Set of socks, Omsa socks

349 ₽ More details

Set of socks, Omsa socks

349 ₽ More details

Paints

When the heating system is running in the house, there is a risk of the coolant freezing, especially during the cold season. As a result, an accident may occur. You can avoid it if you replace ordinary water with a special composition. Non-freezing heating fluid differs from water in that its freezing point is significantly lower.

This substance freezes at very low temperatures

Advantages and disadvantages

The special liquid has a number of features. It has both pros and cons. Benefits of antifreeze:

- the composition retains its characteristics and properties, even if it is constantly in the heating system;

- does not freeze at sub-zero temperatures;

- scale does not form in equipment and pipes;

- does not affect the condition of seals and gaskets: they will not dissolve, dry out or swell.

But when pouring non-freezing liquid into the heating system, there are also disadvantages:

- it has lower heat transfer properties;

- acts aggressively towards metal;

- in the event of a leak, harmful substances will be released.

In addition, antifreeze is viscous, so when choosing equipment for a heating system, you need to take its characteristics into account.

Good to know: how to choose the right antifreeze for heating.

In this video you will learn the benefits of anti-freeze:

What kind of anti-freeze liquid should I pour into the heating system?

To summarize, you can determine which antifreeze liquid to pour into the heating system. If you have definitely decided that you will be pouring anti-freeze into the circuit, then it is better to opt for propylene glycol or glycerin compositions. The former are more expensive, while the latter have insignificantly lower thermal conductivity and greater weight. Considering the fact that propylene glycol antifreezes are the most modern, many consumers choose them. It is better not to deal with ethylene glycol compounds, since the likelihood of contact with a person is quite high, and servicing a circuit with a toxic substance is quite problematic.

Antifreeze classification

There are many types of these products on the market. Antifreeze liquid for heating boilers can be made based on an aqueous solution of glycerin, ethylene glycol, propylene glycol, and so on. Since all substances are highly aggressive, the liquids contain special additives.

Each type has certain specific characteristics:

- Ethylene glycol-based liquid is common among buyers because it has the most affordable price. But it is the most toxic and cannot be used for double-circuit boilers. May pose a health hazard if released into water supplies. If the boiling point rises above 110 degrees, the substance may produce a precipitate that can stop the operation of a number of system elements;

- from propylene glycol - the properties of the composition are almost similar to the previous one, but it is less harmful and safer;

- based on glycerin - environmentally friendly antifreeze, non-toxic, protects the system from corrosion. When it turns into a solid state, it does not increase its volume, and in order for the system to start, it just needs to be warmed up;

- from a natural bischofite solution - has a high level of heat transfer and heat capacity, the freezing point is low and the boiling point is high;

- salt carriers - are produced on the basis of solutions of sodium, calcium and other mineral salts. They have high corrosiveness to pipes.

The product can be sold both in finished form and in the form of a concentrate for preparing a solution. Different types of antifreeze have their own freezing point. Experts believe that it is best to use compounds whose freezing point is 20-25 degrees below zero.

Rules for diluting propylene glycol

To prepare a coolant based on concentrated propylene glycol, demineralized water is used. Dilution in different proportions, by volume or weight, is acceptable. For convenience, you can use the following information:

| Volume concentration in % | Density at 20°C, g/cm3 | Freezing temperature, °C |

| 25 | 1,023 | -10 |

| 30 | 1,029 | -13 |

| 35 | 1,033 | -17 |

| 40 | 1,037 | -21 |

| 45 | 1,042 | -26 |

| 50 | 1,045 | -32 |

Propylene glycol coolants are not used in systems with galvanized pipes; prolonged exposure leads to peeling of the material.

Keep in mind that when preparing working trains, precautions and fire safety measures must be observed. Work may only be carried out in a well-ventilated area, wearing personal protective equipment. But it is better to buy a ready-made solution and entrust pouring the liquid into the system to professionals.

