Heating radiators have become a part of modern life. Invisible helpers warm our home, making it truly cozy and comfortable to live in. Cast iron, steel, aluminum, made of brass or copper - sooner or later they all take on a less than marketable appearance. In this case, despite some financial and thermal losses, the best option to hide visible flaws would be to purchase a protective screen for the heating radiator. The question immediately arises of what material or design to choose in order to eliminate heat losses as much as possible and not lose money on the price. The editors of Seti.guru, as always, have collected the most interesting ideas for decorating your home.

You can use the battery in this way, or you can come up with an interesting solution using a modern screen for the radiator

Main functions of battery housings

Unlike protective screens, which only hide the facade of the radiator, the casing completely hides the battery, masking it from all sides.

As a result, it has several functions:

- decorative,

- protective,

- sanitary,

- heating the room.

Depending on the material from which the casing is made, a particular function may be more pronounced compared to its performance by a screen made of another material. For example, a metal casing transfers more heat from a hot radiator to the room than a wooden casing, but a wooden casing can be used as a stand or nightstand.

Aesthetic appeal is initially the main requirement for an installed casing. By its design, it is a box that can completely hide the radiator and heating pipes. But if you don’t focus only on this purpose, then well-chosen casing-screens will serve as a decorative decoration for your home, like pieces of furniture.

The protective function of the casing boxes is to protect against burns and protection from sharp protruding elements of the radiator. In families with small, restless children, this function often comes first.

Cast iron radiators are powerful dust collectors with difficult access to contaminated areas. The casing is much easier to clean than the radiator itself; it can be washed or cleaned with a vacuum cleaner. This is especially important for residents who are allergic to dust, since its concentration in the air will be much lower.

A casing that, despite all its visual appeal, reduces the efficiency of home heating and disrupts the comfort of the apartment microclimate is worthless. On the contrary, with the help of the casing it is possible to optimally distribute and direct air flows. According to the recommendations, more than 50% of the front part of the casing should not be covered, so as not to shield thermal radiation from the radiator surface. To facilitate convective flows, the design of the boxes should not impede the free circulation of air.

Purpose

The radiator protector has three main functions:

- Protective. The panels protect against burns and other damage that can result from contact with the radiator.

- Camouflage. Screens hide unsightly elements of the heating system.

- Decorative. The devices make it possible to equip heating radiators according to the design solution.

In addition to performing all the above functions, protective panels should not reduce the efficiency of heating the room.

Materials for making battery casings

The choice of materials for casings is limited due to specific requirements for ensuring high heat transfer from the screen and unimpeded air convection. Therefore, according to the materials of the casing, they are divided into:

- metal,

- wooden,

- plastic,

- made from MDF.

Metal casing

They are made of aluminum or steel. An ideal option for improving battery heat transfer due to the front panel and side walls of the casing. The front panel is made of perforated sheet or expanded metal mesh. Casings made of stainless steel or steel coated with powder enamel look very nice.

Wooden casings

Wood in the interior of a home looks most comfortable. A wooden casing is most appropriate in the case of a radiator that protrudes beyond the window sill. A skilled craftsman will be able to combine both protective functions and the most daring design concept in a wooden structure. The presence of natural wooden products in the home environment has a healing effect on the human body.

It is important! To prevent warping of the casing walls from the high temperature of the radiator, it is necessary to moisten the wood. To do this, you can place an open container of water inside the casing next to the radiator.

Plastic casing

This is the most inexpensive option; in addition to the price, it also impresses with its light weight and rich range of colors for painting. However, the disadvantages outweigh the material; it is short-lived and releases vinyl chloride when aging from exposure to heat. When temperature changes occur, plastic panels begin to warp and their shape becomes distorted. The shelf life does not exceed 5 years.

MDF casing

Structures made of MDF coated with a wood texture are not subject to temperature deformation and allow you to cut out artistic designs in any style. Easy to clean with a damp cloth or vacuum cleaner.

