Rock wool getting wet in the attic can be due to at least a few reasons. Due to a leak or damage to the roof, an incorrectly positioned vapor barrier, lack of ventilation or errors in its execution. Regardless of the reason, the result is the same. Mineral wool is wet. Does this type of cotton wool still fulfill its role? How to dry it?

Mineral wool primarily insulates. In winter it protects from cold, in summer it protects from heat. Increases fire resistance, provides sound insulation, thanks to it the house becomes quieter. When choosing mineral wool, you should bet on products with increased hydrophobization . These are materials from which moisture evaporates very quickly.

Signs that mineral wool is wet may include higher heating bills, increased indoor humidity in the attic, leaks appearing in the eaves or attic, and mold on roof structural members.

It must be remembered that you cannot install wet mineral wool . If it happens that the cotton wool gets wet during transportation or storage, you should first unroll it and dry it thoroughly. Only after it has dried can you begin to install it.

Properties and application features of the material

The main property that determines the effectiveness of a particular insulation is the thermal conductivity coefficient.

It characterizes the heat loss occurring through a layer of material 1 m thick in an area of 1 m2 for 1 hour with a temperature difference on opposite surfaces of 10 ° C.

For various forms of mineral wool, this figure is 0.03 – 0.045 W/(m*K).

A distinctive feature of fiber insulation is the dependence of their thermal insulation properties on moisture content.

When wet, droplets of water envelop the fibers and gradually penetrate into the volumetric structure, gradually displacing air from there.

An increase in the amount of water inside, between the fibers, leads to a sharp drop in thermal insulation characteristics. The situation is further aggravated by the fact that water that gets inside is extremely difficult to remove outside.

The insulation can absorb up to 70% of its mass in water. Naturally, under these conditions, the efficiency of its work will tend to zero.

Despite the criticality of getting wet, the scope of application of mineral wool is extremely wide. When building a house, its use is possible almost everywhere where direct contact with water is excluded:

- Hollow walls (frame and brick, made using well masonry technology);

- External surface of wooden or brick walls;

- Internal partitions;

- Floors;

- Interfloor ceilings;

- Roof.

Mineral wool as an excellent insulation material: practical tips for use

Mineral fiber, being one of the most popular insulation options for construction today, has a number of qualities that guarantee low thermal conductivity and high resistance to external influences. Mineral wool offers ample opportunities for maintaining optimal temperature conditions in the room with a relatively simple method of installation.

Compliance with simple rules that are recommended to be followed when working with insulation such as mineral wool will ensure guaranteed high quality work and long-term preservation of its heat-insulating properties.

Necessary information for working with mineral wool

The specificity of the installation of mineral wool, its transportation and storage is to provide the conditions necessary to preserve its qualities for the longest possible time. Typically, recommendations are given by manufacturers for a specific brand and type of material, however, there are a number of simple universal rules that must be followed when working specifically with mineral wool.

Basalt mineral wool: transport and store correctly

Transportation with subsequent storage has its own characteristics, since mineral wool for insulation can quickly absorb moisture from the air. Therefore, transporting it in closed vehicles with subsequent storage in dry rooms is a prerequisite to prevent loss of the most important qualities.

Additional recommendations on transportation conditions and storage features of mineral wool include:

- Mats should be transported and stored compressed and in packages - this makes it possible to reduce the occupied volume.

Protection of wool during installation

To prevent the basalt insulation from getting wet during installation, it is worth protecting the installation site from rain. For this purpose it is very convenient to use inventory scaffolding. And on these scaffoldings, lay boards along the upper rungs of the top row and stretch the film.

It will turn out cheap and cheerful. Not only the building materials will be dry, but also the installers themselves who work on the walls.

To drain rainwater from film roofs on scaffolds, the easiest way is to use 3-4 drainage pipes with a diameter of 110 mm, into which the water accumulating on the film will be drained. This will allow you not to get wet under an unexpected “waterfall”, when water that does not have a drain bends the film and rushes down in an “unfortunate” place.

