Today we will talk to you about induction heating. Many are trying to present induction boilers as something innovative that will supposedly save us money and ensure the existence of our heating system. But what really?

In fact, induction boilers are units that are very expensive, bulky, inconvenient to use and not endowed with a sufficient number of properties and qualities that are necessary for the normal operation of a modern electric heating boiler.

Those people who invent these boilers and try to sell them to you do not tell the consumer anything about these aspects of their products, but only highlight positive qualities. Here we will display all the pros and cons of induction heating at home

How does an induction heating boiler work?

Let's remember the physics of the school curriculum. If a ferromagnetic conductor is placed in an alternating electromagnetic field, then the energy of the electromagnetic field will irreversibly transform into the thermal energy of this conductor. The physics of the process is described by two Maxwell laws and the Lenz-Joule law, which are not of interest to us here.

That is, if an alternating current is passed through a coil (inductor), then the electrical energy of the inductor will contactlessly transform into the thermal energy of a conductor placed in the field of the coil. After which the conductor can be used as a heating element of the heating system.

The word “contactless” is important in this principle. That is, in this system there are no losses due to the resistance of contact groups and wires. That is why induction electric boilers are considered the most economical (very high efficiency).

What is electric heating

Let's figure it out. Electric heating is an artificial process of increasing temperature due to energy supplied from outside. There are several ways to convert electrical energy into heat: without contact with a heated object (induction-coolant) and in contact with a heated object (heating-coolant). It is in comparison with a heating element boiler that enterprising marketers manage to “intelligibly convey” information about the “incredible” induction boiler to a potential buyer. By the way, you cannot find such a boiler used for domestic needs in any European country.

The use of induction heating is limited exclusively to heating processes of metal and other conductive materials

Induction boiler design

Compared to other designs of heating boilers, the design of an induction boiler is as simple as possible. The design includes the following main parts:

- An element that creates an alternating electromagnetic field (coil);

- Heat exchanger(s). They are the coil core and part of the body;

- Electrical cabinet in which the boiler control is concentrated;

- Supply conductors and pipes to the coolant inlet and outlet.

The remaining elements of the boiler depend on the manufacturer and are not fundamental for operation.

In terms of design, or rather simplicity of design, induction electric boilers are closest to electric heating element boilers. We will compare them with them further.

What to build a boiler from

When designing you will need:

- Plastic pipe as a body part;

- Stainless steel wire as a heating element;

- A piece of copper wire for an inductor;

- Adapters plus ball valves when connecting the boiler to a common system;

- Pliers with wire cutters.

Having prepared everything you need, you can start assembling.

Comparing an induction boiler and a heating element boiler

Induction and heating element boilers are the same type, electric heating boilers, that is, boilers in which electrical energy is converted into heat. Comparing them we can say:

- Both boilers have high efficiency tending to 100%;

- The cost of heating the coolant is the same;

- Heating element boilers are cheaper;

- Induction boilers are easier to use and more reliable.

However, the induction boiler has significant advantages:

- Scale does not form on the heating element;

- You can use almost any coolant, not just water;

- They operate silently and do not require a specially equipped room.

Should they be used for heating a private home: let’s look at known misconceptions

As we said earlier, the use of induction electric boilers is justified only in industry. However, it is worth confirming the words by analyzing all the known myths in more detail.

Efficiency and profitability

An example of compact piping of an electric induction boiler in the heating system of a private house.

Despite sellers’ assurances of high efficiency, all modern electric boilers have about 99%. This means that, for example, at maximum load, a boiler producing 9 kW of thermal energy will consume 9.091 kW of electricity. However, over time, due to scale formation, the efficiency of heating element models decreases to 90 or even 80%, since more time and power are required to ensure the same heat transfer through the scale layer. In induction boilers, scale does not form and the efficiency remains unchanged.

But even in heating element models the problem can be almost completely solved:

- filtering the coolant being poured;

- installing softening filters;

- using the same coolant without draining it every season. Minerals will settle once on the heating elements and turn into an insignificant layer of scale, which practically does not affect the heating efficiency, after which they will simply have nowhere to come from.

In addition, in any case, you can always replace heating elements; they are inexpensive, and replacement is not difficult to do yourself. Savings can also be achieved by effective automation that controls the power of the electric boiler in accordance with needs, which is available in induction boilers, but is often inferior to heating elements or even electrode models.

We will deal with it later, but for now we can conclude that the efficiency of all modern electric boilers is the same, and the absence of scale is not worth an overpayment of more than 50%.

Efficiency and selection criteria for energy-saving electric heating boilers

Reliability

Another frequent argument in favor of electric induction devices is their reliability: the design is as simple as possible, which means there is simply nothing to break in it.