Screen maintenance

Protective products require maintenance as they are used. If this is not done in a timely manner, then dust and dirt can eat into the grille, changing the appearance. The cleaning method depends on the material and its finishing. It is usually sufficient to wipe the external surfaces with a damp cloth once a week.

Removal to clean the screen and radiators is carried out after the end of the heating season and always before starting the radiators in the fall - in the summer, when the windows are open, the formation of a dusty layer is especially intense, and at high temperatures the battery begins to burn.

A little about heat engineering and radiator grilles

Even if you need radiator grilles for decoration, do not forget that the radiators must heat the room. Any screen reduces heat transfer, even the most delicate and delicate one. Another question is that one will reduce the amount of heat transferred by 10-15%, and the other by 60% or even more. It is unlikely that you will want to sit in a beautiful but cold room, so when choosing a decorative grille you need to take into account how the heat will spread.

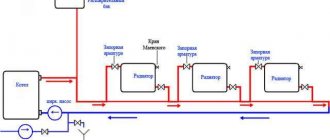

The principle of heat transfer from a heating radiator without a grille is shown in the figure. The main idea is that air should come from below, pass along the battery, heat up, and go up. This is how our heating works. When choosing a grille or screen, you need to remember this. For normal air circulation, it is necessary that there is a gap at the bottom and no cover at the top. As a last resort, the lid should have a large perforation area.

Not a bad option - large holes allow air to move freely

But if you look at many of the decorative grilles, you can immediately tell that the room will be cold. This especially affects grilles on heating radiators in the form of a box, which have walls on all sides. If they are very lacy, as in the photo above, there is no particular problem, but if they are made of solid wood (as in the photo below), with almost no or minimal perforations, be prepared for heating inefficiency.

The top of the battery is covered with a solid layer of wood without holes

Wood is, of course, an aesthetic material, but it has a high heat capacity. Until the wood heats up, the room will be cold. And since the array is located above the radiator and there are no holes for circulation, the radiator under such a grille will be hot, but the room will be cold.

How to choose a model taking into account the rules of heating engineering

In order not to make a mistake when choosing or manufacturing a grille or screen, you need to take into account some points. Especially for its readers, the editors of Seti.guru have collected the best ideas for preserving heat using decorative radiator grilles:

- To make the screen better “hold” heat and heat up, the back of the battery can be painted a dark color.

- The space behind the radiator battery can be covered with a special reflective film, which will provide stronger heating.

Battery with reflective screen made of isolon - It is better to choose a box or radiator grille with perforations on the top panel.

Metal battery with perforation - The distance between the slats in the front panel directly affects the percentage of heat transfer; the larger they are, the more efficient the heating is.

- It is better to choose designs equipped with an aerodynamic visor. It is very convenient if the radiator is “hiding” under the windowsill. In this case, the metal canopy will prevent air from accumulating directly above the battery and will redirect it into the room.

- You can improve the radiator grille with a homemade injector. If you install two directional blades correctly, they will collect a warm air flow and direct it towards the room.

This is what an ideal decorative radiator grille should look like.

The ideal device for a proper radiator battery with a screen

Tasks and materials

Most often, grilles are installed on heating radiators for decoration - not all heating devices look attractive, but the grilles are sometimes made very beautiful. The second task that battery screens often perform is to cover sharp and hard edges. This is relevant in families with children, especially if old-style cast iron radiators, the “accordion” type, are installed. Their shape is dangerous, and their appearance is unattractive; they would only be suitable in loft-style rooms.

Grates for heating radiators are made from different materials:

- Metal screens for batteries are produced in large quantities. They are made from thin sheet steel, which is then coated with paint. For the most part, they don't cost much, but they also look average. The service life depends on the quality of the paint. Powder enamels are preferable. They last longer, maintaining their attractiveness for decades. From the point of view of the effect on heating, metal screens for radiators are the best choice. The metal heats up quickly, and then it begins to radiate heat. So the option is inexpensive (usually) and does not greatly affect the temperature in the room (if there is perforation).

