Today's daily life is not possible without heating systems. Throughout its development, heating equipment has received more and more functional elements, and one of these improvements is the expansion tank. But what exactly is this part for? As you know, when water is heated, it increases its volume and decreases its density. In closed systems, excess moisture remains inside the pipes, increasing the likelihood of equipment failure. And it is the expansion tank that collects all the excess moisture, thereby protecting your equipment, and accordingly, the room.

Why do you need an expansion tank for heating?

When the heating system operates, the coolant often changes its temperature - it either heats up or cools down. It is clear that the volume of liquid changes. It either increases or decreases. Excess coolant is forced out into the expansion tank. So the purpose of this device is to compensate for changes in the volume of coolant.

Operating principle of an expansion tank for heating

Types and device

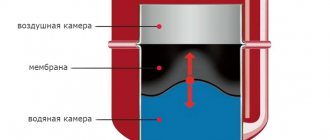

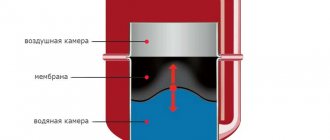

There are two water heating systems - open and closed. In a closed system, coolant circulation is provided by a circulation pump. It does not create additional pressure, it simply pushes water at a given speed through the pipes. In such a heating system there is a closed expansion tank for heating. It is called closed because it is a sealed container, which is divided into two parts by an elastic membrane. In one part there is air, in the other the excess coolant is displaced. Due to the presence of a membrane, the tank is also called a membrane tank.

Closed type

An open heating system does not require a circulation pump. In this case, an expansion tank for heating is simply any container - even a bucket - to which heating pipes are connected. It doesn't even require a lid, although it may have one.

Open type

In the simplest version, it is a container welded from metal, which is installed in the attic. This option has a significant drawback. Since the tank is not sealed, the coolant evaporates and it is necessary to monitor its quantity - top up all the time. This can be done manually - from a bucket. This is not very convenient - there is a risk of forgetting to replenish water supplies. This threatens to cause the system to become airy, which can lead to its breakdown.

Automated water level control is more convenient. True, then, in addition to the heating pipes, you will also have to run a water supply into the attic and also somewhere to route the overflow hose (pipe) in case the tank overflows. But there is no need to regularly check the amount of coolant.

The main functions of an expansion tank for heating or why is it needed at all?

The expansion tank in individual heating systems has the important role of receiving excess coolant water. When heated, water can change its volume, and in heating systems the temperature of the coolant is not a constant value. Thus, when creating a completely closed, sealed hot water circulation system, there is a significant risk of rupture of the connecting elements due to increased pressure. Water is a practically incompressible substance and even the most reliable connection made of soldered plastic, as well as any metal, cannot resist its pressure.

Let's look at how an expansion tank works in an individual heating system, what types of expansion tanks there are, how to choose the right equipment and what subtleties need to be taken into account when installing it in a private home.

Operating principles of the expansion tank

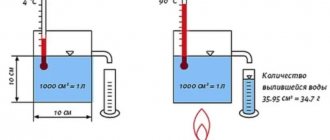

Let's give a simple physical example. Let’s say the temperature of the liquid coolant, water, in our heating system has risen by only 10 degrees. This may be due to more intense operation of the heating device caused by the lower temperature outside. After such a temperature rise, the volume of water circulating in the closed system will increase by 0.3 percent.

It would seem - not a very large value. However, water (or antifreeze used as a coolant) is incompressible, that is, strong excess pressure gradually builds up in the system. To prevent such pressure from destroying the connecting elements of the heating system, the water must be given space to expand. This space will be the expansion tank. When the coolant is cold, it is not completely filled, but when heated, the water level in it increases, which maintains the pressure in the water circulation system at a normal level.

Volume calculation

There is a very simple method for determining the volume of an expansion tank for heating: 10% of the volume of coolant in the system is calculated. You should have calculated it when developing the project. If this data is not available, you can determine the volume experimentally - drain the coolant, and then fill in a new one, measuring it at the same time (put it through a meter). The second way is to calculate. Determine the volume of pipes in the system, add the volume of radiators. This will be the volume of the heating system. From this figure we find 10%.