This is true, but it applies to absolutely all high-quality electric boilers, since, unlike gas boilers, the only element that can fail under proper operating conditions is the heating element. But even with cleaned and soft coolant, they last at least 5-7 years.

Other elements in models from well-known manufacturers, such as a circulation pump, automation, a set of sensors or an air vent, according to practice, rarely fail during the first 10 years of operation.

Safety

Even with modern models, safety is not easy, since powerful inductive electric boilers create a serious load on the electrical network and distort the sine wave. It is necessary to connect the boiler unit only if the wiring is in excellent condition, preferably through a voltage stabilizer. In addition, the magnetic field is not isolated in any way, which can negatively affect the operation of nearby electronics.

Automatic and temperature control

Typical control cabinet for an induction boiler.

An induction electric boiler is controlled using a separate control panel, which has fairly precise settings, but does not imply programming the operation of the boiler for the next day or week.

In well-known heating element models, the temperature is controlled more precisely: by degrees, thanks to a temperature sensor. In addition, in many models it is possible to install a room thermostat, which allows you to more efficiently and correctly regulate the operation of the boiler according to the temperature of the air in the room, and not the coolant at the outlet.

How to choose a room thermostat for an electric boiler and save up to 30% every month

Weight and dimensions

An example of using several low-power electric boilers in one system.

The dimensions of induction boilers are really small, which allows you to install them almost anywhere in the house. However, this is not such a significant advantage over the already compact heating element models or extremely small electrode boilers, slightly larger than the main pipe.

The weight of induction heaters in most cases is 2 times more than heating elements models, in the range of 50-80 kg.

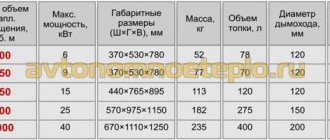

Power of induction boilers

Typically, induction boilers are produced in series with the following power division:

- Power 2.5–10 kW (supply voltage 220V/380V, current frequency 50 Hz)

- Power 15–60 kW (supply voltage 380V, current frequency 50 Hz).

Starting from a power of 5-7 kW, a three-phase electrical network of 380±3% Volt is required to power the boiler.

It is worth noting the size of induction boilers. Thus, a SAV boiler with a power of 10 kW has external dimensions (height x diameter) of 1000 x 121 mm and such a boiler weighs 70 kg without a control system.

As you already understood from the dimensions, the appearance of an induction boiler is a large metal cylinder or several cylinders. Let's look at the photo.

Reviews of induction electric boilers: advantages and disadvantages

Let’s summarize by analyzing all the real characteristics, installation practices and owner reviews:

| Advantages | Flaws |

| No scale formation process | High cost (60-100% more expensive than heating elements or electrode models) |

| Compact dimensions | Mediocre automation and controls in the form of a control cabinet with step-by-step power adjustment |

| Coolant heating rate (on average 1.5-1.7 times higher) | It is not possible to organize control using a room thermostat |

| Reliability, breakdowns in the first 8-12 years of operation of induction boilers of any power are rare | High load on the electrical network at home, curvature of the sinusoid, increasing the risk of voltage surges |

| Possibility of using oil, antifreeze or ethylene glycol-based coolant as a coolant | Unlike heating element models, a circulation pump, a safety group, and an expansion tank are rarely supplied with the boiler |

| It is worth remembering that heating a house using electricity in general is expensive. For a house with an area of 100-150 sq. m. this is about 9-13 thousand rubles. per month. |

Boiler control system

As a rule, manufacturers supply a control system with the boiler. Essentially this is an assembled electrical cabinet with the following equipment.

- Start relay;

- Thermostat (electronic);

- Thermocouple (temperature sensor);

- Automatic circuit breakers;

- Reactive power saving unit

- Surge protection

For boilers from 7 kW

- Start relay heatsink with fan

- Thermal overload relay.

DIY vortex induction heater (VIN)

The main problem with any system with a temperature difference is the heating element or reactor. This is the place where excess energy is generated, which is transmitted directly (as in the case of electric heating elements) or converted (as in the case of VIN).

Theoretically, the boiler can be assembled from a large sealed pan, to which two pipes (supply and return), a pump and an expansion tank will be connected. We mentally connect the pipes to a chain of radiators, and place the pan on the gas stove. We fill the system with water (or antifreeze), turn on the pump and ignite the gas - the boiler is ready. Of course, its efficiency will be relatively low, so it’s worth thinking about a cheaper source of energy, since the system itself is quite functional.

For this purpose, we will need the microwave effect, on which the action of an induction cooker is based. It is good because it heats the agent very quickly, harmlessly and safely. Now, if you install not a hypothetical, but a real cast-iron or steel container on such a stove, and include it in the heating circuit, you can heat a three-room apartment, consuming 1.8–2.5 kW/hour (slab power). For comparison, the initial power of an electric boiler with heating elements is 6 kW.

