- We offer to buy bimetallic sectional radiators with delivery in the Tavago online store.

- Price for Bimetallic sectional radiators from 545 rubles.

- Read instructions and reviews about Bimetallic sectional radiators.

Bimetallic heating radiators are one of the most efficient and reliable types of radiators that can be installed and operated as part of any heating system. Such radiators give off a large amount of heat and at the same time have a long service life compared to other analogues. It is these qualities that have ensured their wide popularity and widespread use for heating areas of any size and any purpose.

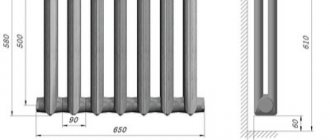

Bimetal sectional radiator design

Bimetallic heating radiators are devices consisting of two main parts, each of which is made of different types of metal. This is precisely what determines the name given to the radiator. Typically, stainless steel is used to make the interior. These materials are characterized by high resistance to aggressive influences from the coolant. In this case, the pipes are located both vertically and horizontally, and coolant circulates through them.

The outer part of the radiator is nothing more than a casing with fins. Most often, the casing is made of aluminum, and this choice is due to high thermal conductivity and the short time required for complete heating. Aluminum quickly releases heat into the room, increasing the overall air temperature.

The two parts of the radiator are connected to each other using the high-pressure casting method. Spot welding can be used somewhat less frequently for these purposes. To secure individual sections, nipples and special gaskets made of paronite or silicone are used that can withstand constant exposure to high temperatures.

Sectional radiators consist of several sections, each of which has equally directed threads on both sides. Using this thread, the sections are mounted into each other - connecting nipples and sealing gaskets are screwed into them. Thus, the structure can be assembled from almost any number of sections, which allows in each individual case to ensure the required level of heat transfer for the room.

In appearance, a bimetallic radiator is practically no different from its aluminum counterparts. The only parameter by which they can be distinguished is weight. Since bimetallic models have an internal steel filling, it weighs significantly more.

Due to the ability to quickly and efficiently heat areas, as well as a long service life, you can buy a bimetallic heating radiator to heat rooms of any size. You just need to purchase a sufficient number of sections.

Calculation of heating batteries per area

One of the most important issues in creating comfortable living conditions in a house or apartment is a reliable, correctly calculated and installed, well-balanced heating system. That is why creating such a system is the most important task when organizing the construction of your own home or when carrying out major renovations in a high-rise apartment.

Despite the modern variety of heating systems of various types, the leader in popularity is still a proven scheme: pipe circuits with coolant circulating through them, and heat exchange devices - radiators installed in the premises. It would seem that everything is simple, the batteries are located under the windows and provide the required heating... However, you need to know that the heat transfer from the radiators must correspond to both the area of the room and a number of other specific criteria. Thermal calculations based on the requirements of SNiP are a rather complex procedure performed by specialists. However, you can do it on your own, naturally, with acceptable simplification. This publication will tell you how to independently calculate heating radiators for the area of a heated room, taking into account various nuances.

Calculation of heating batteries per area

But, first, you need to at least briefly familiarize yourself with existing heating radiators - the results of the calculations will largely depend on their parameters.

Briefly about existing types of heating radiators

The modern range of radiators on sale includes the following types:

- Steel radiators of panel or tubular design.

- Cast iron batteries.

- Aluminum radiators of several modifications.

- Bimetallic radiators.

Steel radiators

This type of radiator has not gained much popularity, despite the fact that some models are given a very elegant design. The problem is that the disadvantages of such heat exchange devices significantly exceed their advantages - low price, relatively low weight and ease of installation.

Steel heating radiators have many disadvantages

The thin steel walls of such radiators do not have enough heat capacity - they heat up quickly, but also cool down just as quickly. Problems can also arise with water hammer - welded joints of sheets sometimes leak. In addition, inexpensive models that do not have a special coating are susceptible to corrosion, and the service life of such batteries is short - usually manufacturers give them a fairly short warranty in terms of service life.

In the vast majority of cases, steel radiators are a one-piece structure, and it is not possible to vary the heat transfer by changing the number of sections. They have a rated thermal power, which must be immediately selected based on the area and characteristics of the room where they are planned to be installed. An exception is that some tubular radiators have the ability to change the number of sections, but this is usually done to order, during manufacture, and not at home.

Cast iron radiators

Representatives of this type of battery are probably familiar to everyone from early childhood - these are the types of accordions that were previously installed literally everywhere.