Reasons for getting wet insulation on the roof

First:

the hydrobarrier or superdiffusion membrane was damaged during installation. That is, the seal of the film is broken with a self-tapping screw or nail. Also, quite often, this occurs due to excessive tension of the hydraulic barrier. According to the standards, it must be installed with a slight sag, so as not to create tension in the material, and so that condensate water can be collected and discharged at the sagging point.

The second reason could be

— lack of gluing at the joints of the canvases, which leads to the penetration of condensate moisture by rising wind currents.

The third reason

is poor fastening at the junction of the chimney and ventilation pipes. It should be noted that the edges of the hydrobarrier must be fixed vertically, upward, to the wall, and a pressure bar must be installed.

The fourth reason

may be the use of low-quality superdiffusion membranes, which are often present in cheap segments.

These are the main reasons that occur when working with hydraulic barriers. But water in the insulation can also appear due to poor installation of the vapor barrier.

This happens especially often when wet work is being carried out in the house in the autumn-winter time, and the roof is already insulated. At the same time, the difference in temperatures inside and outside is noticeable, and all the condensation, rushing upward, gets into the insulation if your vapor barrier is not glued, or is not glued tightly at the joints.

Check the tightness of the films until they are completely closed, be sure to glue the joints and abutments to the walls.

What to do with the insulation if it is already wet?

Take it out and dry it, or buy new insulation. But you can’t leave it wet in the rafters, as mold may form on the wood.

Remember that only professional builders, or the developers themselves who have thoroughly studied these technologies, should carry out insulation work.

Rock wool getting wet in the attic can be due to at least a few reasons. Due to a leak or damage to the roof, an incorrectly positioned vapor barrier, lack of ventilation or errors in its execution. Regardless of the reason, the result is the same. Mineral wool is wet. Does this type of cotton wool still fulfill its role? How to dry it?

Mineral wool primarily insulates. In winter it protects from cold, in summer it protects from heat. Increases fire resistance, provides sound insulation, thanks to it the house becomes quieter. When choosing mineral wool, you should bet on products with increased hydrophobization

. These are materials from which moisture evaporates very quickly.

You must remember that you cannot install wet mineral wool.

. If it happens that the cotton wool gets wet during transportation or storage, you should first unroll it and dry it thoroughly. Only after it has dried can you begin to install it.

Technology of insulating the facade of a house with mineral wool under plaster

Unlike wool for interior work, façade mineral wool is denser and hydrophobic (repels water).

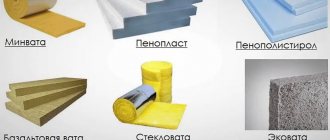

Mineral wool for insulating the outside of a wooden, brick and other house is produced exclusively in the form of slabs with dimensions of 0.6x1.2 m and 0.5x1 m. The thickness of the material can be 5, 10, 15 cm. The most popular type is 10-centimeter mineral wool slabs . Mineral wool is available in three varieties: basalt; fiberglass; slag

At the same time, basalt glass wool, due to its record low thermal conductivity, is considered the best option for insulating the outside of a wooden house.

Pros and cons of using mineral wool for external thermal insulation of a house The popularity of insulation is due, first of all, to: the low thermal conductivity of the material, and consequently, high thermal insulation characteristics; excellent sound insulation; good level of fire safety (after all, mineral wool does not support combustion); vapor permeability (provides “breathing” of the house, which is especially important if the house is not wooden, but stone); resistance to fungi and rodents; relative environmental friendliness and safety of the material (harmful substances are released only when heated to more than 300 ° C); simplicity of installation technology.

