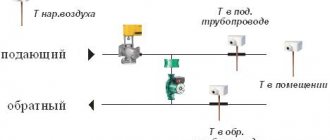

Temperature sensors used in boilers can be internal and additionally external (remote). Internal ones regulate the operation of the boiler depending on the temperature of the coolant, which implies not the most accurate measurement method and the presence of inertia. External temperature sensors transmit information about the air temperature indoors or outdoors, which allows you to accurately regulate the power of the boiler unit and stably maintain the set temperature level even with constant sudden changes in weather conditions.

The cost of external sensors ranges from 1,300-2,500 rubles; you can connect and configure their operation yourself.

How does the sensor interact with the boiler?

Depending on the boiler model, there are 2 ways of interaction: directly and through the room thermostat.

You can connect a temperature sensor directly only to boiler models with this capability (appropriate automation and terminal block/connector on the boiler); this capability is reported in the technical specifications of the model. For example, models such as the Baxi ECO Four line, the Baxi LUNA-3 line, Buderus Logamax U072, Viessmann Vitopend 100-W and most other modern models of gas boilers have the ability to connect temperature sensors.

Connection of external control is directly supported by both electric and solid fuel boilers.

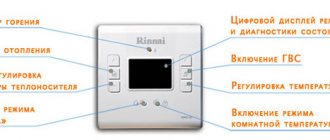

If the boiler has a simple, low-functional automation system, it is better to connect an external sensor via an electronic room thermostat with programming capabilities. Programming the operation of the boiler allows you to set a pattern for the operation of the heating system, for example, reducing the temperature to 15 degrees during working hours when the owners are not at home, which will allow you to significantly save on heating, regardless of the type of fuel used. The cost of a good thermostat is about 1,500-3,000 rubles, but if used correctly, it will pay for itself within a few months of operation.

An example of a room programmable thermostat (model – Teplocom TS-Prog-2AA8A).

A room thermostat already has a built-in temperature sensor that measures the temperature in the room in which it is installed. To implement weather-dependent control, you need to purchase a universal outdoor temperature sensor. Thermostats that already include an outdoor temperature sensor are sold extremely rarely. However, the package often includes a temperature sensor for heated floors.

How to choose a room thermostat and save up to 30% per month on heating

In general, to organize an optimal control scheme for the heating system, three temperature sensors are sufficient: external indoor, outdoor and for heated floors.

Mounting the temperature sensor on the wall

Wall mounting.

In order to gain access to the mounting holes and terminal block, you need to unscrew the protective plastic cover. Once the location where the temperature sensor will be placed is determined, the centers of the mounting holes are marked. Next, unscrew the nut designed to seal the cable. After this, two wires are connected to the sensor. At the final stage, the sealing nut is tightened and the housing cover is closed.

Design and principle of operation

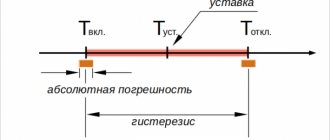

Thermal sensors are in most cases heat-sensitive liquids or metals placed in a small sealed housing: when heated, heat-sensitive liquids expand, and the metals form a resistance or thermoelectric effect (when the contacts of connected conductors are at different temperatures).

Thus, with the help of the mechanical action of temperature-sensitive elements, information is transmitted to the thermostat or directly to the boiler automation, which regulate the burner power and turn the boiler on or off. Information from external temperature sensors is always a priority, which means that the thermostat sets the boiler operating mode (up to complete shutdown or unscheduled ignition) regardless of the internal automation program.

Outdoor models are additionally placed in a plastic protective case that protects them from mechanical stress and moisture.

Features of operation

In order to obtain a metrological characteristic with a given error and develop the service life of the device, it is necessary:

- periodically (at least 2 times a year) check the technical condition of temperature sensors;

- within the time limits specified by the manufacturer in the accompanying documentation for the product item, carry out installation-free or laboratory verification of the thermoelement;

- pay attention to the correct connection of the terminals of the device with the power element (unit) and the connected secondary circuits on the boiler;

- when determining the connection terminals on the electronic board, check the correspondence of the contact markings with a multimeter in dialing mode;

- do not open, protect the device from strong impacts, extreme temperatures and high pressure.

Existing types

Classification by temperature measurement method

- thermocouples are the very first and highly accurate sensors, but the accuracy of their readings is quite difficult to take and interpret into an automation program. Their action is based on the interaction of two different metals soldered together. When they are heated, a weak electric current occurs;

- thermistors are simpler to interpret and more accurate sensors, the action of which is based on an increase in the resistance of heat-sensitive materials as the ambient temperature increases;

- pressure sensors - their action is based on the expansion of a heat-sensitive liquid or gas when heated, which creates a certain pressure in a closed volume;

- digital are modern sensors (digital thermometers) that work on the principle of calculation and conversion. They are distinguished by high accuracy (up to 0.5°C) and a wide range of measured temperatures (from -55°C). Well-known examples are DS18B20, LM75A.