The MS-140-500 cast iron radiator, familiar to everyone since childhood

Perhaps such MS-140-500 batteries were not particularly elegant, but they faithfully served more than one generation of residents. Each section of such a radiator provided a heat output of 160 W. The radiator is prefabricated, and the number of sections, in principle, was not limited by anything.

Modern cast iron radiators

There are currently many modern cast iron radiators on sale. They are already distinguished by a more elegant appearance, smooth outer surfaces that make cleaning easier. Exclusive versions are also produced, with an interesting relief pattern of cast iron casting.

With all this, such models fully retain the main advantages of cast iron batteries:

- The high heat capacity of cast iron and the massiveness of the batteries contribute to long-term retention and high heat transfer.

- Cast iron batteries, with proper assembly and high-quality sealing of connections, are not afraid of water hammer and temperature changes.

- Thick cast iron walls are little susceptible to corrosion and abrasive wear. Almost any coolant can be used, so such batteries are equally good for both autonomous and central heating systems.

If we do not take into account the external characteristics of old cast iron batteries, then the disadvantages include the fragility of the metal (accentuated impacts are unacceptable), the relative complexity of installation, which is associated largely with massiveness. In addition, not all wall partitions can support the weight of such radiators.

Aluminum radiators

Aluminum radiators, having appeared relatively recently, quickly gained popularity. They are relatively inexpensive, have a modern, quite elegant appearance, and have excellent heat dissipation.

When choosing aluminum radiators, you need to consider some important nuances

High-quality aluminum batteries can withstand pressures of 15 atmospheres or more and high coolant temperatures of about 100 degrees. At the same time, the thermal output from one section of some models sometimes reaches 200 W. But at the same time, they are lightweight (section weight is usually up to 2 kg) and do not require a large volume of coolant (capacity - no more than 500 ml).

Aluminum radiators are offered for sale as stacked batteries, with the ability to change the number of sections, and as solid products designed for a certain power.

Disadvantages of aluminum radiators:

- Some types are highly susceptible to oxygen corrosion of aluminum, with a high risk of gas formation. This places special demands on the quality of the coolant, which is why such batteries are usually installed in autonomous heating systems.

- Some aluminum radiators of a non-separable design, sections of which are made using extrusion technology, may, under certain unfavorable conditions, leak at the joints. In this case, it is simply impossible to carry out repairs, and you will have to replace the entire battery as a whole.

Of all aluminum batteries, the highest quality ones are those made using anodic oxidation of the metal. These products are practically not afraid of oxygen corrosion.

Externally, all aluminum radiators are approximately similar, so you need to read the technical documentation very carefully when making a choice.

Bimetallic heating radiators

Such radiators compete with cast iron ones in terms of reliability, and with aluminum ones in terms of thermal output. The reason for this is their special design.

The structure of a bimetallic heating radiator

Each section consists of two, upper and lower, steel horizontal collectors (item 1), connected by the same steel vertical channel (item 2). The connection into a single battery is made with high-quality threaded couplings (item 3). High heat transfer is ensured by the outer aluminum shell.

Steel internal pipes are made of metal that is not subject to corrosion or has a protective polymer coating. Well, under no circumstances does the aluminum heat exchanger come into contact with the coolant, and it is absolutely not afraid of corrosion.

This results in a combination of high strength and wear resistance with excellent thermal performance.

Prices for popular heating radiators

Heating radiators

Such batteries are not afraid of even very large pressure surges and high temperatures. They are, in fact, universal and suitable for any heating systems, however, they still show the best performance characteristics under conditions of high pressure in the central system - they are of little use for circuits with natural circulation.

Perhaps their only drawback is their high price compared to any other radiators.

For ease of reference, there is a table showing the comparative characteristics of radiators. Symbols in it:

- TS – tubular steel;

- Chg – cast iron;

- Al – ordinary aluminum;

- AA – aluminum anodized;

- BM – bimetallic.

| Chg | TS | Al | AA | BM | |

| Maximum pressure (atm.) | |||||

| working | 6-9 | 6-12 | 10-20 | 15-40 | 35 |

| crimping | 12-15 | 9 | 15-30 | 25-75 | 57 |

| destruction | 20-25 | 18-25 | 30-50 | 100 | 75 |

| Limitation on pH (hydrogen value) | 6,5-9 | 6,5-9 | 7-8 | 6,5-9 | 6,5-9 |

| Susceptibility to corrosion when exposed to: | |||||

| oxygen | No | Yes | No | No | Yes |

| stray currents | No | Yes | Yes | No | Yes |

| electrolytic couples | No | weak | Yes | No | weak |

| Section power at h=500 mm; Dt=70 ° , W | 160 | 85 | 175-200 | 216,3 | up to 200 |

| Warranty, years | 10 | 1 | 3-10 | 30 | 3-10 |

Video: recommendations for choosing heating radiators

You may be interested in information about what a bimetallic battery is

How to calculate the required number of heating radiator sections

It is clear that a radiator installed in the room (one or more) must provide heating to a comfortable temperature and compensate for the inevitable heat loss, regardless of the weather outside.

