Any heating system after installation or complex repairs needs to be tested for functionality; for professional purposes, a special pump is used for pressure testing the heating system, designed for testing heating systems under pressure. Pipes, various water intake tanks and mechanisms can be tested for leaks; water, antifreeze or hydraulic oil are used as the working fluid in these devices.

Pumps for pressure testing the heating system are used after installing all components and filling the pipes with liquid; the required pressure in the line (2 - 3 times more than the working pressure) is set using special limit valves and controlled by a built-in pressure gauge.

Rice. 1 Manual and electrical crimping equipment - appearance

Feeding the boiler heating system from the water supply: what is it?

Operation of the piping leads to a decrease in the amount of coolant in it. The free space fills with air, creating traffic jams. As a result, the equipment overheats , which causes breakdowns.

Water is lost in the following situations:

- In an open circuit, the liquid evaporates in the expansion tank.

- The air vent also removes water vapor.

- When the overheating protection mechanism is triggered, the coolant is discharged.

- There are invisible cracks in the harness.

- Pipes become covered with scale or rust.

To avoid problems, use heating recharge from the water supply. In most cases, it works autonomously, measuring the current volume of water and replenishing the deficiency. This restores the system's standard pressure. For this, cold water supply or a special liquid stored in a storage tank is used.

How to do it: feed or return diagram

The process is performed in one of two ways:

- Manual is done in small systems, since pressure changes in them are smaller. The latter are determined with a pressure gauge. Having detected a deviation from the norm, open the make-up valve and wait for the value to be restored.

- The automatic installation independently processes the data and takes measures to resolve problems.

Photo 1. Scheme of automatic installation of a heating system make-up station, data is processed independently.

The difference is that there is no need to monitor the readings , but due to the constant operation of the device, energy consumption increases.

Important! Recharge is not required constantly, but the equipment does not need to be idle. Using the device, you can fill an empty pipe with coolant , carry out pressure testing or flush the pipes.

Most often, residential private houses are heated with a water heating system, in which the heated liquid (not only water can be used, but also special antifreeze - non-freezing liquids) moves through pipes and transfers heat to heating radiators.

Heating systems can be divided into two types:

- with natural circulation of fluid throughout the system,

- with forced movement of coolant.

In the case of forced circulation, the coolant moves thanks to a circulation pump.

Classification of pressure testing pumps

Of the huge variety of equipment, only a few should be highlighted:

Plate type.

Rotary-translational type, the main organ of which is special plates that rotate together with the rotor.

Membrane type, designed for crimping large volumes of urban communications networks. In them, liquid is pumped due to a membrane, which in turn is driven by compressed air. The main advantage of this model is the absence of constantly touching elements.

Piston type. These machines operate by moving a piston, similar to that found in a car's internal combustion engine. The operating principle is the same. Taking in air through one valve, it compresses it and, under pressure, expels it through another valve.

Operating principle of the coolant

In practice, all owners of autonomous heating systems, without exception, sooner or later are forced to solve the problem of reducing the volume of coolant in the heating system and use make-up pumps.

The only difference is that in open systems the coolant decreases systematically and quite quickly, while in closed systems it decreases more slowly.

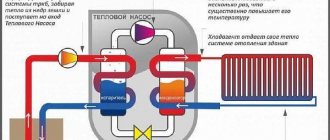

When circulating through the heating system, the coolant is heated by the heat generator, passes through the radiators and gives off part of its heat to heat the rooms. Then the coolant, which has already cooled, returns to the boiler and heats up again to go to the heating radiators. This cycle repeats over and over again as long as the heating system is running.

If the volume of liquid decreases significantly in volume, then, in addition to reducing efficiency, the heating equipment may fail, and the system will become airy. In order to avoid such a nuisance, they use make-up pumps for the boiler room, integrating them into special automatic make-up units.

Pump classification

Based on operational characteristics, all models of crimping machines are divided into the following categories.

Pneumatic. They are in the electric class, but their cost is significant, although the pressure created is no greater than that of electric ones. An electric pressure testing pump does not require any effort on the part of the owner, but its weight and dimensions will complicate transportation. The discharge pressure is at the medium level.