As disadvantages it is worth noting:

change in the volume of insulation and the appearance of cracks in it (occurs only when there is no reinforcing layer); If mineral wool is not treated with a hydrophobic solution, all its thermal insulation characteristics will come to naught, because it almost instantly absorbs moisture. Materials and tools for performing the work To install insulation under plaster you will need:

guide profiles; building level; glue; mineral wool; mesh for reinforcement; spatula and facade plaster; dowels Preparing the surface of the facade Before starting to work with insulation and plaster, it is necessary to clean the surface of the walls from oil stains and dirt and level them. According to technology, all metal elements that may rust must be removed from the walls outside. If these are strategically important metal elements, then it is necessary to ensure the flow of oxygen under the plaster, i.e. this immediately excludes the use of acrylic-based plaster.

The principle of facade insulation with mineral wool

The insulation material must have low thermal conductivity. Therefore, mineral wool, namely its variety with a density of 140 kg/m2, is ideal.

If there are remnants of the old coating on the walls, be it paint, plaster or anything else, then insulation cannot be placed under the plaster. Before starting insulation, it is worth using sags to mark the boundaries of the zones. Sags are strong nylon cords pulled between the reinforcement pins (these pins must then be removed, so do not drive them in too tightly), fixed at a designated point in a vertical, horizontal position and diagonally. Sags are installed to evaluate wall geometry Once the sags are installed, it becomes much easier to evaluate the wall geometry. The sags must be attached so that they retreat at least 1 cm from the mineral wool. After the wall is marked, you can begin installing the guide profiles.

There are three such basic stages: Installation of thermal insulation. Reinforcement. Carrying out decorative finishing.

Stages of insulating a façade with mineral wool Scheme of an insulation cake with installation of mineral wool First of all, it is worth installing a base profile or strip into the wall, which will serve as a supporting guide for the first row of insulating material; in addition, it will control the gap between the bottom row of mineral wool and the wall, and also protect the mineral wool from penetration of rodents and pests. It is also important that the profiles protect the plaster layer from mechanical deformation and tightly join the plaster with expansion joints. The façade is insulated using mineral wool with a density of 140 kg/m2. Mineral wool is fixed to the load-bearing walls of the facade using driven dowels or special glue. After this, a strip of reinforcing mesh (width from 25 to 35 cm) should be attached directly to the mineral wool under the profile. After the reinforcement is glued to the mineral wool, the lower edge of this mesh can be wrapped onto the profile, which completely insulates and makes the insulation monolithic. The reinforcing construction mesh is attached to the mineral wool using adhesive-reinforcing plaster.

Thermal insulation of the facade with mineral wool. The reinforcing mesh prevents the mineral wool from destruction. To decorate the mineral wool slabs, you can use decorative plaster on a silicate, mineral, acrylic or silicone base. After the plaster has dried, it can be painted with any color that suits the overall color scheme of the façade. It is extremely important that all materials used in the work are suitable for each other in all respects. For example, thermal insulation and plaster must be compatible with each other regarding the thermal expansion parameter, have the same thermal conductivity coefficient and approximately the same level of hygroscopicity. If you ignore the rules for compatibility of materials, the plaster will crack and crumble extremely quickly, and the insulation will reduce its effectiveness.

Ventilation without errors

One of the more common causes of damp mineral wool is problems associated with roof ventilation. Good ventilation allows air to circulate over the insulation, which allows condensation to systematically evaporate from it

This is why careful design of roof ventilation is so important.

Arkady Shchelyunin, Astrakhan. Question: Good afternoon, it’s raining, autumn. We didn’t have time to make cotton wool on the façade of the expanded clay concrete house. What should we do now? It rains every day. We are afraid that the cotton wool will get wet. Then winter. How to dry it?

Sergey Zaitsev, Moscow, specialist.

Answer: Good afternoon, Arkady. In answer to your question, I can advise you the following. First of all, you are right. If it falls under heavy and prolonged rain, it will absorb moisture. Despite all the advertising assurances of the manufacturers, in the photo with beautiful drops of water on the cotton wool, however, basalt insulation absorbs moisture very well.