The most common form, and the design can be anything

The forging is very beautiful

Wood always looks solid

Openwork decorative grilles for batteries are usually made from MDF and HDF

Plastic washes well, is durable and unpretentious

Screen for glass radiators

Used in the manufacture of decorative grilles for radiators and more exotic materials. For example, bamboo and rattan. Such products are more demanding for interiors and are rare.

Rattan screen on wooden frame

There are also combined grilles. Most often there is a wooden frame on which some kind of decorative mesh is stretched. Bamboo and rattan wickers are most often attached to such a frame. MDF and HDF panels are usually mounted on a wooden frame.

Instructions for DIY production and installation

Any of the materials considered can be used to make screens yourself. It is necessary to objectively assess your skills, take into account the availability of tools and the availability of components for sale.

The work is carried out according to a single algorithm:

- Choose a design based on a photo or sample.

- Measurements are taken of the radiator and installation location: height, width, depth of the niche.

- Make a sketch and, if possible, an accurate drawing of the screen.

- The instrument is being prepared.

- Purchase materials, including consumables (paint, fasteners).

- A frame is made and sheathed with the selected material.

- Finishing is carried out.

- Attach using the chosen method to the wall or floor.

You can inspect the model you like at a construction supermarket and then start making it yourself.

Glass or mirror screen

You will need:

- drill or screwdriver;

- hammer drill for drilling a wall for fasteners;

- glass drill bit.

- a glass cutter and a diamond block, if you are cutting the glass yourself.

Glass or mirror can be ordered according to the required sizes in stores or workshops, and the edges will be processed there. The price of glass (at least 6 mm) with a cut ranges from 1,000 to 2,000 rubles per square meter. Holders will cost from 1,000 rubles. per set.

Additionally, holder brackets can be purchased.

Holder brackets.

They can be of different designs, but must hold the panel in a vertical position.

Self-production algorithm:

- The glass is cut to the required size, taking into account gaps for air circulation.

- Treat the edge with a diamond stone or fine sandpaper.

- Using a crown of the required diameter, drill a hole for the holder. The drill is set to minimum speed, and as you work, the drilling site is watered with water.

- Make markings to install the holders on the wall or floor.

- Drill a hole and attach the brackets.

- Install the glass on the holders.

Before drilling, try to perform the operation on an unnecessary piece of glass.

Another no-drilling option involves using prefabricated brackets and nickel-plated posts. All materials can be purchased at any construction supermarket.

The surface can be covered with a tinted film of the same color or with a pattern.

Protective box made of MDF, HDF

Prepared:

- drill (screwdriver), hammer drill or impact drill for concrete walls;

- jigsaw;

- a hacksaw with fine teeth complete with a miter box;

- construction corner, ruler or tape measure;

- a set of screwdrivers of the required configuration;

Buy:

| perforated MDF or HDF panel of the required size - from 600 RUR/m2 | |

| MDF panels of the required width for the top side and side walls from 200 rub. for a 3-meter piece, the upper part can be made from a solid piece of board | |

| planed block 20x30 mm from 30 rubles/linear. meter | |

| self-tapping screws 35x25 mm from 30 kopecks/piece. | |

| 12 steel corners for assembling the frame from 5 rubles/piece. | |

| wooden or MDF corner for finishing from 50 rub./l.m. | |

| furniture hangers for attaching the frame to the wall from 2 rubles/piece. | |

| hidden nails or glue for installing decorative corners |

MDF panels can be replaced with laminate.

Sequence of work:

- Conduct final measurements of the opening.

- Make a drawing.

- The HDF panel is cut and cut to the required dimensions, it is advisable to maintain the symmetry of the pattern.

- Mark and cut off the frame bars.

- Using steel corners, assemble the frame.

