In a heating system, a very important element is the heating expansion tank. Such a device serves to accept excess coolant at the moment when it expands, thus preventing rupture of the pipeline and taps.

Heating expansion tank

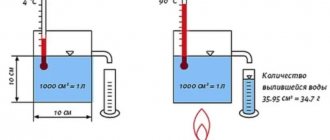

The principle of operation of an expansion tank for heating is as follows: when the temperature of the coolant rises by 10 degrees, its volume increases by about 0.3%. Since the liquid is not burned, excess pressure appears that needs to be compensated. This is precisely why an expansion tank is installed.

Types of expansion tanks

Different types of expansion tanks are used in different heating systems. Previously, systems without circulation pumps used an open expansion tank for heating. But such tanks had many disadvantages, so nowadays they are used very rarely. Due to the fact that air gets into such an expansion tank for heating, corrosion appears, and the liquid evaporates faster and must be constantly replenished. Such a tank must be placed at the highest point of the heating system, and this is not always easy to implement.

Open expansion tank for heating

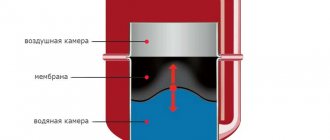

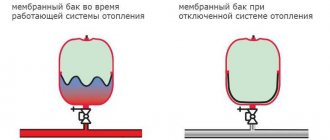

In such heating systems, where the coolant circulates using a pump, a closed expansion tank for heating is installed; the calculation here is that it is a sealed container that has an elastic membrane inside. A membrane (balloon or diaphragm) divides the tank into two parts. Air or inert gas under pressure is pumped into one part, and the other part is intended for excess coolant. The membrane inside the tank is elastic, so when the coolant enters there, the volume of the air chamber becomes smaller, the pressure in it increases, thus compensating for the high pressure in the heating system. When cooling, the reverse process occurs.

Construction of closed expansion tanks

A closed expansion tank for heating, a flat tank can be flanged (have a replaceable membrane) or with a non-replaceable membrane. The second type is in quite high demand due to its relatively low cost. But flanged expansion tanks are better in many ways - the pressure here can be higher, and if the membrane ruptures, it can be replaced.

The flanged expansion tank of the heating system can be either vertical or horizontal.

Here, the liquid, when it enters the tank, has no contact with the metal surface, since it is located inside the membrane. If the membrane is damaged, it can be replaced through the flange.

Vertical and horizontal flanged tanks

Tanks that do not have a replaceable membrane are fixed rigidly around the entire perimeter. From the very beginning, the diaphragm is pressed against the inner surface, since the volume of the expansion tank for heating is completely filled with gas. After this, the pressure in the heating expansion tank increases, and the liquid goes inside. When the system starts up, the pressure can rise sharply, so this is when the membrane can be damaged.

Diaphragm expansion tank

How to install?

There are no significant restrictions affecting the installation location of the expansion tank in the system. Nevertheless, it is advisable to carry out the installation at any convenient point in the return line of the existing heating system.

The reason is that the coolant there is cooler. And this allows you to significantly extend the life of the expansion tank and its membrane.

In addition, if you install the tank near a solid fuel boiler, then in certain situations steam may enter the coolant chamber. As a result, the container will lose the ability to compensate for the expansion of the coolant.

Installation of the tank can be done in two ways. These include installation:

- on the wall;

- on the floor.

But it should be understood that the first option is intended only for cases where the expansion tank has a moderate volume.

Tanks should be installed as far as possible from boilers. And the optimal solution would be to locate it in the return line. Since the coolant temperature there is noticeably lower, which eliminates premature failure of the membrane

You should not skimp on connecting the tank to the heating system.

So this procedure should be performed using:

- a shut-off valve with a so-called “American” - this design element will allow you to quickly remove the tank from service and, if necessary, replace it, without waiting for the coolant to cool down;

- a tee with a drain tap, which will allow you to quickly empty it before replacing the tank;

- pressure gauge for measuring pressure;

- safety valve or nipple to regulate the pressure inside the equipment.

After installing the tank, it must be configured correctly, taking into account the manufacturer’s recommendations given in the instructions for the purchased equipment. So that the pressure in the tank is appropriate, i.e. less than in the system, which will allow the membrane to deform when the coolant heats up.

If the calculations were carried out incorrectly and the heating system contains a tank of a smaller volume than required, then it will not cope with its duties, but the error can be corrected.

Why do you need to purchase and install a second container in the system? The capacity of which is the difference between the required volume and that available in the tank operating in the system. This method will reduce financial losses.

Selection of expansion tank

Choosing an expansion tank for heating is a responsible matter. In this case, you should definitely pay attention not only to its type and size, but also to the membrane - the following indicators are important: resistance to the diffusion process, operating temperature range, durability, compliance with sanitary requirements.

