Modern heating systems require timely maintenance as one of the conditions for long-term and trouble-free operation. And if in the components and systems of a heating boiler this is done using special equipment and equipment, then for the coolant and radiators such maintenance comes down to constantly maintaining cleanliness standards. This is where mud collectors for heating systems are needed - indispensable devices for preventing the sedimentation of sludge and dirt in pipes and radiators.

Selection and installation of mud filters in water supply and heating systems

Mechanical cleaning filters are the most important part of any home water supply system. They retain sludge - coarse particles of dirt and sand, purifying the water and ensuring the safety of equipment.

- 1 of 1

On the picture:

Operating principle.

The simplest models of dirt filters consist of a tube into which a metal mesh is inserted, and at the bottom there is a small branch - a reservoir for dirt that has not passed the barrier. In corner filters this branch is located at an angle to the pipe, and in linear filters it is strictly perpendicular. The filter is installed on the water supply or heating system and traps debris larger than 100 microns.

Dirt filter for heating - selection, installation and maintenance

The dirt trap in a home heating system is as small as it is important. An inexperienced viewer, contemplating the intricacies of pipes in a home boiler room, may think that such a small piptik - a coarse filter for the heating system - is just an unnecessary worry, you can do without it, because clean water was poured in... from the tap... Not suspecting that the mud trap is actually In fact, this is the boss of the heating system in his house. Next, let's look at where the dirt comes from, how to deal with it, how to install a filter in the system and how to clean it - why is the system clogged?

Where does dirt come from in heating, why is there no fluid movement?

Where does scale come from in a kettle, since clean water was poured in? But there are 50 kettles of water in the heating system - you can imagine how much sediment accumulates from it. And if the water changes, due to a leak, during the repair process, an additive will come accordingly. Also, a huge number of pieces of metal, enamel, thread, and something else “without a name” will be torn off from the entire internal surface of the system. But this is all child's play, compared to what happens if a corroded part is discovered, the whole mass gradually turning into sediment. And steel pipes can become sources of just mountains of rust.

Experts recommend: if the heating in the house has become “worse” to work, if the circulation of liquid is disrupted, the pump “does not press”, first of all check and clean the filter - the dirt trap.

What filters are used in home heating systems

In most cases, brass strainers are installed in the home heating system. They are simple, but they get the job done. All particles carried by the flow with a size of more than 0.5 mm are retained by a metal mesh and settle in the settling tank. The filter is extremely cheap, easy to install and maintain.

The most common thread diameter - 3/4 or 1 inch - is selected in accordance with the diameter of the main pipeline at the installation site.

Below are the characteristics in the photo of mesh brass dirt filters depending on the diameter.

Design options for rough cleaning of the heating system

Mud collectors of other designs are less common. The increased price of some does not provide benefits in most cases.

- Made from polypropylene - welded, and that's it...

- With additional magnetic catcher in the sump.

- With flush tap.

- On flanges, with pipe diameters greater than 2 inches.

- The body is made of cast iron, it can also be transparent...

How to maintain a dirt filter

If the system stops working normally, you need to inspect the dirt filter - tighten the sump cover nut. This is done carefully with the appropriate key. The seal under the nut is a copper washer, so a significant moment of force is needed to break the nut out of place, after which the rotation is already easy. A tray is placed to collect a small amount of coolant, which is inevitably lost when the sump lid is opened. Then the metal mesh is removed and cleaned.

But first you need to close the shut-off valves, which should be installed near the sludge filter on both sides. Otherwise, all the coolant from the system can be released through it, and the first portion will also flow under pressure...

The main rule for installing a mud pan

If you do not install the coarse filter correctly in the heating system, it will not work as expected, and blockages will occur without the ability to properly clean it.

The rule is simple - the sump must be facing downwards. It is under the influence of gravity that all trapped particles settle in the settling tank.

It is allowed, if the filter is positioned horizontally, to be turned with a sump closer to the horizontal position for ease of maintenance, for example, if equipment is in the way from below. But in any case, the sump should be turned slightly downward.

How to install a cleaning filter in a heating system, diagram

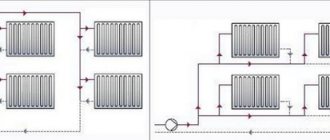

The filter is installed on the return line in front of the main equipment that it protects, as a rule, in front of the pump in a given branch or in the entire system.

With an automated boiler, the filter is installed on the return line before entering the boiler - between the shut-off valve and the boiler shut-off valve.