Shape may vary

Formula

The second way to determine the volume of an expansion tank for heating is to calculate it using the formula. Here you will also need the system volume (indicated by the letter C), but other data will also be needed:

- the maximum pressure Pmax at which the system can operate (usually the maximum boiler pressure is taken);

- initial pressure Pmin - from which the system begins operation (this is the pressure in the expansion tank, indicated in the passport);

- coolant expansion coefficient E (for water 0.04 or 0.05, for antifreeze it is indicated on the label, but usually in the range of 0.1-0.13);

Having all these values, we calculate the exact volume of the expansion tank for the heating system using the formula:

Formula for calculating the volume of an expansion tank for heating

The calculations are not very complicated, but is it worth bothering with them? If the system is open, the answer is clear - no. The cost of the container does not depend very much on the volume, plus you can make it yourself.

Expansion tanks for closed type heating are worth counting. Their price depends greatly on volume. But, in this case, it is better to take it with a reserve, since insufficient volume leads to rapid wear of the system or even its failure.

If the boiler has an expansion tank, but its capacity is not enough for your system, install a second one. In total, they should give the required volume (the installation is no different).

What will result from insufficient expansion tank volume?

When heated, the coolant expands, its excess ends up in the expansion tank for heating. If all the excess does not fit, it is released through the emergency pressure relief valve. That is, the coolant goes into the sewer.

Working principle in graphical representation

Then, when the temperature drops, the volume of coolant decreases. But since there is already less of it in the system than there was, the pressure in the system drops. If the lack of volume is insignificant, such a decrease may not be critical, but if it is too small, the boiler may not work. This equipment has a lower pressure limit at which it is operational. When the lower limit is reached, the equipment is locked. If you are at home at this time, you can correct the situation by adding coolant. If you are not there, the system may unfreeze. By the way, working at the limit also does not lead to anything good - the equipment quickly breaks down. Therefore, it is better to play it safe and take a slightly larger volume.

Calculation of tank volume

To determine the volume of the tank, you can follow the simplest path. That is, take 10% of the volume of coolant used, which is calculated at the design stage of the heating system. Or you can drain the old coolant and fill in a new one, measuring the volume with a meter.

You can also find out the volume of radiators and pipes, this way you will get the volume of the heating system, from which you will need to take 10%.

There is also a way to calculate the tank using the formula:

V=(E*C*(Pmax+1))/(Pmax+Pmin), where

E – coefficient of expansion of the coolant indicated on the packaging,

Pmax and Pmin are the maximum and minimum operating pressure of the system, respectively.

It should be said that for an open heating system no calculations need to be made, but for a closed one it is still worthwhile. Moreover, if the boiler already has a built-in tank, if its volume is insufficient, a new one is installed.

If there is insufficient tank volume, the volume of coolant decreases and the pressure in the heating system drops as it begins to drain into the sewer. If there is a critical shortage of coolant, the operation of the boiler may simply stall.

If you are at home at this moment, you will just need to add coolant. If you are not at home, the heating system will begin to defrost. And there is nothing good about operating a boiler in critical condition either.

Therefore, it is always better to carry out similar calculations and purchase a slightly larger tank than required.

Tank pressure

In some boilers (usually gas ones), the passport indicates what pressure must be set on the expander. If there is no such record, for normal operation of the system, the pressure in the tank should be 0.2-0.3 atm lower than the working one.

The heating system of a low-rise private house usually operates at 1.5-1.8 atm. Accordingly, there should be 1.2-1.6 atm in the tank. The pressure is measured with a conventional pressure gauge, which is connected to a nipple located in the upper part of the container. The nipple is hidden under a plastic cover; unscrew it and gain access to the spool. You can also relieve excess pressure through it. The principle of operation is the same as that of a car spool - you bend the plate with something thin, bleeding the air to the required levels.

Where is the inflation nipple located?

You can also increase the pressure in the expansion tank. To do this, you will need a car pump with a pressure gauge. Connect it to the nipple and pump it up to the required readings.