Today there is a wide range of expansion tanks for heating systems on the market.

In addition, it is necessary to determine the ratio of the boundaries of the pressure range, which is extremely permissible. Before purchasing a tank, be sure to check whether it meets existing quality and safety standards.

Possible breakdowns

With prolonged use, the membrane may burst.

During operation of the equipment, owners are advised to inspect the housing for leaks and damage every six months. It is also necessary to measure the pressure in the gas chamber. The condition of the membrane is checked once every 2 years. If there is no use for a long time, the water is drained from the tank.

Common faults:

- Pressure drop in the gas compartment - it is necessary to pump air through the nipple using a pump.

- Damage to the housing - mechanical stress or corrosion can cause a crack to appear. The seal of the container can be restored at a service center.

- Leaking from the air valve - due to high loads and hot water, the rubber may crack. It is better to replace the damaged part in a timely manner.

You can repair the equipment yourself. To replace the membrane, you will need to drain the water, remove the container and relieve the pressure. Then unscrew the flange bolts holding the rubber part. The old membrane is removed and replaced with a new one. All procedures are carried out in reverse order.

Calculation of tank volume

First of all, let’s determine the relationship between the required volume and the parameters that influence it. When making calculations, it must be taken into account that the larger the capacity of the heating system and the higher the maximum temperature of the coolant in it, the larger the tank should be. The higher the permissible pressure in the heating expansion tank, the lower it can be. Of course, the calculation method is quite complex, so it is better to consult a specialist. After all, a mistake in choosing an expansion tank can cause frequent operation of the safety valve or other troubles.

The volume is calculated using a special formula. Here the main quantity is the total volume of coolant that is present in the heating system. This value is calculated taking into account the power of the boiler, the number and types of heating devices. Approximate values: radiator – 10.5 l/kW, floor heating system – 17 l/kW, convector – 7 l/kW.

To make a more accurate calculation of a device such as a vacuum expander for heating, the formula is used: Tank volume = (Volume of water in the heating system * Expansion coefficient of the coolant) / Efficiency of the expansion tank. The expansion coefficient for water is 4% when it is heated to 95 degrees. To determine the efficiency of the tank, another formula is used: Tank efficiency = (Highest pressure in the system - Initial pressure in the air chamber) / (Highest pressure in the system + 1).

Expansion tank useful volume coefficients

Thus, the vacuum expansion heating tank is selected taking into account the strength and temperature characteristics, which should not exceed the permissible values at the connection point. The volume of the tank can either be equal to or greater than the result obtained as a result of the calculations.

Common problems

Expansion tanks, like any other heating units, are subject to a number of specific problems. Let's get to know them.

The most common breakdown of such units is the rupture of the membrane part. As a rule, this occurs due to too high pressure (above normal) or uneven loads. Please note that replaceable elements break much more often than compressed ones, since stronger materials are used for the latter, because they can be changed at any convenient time.

The problem of a damaged membrane can lead to many unpleasant consequences. For example, this often causes water to leak from the air valve.

If the membrane is not replaced in time, its rupture will lead to the fact that over time the tank will simply fail. This is due to the fact that liquid gets on the inner surface of the tank, after which it can become covered with rust and become unusable.

Also, users quite often encounter damage to the tank body. If such a problem occurs with your equipment, it is better for you to seek help from a specialist. Do not attempt to repair damaged cabinet elements yourself, especially if you have never encountered such work before.

There are also cases when the expander boils. Most often, this problem occurs in homemade open-type structures. The main essence of this problem is the lack of circulation speed (or its complete absence).

Here are the main reasons for such breakdowns.

- Reduced wiring diameter. The main single-pipe heating circuit is usually installed with a pipe that is no less thin than DN 32.

- No slope. After the heating boiler, you need to make a so-called accelerating manifold. To do this, the pipe must be raised to the upper section of the circuit, where the expander is installed. The remaining part of the contour should be laid with a downward slope.

Many users are wondering how to fix such a serious problem without completely dismantling and reinstalling the heating system. The answer is simple - you need to install a circulation pump. This part works great in many systems (especially the open type). The pump must be placed on the return line directly in front of the boiler.

Another problem with expansion tanks is air blockage in the heating system circuit. To avoid colliding with it, you need to monitor the volume of water.

Installation of expansion tank

Installation of the expansion tank of the heating system is done in accordance with the project and instructions. Your best option would be to have a specialist do this. If this is not possible, then at least consult with him. The installation of an expansion tank for heating, if it is an open type, is carried out at the highest point of the heating system. A closed tank can be placed almost anywhere, but not directly after the pump.