Therefore, you can’t get it wet in heavy rain. If during the installation process the cotton wool on the walls gets wet by rain, it’s not a big deal. But if you leave it in the rain for a day, then you won’t be able to really dry it before installation.

So, we do 3 things.

Advantages and disadvantages of floor insulation with mineral wool

- This coating does not burn in fire. It can withstand temperatures up to a thousand degrees Celsius and does not lose its properties.

Mineral wool is resistant to high temperatures

- Mineral wool can act as a sound insulator.

- Mineral wool is a relatively inexpensive insulation product.

- This material does not need to be replaced throughout its entire service life.

- Simple installation process.

Mineral wool, like any floor insulation product, has disadvantages. One of them is good absorbency. For this reason, experts do not recommend using mineral wool in a damp room, such as a bathroom. However, it is possible to avoid swelling of this coating.

Why does mineral wool get wet?

The thermal conductivity coefficient of mineral fibers is 0.031-0.042 W/m2 *K. This means that a layer of glass wool 5 cm thick is equal to the thermal effect of a meter-long brick wall. But the thermal insulation properties disappear when moisture penetrates the fibers.

Reasons for getting wet:

- The waterproofing membrane was damaged when laying insulation. They pulled the canvas too tight and accidentally pierced it with a nail or self-tapping screw.

- The film joints were not taped. As a result, condensation penetrates into the mineral wool fibers.

- The waterproofing near ventilation and chimneys was not fixed tightly enough.

- A low-quality diffuse membrane was used.

Risk of getting wet: the dangers of damp insulation

Wait for the wet roof insulation

will dry on its own - a dangerous misconception. Wet mineral wool does not retain heat. In addition, it becomes a source of unpleasant odors, the spread of mold and bacteria. Well, and the “cherry” in the troubles of the roofing pie: wooden rafters are destroyed, metal structural elements rust at an accelerated pace. The result is a major roof repair.

To avoid problems, check the condition of the insulation:

- if there are streaks or drops on the walls of the attic;

- cracks have appeared on the roof, the roofing elements do not fit tightly;

- In places where snow accumulated, the roof sagged.

Wet business: what to do with wet insulation

Having discovered that the thermal insulation is wet, there are two options for the development of events. If the fibers are wet only on top and in a small area, it is possible to dry this area. This requires two conditions: a draft and clear, warm weather.

URSA experts recommend replacing insulation that is wet through. The main thing is to avoid making the same mistakes when installing new material.

How to fix the problem and keep the insulation dry

To protect your newly insulated roof from getting wet, consider these professional tips:

- It is advisable to carry out installation in dry weather;

- before installing mineral wool, cut the waterproofing film into layers of the required length;

- Having fixed the insulation, immediately cover it with a protective membrane;

- glue the joints of the film, secure it to the rafters with a construction stapler;

- Walk only on the boardwalk so as not to tear the waterproofing.

You can select a special insulation material for pitched roofs and waterproofing for it at https://www.ursa.ru/construction-solutions/skatnie-krishi/.

Proven materials, competent installation and the roof will remain dry in any weather!

Question:

Hello. My insulation material got wet on the roof - . The company's builders say that it is rock-solid and it will dry out quickly. Is it true? What could be the consequences of getting Rockwool, a thermal insulation material, wet?

Konstantin

Answer:

Hello, Konstantin.

The insulation material could become wet for the following reasons:

1. Leaking roof covering.

2. The integrity of the vapor barrier layer has been compromised.

It is true that mineral wool can dry out after being moistened, but certain conditions must be observed. It is necessary to ensure that air can move freely in the under-roof space. It is thanks to this that moisture will be removed from the insulating material. To achieve this, you need to make a ventilation gap, which can be either single or double, it all depends on the type of structure.

Based on our experience in thermal insulation, we can say that a properly installed and well-ventilated under-roof space will help dry the wet insulation and the already dried material will not lose its thermal performance.