Mechanical pressure testing pump up to 1300 atm. is a complex mechanism. Its capabilities are enormous, but given the cost, it can only be used on a cosmic scale to test the networks of megacities.

If you are interested in all of the above, then it is not too late to consider the detailed characteristics. Perhaps they will change your choice.

Reasons for reducing coolant volume

In the case of an open heating system, the coolant constantly evaporates from the expansion tank, since the liquid is hot and the tank is open. In addition, evaporation also occurs in the air vent, in the safety valve, when pressure increases, and at equipment connections (microleaks form). The internal surfaces of metal pipes are subject to constant corrosion, which reduces their thickness, and, as a result, there is more space unfilled with liquid in the system.

When air is removed from the system through Mayevsky's taps, coolant also leaks. In addition, during regular maintenance work, part of the liquid is drained when dirt filters are cleaned, pipes are repaired, or faulty equipment is replaced.

Mechanical

A manual pressure tester consists of a system of hoses, indicators, a handle for creating pressure and a housing in which it all is located. Such equipment can also be used as a drive for clamps and hydraulic tools. Their importance is extremely important in those places where there are problems with electricity and water supply.

The advantages of such a device are many times greater than the disadvantages. Compact dimensions, the ability to use in limited space, durability and reliability completely cover the fact that they can only work with small volumes. Despite the fact that such a pump requires the use of human muscles, it is the best option today.

Operating principle of the automatic recharge unit

Once a drop in system pressure is detected, the adjustable pressure sensor is activated and the pump contacts are closed. The coolant is topped up either from the water supply or from a storage tank. After reaching the required coolant pressure in the system, the pump turns off.

Such a device has another undeniable advantage - using a make-up pump you can pump coolant into the system without disassembling the heating system. This may be necessary to repair or replace the coolant.

Electrically driven pumps

A pump of this type, as a rule, is in great demand only among real professionals, and then only to commission a heating circuit for a new residential premises or for preventive maintenance.

The main period for carrying out work using such a device is the time of annual switching on of the heating network, that is, the period from the end of November to May.

Such a machine is capable of pumping pressure up to 60 atm. However, there are also monsters that produce 500 atmospheres, but, as a rule, they are installed in high-pressure facilities. When purchasing an electric pressure test pump, you will receive a 20-liter tank, a new generation pressure gauge, and a suction and discharge hose, the length of each of which varies from 3 to 11 meters.

The operating speed starts from 3 l/min and higher. The main dominant factors of these particular pumps are enormous productivity, elimination of physical work for operators and complete automation. In addition, electric pumps are capable of maintaining the same pressure for a certain period without raising or lowering it.

How to choose

The heating system's make-up pump has a different task than the circulation pump, which ensures the movement of the coolant along the heating circuit. The charge pump should provide more pressure with a small flow. Vane, vortex and close-coupled pumps are suitable.

Make-up equipment usually has a low efficiency (only about 45%). But in this case this is not significant. The heating booster pump only switches on periodically and does not operate for long.

When purchasing a recharge pump, you should pay attention to:

- For the pressure that is needed. It must necessarily be higher than the pressure in the “return” of the heating system, and, in addition, it will need to overcome the resistance of the pipeline and pressure sensor.

- For expenses. For closed heating systems, a leak of approximately 1/2 percent of the total volume of coolant in the boiler circuit and heating system is considered normal.

The volume of coolant is determined either empirically or at the rate of about 15 liters/kW of boiler power.

This is a classic mechanical pump for pressure testing. They can fill the outline

In country houses and where the heating circuit is turned on only from time to time, ordinary water cannot be filled. It freezes, which leads to rupture of pipes and batteries, and the boiler may break down. Therefore, in such cases, special antifreeze compounds are used, which are popularly called by a beautiful foreign word - antifreeze. We talked about whether it is possible to pour antifreeze into the heating system in one of our articles. In short, you can, you can read more here.

Today we will talk about how to add antifreeze to the heating system. Let's look at the technique step by step. We will help you determine which pump to use and where to connect it. There are some tricks that you can use to cope with the task yourself.

Recommendations for future use

Before starting work, you must carefully check all elements of the equipment.

Checking measuring instruments and calibrating them if necessary.

Checking the tightness of the hoses and the functionality of the control unit.

