Single-pipe heating system diagram

Single-pipe heating system: vertical and horizontal distribution.

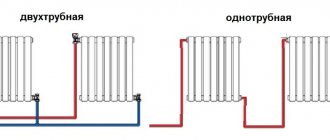

In a single-pipe heating system, the supply of hot coolant (supply) to the radiator and the removal of cooled coolant (return) are carried out through one pipe. All devices relative to the direction of movement of the coolant are connected to each other in series. Therefore, the temperature of the coolant at the inlet of each subsequent radiator along the riser is significantly reduced after heat is removed from the previous radiator. Accordingly, the heat transfer of radiators decreases with distance from the first device.

Such schemes are used mainly in old central heating systems of multi-storey buildings and in autonomous gravity-type systems (natural coolant circulation) in private residential buildings. The main defining disadvantage of a single-pipe system is the impossibility of independently adjusting the heat transfer of each radiator separately.

To eliminate this drawback, it is possible to use a single-pipe circuit with a bypass (a jumper between the supply and return), but in this circuit, the first radiator on the branch will always be the hottest, and the last the coldest.

Multi-storey buildings use a vertical single-pipe heating system.

In multi-storey buildings, the use of such a scheme allows saving on the length and cost of supply networks. As a rule, the heating system is made in the form of vertical risers passing through all floors of the building. The heat output of radiators is calculated during system design and cannot be adjusted using radiator valves or other control fittings. Given modern requirements for comfortable indoor conditions, this scheme for connecting water heating devices does not satisfy the requirements of residents of apartments located on different floors, but connected to the same heating system riser. Heat consumers are forced to “endure” overheating or underheating of air temperature during the transitional autumn and spring period.

Single-pipe heating in a private house.

In private houses, a single-pipe scheme is used in gravity heating networks, in which hot water circulates due to the differential densities of heated and cooled coolants. Therefore, such systems are called natural. The main advantage of this system is energy independence. When, for example, in the absence of a circulation pump in the system connected to the power supply networks and in the event of power outages, the heating system continues to function.

The main disadvantage of the gravity single-pipe connection scheme is the uneven distribution of coolant temperature across the radiators. The first radiators on the branch will be the hottest, and as you move away from the heat source, the temperature will drop. The metal consumption of gravity systems is always higher than that of forced ones due to the larger diameter of the pipelines.

Video about the installation of a single-pipe heating circuit in an apartment building:

General classification

Heating systems for large urban buildings can be classified depending on the type of heat source and the piping layout used to connect the heating devices. Heat supply to apartments can come from:

- centralized urban heating networks;

- an autonomous boiler house serving only one building;

- individual boilers installed in each individual apartment.

To distribute heat to individual rooms, the heating scheme of an apartment building may include the following general house piping schemes:

- single-pipe;

- two-pipe;

- collector or beam.

Each of these schemes and their advantages and disadvantages will be discussed in more detail below.

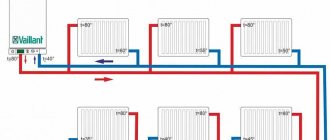

Two-pipe heating system diagram

In two-pipe schemes, the supply of hot coolant to the radiator and the removal of cooled coolant from the radiator are carried out through two different pipelines of the heating systems.

There are several options for two-pipe schemes: classic or standard, associated, fan or beam.

Two-pipe classic wiring

Classic two-pipe heating system wiring diagram.

In the classical scheme, the direction of movement of the coolant in the supply pipeline is opposite to the movement in the return pipeline. This scheme is most common in modern heating systems, both in multi-storey buildings and in private individual ones. The two-pipe circuit allows you to evenly distribute the coolant between radiators without loss of temperature and effectively regulate heat transfer in each room, including automatically through the use of thermostatic valves with installed thermal heads.

Such a device has a two-pipe heating system in a multi-story building.

Associated scheme or “Tichelman loop”

Associated heating wiring diagram.

The associated scheme is a variation of the classical scheme with the difference that the direction of movement of the coolant in the supply and return is the same. This scheme is used in heating systems with long and remote branches. Using a passing circuit allows you to reduce the hydraulic resistance of the branch and distribute the coolant evenly across all radiators.