If the pump is remote, then a typical example of installing a filter in front of the pump is shown in the diagram; taps are also required to be able to service the filter, the service life of which is 1 year.

The expert advised: don’t get confused. Carelessness in installing the filter will cost the system a stop and possible equipment failure. An arrow on the body of the mud pan indicates the direction of fluid flow. Only install the filter correctly in relation to the direction of flow.

Specifications

| Mud collectors for heating systems | |||||||||

| Conditional diameter, DN | Weight | Conditional pressure | D.H. | DH1 | DH2 | H | H1 | h | L |

| 32 mm | 201.9 kg | 1.6 MPa | 159 mm | 32 mm | 32 mm | 1120 mm | 1168 mm | 700 mm | 850 mm |

| 40 mm | 16.3 kg | 1.6 MPa | 159 mm | 40 mm | 45 mm | 360 mm | 406 mm | 260 mm | 345 mm |

| 50 mm | 19.4 kg | 1.6 MPa | 159 mm | 57 mm | 57 mm | 410 mm | 456 mm | 290 mm | 365 mm |

| 65 mm | 29.4 kg | 1.6 MPa | 219 mm | 76 mm | 89 mm | 490 mm | 534 mm | 340 mm | 425 mm |

| 80 mm | 33.5 kg | 1.6 MPa | 219 mm | 89 mm | 108 mm | 525 mm | 569 mm | 375 mm | 425 mm |

| 100 mm | 62.2 kg | 1.6 MPa | 325 mm | 108 mm | 133 mm | 620 mm | 662 mm | 450 mm | 525 mm |

| 125 mm | 70.4 kg | 1.6 MPa | 325 mm | 133 mm | 159 mm | 690 mm | 732 mm | 470 mm | 525 mm |

| 150 mm | 118 kg | 1.6 MPa | 426 mm | 159 mm | 194 mm | 875 mm | 928 mm | 550 mm | 650 mm |

| 200 mm | 266.7 kg | 1.6 MPa | 530 mm | 219 mm | 273 mm | 1105 mm | 1163 mm | 700 mm | 850 mm |

| 250 mm | 266.7 kg | 1.6 MPa | 530 mm | 219 mm | 273 mm | 1105 mm | 1163 mm | 700 mm | 850 mm |

How does a heating system return filter remove mechanical impurities?

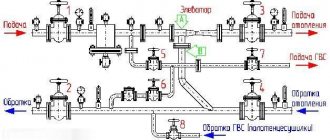

Industrial boiler houses and large real estate properties are equipped with gravity-type mud collectors. To connect to the pipeline, a wide flange connection with a sealing gasket is used. During installation, the housing is installed vertically. The septum is fixed along the central axis, leaving ducts in the lower and upper parts. Such a simple addition changes the direction of liquid flow and cuts off mechanical impurities. They accumulate at the bottom. Contaminants are regularly removed during preventative maintenance.

In household systems, a filter is used on heating systems with a removable mesh. The diameter of the main part is approximately equal to the dimensions of standard pipes. For connection, couplings with external (internal) threads are used. An oblique outlet with a built-in separator is directed downward in the direction of the water flow. The correct position is indicated by an arrow on the body.

“Self-cleaning” modifications are more convenient for users. Such filters for heating the return of a wall-mounted boiler are equipped with a valve in the bottom part. Through it, contaminants are washed into the drainage. Completely autonomous products are complemented by a solenoid valve and a control unit. The timer is set to the optimal time interval corresponding to the actual concentration of impurities and operating mode.

To retain steel particles, filters with permanent ring magnets are installed. To increase efficiency, in some modern models the operating elements are placed in the central part. This solution increases the resistance to water flow, so it is necessary to control the resulting outlet pressure level. It should be remembered that the automation of a gas boiler can turn off the equipment if the pressure is insufficient.

Useful tips

To increase the service life of filters, you should follow these tips:

- evidence that the filter is clogged is a decrease in water pressure in all faucets;

- the more intense the water flow, the more often the structure should be cleaned; it is recommended to do this every 3 months;

- before unscrewing the outlet of the mud trap, you should substitute a basin or bucket, and also open the tap on one of the mixers;

- When cleaning cartridge filters, it is recommended not to wait until the walls of the flask are covered with a brown coating;

- If a stole gasket is used, the plug should be made hot before unscrewing, using a gas torch or a regular lighter.