The basic value for calculations is always the area or volume of the room. The professional calculations themselves are very complex and take into account a very large number of criteria. But for household needs you can use simplified methods.

The simplest methods of calculation

It is generally accepted that to create normal conditions in a standard living space, 100 W per square meter of area is sufficient. Thus, you just need to calculate the area of the room and multiply it by 100.

Q = S × 100

Q – required heat transfer from heating radiators.

S – area of the heated room.

If you plan to install a non-separable radiator, then this value will become a guideline for selecting the required model. In the case where batteries are installed that allow the number of sections to be changed, another calculation should be made:

N = Q / Qсy

N – calculated number of sections.

Qс – specific thermal power of one section. This value must be indicated in the technical data sheet of the product.

As you can see, these calculations are extremely simple and do not require any special knowledge of mathematics - just a tape measure to measure the room and a piece of paper for calculations. In addition, you can use the table below - it shows already calculated values for rooms of different sizes and certain capacities of heating sections.

Section table

However, you need to remember that these values are for the standard ceiling height (2.7 m) of a high-rise building. If the height of the room is different, then it is better to calculate the number of battery sections based on the volume of the room. For this, an average indicator is used - 41 W of thermal power per 1 m³ of volume in a panel house, or 34 W in a brick house.

Q = S × h × 40 (34)

where h is the height of the ceiling above the floor level.

Further calculations are no different from those presented above.

Detailed calculation taking into account the characteristics of the room

Now let's move on to more serious calculations. The simplified calculation method given above can present a “surprise” to the owners of a house or apartment. When installed radiators do not create the required comfortable microclimate in residential premises. And the reason for this is a whole list of nuances that the considered method simply does not take into account. Meanwhile, such nuances can be very important.

So, the area of the room and the same 100 W per m² are again taken as a basis. But the formula itself already looks a little different:

Q = S × 100 × A × B × C × D × E × F × G × H × I × J

Letters from A to J conventionally indicate coefficients that take into account the characteristics of the room and the installation of radiators in it. Let's look at them in order:

A is the number of external walls in the room.

It is clear that the higher the contact area between the room and the street, that is, the more external walls there are in the room, the higher the overall heat loss. This dependence is taken into account by coefficient A :

- One external wall – A = 1.0

- Two external walls - A = 1.2

- Three external walls - A = 1.3

- All four external walls - A = 1.4

B – orientation of the room to the cardinal points.

The maximum heat loss is always in rooms that do not receive direct sunlight. This is, of course, the northern side of the house, and the eastern side can also be included here - the rays of the Sun appear here only in the mornings, when the luminary has not yet reached its full power.

The warming of rooms largely depends on their location relative to the cardinal directions.

The southern and western sides of the house are always heated by the Sun much more strongly.

Hence the values of coefficient B :

- The room faces north or east – B = 1.1

- Southern or western rooms – B = 1, that is, may not be taken into account.

C is a coefficient that takes into account the degree of insulation of the walls.

It is clear that heat loss from the heated room will depend on the quality of the thermal insulation of the external walls. The value of coefficient C is taken equal to:

- Average level - the walls are laid with two bricks, or their surface insulation is provided with another material - C = 1.0

- External walls are not insulated - C = 1.27

- High level of insulation based on thermal engineering calculations – C = 0.85.

D – features of the climatic conditions of the region.

Naturally, it is impossible to put all the basic indicators of the required heating power “with the same brush” - they also depend on the level of winter negative temperatures characteristic of a particular area. This takes into account the coefficient D. To select it, the average temperatures of the coldest ten days of January are taken - usually this value is easy to check with the local hydrometeorological service.

- – 35 °C and below – D= 1.5

- — 25 ÷ — 35 °С – D= 1.3

- up to – 20 °С – D= 1.1

- not lower than – 15 °С – D= 0.9

- not lower than – 10 °С – D= 0.7

E – coefficient of ceiling height of the room.