Closed heating system

One of the options for installing an expansion tank in the heating system

It is necessary to pay special attention to such an issue as fastening the heating expansion tank, since the mass of the tank, which is filled with water, increases significantly. Another important point is the possibility and convenience of servicing the tank and free access to it.

Advantages and disadvantages

The rubber is hermetically sealed, so air does not enter the system.

The main advantage of the equipment is the prevention of leaks and other emergency situations that occur during pressure surges. Tanks are necessary in long circuits. They contain a significant volume of water, which, when expanded, creates an increased load on joints, radiators and pipes.

Advantages of the equipment:

- prevents air from entering the line;

- the equipment is designed for water of any quality;

- there is no evaporation of liquid;

- emergency pressure rise is prevented;

- installation possible anywhere;

- Maintenance of the system is simplified; regular refilling of coolant is not required.

The disadvantages include heat loss and the rather high cost of membrane tanks compared to open-type tanks.

Installation Requirements

It is quite possible to install the unit even with your own hands. It is absolutely not necessary to call a specialist for this. The main thing is to strictly follow the installation rules and carry out everything according to the design of the expansion membrane tank.

An expander with a volume of 30 liters or more should not be attached to load-bearing walls. As a rule, large tanks are installed directly on the floor on special steps. During installation, you must ensure that:

- the circumference of the adapter was ¾, and the return had a corresponding thread;

- during the installation process, the structural elements did not interfere with the work;

- no excessive load was placed on the tank;

- you had paronite heat-resistant gaskets at your disposal;

- the container was equipped with a special locking mechanism that allowed the gas pressure to be adjusted.

How it works and what it is needed for

As we have already said, a compensation tank is needed for the efficient uninterrupted operation of the heating system. This device collects the liquid that has expanded as a result of heating, preventing accidents and leaks. During cooling, the coolant is evenly distributed throughout the pipes.

In the absence of an expansion tank, the operating pressure will rise to a critical point of 3 atmospheres, as a result of which the emergency valve will be activated and excess liquid will be discharged. In addition to the heating system, the expansion tank is used in hot water supply.

Expansion tank device

After using hot water from the boiler, this device will fill with cold liquid. During heating, it will have nowhere to go and an accident will occur. The compensation tank serves to prevent such accidents. Instead of a tank in a hot water supply system, you can use an emergency valve, but frequent activation of it leads to leaks and damage to the device.

The main functions of the expansion tank are:

- Collection of excess coolant;

- Filling pipes with water when there is a lack of liquid;

- Collection of accumulated air or water vapor that is released as a result of the operation of the heating system;

- Balancing operating pressure by increasing or decreasing the volume of liquid.

Scheme of operation of an expansion tank

At the moment, you can find many different models of compensation tanks on the construction market. All these devices can be divided into two types: open and closed. Despite the external similarity, the installation of these devices is carried out using different technologies.

Note! Open expansion tanks are used less and less; they are ineffective and require constant refilling of coolant. Closed compensation tanks differ from analogues in their compact overall dimensions. Such devices operate without human intervention.

Open type plastic heating tank

The standard material for an expansion tank is metal, but such containers often corrode when exposed to air and water. The way out of this situation is to install a plastic tank, for example, a plastic 20-liter canister with a cut bottom, or a plastic bucket.

At the bottom of such a container, a tap is installed on an elastic band, then a piece of hose is secured, which is securely fixed in the metal pipeline.

Benefits of using closed appliances

- Small dimensions of the tank, easy installation and maintenance of the tank.

- Tightness (evaporation is excluded, replacement of water with antifreeze is acceptable).

- There is no danger of underfilling (overfilling) or freezing.

- Accelerated heating, automatic regulation.

- Regulation of pressure surges.

- Slight temperature fluctuations in the boiler connection areas.

- No heat losses.

- Adding or decreasing room temperature.

- Installation in a place free for access.

- Narrow pipe diameter – cheaper cost.

The main advantage is versatility: it is possible to include a boiler, convector heater, heated floor, and radiators of different configurations into the system.

Installation instructions

When planning to install the device yourself, we must not forget about the need to first study the installation manual in detail. If you do not have the necessary documentation, you should definitely contact the retail outlet where you purchased the product. Otherwise, understanding the nuances of the equipment will be much more difficult. And every mistake will subsequently only result in additional costs.

According to the advisory document included with the device, design changes are not permitted. Repair or installation work may only be carried out by persons who have access to perform a specific activity.

When replacing a failed tank part, you should replace it with only the original. After all, according to the instructions, it is prohibited to use elements of inadequate quality. The installation manual also contains a detailed description of safety precautions that must be strictly adhered to during installation of the unit.

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)