All of the above procedures are carried out with the tank disconnected from the system. If it is already installed, there is no need to remove it. You can check the pressure in the expansion tank of the heating system on site. Just be careful! It is necessary to check and adjust the pressure in the expansion tank for heating when the system is not working and the coolant has been drained from the boiler. For the accuracy of measurements and tank settings, it is important that the pressure on the boiler is zero. That’s why we drain the water carefully. Then we connect the pump with a pressure gauge and adjust the parameters.

How to select and install an expansion tank

First of all, the selected expansion tank must correspond in its geometric dimensions to the volume of coolant in the system. Pay special attention to this when choosing. Purchasing an excessively small tank can reduce its effectiveness to zero.

Pay special attention to the characteristics of the membrane device. It must maintain its operating properties over the entire temperature range planned in the heating system. Also, the membrane must withstand possible pressure surges, for which it must have a certain margin of flexibility.

It is necessary to install an expansion tank in the heating system of a private house according to a prepared project; if you yourself are not able to prepare such a project, be sure to seek help from professionals!

Remember that open tanks for expansion of coolant can only be installed in the upper part of the heating system. They usually have a threaded connection located at the bottom of the device.

In this case, a closed expansion tank can be installed anywhere in the heating system. It is desirable that its installation location be located directly after the circulation pump in the direction of movement of the coolant .

tank installation

Please note that an expansion tank of any type, when filled with water, significantly increases its mass, which imposes additional requirements on the strength of its fastening system. Provide free access to the heating tank, especially for devices with a replaceable membrane.

When installing an expansion tank, a pressure gauge and a safety valve are also installed in the heating system, which will serve as the “last line of defense” in case of unplanned excessive expansion of the coolant.

If you carefully select and install everything correctly, you can be sure of long and uninterrupted operation of the heating circuits.

Where to put it in the system

The expansion tank in a closed system is placed after the boiler before the pump, that is, so that it creates a flow in the opposite direction. This way the system works more reliably. So the specific installation location depends on where you have the circulation pump.

Installation diagram of an expansion tank for heating

It is connected to the system via a tee. You cut a tee into the pipe, direct the perpendicular outlet upward, and screw the tank onto it. If the wall does not allow you to place a container, you will have to make an elbow, but the tank will be turned upward. Now we can assume that the expansion tank is installed.

Installation example with tap

But for the convenience of checking, it is advisable to install another tee after the tank, and install a shut-off valve on the free outlet of it. This makes it possible to check the membrane tank without draining the entire system - it cuts off the tank. Turn off the tap and bleed water from the boiler. Check the pressure on the disconnected branch (in the boiler). It must be zero. Afterwards, you can carry out all other setup work.

Advantages of a closed heating system

- The first advantage of a closed heating system is that the tank can be installed wherever it is convenient for you, but in an open one, only in the attic or at some other high point in the system. And due to the tightness, the coolant practically does not evaporate.

- The coolant is always saturated with air in an open heating system, which leads to corrosion in heating pipes and radiators. In a closed environment, as you understand, this cannot happen.

- In a closed system, there are fewer losses in the tank than in an open system, which heats up very quickly and has increased sensitivity. Plus, the temperature difference in a closed system is smaller, which allows you to use heating equipment longer.

- The closed system is suitable for a wide variety of radiators, convectors and air curtains; you can connect a “warm floor” system. Plus, you can add an indirect heating boiler for domestic hot water to a closed system.

Criterias of choice

First of all, the tank is selected based on the volume of water that can be stored there. There are containers on sale from 24 to 1000 liters. In this case, the volume of liquid occupies only 30% of the total. This is necessary to build up the required pressure.

A feature of small-volume tanks is the absence of a nipple to remove excess air. This may create inconvenience during operation. Large tanks are better at maintaining constant pressure in the system, have a nipple and are more versatile in maintenance.

Depending on the available space for installing a storage tank, you can choose a horizontal or vertical model. In horizontal ones the volume is always smaller; they can be mounted on the wall. Vertical ones have legs for installation; the volume of liquid in them is larger.