- Hangers are attached for further installation.

- The top and sides are covered with MDF panels.

- Secure the perforated panel using self-tapping screws screwed into the corners.

- The box is finished with a decorative corner.

- Mark holes in the wall, drill and screw in screws on which the box will be hung.

- Place the screen in place.

If necessary, the entire structure can be removed in a few seconds.

Some of the purchased MDF screens have sufficient thickness and strength so as not to make a frame; then the panels are connected using furniture corners. You can watch the video for more details:

Steel screens are made using similar schemes.

Forged gratings

To work, in addition to the hammer drill, you will need an angle grinder, an arc welding machine, a protective mask and electrodes.

Blanks for the grating are purchased at a construction supermarket. The price depends on the part configuration and size.

To obtain the grid:

- The frame is welded from a steel angle or profile pipe.

- Monograms and racks are welded.

- Clean the weld areas with a grinder.

- Paint the finished product.

- Attach the grille to the wall or floor.

Important! Welding cannot be carried out indoors, since the gases released are toxic, and the smell does not disappear from the room for several days. Observe fire safety measures: protect flammable objects and the floor with screens, prepare a supply of water in case of fire.

Types and forms

In addition to different materials, radiator grilles come in different designs. All this together creates a huge number of options.

- Flat screens. Most often used if the radiator is installed in a niche. In this case, the flat panel is attached to bars fixed around the perimeter of the niche. In addition, glass screens for batteries also have this shape, but are attached to special pins embedded in the wall. This type of decorative grille for heating radiators is also called “facades”.

Flat screens are installed if the radiator is hidden in a niche

Attached grille-box for radiator

These are only the main types of screens and grilles covering heating radiators. Fantasy is limitless, there are very interesting models, but they are most often made by craftsmen with their own hands.

What not to do

Place the unit too low.

If the distance between the floor and the bottom of the radiator is less than 10 centimeters, heat transfer efficiency decreases and cleaning becomes more difficult.

Do not lift the device too high.

When the gap between the floor and the radiator is more than 15 centimeters, the air temperature gradient increases relative to the height of the room, especially in the lower part.

Do not install the device close to the wall.

The distance between the top of the radiator and the window sill is at least 15 centimeters. Anything less degrades heat flow.

Mounting features

Grilles on heating radiators must be mounted in such a way that you can easily and quickly access heating appliances and pipes. Periodically, at least twice a year, the heating system elements must be cleaned of dirt and dust, so access is necessary. In addition, emergencies arise from time to time. In this case, a quick reaction is required and there is no time to unscrew the fasteners. Therefore, try to come up with a fastening system that allows you to remove the screen in one motion.

Attached and mounted

The easiest way is with mounted or attached screens. They are removed/retracted in seconds. But flat, covering radiators in niches and box screens that are attached to the wall are the most problematic. But even here everything is solved simply. You can secure the box to the wall using two strips: one on the box, the second on the wall. The whole secret is that the top edge of the planks is beveled (you can see it in the picture). The one that is nailed to the wall has a slope towards the wall, the one on the frame has a slope towards the grating. When the box is installed in place, it turns out something like a lock.

How to fix a screen box for a heating radiator on the wall

Another option is to attach metal plates to one of the strips and magnets to the other. Or attach not a wooden plank to the wall, but a metal corner, for example.

In the case of flat screens, the solution may be the same - metal plates and magnets. Another option is hooks and loops. It is easy to implement, but not very convenient to use: while you get into loops, you have to suffer. There is also a difficult-to-install but convenient way: make a screen like a sliding door.

Sliding screens for radiators

You can take the guides that are sold for furniture doors, install them, and insert the screens into the corresponding grooves. If you do not plan to actively use the niche near the battery, you can not install roller mechanisms, but it will be difficult to move them away. This method, by the way, can also be used for the box lattice. It can then be nailed “tightly” to the wall, and the front wall can be made movable.