Wall-mounted outdoor temperature sensor in a protective housing.

Classification by placement method

- overhead – applied to pipes, radiators or water heated floor systems;

- submersible - immersed in a coolant, for example, again, in a system of water heated floors;

- room - weakly protected from external influences, having a small range of measured temperatures and therefore intended for measuring air exclusively indoors;

- outdoor - resistant to mild mechanical stress and moisture, often additionally protected by a housing, have a higher range of measured temperatures.

Please note that there are no small wireless sensors, since they require at least a controller to power them, read them and transmit the signal. Therefore, a thermostat that includes a room sensor can be wireless, but not the small temperature sensor itself for the heating boiler.

Programmable thermostats

Programmable thermostat is a digital regulator of the temperature of the coolant in the heating system and the air in the heated room. It consists of a thermostatic head in the form of a bellows with a rod filled with liquid/gas, and an electronic part with a programmer. Depending on the entered operating algorithm, the rod reduces or completely shuts off the coolant supply. Using the keys and display of the programmable “thermo”, temperature parameters, day and time of start, and duration of the mode are set. The device will perform all subsequent actions independently.

How to choose a remote temperature sensor

The choice depends on how the sensor will interact with the boiler: directly or through a thermostat.

Connected directly to the boiler

The choice here is small: as a rule, these are 1-3 models developed by the same manufacturer as the boiler. Their compatibility with specific models or lines of boiler models is indicated in the technical specifications and instructions. The cable for connecting the temperature sensor to the boiler (usually two-core with a cross-section of 0.5 mm2) must be purchased separately. The exact requirements for cross-section and resistance are indicated in the sensor instructions.

Connectable to thermostat

External temperature sensor for the Gira 130200 thermostat.

In rare cases, an outdoor sensor is included with a room thermostat, but most often a sensor for measuring the temperature of heated floors is included in the kit. To take into account the outdoor temperature, universal outdoor temperature sensors are connected to the thermostat: from Gira, Tim, Shuft (ATF2-NTC10K) or Teplolux (TST02). It is important to pay attention to:

- range of measured temperatures - for example, for Teplolux TST02 it is from +5 to +45 ° C, which is not applicable in the cold season;

- degree of moisture protection;

- measurement accuracy/error – an error of +-1°C is considered acceptable, a good result is +-0.5°C;

- cable length - as a rule, a 2-6 m long cable is already connected to the temperature sensor.

Connecting an outdoor temperature sensor

Electrical connection.

Important! Before connecting the sensor, you must turn off the power to the boiler.

For connection, a solid cable of 2 * 0.5 mm, no more than 30 m long, without any connections, is used. It must be laid through a hole in the wall to the gas boiler, where it is connected without observing polarity to its terminal block. Also during installation, a sealed sleeve is used to insulate the cable.

How to connect a temperature sensor to a boiler

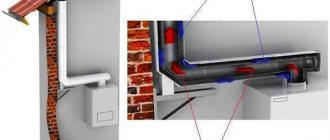

An outdoor temperature sensor for a heating boiler is installed on the outside of the wall of a heated building in compliance with the following requirements:

- the wall should be exclusively north or northeast to avoid direct sunlight. If a hit is still expected, it is necessary to protect the sensor with a visor;

- If possible, it is necessary to avoid installing the sensor in places of high humidity and a high degree of mold formation;

- the wall must have a thickness and degree of thermal insulation sufficient to prevent the sensor from heating up with the heat of the heated room;

- It is also not recommended to install the measuring device near an air conditioner, chimney, exhaust or supply ducts, or any other structures that can affect the measurement results.

The sensor itself is attached to the wall with anchor bolts, for example 5x25, connected to the corresponding connector/terminal of the boiler or thermostat using a two-core cable (cross-section and resistance parameters are indicated in the temperature sensor instructions), the connections are hermetically sealed with a coupling.

Correct installation and connections do not cause any special problems, since detailed algorithms are always described in the instructions.

An example of an installation algorithm from the instructions for the Baxi temperature sensor.

Temperature sensors do not require adjustment or calibration, and their performance and accuracy are tested in practice (at room temperature).

Where to install

DT is set extremely close to the controlled parameter. So in double-circuit boilers they are placed on the return line before entering the boiler, at the outlet from it in the supply pipeline, at the outlet from the unit in the DHW circuit.

DT for monitoring the outgoing temperature of flue gases is installed at the outlet of the boiler in front of the mouth of the chimney. Wireless diesel engines for the boiler unit are placed directly on the controller or on the gas shut-off valve. Wired - connected by the option designated by the equipment manufacturer.

Prices

| Manufacturer (intended for manufacturer's boilers) | price, rub. |

| Specialized | |

| BAXI | 1 400 |

| Protherm S010075 for boilers Panther, Cheetah, Skat | 2 550 |

| Ariston | 2 100 |

| Ferroli | 1 100 |

| Universal | |

| Shuft ATF2-NTC10K | 2 100-2 250 |

| Gira 130200 | 2 280-2 900 |