In addition to these two indicators, the selection is made taking into account the following criteria:

- the pressure that can be created in the system thanks to the membrane tank;

- Is it possible to periodically change the membrane or is it permanent;

- Is it possible to store drinking water or is rubber intended only for technical fluids;

- case material – steel or plastic.

For a family of 2 – 3 people, a capacity of up to 25 liters is sufficient. If there are more people and a pump is installed that pumps about 3.5 tons of water per hour, you can install a container with a volume of 50 liters. For very high flow rates, for example in an apartment building, a 100 liter tank is suitable.

Installation stages

Sometimes, in addition to the main tank, it is necessary to install smaller containers. In this case, the displacement will be calculated taking into account all the tanks included in the system.

After choosing a model, you must follow the rules for installation:

- the diameter of the pipes must be the same or larger than the inlet opening of the tank;

- fittings are used dismountable;

- it is necessary to choose the right place so that it is convenient to carry out repair work;

- the metal body is grounded;

- the tank is installed closer to the pump; there should be no other equipment between them that can increase the pressure in the system.

Installation steps:

- Installing filters on a pump that will pump water from a well. This is necessary to prevent sand from accumulating in the membrane and erasing it.

- A five-terminal part is installed to which a pressure gauge, relays and protection sensors will be connected, as well as a shut-off ball valve and a tee.

- The container is mounted on the wall or mounted on legs and screwed with anchor bolts.

- A flexible line connects the tank and the five-pin part.

- A pressure gauge and sensors are installed.

It is advisable to provide a means for draining water in case of emergency repairs.

Selecting a suitable tank

Choosing an expansion tank for heating is a fairly easy process. We already know how to choose the appropriate model by volume and how this or that tank works. For an open-type heating system, we choose the simplest model, plastic or metal. For a closed heating circuit, we recommend purchasing a tank with a replaceable membrane. Initially, such a purchase will result in significant expenses. But if the membrane suddenly breaks, you can simply replace it - replacement costs several times less than buying a new container.

When choosing an expansion barrel, you should not skimp. An extra ruble spent will turn into two saved on repairs.

We'll tell you how to choose a tank by manufacturer. Products of domestic and foreign brands are in use; prices, as a rule, differ from each other slightly - within 10-20%. If you suddenly find a suspiciously cheap tank from China, we advise you to beware of such a purchase. It is quite possible that purchasing such a cheap tank will result in a permanently torn membrane - you will spend more on repairs. Special attention should be paid to the form. Classic barrel-shaped expansion tanks for heating are more familiar and common. You can see them in almost any plumbing store. They are characterized by a wide range of capacities and are designed for installation in individual boiler rooms where there is no constraint in free space. If the boiler is located in the kitchen or in a room where a large tank would be noticeable, we recommend purchasing a compact flat tank.

Also on sale are expansion tanks for indirect heating boilers - they are designed to accept excess water generated as a result of heating in the main tank of the unit. Their operating principle is approximately the same, and the required volume is calculated and selected according to the volume of the boiler itself (taking into account the expansion coefficient of 4%).

What will result from an incorrectly selected expansion tank?

If, when heating the coolant in the heating system, the volume of the expansion tank is not enough, then the excess coolant will be drained through a special emergency valve. After the system cools down again, there will be a lack of coolant. Plus, the pressure in the heating system will drop.

Boilers and other equipment have a lower pressure threshold, above which the heating simply will not start. Regular topping up of coolant will help correct this situation.

If this situation occurs constantly, the risk of equipment failure increases. Therefore, it is better to select the expansion tank correctly.

Operation and Maintenance

Before commissioning, settings must be made. To do this, drain the water completely and measure the pressure with a pressure gauge. If it does not meet the required requirements, it is brought to the required values using a car pump. The difference in maximum and minimum pressure should be within 1.5 bar.

Maintenance is carried out to check the pressure in the air or gas compartment. New containers do not require detailed inspection. In older systems, the housing may crack or the integrity of the membrane may be damaged and will have to be replaced.

Prices for a membrane expansion tank for water supply depend on the materials of manufacture, the brand of the manufacturer, as well as the potential volume of water that can be stored inside. The kit may include installation parts, a pressure gauge and a dry-running relay.