General assessment of the crimper’s capabilities for working at the upcoming site.

Compared to the mechanical one, the electric version has an advantage because it has a large power reserve and is capable of pumping up pressure several times greater.

It is worth remembering that the range of operating temperatures in which the crimper can be used ranges from 6 to 40 degrees.

How to pump antifreeze into the heating system

Before pouring antifreeze into the heating system, make sure that the pipes and heat exchangers are clean. If necessary, the entire circuit is first cleaned. To pour antifreeze into heating pipes correctly, you need to completely fill all the voids in the circuit so that there are no air pockets left. Air can only accumulate in batteries, if, of course, the circuit is made without errors. If air pockets accumulate somewhere in the circuit besides the batteries, then air vents are installed there. How to pump antifreeze into the heating system:

- connect the hose from the pump for pumping antifreeze into the heating system to any pipe through which liquid can be poured;

- turn on the supercharger;

- when the pressure gauge needle reaches a reading of one and a half atmospheres, the pump turns off;

- air is drained from all radiators;

- the pump is turned on again to pump antifreeze into the heating system until the pressure again reaches the previous level;

- check the presence of air in the heat exchangers and places where it may accumulate.

After the procedure is completed, the boiler is turned on. After it has been running for some time, about a day, you need to check the circuit again for the presence of air in it. Also pay attention to the pressure gauge. There should be one and a half atmospheres in the circuit. If the pressure gauge readings do not match, adjustments must be made. Most often you have to recharge the system, although it is possible that you will need to drain a certain amount of coolant.

Before pumping antifreeze into the heating system, you can immediately open all air vents. In this case, you need to place some kind of reservoir under each Mayevsky tap; a half-liter jar will do. The hole in the tap is very small, no thicker than a needle, so a flood is not expected.

It is more convenient to use the help of another person, since filling a closed heating system with antifreeze is much more convenient and faster for two people. It is necessary for someone to monitor the operation of the pump, the level of antifreeze in the tank from which it is pumped, and the pressure in the circuit. The second person monitors Mayevsky’s taps and closes them one by one when coolant flows out of the hole.

Hand pumps

In multi-storey buildings, it is quite common that due to the extraordinary length of the housing and communal services networks, which are responsible for transferring heat to apartments, a leak occurs.

According to GOST standards, Khrushchev-type houses should be under a pressure of 9 atm, but due to the reason mentioned above, it is not always this way. The main source of such leakage is the relative wear of the pipes.

Therefore, manual pumps are more used in private houses, since they do not contain complexly branched and long communications.

Of the advantages of a hand pump, it should be especially noted that it is quite inexpensive, and its ease of maintenance and mobility make it an excellent assistant. Such models are usually equipped with containers with a volume of no more than 15 liters. Their sleeve length ranges from two meters and above. It is covered with a special protective layer that does not allow it to expand. It is this sleeve, made of high-quality and durable materials, that is the connecting element of the network, the pump and the pressure gauge installed on it.

The fluid is pumped using a lever driven by human muscles.

The only drawback of such equipment is the relatively low speed, which makes it difficult to carry out crimping work with large volumes of communication networks. The maximum pressure that such a pump can create is 250 atm. There are models of manual crimpers up to 1300 atm.

In order to operate networks of high-rise buildings or large complexes, it would be advisable to use electric pumps.

Which pipe should I pour antifreeze through?

This is what the feed tap looks like

Before you get started, you need to know how to fill your heating system with antifreeze. There are two types of heating circuits. In one, the coolant is in contact with air, and in the other, circulation takes place in a completely closed circuit. The operating principle of these circuits is different, but they are united by the fact that antifreeze can be used in both. To pour antifreeze into the heating circuit you will need a pump. Coolant can be poured into open circuits in buckets, but in the case of non-freezing liquid this will take too long.

Antifreeze is poured into the heating system, in theory, through a make-up valve, if one is available. If it is not there, then the following options are possible:

To fill the heating circuit with antifreeze through the radiator plug, you need to unscrew it and screw in a tap instead.

A pump is connected to this tap, thanks to which antifreeze enters the pipes. After filling the heating system with antifreeze is completed, the tap remains at the end of the battery. This will allow you to recharge the system during operation, as well as use it as a drain when you need to empty the circuit of coolant.