The nuances of making a heating screen with your own hands

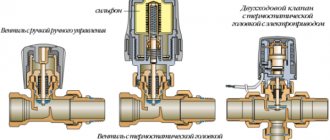

Before you create a screen for a heating radiator with your own hands, you need to decide on the material. Typically, home craftsmen opt for metal and wooden structures. The simplest solution is to use ready-made circuits. The main thing for a beginner is not to forget to provide slots or removable elements for access to shut-off valves and the Mayevsky tap. For approximate planning of material consumption, the following drawing diagram is suitable.

Drawing diagram of screen assembly for radiator battery

Learn more about how to assemble a decorative screen in this video:

Today we decided to be original and present a rather unexpected design option for a decorative screen for a battery. So, let's begin. First of all, let's prepare the necessary materials. We will need: a large photo frame (it should be slightly wider than the size of the battery), burlap or any fabric with a dense structure. It is important that the piece of material is twice the size of the frame. A ball of thread, buttons, hooks, ribbons.

| Image | Action |

| We cut the burlap into two rectangles, which are slightly larger than the edges of the frame (about 2-3 cm). | |

| In one of the pieces we cut a hole to the size of the desired “heat catcher”. We make cuts in the fabric of the same length, like sun rays, towards the edges of the frame. | |

| We bend them and fasten them, just like trouser straps (holes where the belt is threaded). | |

| We thread the thread into the holes formed and stretch the fabric. | |

| We weave our “web” according to the proposed scheme. | |

| As a result, we got this wicker center. We attach a thread with pre-strung beads to it. | |

| We hang it on hooks previously screwed to the window sill. The second part of the material is used as a damper. |

Interesting design options for battery screens: photo ideas

In addition to the technical side of the issue, the aesthetic side is no less important. There are grille and screen options that are more of a design element rather than a technical detail. Some of them are in the photo.

The decorative panel that covers the radiator itself looks like the work of an avant-garde sculptor

Looks like a chest from a fairy tale. This is made using laser cutting

Openwork always looks attractive

Option for designing grilles for heating radiators in a modern style

Making a backlight is an original idea

Repeating the pattern on the wallpaper is a stylish solution

Make not just an attached box, but a functional thing

Glass screens can have any design, be it a landscape, an ornament, even your personal photo

A stylish version of a metal screen for rooms in minimalist and high-tech styles

Often in apartments, especially older buildings, it becomes colder every year in winter. People have to purchase and use electric heating appliances, which leads to a significant increase in the cost of utilities. But why overpay for excessive energy consumption if there are cheaper options to correct the situation? Today we will talk about simple ways to increase the heat transfer of heating batteries , which do not require significant costs, and which any home craftsman can implement. It is worth considering the reasons leading to a decrease in room temperature.

Where does the heat go?

Heating devices in buildings are installed under the windows.

The goal is to warm the air inside and create a thermal curtain that prevents the penetration of cold from the street.

Heat spreads from a heated object to a cold one.

The wall temperature is lower than that of the radiator.

In the cold season, the surface behind it heats up to 35-40 °C.

Instead of heating the air inside a warehouse or office, some of the energy is used to heat the external walls.

Frequent reasons for a decrease in heat transfer from a heating battery

Most often, the reason for the decrease in heat transfer from radiators is scale and rust that accumulates inside. If the radiator itself is flushed (which utilities should do annually), the heat transfer will increase significantly. The same applies to heating risers. However, it will not be possible to carry out such a procedure on your own due to the fact that when carrying out such work (even in summer), it is necessary to drain the water from the system. You can’t do this without the help of specialists. The same applies to replacing radiators from cast iron to bimetallic ones - they have greater heat transfer. Therefore, we will not dwell on such complex and time-consuming options. It’s better to consider simpler methods that any home craftsman can do, even without experience in this field.