As already mentioned, 100 W/m² is an average value for standard ceiling heights. If it differs, a correction factor E :

- Up to 2.7 m – E = 1.0

- 2.8 – 3.0 m – E = 1.05

- 3.1 – 3.5 m – E = 1.1

- 3.6 – 4.0 m – E = 1.15

- More than 4.1 m – E = 1.2

F – coefficient taking into account the type of room located above

Setting up a heating system in rooms with cold floors is a pointless exercise, and owners always take action in this matter. But the type of room located above often does not depend on them in any way. Meanwhile, if there is a living or insulated room on top, then the overall need for thermal energy will decrease significantly:

- cold attic or unheated room – F= 1.0

- insulated attic (including insulated roof) – F= 0.9

- heated room – F= 0.8

G – factor taking into account the type of windows installed.

Different window designs are subject to heat loss differently. This takes into account the G factor:

- conventional wooden frames with double glazing – G= 1.27

- the windows are equipped with single-chamber double-glazed windows (2 glasses) – G= 1.0

- single-chamber double-glazed window with argon filling or double-glazed window (3 glasses) - G= 0.85

N – coefficient of glazing area of the room.

The total amount of heat loss also depends on the total area of windows installed in the room. This value is calculated based on the ratio of the window area to the room area. Depending on the result obtained, we find the coefficient H :

- Ratio less than 0.1 – H = 0.8

- 0,11 ÷ 0,2 – H = 0.9

- 0,21 ÷ 0,3 – H = 1.0

- 0,31÷ 0,4 – H = 1.1

- 0,41 ÷ 0,5 – H = 1.2

I is a coefficient that takes into account the radiator connection diagram.

Their heat transfer depends on how the radiators are connected to the supply and return pipes. This should also be taken into account when planning the installation and determining the required number of sections:

Diagrams for inserting radiators into a heating circuit

- a – diagonal connection, supply from above, return from below – I = 1.0

- b – one-way connection, supply from above, return from below – I = 1.03

- c – two-way connection, both supply and return from below – I = 1.13

- d – diagonal connection, supply from below, return from above – I = 1.25

- d – one-way connection, supply from below, return from above – I = 1.28

- e – one-sided bottom connection of return and supply – I = 1.28

J is a coefficient that takes into account the degree of openness of installed radiators.

Much also depends on how open the installed batteries are to free heat exchange with the room air. Existing or artificially created barriers can significantly reduce the heat transfer of the radiator. This takes into account the J factor:

The heat transfer of batteries is affected by the place and method of their installation in the room.

a – the radiator is located openly on the wall or not covered by a window sill – J = 0.9

b – the radiator is covered from above with a window sill or shelf – J = 1.0

c – the radiator is covered from above by a horizontal projection of the wall niche – J = 1.07

d – the radiator is covered from above by a window sill, and from the front side it is partially covered by a decorative casing – J = 1.12

d – the radiator is completely covered with a decorative casing – J = 1.2

⃰⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰⃰ ⃰⃰⃰⃰⃰⃰⃰⃰

Well, finally, that's all. Now you can substitute the required values and coefficients corresponding to the conditions into the formula, and the output will be the required thermal power for reliable heating of the room, taking into account all the nuances.

After this, all that remains is to either select a non-separable radiator with the required thermal output, or divide the calculated value by the specific thermal power of one section of the battery of the selected model.

Surely, to many, such a calculation will seem overly cumbersome, in which it is easy to get confused. To make the calculations easier, we suggest using a special calculator - it already contains all the required values. The user can only enter the requested initial values or select the required items from the lists. The “calculate” button will immediately lead to an exact result, rounded up.

Calculator for accurate calculation of heating radiators

Go to calculations

The author of the publication, who is also the compiler of the calculator, hopes that the visitor to our portal received complete information and good help for independent calculations.

You may be interested in information on how to choose an electric boiler.

Bimetal and semi-bimetal: what is the difference?

Conventional bimetallic radiators have a casing made of aluminum. The rest of its parts are made of other metals. During the manufacturing process, steel cores are placed into special molds and then filled with molten aluminum. After solidification, this metal does not come into contact with the coolant in any way, and serves solely as a heat exchanger. Such batteries are best suited for installation as part of any heating systems.

If we talk about semi-bimetallic radiators, then in their design the steel pipe is present only in the vertical part of the radiator. The horizontal passages remain aluminum. It is possible to install such batteries as part of a central heating system, but since the coolant in such systems can rarely boast of purity and the absence of alkaline impurities, such radiators may last less than completely bimetallic ones.