Average cost of induction electric stoves

| Name | Manufacturer | Number of burners | Power, W | price, rub. |

| Kitfort Kt-101 | China/Russia | 1 | 2000 | 3000 |

| Philips HD4959/40 | Netherlands | 1 | 2200 | 6000 |

| Haus Muller 453 | China/Sweden | 1 | 2000 | 6200 |

| Hendi (239780) KITCHEN LINE 3500 (professional) | Netherlands | 1 | 3500 | 12000 |

| INDOKOR IN3500 | South Korea | 1 | 3500 | 12600 |

| ENERGY EN-914 | China/China | 1 | 1100 | 1800 |

| Oursson IP2310T/BL | China | 2 | 2400/1800 | 8000 |

| KROMAX Endever | Sweden | 2 | 2200/1750 | 8000 |

Boiler installation - general notes

- To operate an induction boiler, a dedicated power supply group with a cross-section of the supplied cable corresponding to the power of the boiler is required. The selection of the section is carried out according to the following table;

- IR can only be installed vertically;

- In a heating system where induction boilers operate, the installation of a circulation pump is mandatory;

- The distance from the boiler body to the nearest objects should not be less: 300 mm on the side and 800 mm on the top and bottom.

Conclusion

Induction heating boilers consume the same amount of kW of heat as heating elements. There are no miracles. The induction heating method has a number of advantages and is widely used only in industry.

The use of induction heating in domestic conditions requires high quality components and assembly of the heat generator. To do this, it is necessary to increase the level of production capacity of domestic enterprises producing induction boilers, introduce international standards and quality control methods

When purchasing a heating boiler, pay attention to whether the manufacturer has ISO 9001 standard - quality management system standard and other international certificates and international awards

Be sure to inquire about the terms of warranty service for the heat generator. And don’t be shy about legal liability in case of electric shock. You shouldn’t believe the unfounded assurances of sellers that something like this has never happened in 30 years. You need specific answers to the questions of who is responsible and in what documents this is stated. Do not forget that all permits for the use of electric heaters in fire hazardous areas must be supported by appropriate certificates.

Device and principle of operation

The main element of an induction boiler is a transformer with a toroidal winding. The device of such a boiler itself consists of the following elements:

- The body of the unit, which is made of metal.

- A layer of electrical protection and thermal insulation.

- The core is a ferrimagnetic tube.

The core winding acts as the primary winding, and the secondary winding is the boiler body. Also included in the package:

- Circuit breakers.

- Temperature sensor, which is built into the boiler body.

- Electronic thermostat.

Not only ordinary water and antifreeze, but also oil can act as a coolant in such a system.

Operating principle

The name induction electric boiler contains the principle of its operation - electromagnetic induction. When voltage is applied, the following processes occur:

- An electromagnetic field is created.

- The core heats up to a temperature of 750 °C.

- The coolant enters through special pipes and, passing through the core, heats up, then transferring the heat to the heating radiators of the house.

This heating method allows you to heat a large volume of coolant in a short period of time. At the same time, the convection currents created make it possible to do without a circulation pump.

Advice! The absence of a circulation pump is justified in small heating systems. When heating a two-story house with an induction boiler, its presence is mandatory.

Connections and flanges

The second drawback in comparison is the large number of sealing connections (heating elements, flanges) and their complete absence in an induction boiler. Here these advantages and disadvantages can even be swapped.

After all, if the heating element does fail, you can easily replace it. Or simply exclude it from the circuit for a short time, set the jumpers differently and continue working.

But if the coil burns out (due to an interturn short circuit), how much will the repair cost you? And will you be able to keep warm with such a breakdown?

Features of self-production

In order to make an induction heater, you must have experience in electrical work and assembling homemade electrical appliances, as well as skills in processing metal and other materials and be able to install wiring. Therefore, in their absence, it is better to entrust such work to professionals. In this case, the general algorithm for manufacturing the device consists of the following sequential stages:

- Making a heater. As a rule, a section of thick-walled metal pipe with adapters at the ends is used, enclosed in a heat-resistant plastic tube of a larger diameter.

Application

Heating based on eddy currents created by electromagnetic fields can find its application in:

- heating a residential property, house, bathhouse, garage, industrial or administrative building;

- in the hot water supply system;

- heating of buildings and structures that have certain requirements for heat sources (for safety).

Features of installation and operation

Remember that the boiler winding will cause heating of any metal element caught in the magnetic field it emits.

Therefore, the device should be placed no closer than 80 cm from the floor or ceiling and at least 30 cm from walls and other devices.

To ensure proper heat removal, the working fluid must be pumped by a circulation pump; natural circulation may not be enough.

This is especially true for the option with a heater in the form of wire scraps.

Before turning it on, you need to make sure that there is coolant - if the device is started “dry”, the polypropylene pipe will quickly melt.