Important! Do not mix coolants from different manufacturers. Each brand uses its own package of corrosion inhibitors, which can conflict in composition and lead to loss of properties.

Recommendations for selection

Water, unlike any antifreeze, is an environmentally friendly liquid. However, it can cause scale and corrosion. However, if the family lives in the house permanently, water is a more acceptable option for heating.

But special liquids are best used when the heating is turned on from time to time during the cold season. The fact is that if the heating was not started when cold weather set in, there is a risk of pipe breakage due to an increase in the volume of water when it turns into a solid state. With antifreeze this problem is eliminated.

When choosing antifreeze you need to rely on the heating system itself

The elements themselves for the heating system must be selected taking into account what exactly will be used - water or antifreeze, then there will be much less risks. But if the heating system has been operating for a long time and it was decided to change the water to anti-freeze, then when choosing one or another type it is recommended to consider the following:

- A certain type of anti-freeze for heating a private house should be selected based on the design of the heating system itself. It is important here what metal its parts are made of, what power the pumps and radiators have, and what type of boiler is used;

- the composition must be reliable and of high quality;

- navigate the properties of additives contained in antifreeze in order to know how it can affect the equipment material;

- the antifreeze liquid must be diluted strictly according to the instructions;

- When using, do not forget about the service life of antifreeze (in most cases it can be used for no longer than 5 years).

If you are purchasing liquid for the first time, you can contact a specialist in the store, who will advise the most suitable option for each individual case. The right choice is a guarantee that the heating system will work fully.

Conclusion

Glycol coolant is more technologically advanced, safe and effective than water. In some operating conditions it is indispensable. On sale you can find both ready-made formulations and solutions of glycols of various concentrations with a package of additives, which theoretically can be adjusted to the required parameters.

Self-mixing of ethylene and propylene glycol with water is carried out before filling the system, taking into account the manufacturer’s recommendations. But it is best to purchase a solution of ethylene or propylene glycol in bulk. A variety of options, high-quality anti-corrosion additives made in Belgium - all this guarantees long-term and productive operation of the system.

You may be interested in the following products

| Name | Price per kg, rub. VAT included | Purchase |

| Ethylene glycol solution | from 37.65 rub./kg | Order |

| Propylene glycol solution | from 37.65 rub./kg | Order |

| Boiler water | from 33.25 rub./kg | Order |

Volume calculation and filling

To avoid emergency situations, liquid must be poured into the heating system strictly in a certain volume. It is calculated taking into account the following factors:

- type of heating system;

- its material;

- internal volume of the boiler;

- the area of the room that is planned to be heated.

It is recommended to carry out calculations according to the instructions for the equipment, and also take into account whether antifreeze can be used in it at all. But there are situations when the technical documentation does not contain any information on this matter, then the calculation is carried out by studying the relevant literature. And in some cases, you will need the help of a specialist who will help you carry out all the calculations and put the system into operation.

After filling, do not forget to test the equipment

You also need to know how to properly fill the coolant into the system. If there is already old media in it, then it will need to be drained. It is also necessary to check the degree of contamination; the system may need to be cleaned first, otherwise mixing two anti-freeze agents will cause an unexpected chemical reaction.

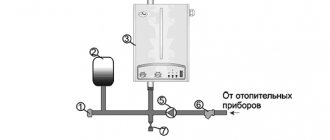

In a closed system, the filling point should be located below other heating devices. Antifreeze is poured using pumping equipment, but the pressure in the pipes must be no higher than 3 atmospheres. And if it is open, then filling must be done through the upper expansion tank.

After this, the operation of the equipment is tested. The temperature in the system increases, during which the tightness of the components and the absence of unnecessary noise during the circulation of the coolant are checked.

During the period of use of the system, antifreeze will need to be added periodically, so it is better to purchase it with some reserve.

Features when starting the heating system

Different compositions of solutions affect the operation of the heating system. Thus, the presence of ethylene glycol affects the initial stage of system startup. The heating process must be started at low power, then gradually increased to the required level. This method will reduce the toxic effects of this substance.