Copper-aluminum heating radiators

They should not be confused with bimetallic ones. These are two different devices. Copper-aluminum batteries are by far the most expensive. The reason is the materials used: copper and aluminum.

The coolant in such radiators moves through copper tubes, and heat is removed through special aluminum fins.

According to their characteristics, such batteries are 90% convectors. That is, they work on the principle of convection, not radiation.

Simply put, such batteries warm up the room very quickly and the room cools down very quickly when these home heating radiators are not heated. It is better to install such heating radiators in a house in which you want to quickly heat up the room and are ready for quick cooling.

Criteria for choosing bimetallic radiators

When choosing a bimetallic radiator, you should take into account a number of criteria, which will directly determine the quality of the system and the duration of its operation. We are talking about the following selection criteria:

- Reliability of the design. Since the radiator is constantly exposed to increased pressure, its design must be prepared to work in such conditions. This issue is especially acute if you intend to use a radiator as part of a central heating system;

- Manufacturing materials. The materials from which the radiator is made must be able to easily withstand the effects of alkalis contained in low-quality coolants, and also be resistant to corrosive processes;

- Strength. The radiator must be resistant to mechanical loads. This is more about the outer case. When choosing a model, this point can be checked by applying some pressure on the ribs with your fingers. If they bend, then you have a low-quality model;

- Pipe thickness. Radiator pipes must have a width of at least 3 mm. Otherwise, they will quickly become unusable and require complete replacement;

- Gaskets and nipples. As we noted above, these elements are used to secure the radiator sections, and they must provide reliable and durable fasteners;

Width of ribs. The front part of the fin in a high-quality radiator necessarily exceeds the 70 mm mark in width. Taking into account all these criteria, you can choose the highest quality and reliable bimetallic radiator.

Comparison of panel heating radiators for home with sectional ones

The advantage of such heating equipment is, first of all, the absence of a large number of connections. Unlike sectional ones, they have only 4: a Mayevsky tap, a plug and 2 inputs. This ensures that there are absolutely no leaks caused by low-quality gaskets.

As for size, the advantage of sectional heating radiators for a home is that they can be expanded by adding new sections, but they do not differ in a special choice of height. As a rule, we are talking about 200, 350 or 500 mm. Panel varieties benefit from the fact that even 900 mm radiators (in height) can often be found on sale. They can be up to 5 m in length.

In terms of power, panel steel devices are also available in a wide range. With one frontal size, the consumer can receive 5-6 different power levels, mainly due to an increase in its width and the number of heating panels, as well as fins.

The disadvantage of a steel panel heating radiator for a home is that it is not intended for a multi-storey high-rise building equipped with a riser heating system, because its operating pressure is 6 atmospheres. In all other respects, it is in no way inferior to the sectional variety. It is better not to install such a heating radiator in an apartment building.

If we talk about fastening methods, then in addition to the sectional equipment it is necessary to additionally purchase a set of brackets and a so-called radiator set, which includes a plug, a Mayevsky tap, 4 plugs and 2 brackets. The complete set of a panel steel radiator, by default, already contains all the listed fasteners. The advantage of a panel device is obvious.

Another plus is the fairly simple installation process, which was made possible thanks to a very convenient and well-thought-out bracket system. Without going into details, such fasteners allow you to install a steel panel radiator “tightly”, that is, without the slightest play or wobble. Whereas with sectional heating equipment everything is different - it is very difficult to adjust the brackets so that the radiator does not swing. The cost and time of adjustment increases precisely due to the ill-conceived system of brackets designed for sectional batteries.

Well, and of course, again about gaskets. They often fail in sectional home heating radiators, especially when the heating system is filled with antifreeze. Panel devices are protected from this due to the absence of gaskets themselves. Therefore, it is better to install panel heating radiators in the house.

From all of the above, it is easy to understand why sectional aluminum and steel panel batteries remain the most popular, and in cottage construction consumers give preference to the latter. Largely due to their ability to use anti-freeze, a wide selection of capacities and a convenient fastening system.

Calculation of the number of sections of bimetallic radiators

First, multiply the area of the room by the height of the ceiling. We get the volume of the room. Then we divide the resulting volume by a factor of 30. The resulting number is the power in kW that is necessary to heat this room. If the room is corner, i.e. has not one, but two walls bordering the street, then we add 20% to the resulting power. Also, if the glazing area is unusually large, each square meter of glass is considered as an additional 0.1 kW to the radiator power.