Having figured out how to remove debris from the filter, it is worth remembering the regularity with which it is important to do this. In the process of clearing the blockage, it is important to take into account the design features of the installed model, as well as maintain the tightness of the threaded connections during reassembly

Installation

Installation of the strainer must be carried out in accordance with the manufacturer's instructions, which should be read before installation. However, there are general installation recommendations that are suitable for most models:

Correct installation of the filter in vertical and horizontal positions.

- The filter must be installed in the correct direction (indicated by the arrow on the device body);

- For horizontal installation, the filter is mounted with the plug with the mesh down;

- If the device is mounted on a vertical pipeline, the coolant flow should move from top to bottom (the plug “looks” down). If the flow moves from bottom to top, a standard oblique filter will not perform its function. In this case, all solid contaminants will settle at the junction (corner) of the horizontal and vertical pipelines;

- After installing the filter, its housing should not experience pressure from the pipes connected to it;

- To clean or replace the mesh, the pipeline next to the filter must be equipped with shut-off valves that allow shutting off the flow of coolant to the area.

How often does it need to be cleaned?

Due to water purification and retention of various debris, which does not disappear over time, it begins to accumulate. For this reason, over time, the water filter installed on the pipe becomes clogged. This leads to a decrease in water pressure, and over time, its complete absence. When such situations occur, it is necessary to clean the internal structural elements, for which the device should be removed, disassembled and washed.

Worth knowing! When the filter is sealed along with the water meter, you need to call a technician from the management company who will remove the seals. Once cleaning is complete, it is recommended to install a non-return valve, allowing cleaning to be carried out without the need to call a specialist further.

Magnetic models of heating filters

Initially, the development of filters for a heating system with a magnet was designed only for water supply. However, their unique performance qualities have contributed to their use in heating.

The design consists of two permanent magnets with different poles located opposite each other. The metal elements in the water are small in size, therefore, once they enter the field of action of the magnetic heating filter, they remain on its surface. But how to clean it later? In fact, even after 10 years of operation, the level of contamination of the walls will be extremely low. This will not impact capacity on this portion of the system.

In addition to magnets, the composition may include heating dirt filters. But the main selection criterion is the design. It can be of two types:

- Removable . It consists of two plates installed on the heating pipe. Characterized by simple installation and the ability to quickly replace;

- Fixed . This is a pipe made of ferrimagnetic alloys. Unlike the model described above, monolithic magnetic filters for heating systems have a longer service life and are also characterized by high magnetic field performance.

The cost depends on the model, and in particular, its type and size of the magnetic part. The simplest filter with magnets for heating costs about 600 rubles. But a design with optimal operating parameters will cost 4-5 thousand rubles.

Is it worth installing all the described types or is it enough to get by with a coarse filter in the heating? Much is determined by the preliminary preparation of the coolant and the material used to make the pipes. For an autonomous system with plastic lines filled with distilled water, a filter with a sump is sufficient. When connecting to central heating, it is best to install all three types, since water in most cases contains a large amount of impurities and pollutants.

Additional nuances of installing and selecting a coarse filter can be found in the presented video material.

Subscriber mud collector: scope of application

In systems that require periodic draining of the coolant and refilling the system, foreign impurities and dirt will always be present. To ensure proper operation of the system, the need to use mud filters for water in centralized heating systems does not raise any questions; the use of mud filters there is mandatory. However, when independently designing small autonomous heating systems (for example, in private houses), the use of mud filters is often neglected, mistakenly believing that in a small closed circuit there cannot be foreign impurities in the coolant, and installing a mud filter is overkill. In fairness, we should give this opinion its due - the system will indeed function without a dirt-collecting device and you can do without it. But first, we recommend weighing all the consequences of the absence of a mud trap in the local heating system.

Why do you need to install a mud trap?

Regardless of the type of coolant used and the method of its initial purification, its basis will always be water, which will inevitably begin to interact with the metal elements of the system (and such elements are present in absolutely any heating system). This will lead to the formation of rust particles, which, circulating in the system, will accumulate in various areas of the system, such as welding deposits, uneven pipes, narrowings and sharp turns of the pipeline, etc. In turn, the accumulation of these particles leads to difficulty in the movement of the coolant. Due to the decrease in the circulation rate of the coolant, it is necessary to increase its temperature in order for the temperature regime in the room to reach the desired parameters. Accordingly, this leads to an increase in the load on the boiler and other critical elements of the system. Thus, due to contamination and other related factors, the operating life of the system will be significantly reduced, the heating efficiency as a whole will also be reduced, which means that energy consumption and costs associated with the inevitable additional maintenance and repair of equipment will increase. Proper installation of a mud trap in the heating system will eliminate most of these problems or, at a minimum, delay their occurrence.