A product based on propylene glycol does not require such adjustments when starting heating equipment.

When all the requirements are met, then there is no need to be afraid of using “anti-freeze” as a coolant. It will solve a lot of problems if used skillfully.

Prices for non-freezing liquid vary, and so does the quality. The policy here should be this: when it is not possible to buy a good product, it is better to stick with water. In this case, you must ensure that the coolant is drained from the system before the onset of frost, or turn on the heating devices on time.

Limitations and Cautions

As mentioned, you should choose the right anti-freeze for the heating system of a private house, depending on its type. In addition, you need to consider that it is not suitable for all boilers. If the recommendations are ignored, the equipment may fail due to damage to the pipes.

It is not recommended to use antifreeze if the equipment has a galvanized surface. In this case, the protective layer quickly collapses, and the element will fail over time. Since it has a high viscosity, the heating system must be equipped with additional circulation pumps. Moreover, their productivity depends on the critical level of freezing temperature: the lower it is, the higher the productivity should be.

Antifreeze must be changed strictly according to the manufacturer's instructions. Over time, it loses its properties, which negatively affects the operation of the entire system. It is not recommended to use automotive antifreeze, since they are made primarily from unsafe substances.

If antifreeze is in the form of a concentrate, it should only be diluted in distilled water. Running water contains many foreign substances that, when combined, can cause a dangerous chemical reaction.

Other components

Recipes for factory-made antifreeze liquids necessarily contain surfactants. They are designed to remove dirt, soot, grime, oil and anything else that may limit visibility from the glass surface.

For a liquid to be effective in cleaning glass, very few surfactants are required. Flavorings are also used in the production process. They serve to give the product a pleasant smell. Manufacturers often use the scent of apples, citrus fruits or any other product with a persistent and “tasty” aroma. Dyes color liquids in different colors. This makes it easier for the buyer to identify the desired product. Separately, it is necessary to say about water. For the manufacture of the highest class products, distilled is best suited. In some cases, it is possible to use artesian water with a minimum of salts. But the most ordinary one (from the tap) is not suitable for making anti-freeze.

Is it possible to do it yourself

Antifreeze is a solution in which water makes up up to 70% of the total volume, the rest are additives that reduce the crystallization threshold to a minimum. These include the main component (glycerin, ethylene glycol and others) and additives that prevent the formation of foam and crystalline sediment as the temperature increases.

And if you can choose the main component yourself, then choosing the right additive is difficult, since their full composition has not been fully studied and the manufacturers do not disclose it. For this reason, making the composition at home correctly will not work.

If you ignore this recommendation and make an anti-freeze solution for heating your home yourself, the following consequences are possible:

- when the coolant heats up, the level of foam increases, which leads to the rapid formation of sediment on the walls of radiators and pipes;

- due to the decrease in heat transfer of a homemade anti-freeze, the heating efficiency will decrease significantly;

- homemade heating fluid can be bad for steel due to the large amount of oxygen, and corrosion will accelerate.

To prevent this from happening, using low-quality or homemade antifreeze is strictly prohibited. The liquid should be selected only from a factory-produced and reliable manufacturer.

Before pouring antifreeze into the heating system, you need to carefully re-read the instructions for it; the use of this heating element may be prohibited. The liquid itself must be selected correctly and all requirements for use must be observed.

Is it possible to dilute the coolant with water?

It is better to ask this question to the manufacturer. Some working compositions are not recommended to be diluted with water, others are perfectly diluted without loss of thermophysical properties. For example, concentrated solutions of glycols can be purchased in bulk and then independently brought to a given working concentration. The only requirement is to use demineralized water when diluting, because... High salt content may cause sediment to form.

How to choose the right liquid

Today, there are hundreds of product options on the market for heating devices and consumables for them.