Fan (radial)

A fan or radial scheme is used in multi-storey construction for apartment heating with the possibility of installing a heat meter (heat meter) in each apartment and in private housing construction in systems with floor-to-floor piping. With a fan-shaped scheme in a multi-storey building, a collector is installed on each floor with exits to all apartments of a separate pipeline and an installed heat meter. This allows each apartment owner to account for and pay only for the heat they consume.

Fan or radiant heating system.

In a private house, a fan diagram is used for floor-to-floor distribution of pipelines and for radial connection of each radiator to a common collector, i.e., each radiator has a separate supply and return pipe from the collector. This connection method allows you to distribute the coolant as evenly as possible across the radiators and reduce hydraulic losses of all elements of the heating system.

Note! When distributing pipelines in a fan pattern within one floor, installation is carried out in solid (without breaks or branches) sections of pipes. When using polymer multilayer or copper pipes, all pipelines can be cast into a concrete screed, thereby reducing the likelihood of rupture or leakage at the junction of network elements.

Coolant used for heat supply

Hot water is used as a heat carrier circulating through pipelines and radiators. In central heating networks and autonomous boiler houses, it is specially treated to remove dissolved oxygen, hardness salts and insoluble impurities. This makes it possible to reduce the corrosive effect on metal pipes, avoid scale deposits and the formation of silty blockages.

Prepared water is more expensive than regular tap water and therefore its drainage to repair the heating system of an apartment building and its subsequent filling to start it up can only occur with the permission and under the control of the heat supply or operating organization. Unauthorized drainage of coolant from heating entails administrative punishment in the form of a fine.

In individual apartment heating, such preparation is not provided due to the small amount of circulating water and the guarantee that there is no leakage.

Types of radiator connections

The main methods of connecting heating system devices are several types:

- Lateral (standard) connection;

- Diagonal connection;

- Bottom (saddle) connection.

Side connection

Lateral radiator connection.

Connection from the end of the device - supply and return are located on one side of the radiator. This is the most common and effective connection method; it allows you to remove the maximum amount of heat and use the entire heat transfer of the radiator. As a rule, the supply is at the top and the return is at the bottom. When using a special headset, it is possible to connect from bottom to bottom, this allows you to hide the pipelines as much as possible, but reduces the heat transfer of the radiator by 20 - 30%.

Diagonal connection

Diagonal radiator connection.

Connection diagonally to the radiator - the supply is on one side of the device from the top, the return is on the other side from the bottom. This type of connection is used in cases where the length of a sectional radiator exceeds 12 sections, and a panel radiator is 1200 mm. When installing long radiators with side connections, there is uneven heating of the radiator surface in the part furthest from the pipelines. To ensure that the radiator heats up evenly, a diagonal connection is used.

Bottom connection

Bottom connection from the ends of the radiator

Connection from the bottom of the device - supply and return are located at the bottom of the radiator. This connection is used for the most hidden installation of pipelines. When installing a sectional heating device and connecting it using the bottom method, the supply pipe approaches on one side of the radiator, and the return pipe on the other side of the bottom pipe. However, the heat transfer efficiency of radiators with this scheme is reduced by 15-20%.

Bottom radiator connection.

In the case when the bottom connection is used for a steel panel radiator, then all the pipes on the radiator are located at the bottom end. The design of the radiator itself is made in such a way that the supply flows through the manifold first to the upper part, and then the return flow is collected in the lower radiator manifold, thereby not reducing the heat transfer of the radiator.

Bottom connection in a single-pipe heating circuit.

Supply from city networks

We inherited centralized heat supply to multi-storey residential buildings as a legacy of planned management since the existence of the Soviet Union. Today, this method of providing housing with thermal energy is still the most common.

The main advantage of central heating is that residents of houses do not have to deal with issues related to the operation and repair of equipment and pipelines. The annual launch and necessary overhaul of networks is the responsibility of the city heat supply organization. With centralized and autonomous heating, individual elements can be repaired or altered only in agreement with the heat supply organization.

The disadvantages of such engineering systems are considered to be large heat losses in distribution networks, the dependence of the population on the quality of work of the heat supply organization and the inability to provide individual comfort conditions.

The design supply temperature in urban networks can be in the range of 90-115˚C, and existing standards for the safe operation of equipment prohibit heating accessible hot surfaces above 60˚C to prevent possible burns.