Why is it worth installing a filter on your heating system?

Photo of a working system

Many users may quite logically be interested in the question of whether it is necessary to install filters for heating systems? It is worth noting that even without organizing cleaning, the equipment can function normally, another question is how long?

First of all, such an installation is necessary to ensure reliable and uninterrupted operation of heating equipment, eliminating emergency situations and failures.

The price of heating filters is not so high; its timely purchase and installation will cost much less than later repair or replacement of heating elements. Not to mention the fact that an accident in the heating system will lead to such unpleasant consequences as cold and discomfort in the house (after all, it is during the cold season that the thermal regime must be maintained).

The advantages of the installation include:

- reliable protection of the system from blockages;

- it is not necessary to change the water (coolant) so often;

- the service life of heating equipment is extended;

- cost savings;

- confidence in the reliability and uninterrupted operation of the system.

Purpose of the expansion tank

The compensation tank of the heating system is designed to maintain the required pressure in the heating network. During thermal expansion of the liquid, excess coolant enters the container. If it were not there, this would lead to a significant excess of pressure in the pipeline and an emergency.

When the expanded coolant enters the tank, the pressure in the system normalizes. After the water has cooled, the liquid from the tank again enters the heating circuit. This ensures the stability of the indicator in the network regardless of the coolant temperature.

Expansion tank device

There are expansion tanks of open and closed type. The first variety is the simplest - it is an ordinary barrel with a lid. There is a pipe cut into it from below for connecting to the heating system, and on top there is a pipe for emergency drainage of the coolant into the sewer. An open expansion tank is installed at the highest point of the network.

Coarse filter

The filter is installed when connecting the heating system to the central water supply. It is a flask with a filter element inside. The connection can be flanged or coupling, depending on the diameter of the water supply pipes. Necessary for filtering large contaminants. Effectively retains dirt, sand, large abrasive impurities. It will reliably protect the heating system from large elements, but will let small ones through. It is also not capable of chemical cleaning or water softening. He cannot purify the water to the desired state on his own. Doesn't take up much space. The coarse filter is the first line of defense for your home's water supply.

Design features and operating principle

The mud filter for the heating system performs the function of cleaning the coolant from contaminants in the hot water supply and heating systems. Externally, it looks like a pipeline expansion unit with water filtration using a special mesh and changing its movement. Under the mesh, contaminants precipitate and rust particles begin to accumulate again.

The operation scheme of any filter for water purification is quite simple: the coolant first enters the pipe, after which it moves into the inner part of the housing, and dirt particles fall to the bottom. After this, water from the internal cavity of the mud trap enters the filter in the outlet pipe. Then the clean coolant is directed into the pipelines.

The cleaning process is carried out as follows: the glass is removed from the outlet pipe. The lower base of the mud pan must be regularly cleaned from dirt that accumulates there. The dirt trap for water purification is connected to pipelines using threads or flanges.

Varieties

To reduce the risk of boiler breakdown, increase the accuracy of measuring instruments and ensure long service life of the equipment , it is important to understand the main types of devices and choose the right one.

Polyphosphate

Polyphosphate units are considered a budget option for pre-purification and softening of water entering the boiler.

The operating principle of such a device is to pass liquid through a flask filled with special crystals. They ensure the formation of a protective film on the inner walls of the boiler and also slow down the formation of scale.

Photo 1. Polyphosphate filter for a gas boiler, filled with special crystals. They slow down scale formation.

The devices have a simple design:

- drain;

- flask;

- filler;

- lid.

The liquid enters the flask with filler through the lid, where it is passed through polyphosphate crystals. Next, it goes through the drain into the gas boiler tank.

Any device of this type requires periodic replacement of the filler - sodium salt crystals. As a matter of fact, this is the only difficulty in servicing them. The average lifespan of such a treatment plant is up to one and a half years.

Electromagnetic or magnetic for softening hard water

Electromagnetic devices are expensive, but the price is completely justified: the installation lasts a long time and allows you to obtain perfectly clean water at the output.

The principle of operation is that when the liquid passes through the flask, the salts in it disintegrate. Thus, scale will not settle on the walls of the boiler. Instead, the filter itself will be clogged with tiny salt particles, which is periodically washed.

Photo 2. Three magnetic filters for a heating system boiler; the scale in them breaks down into tiny particles.

Another characteristic is that under the influence of electromagnetic radiation, not only does the scale disintegrate into small particles, but also a thin film is formed that covers the boiler heat exchanger. Thanks to this, it remains protected and does not corrode for a long time.