You need to find out why it got wet and eliminate the cause. If everything is clear about the leak, then most cases of the thermal insulation material getting wet is the lack of a vapor-proof layer or lining when installing the thermal insulation. A common mistake is poor sealing of seams with double-sided tape or failure to glue overlaps at all. When laying vapor barrier films, it is necessary to glue all 10-centimeter overlaps with double-sided tape.

Don’t forget to inspect the rafter system to see what happened to it when it got wet. Wood structures also dry out, but not as quickly as mineral wool insulation. To ensure better preservation of the rafter system, all wooden parts must be treated with an antiseptic; it will help the tree not absorb water so quickly.

Construction forum

What to do if mineral wool insulation gets wet? Will the insulation retain its properties if it gets wet after drying? These questions often arise when, for some reason, the insulation is wet and obvious traces of wetting and even absorbed water are visible on it. We answer. Mineral basalt wool ROKVUL, IZOROK, KHITROK, IZOMIN, ISOVOL and other similar type of insulation are produced HYDROPHOBIZED, that is, they are impregnated with a binder that has the property of repelling water and, in principle, water that gets on the insulation rolls off and is not absorbed. If the mineral wool is still saturated with water, then the moment is more serious, but not fatal! If you provide sufficient conditions for the insulation to dry!!! then your basalt wool, and Ursa, Uteplit, Izover fiberglass, WILL DRY and will work like normal thermal insulation. Wet insulation loses its properties if the water-saturated areas of the insulation are exposed to negative temperatures... it will simply turn into ice and everything!!! Your structure will freeze. Therefore, it is necessary to provide conditions for drying (most likely this is in the warm season or spring). Or you need to change the insulation if the structure is frozen and there is no time to wait for the heat to dry out the insulation. We remind you that the insulation of their extruded polystyrene foam PRIMAPLEX, PENOPLEX, TEPLEX does not get wet and is not afraid of the external environment.

Protecting wool from rain before installation

We store the finished cotton wool in bales right next to the walls, preferably indoors. In this case, it can be supplied for mounting on walls in windows of the first or second floor, as is more convenient.

Next, if the wall is blank, we make a temporary canopy next to it from boards and film. Nothing global is needed, the main thing is that the water flows onto the ground and not onto the cotton wool. Although it is packed in film bales, this is not protection from heavy rain.

Further, we understand that in heavy rain, especially during prolonged autumn storms, all the water is underfoot, the earth does not have time to absorb such an amount of water. We do not place cotton wool in bales or sheets on the ground, even under a canopy. It is best to use the most common wooden pallets. Their height, 15 cm, is enough to prevent the cotton wool from getting wet from the ground.

In what form is it produced?

Basalt wool is produced in rolls, slabs and cylindrical shapes. The softest material is contained in rolls, in slabs of medium and high hardness. And the cylindrical shape is intended for insulating pipelines.

Double insulation of stone wool - foiling. Stone wool covered with foil is universal; it not only does not release precious heat, but also reflects it and directs it back into the room.

When is a ventilation gap needed? ventilation gap in a frame house

So, if you are thinking about whether a ventilation gap is needed in the facade of your carcass house, pay attention to the following list:

- When wet If the insulation material loses its properties when wet, then a gap is necessary, otherwise all work, for example, on insulating a home, will be completely in vain

- Steam Permeation The material from which the walls of your home are made allows steam to pass through into the outer layer. Here, without organizing free space between the surface of the walls and insulation, it is simply necessary.

- Preventing excess moisture One of the most common questions is: is there a need for a ventilation gap between vapor barriers? If the finish is a vapor barrier or moisture-condensing material, it must be constantly ventilated so that excess water is not retained in its structure.

As for the last point, the list of similar models includes the following types of cladding: vinyl and metal siding, profiled sheets. If they are tightly sewn onto a flat wall, then the remaining accumulated water will have nowhere to escape. As a result, materials quickly lose their properties and also begin to deteriorate externally.