Installation stages

The most reasonable thing is to provide for the installation of a heat-reflecting screen at the construction stage - after rough finishing, before installing the heating.

If the repair is completed and the radiator is in place, you will have to remove it.

The size of the screen must correspond to the working surface of the heating device.

Then it will be invisible and will not spoil the interior.

In production areas where aesthetics are not important, it is worth increasing the area by 10 percent to ensure maximum reflective effect.

The wall under the window is cleaned of dirt and crumbling plaster, defects are puttied, irregularities are removed with sandpaper.

You can start installation.

The heat-reflecting screen behind the radiator is attached with wallpaper glue, “liquid nails” or furniture nails.

If there is enough space, a more reliable option is a lattice base made of thin wooden slats.

Additionally, we obtain a layer of air between the wall and the thermal insulation sheet.

It will have a positive effect on heat transfer.

The radiator returns to its place.

It is important to adjust the position of the device so that a distance of one and a half centimeters (minimum) is maintained between the foil covering and the back side.

If possible, make the gap larger.

The heat-reflecting screen does not require special care.

It is enough to wipe the dust on it sometimes.

If the aluminum layer is scratched or torn, metallized tape will help remove the damage.

Functionality will not be affected by this.

General rules for improving heat transfer from heating radiators

In order not to encounter a decrease in the heat transfer of batteries in the future, it is worth thinking about this at the stage of installing radiators. The basic rules are:

- mandatory insulation of the wall behind the radiator, possible installation of a steel screen;

- installation of bimetallic batteries instead of cast iron ones;

- installation of taps at the inlet and outlet of the radiator (this will allow you, if necessary, to flush sections yourself or add additional ones without disconnecting and draining the entire system).

If you follow these simple rules during installation, it will subsequently be much easier to increase the temperature in the room without turning to specialists for help. And this is additional savings for the family budget.

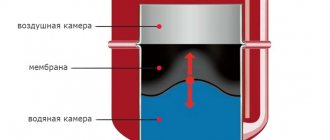

Heat-reflective polyethylene foam screen

Substances have different abilities to conduct heat.

To prevent energy consumption, the heat-reflecting screen must have low thermal conductivity - no higher than 0.05 W/(m*K).

Heat-reflective polyethylene foam screen

It is not recommended to use structures made of flammable substances with a loose structure indoors.

For example, mineral wool, which releases formaldehyde and microscopic dust, is not suitable for the screen.

Although its thermal conductivity coefficient is suitable - 0.039 W/(m*K).

Heat-reflecting screens made of insulating materials based on polyethylene foam have proven themselves to be the best:

- penofol,

- Porilexa,

- isolona,

- stizol,

- tepofol.

They are hypoallergenic and safe for human health.

The thermal conductivity of different types of polyethylene foam ranges from 0.029 to 0.032 W/(m*K).

Four millimeters of such a barrier will retain as much heat as 10 centimeters of mineral wool.

For insulation between the wall and the heating device, a layer of 3-5 millimeters is enough.

Mandatory condition: the heat-insulating screen behind the radiator must be duplicated with aluminum.

Summarize

There are many ways to increase the heat output of heating radiators. Today we looked at only the main ones. However, it should be remembered that it is always easier to think through everything in advance, at the installation stage, than to put in a lot of effort later, without the confidence that the result will be significant. Unfortunately, in Russia everything is done at random. The final advice from the Homius.ru editors would be this: think about the future and spare no expense during installation. The financial resources saved today can turn into costs tomorrow that will be many times greater than your savings.

The most optimal option is that all the heat rises, which creates normal heat exchange

Why do you need foil?

The coefficient of reflection of thermal radiation of polished aluminum is higher than that of other metals.

This means that maximum heat will return inside the room.

You should not use screens with a double-sided metal backing.

The layer of foil on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in construction markets deceive customers by talking about new metallized coatings with fantastic characteristics.

These are fairy tales.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermal reflective screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a heat reflective screen