So, after the necessary calculations, we have obtained the radiator power, but how can we convert it into the required number of sections? It's simple! The resulting power is divided by the heat output of one section in kW. Thus, we get the required number of sections. The heat transfer of the section is indicated in the product characteristics on the website.

And another important point is the height of the radiator. There must be at least 10 cm from the floor level to the bottom edge of the radiator, and there must be at least 10 cm from the top of the radiator to the window sill. This is necessary for free air circulation.

Example: a room of 18 sq.m., ceiling height 2.7 m., has two street walls, glazing area 3 sq.m., window sill height 1 m.

- 18x2.7/30=1.62 kW is needed to heat the room;

- add 10% for heat losses for each street wall: 1.62+20%=1.944 kW;

- add 0.3 kW (3 sq.m. glazing) - we get 1.944 + 0.3 = 2.244 kW;

- divide by the heat transfer of one section 0.185 kW: 2.244/0.185 = 12.129. Rounding up, we get 12 sections

Gravity and pump systems - which heating radiator to choose?

Any type of equipment is suitable for the pumping system. For gravity flow, it is better to install a heating radiator for the house with a large flow between the upper and lower collectors. It is this feature that bimetallic and panel steel models lack, but cast iron and aluminum ones are ideal. Steel convectors, which are essentially a piece of pipe with metal fins, can also be an acceptable alternative.

How to choose the right radiators for an apartment?

Radiators must not only perform their functions, but also fit into the interior

Choosing a radiator for an apartment is a responsible step. Not all types of heating systems on the market today are suitable. Some devices are not able to withstand the load and water hammer that are often encountered in our public utilities. Here it is important to consider not only the material, but also the maximum load of the radiator.

In addition, for the efficient operation of the heating device and its maximum heat transfer, it is necessary to correctly calculate the number of sections.

When choosing a radiator for an apartment, the following factors must be taken into account:

- Total area of the apartment. Based on this parameter, it is necessary to select the radiator power.

- Maximum pressure in the heating system. Each device has its own maximum load.

- Material and maximum temperature that the radiator can withstand. Radiator power. This will be a fundamental factor on the basis of which it is necessary to calculate the number of sections and the total length of the device.

- General design and style of batteries.

When choosing batteries for your apartment, you don’t need to be overly zealous. A low price can cause cold in the room, and the service life of inexpensive radiators does not exceed 5-6 years.

If an accident occurs in the central heating system, cheap batteries can quickly fail due to water hammer.

At the end of the article, we offer you a very detailed lecture on choosing radiators for an apartment.

Methods of wiring and installation of radiators

battery installation

It does not matter what type of battery is purchased, but the general rules for installing them remain standard. It is better to entrust the correct installation of heating radiators to an experienced plumber. It is very difficult for a homeowner who is far from technical problems to determine the angle of the pipes or find the right place to mount the radiator.

Only a professional will tell you which type of connection to prefer: one-sided, bottom or diagonal. It is advisable to resolve such issues in contact with the designer who creates the interior project. He will express his opinion on how organically the radiators can fit into the overall design style.

Advantages of water heating

The principle of its operation is the same for both a city apartment with a centralized coolant supply and for cottages with their own heating boiler. Hot water, flowing through pipes and radiators, carries heat to each room and heats them evenly. Then, gradually cooling, the water returns back to the electric boiler for heating for a new portion of heat.

Compared to the use of electric heaters or underfloor heating systems, water heating is more efficient and economical. The most practical option is to install a warm water floor.

Correct placement of the radiator

If heating equipment is placed under standard conditions, the distance to the floor is selected at a minimum of 22 cm (for a steel panel model). If installation of a battery is required, and in extremely cramped conditions - at least 10 cm. The interval to the window sill should be at least 5 cm. It is also desirable that the window sill does not completely block the radiator, then the circulation of heated air will be ideal.

In rare cases, heating batteries for a home need to be placed behind a screen, which is extremely undesirable from a technological point of view. But if it is impossible to avoid this condition, the following points must be taken into account: the screen must either have technological holes or be located at some distance from the floor and from the window sill so as not to interfere with natural circulation.

But even if all these requirements are met, it is most likely impossible to do without increasing the power of the equipment. You will also need a special thermal head with a capillary tube. In this case, the working element will be located on the radiator instead of the thermal head, and it itself will be taken out into the room, usually onto the wall at a height of 1.5 m. The main requirement: warm air should not “wash” it, otherwise it will “lie.”

Otherwise, the room will be cold - the home heating radiator simply will not be able to perform its function.