In closed circuits there is a membrane expansion tank, for which there is a separate pipe. When the system is full, it is recommended to temporarily remove the expansion chamber. Is it possible to fill the heating system with antifreeze when the tank is not removed? It’s possible, but most likely, after this the expanzomat will still have to be removed and reconfigured. The expansion tank is installed both up and down.

The second method is more preferable, and the valve is installed on the pipe in different ways. Some installers install American valves with a tap in such a way that the shut-off valves remain on the circuit, while some, on the contrary, install them in such a way that the tap is removed together in the expansion chamber.

In the first case, there will be no problems with filling the circuit through the expansion tank pipe. In the second case, you will need to install such a tap. A hose from the pump is connected to the shut-off valve and antifreeze is poured into the pipes. Upon completion of the work, the ball valve is closed and the expansion chamber is installed.

Even if you do not have recharge coming from the pipes, this does not mean that there is none at all. Modern boilers always have a make-up pipe. For this reason, installers may not install another tap in the circuit itself. The boiler feed, if the system operates on water, is often connected to the water supply. If antifreeze is used, the pipe remains free and a pump can be connected to it.

Do you know that you can do alternative home heating with your own hands and not pay contractors? It's possible.

Read about why you sometimes have to resort to heating a wooden house with electricity here.

Types of equipment

According to technical characteristics, all pumps intended for pressure testing are divided into several categories. The first is electric . The second is mechanical.

Several types of electrohydraulic pumps are known, but their use is much less common. And this is despite the fact that the principle of their operation is different, although the functionality is intended for the same functions.

Before you start working with the equipment, you must carefully study the attached instructions. If you live in a private house, then you can assemble a pump for pressure testing yourself. All you need is copper pipes, a check valve, several plugs, a fitting and a pressure gauge. Everything will be assembled by welding into a single mechanism sequentially. For a tighter connection, you can use strands of flax.

The price tag of such a unit will be significantly lower than its market counterpart, but not everyone will be able to assemble it.

How to pump coolant

Pumps for filling the circuit with antifreeze can be different. Any water pump that is used in water supply is suitable for this purpose, since antifreeze can be properly poured into the heating system using any pressure blower of sufficient power. This includes manual and electric pumps, which can pump liquid in different ways. Some of them are immersed in the coolant, while others are not.

Submersible pump

Vibrating submersible pumps operate when completely immersed in antifreeze. Such devices include the well-known “Baby”. It should be said that there is no special pump for filling the heating system with antifreeze. All units have a wide range of applications on the farm. So, for example, “Malysh” can not only pump antifreeze into the circuit, but also lift water from the well.

Electric pump

The electric type pump operates using a motor from a 220 W network. It is mainly used to test the tightness of both heating systems and water pressure systems. Pumps of this class are mainly used by professionals for constant loads. However, this option has many advantages. It is not only simple to repair, but also easy to control, because it is done using one button.

The high level of performance achieved using an electric drive is capable of delivering maximum pressure in a short time. The pump, hidden in a highly durable casing, can serve for a very long time. The bypass type valve allows you to regulate the pressure with light pressure.

The electric pump also has an overheating protection system. If the temperature rises, it reduces the pressure automatically, which helps to quickly cool the device. Small dimensions make the electric pump mobile.

But it’s worth saying a few words about the disadvantages. The high market price does not allow everyone to purchase such a device, and if you also take into account its weight and complete dependence on the network, then this is not only an expensive, but also a very inconvenient option.

The uniqueness of the manual crimping machine

Models of such classification are practically free from all restrictions regarding their application. Naturally, they will not work to their maximum, but they will accurately fulfill the parameters specified by the manufacturer. Thus, a small mobile device for crimping will be, by the way, at home.

Despite all these delights, the main highlight of such a device is its almost zero error. This is achieved due to the fact that the operator independently controls the force supplied to the circuit. If the electric pump drives air as it is told, and not as it sees, then the circuit will begin to collapse over time, which will cause the entire mechanism to malfunction. If any problems with the equipment are detected, the manual crimping machine can be turned off instantly, which cannot be said about its electric counterparts.