Is there a need for a ventilation gap between siding and OSB?

When answering the question of whether a ventilation gap is needed between the siding and OSB (from English - OSB), it is also necessary to mention its need. As already mentioned, siding is a product that insulates vapor, and the OSB board consists of wood chips, which easily accumulate residual moisture and can quickly deteriorate under its influence.

Additional reasons to use a ventilation gap

Let's look at a few more mandatory points when clearance is a necessary aspect:

- Preventing the formation of rot and cracks The wall material under the decorative layer is prone to deformation and deterioration under the influence of moisture. To prevent rot and cracks from forming, just ventilate the surface, and everything will be fine.

- Preventing condensation The material of the decorative layer can contribute to the formation of condensation. This excess water must be removed immediately.

For example, if the walls of your house are made of wood, then an increased level of moisture will negatively affect the condition of the material. Wood swells, begins to rot, and microorganisms and bacteria can easily settle inside it. Of course, a small amount of moisture will collect inside, but not on the wall, but on a special metal layer, from which the liquid begins to evaporate and be carried away with the wind.

Remove, dry, install

It’s worse when the mineral wool that is already installed in the attic gets wet. Then it needs to be dismantled, dried and installed again. This is very important, because wet mineral wool loses its properties. The drier it is, the better its parameters. Water that penetrates the cotton reduces its effectiveness. Even a small amount of water can significantly reduce its parameters. Wet mineral wool does not fulfill its purpose. Instead of insulating, it conducts heat. If there is wet mineral wool in the roof, thermal insulation is reduced and heating bills increase. Wet insulation also has a negative effect on wooden structures, it contributes to the moisture of the rafters, and, as you know, dampness is the main enemy of wood.

Protection of basalt insulation after installation

Well, of course, immediately after installing a section of basalt insulation on the wall, this section is closed. This protects the already installed wool on the walls from slanting rain.

The membrane itself does not tolerate ultraviolet radiation very well, so you should not hesitate with the subsequent decorative coating - siding or any other that you have chosen.

If you are not doing a ventilated façade, but rather, then there is no need to worry too much here. The plaster layer will easily cover the cotton wool, but it will still get a little wet during the installation process.

- The question is asked by Andrey Sukhorukov, Perm: Hello, dear colleagues! I would like to clarify with you how you can protect vinyl siding from the sun and frost? I look at the neighbors...

- Do rising prices for electricity and gas make you personally think about saving energy resources? Try to answer this question honestly. If yes, then this material...

Thermal insulation of an attic roof means three benefits in one solution. Firstly, the house becomes noticeably warmer. Secondly, heating costs are reduced by 30-50%. Well, and thirdly: a residential floor appears. They finished the walls and got cozy rooms under a roof instead of a cluttered attic.

A popular roofing insulation is mineral wool. A material with excellent performance characteristics, non-flammable and affordable.

When is a ventilation gap still necessary?

In what other cases will you need a ventilation gap between the wall and the decorative covering:

- The material of the decorative layer promotes the formation of condensation.

- The wall material under the decorative layer can deteriorate from moisture (rot, cracks, etc.).

Otherwise, all the moisture that will condense on the inner surface of the corrugated sheet will be absorbed, which will be destroyed as a result.

In the case of a ventilation gap, moisture, of course, condenses on the inner surface of the profiled sheet - this is metal. But it does not have direct contact with the surface of wooden walls. And the air current that is present in the ventilation gap carries away this moisture in the form of steam and removes it from the space between the decorative layer and the wall.

Consider which of the above cases is yours and choose whether you need a ventilation gap or not. See what kind of wall material you have.

- Question: Good afternoon, dear gentlemen! Please tell us how best to decorate the outside of a house made of expanded clay concrete blocks (ECB), what façade would be appropriate here, what materials can be used?…

- Recently, people have begun to give preference to wooden houses. The first thing that attracts this natural material is its environmental friendliness. In addition to this, the tree is very good...