It is quite difficult to choose a high-quality and safe antifreeze among them, because each brand uses all sorts of marketing tricks to attract buyer attention to its product. In order not to fall for the bait set by advertisers, the homeowner needs to understand what requirements the heating boiler fluid poured into the circuit must meet

Before you buy heating fluid. the owner needs to find out some technical characteristics of the boilers, as well as familiarize himself with the list of antifreezes compatible with radiators and pipelines connected to the circuit. In addition, it is necessary to clarify the operating parameters of the heating system and operating features. Next, you should study the specific requirements that specialists place on antifreezes that can make the heating system productive, stable and safe.

You should pay attention to the following parameters:

- Operating temperature range;

- heat capacity;

- inertness of the chemical composition;

- presence of anti-corrosion properties;

- no sediment in the liquid when heated;

- stability of chemical properties - density, viscosity, heat capacity;

- no toxic emissions during use.

Functional liquid fuel, gas and solid fuel heating boilers will last much longer if they are filled with antifreeze with a maximum operating temperature range, a stable chemical composition and acceptable performance characteristics that guarantee protection of heating devices from corrosion, scale and solid sediment.

You can buy such liquid only from a trusted manufacturer. But using the wrong antifreeze can lead to a number of undesirable effects. Negative effects that may appear:

- foam formation inside the circuit when heating the coolant;

- precipitation, which provokes overgrowing of pipes and clogging of the boiler heat exchanger;

- corrosion formation;

- the appearance of leaks;

- violation of the boiler tightness;

- release of toxic substances.

If you take anti-freeze, what brand?

Liquids for heating systems

Today's market offers varied offerings of these specific products.

However, there are also leaders here. Heating fluid called “Warm Home” is in great demand among consumers. This product is produced in Russia.

“Warm House” has been successfully used for many years, so we can confidently say that the liquid has stood the test of time. And this antifreeze is best characterized by reviews from homeowners who have considerable experience in operating heating systems using antifreeze liquid.

According to them, this brand does not lose its characteristics over ten heating seasons.

This fully corresponds to the service life declared by the manufacturer. As you know, reviews from satisfied consumers are the best proof of quality.

Also popular are brands such as Energos Universal, Energos Lux, Thermagent, Dixis, etc.

Russian manufacturers produce antifreezes based on ethylene glycol in two versions: with a freezing temperature of up to -30°C, and also with a freezing temperature of up to -65°C.

The above-mentioned manufacturers are actively expanding their range of non-freezing coolants made from food-grade propylene glycol, an environmentally friendly raw material. And this is not in vain, because the demand for heating antifreeze is growing, which means there must be supply.

Cases in which the use of antifreeze is strictly prohibited

When not to use antifreeze

It is not difficult to familiarize yourself with all the advantages of antifreeze from any manufacturer.

This information is actively advertised by brands. On the other hand, we should talk about the features of this liquid, which manufacturers try not to emphasize:

- It is prohibited to use antifreeze in double-circuit boilers. After all, the design features of this heating system are such that coolant can leak from the heating duct into the water supply circuit. And due to its chemical properties, the non-freezing liquid is poisonous.

- It is strictly forbidden to use antifreeze in open systems; in this case, it may evaporate.

- Also, antifreeze should not be used in heating systems with galvanized pipelines. When interacting with them, loss of original properties and chemical changes are possible. It is not recommended to pour antifreeze into cast iron boilers. At the very least, you need to make sure that your unit contains paronite gaskets that can prevent the harmful effects of antifreeze. The technical data sheet of the product will help you with this.

- The heat capacity of antifreeze is lower than water, as a result, radiator batteries of higher power are needed.

- Since the viscosity of the non-freezing liquid is higher, more powerful circulation pumps will be required.

In any case, the final decision is always yours. It is impossible to say for sure which is better, water or non-freezing liquid.

It all depends on individual heating parameters. Before making a final decision on the choice of a particular coolant, you should seek advice from specialists.