Therefore, a special elevator unit was installed at the pipe entry into the building. It mixes the hot coolant from the supply with cooled water from the return, returning from the consumer, changing the temperature to an acceptable one. Calculation of elements, maintenance of elements and change of the elevator control nozzle are carried out only by employees of the heat supply organization.

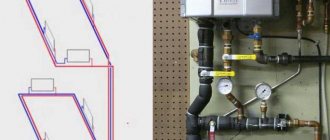

Boilers in apartments

This option for heating an apartment in an apartment building began to be used relatively recently in modern new buildings and residential buildings after reconstruction. Autonomous apartment structures provide the highest level of comfort in the apartment. The owners themselves determine the temperature schedule of the boiler, regardless of third-party heat supply organizations. Such a system starts and turns off only when necessary, avoiding unnecessary consumption of energy resources.

Among the disadvantages of individual heating are the need to provide maintenance and repair of installed equipment and dependence on stable electricity from the network. Many residents were faced with the necessary choice of a company for professional service and the development of additional protection means.

Main criteria for choosing pipes

To wisely and correctly select pipes for your home heating system, consider the following items:

- type of installation of the pipeline complex - surface or hidden (internal);

- estimated pressure power - assessment of the range from basic to maximum possible indicators;

- type of heating system - autonomous or central communications with gravity or forced circulation of the heating composition;

- the maximum temperature for which the coolant is designed;

- configuration features of heating equipment - single-pipe or two-pipe complex.

Only by knowing all these factors can we begin to select the type of material that will perform most effectively under specific specified conditions.

Top heat supply

It is used in buildings with a height of more than seven floors. At each entrance, the coolant is supplied upward to the attic or top floor through a large-diameter main riser. After this, it is taken to single-pipe risers through distribution pipes and lowered down with the sequential passage of each heating device.

For high-rise multi-storey buildings with more than 12 floors, the entire structure can be divided into two or three separate blocks vertically and a separate water flow distribution device for each of them. In this case, the building design often provides for a special technical floor or distribution wiring is carried out inside the apartments. In the basement or technical underground, all risers are again connected to one return pipeline.

The advantages and disadvantages of such systems are fully consistent with the traditional single-pipe systems described above, with an even greater difference in the quality of heating between the upper and lower floors. Quite often, residents of the first floors are forced to live in the cold.

Autonomous boiler room for one building

Heat sources serving only one city house began to be built in the last two decades. Boilers are installed in a special room on the roof, in an extension or in a separate building near a residential building. The level of automation of such a boiler house does not require the constant presence of maintenance personnel and can provide central dispatch control over the operation of the equipment.

The absence of large distribution networks makes it possible to avoid the use of overheated water, which reduces heat losses and increases the level of comfort. The coolant is supplied to the apartments through the main risers located in each entrance or directly through the upper distribution pipes if the boiler room is installed on the roof.

Installing a heating meter

Many are not satisfied with paying for heat at an average tariff based on consumption standards. In this regard, some people prefer to install a heat meter and pay only for the heat received.

The design features of heating systems, in particular, the widespread vertical distribution, do not allow apartment-by-apartment accounting of consumed heat, be it an open or a closed heating system of a high-rise building.

The only way out is door-to-door accounting. In this case, the procedure will be as follows:

- The management organization develops technical specifications for the installation.

- Housing departments or residents purchase a heat meter on their own.

- Based on the documents for the meter, a project for its installation is developed and agreed upon with the heat supply organization.

- The metering device is installed, the heat supply representative seals the meter and draws up the corresponding report.

Find out how a common house heat meter is installed in an apartment building.

Temperature standards

It is quite difficult to regulate heating in a residential apartment building. Even if residents have access to the system and the ability to increase/decrease the heat supply, it is not always possible to find a common language with their neighbors. In this case, it is worth focusing on the current regulations.

Temperature standards are regulated in accordance with GOST R 51617-2000, approved. . According to this document, the minimum temperature in apartments during the heating season should be:

- in living rooms, toilets, and kitchens - at least 18˚С;

- in the bathroom - not lower than 25˚С;

- in corner rooms, regardless of purpose, as well as for families where disabled people live - 2˚C above the established norm.

If the readings in your apartment are lower, you can safely demand an increase in temperature.

Read more about what temperature standards are set in the apartment.