- This page shows a sectional view of a frame wall along with insulation, which is mounted between the frame posts. Simply put, a frame wall in cross-section looks like this...

- If you look at the history of the construction of residential buildings in cold regions, insulating walls with sawdust began to be practiced not so long ago. Sawdust as wall insulation during construction...

- The simplest design of the walls of a frame house is vertical posts connected by upper and lower frames and tied with jibs for additional structural rigidity. When using slab…

The ventilation gap in a frame house is a point that often raises many questions among people who are involved in insulating their own home. These questions arise for a reason, since the need for a ventilation gap is a factor that has a huge number of nuances, which we will talk about in today’s article.

The gap itself is the space that is located between the sheathing and the wall of the house. A similar solution is implemented using bars that are attached on top of the wind barrier membrane and on the external finishing elements. For example, the same siding is always attached to bars that make the facade ventilated. A special film is often used as insulation, with the help of which the house, in fact, is completely wrapped.

Many will rightly ask, is it really not possible to just take and attach the sheathing directly to the wall? Do they just line up and form an ideal area for installing sheathing? In fact, there are a number of rules that determine the necessity or unnecessaryness of organizing a ventilation facade. Let's figure out whether a ventilation gap is needed in a frame house?

When is a vapor barrier necessary?

It is definitely enough to simply formulate the condition of whether a vapor barrier is needed. When insulating with mineral wool, protection from water vapor will be needed when there is a possibility of contact with air coming from the room.

To ensure effective operation, each layer of the thermal insulation “pie” must allow air to pass through to one degree or another. In the direction from room to street, this ability should increase.

Thus, warm air from the room very slowly seeps between the fibers, displacing cold air from there.

These can be vertical frame posts, floor joists or rafters. A wind-waterproofing barrier is installed on the outside (external) side, protecting from the effects of precipitation and strong direct wind.

This scheme is valid when constructing frame walls, floors, attic roofs, and the ceiling of a residential floor in the presence of a cold attic above.

Internal partitions and ceilings between living spaces require a slightly different approach. In this case, humid air can penetrate the mineral wool from any side. To maintain the thermal characteristics of the structure, a vapor barrier is installed on both sides.

Excess moisture is removed through a ventilation gap left under the outer decorative facade.

How to properly insulate a roof to prevent condensation from forming?

When dampness appears on the ceiling, it can lead to serious damage to the roof structures. A humid indoor climate is a common cause of diseases and allergic reactions. To remove the cause of waterlogging, you need to perform proper installation of thermal insulation. Read our article on how to properly insulate a roof to prevent condensation from forming.

How does condensation form, the reasons for its accumulation under the roof arch?

Condensation is water, but how does it get to the ceiling and roof elements? To understand this you need an understanding of thermophysical processes.

There is always moisture in the air in the home in the form of steam. So water can be in a warm air mass. However, when a cold object is encountered in the path of the air flow, all the moisture falls into drops, that is, condensation forms.

Since warm air masses rush upward, and there they are met by a cold roofing structure, all the condensation goes to the roof. An uninsulated roof is a prime candidate for getting wet and should be insulated immediately. But the worst thing is not a wet roof, but the consequences when the metal elements of the roof begin to corrode, and the wooden elements become damp and lose their strength.

How to insulate a roof and get rid of condensation?

The main task of thermal insulation is to move the dew point outside the structure of the house. That is, make sure that the temperature at which steam turns into condensate is outside the roofing pie. Then the moist air in the house will circulate freely and moisture will not form on cold surfaces.

Secrets of roof insulation?

You can insulate absolutely any roof, be it a flat surface or a pitched roof. A universal solution is Rockwool mineral wool, available in different modifications. The springy edges of the mineral wool allow the slabs to easily fit into the attic frame; the products also withstand the load of existing roofs well.