When heating a private home, a fairly important issue is stabilizing the pressure in the boiler. If the pressure is low, the boiler will not be able to function. If the pressure is high, the heating equipment will wear out quickly. In order to stabilize the pressure, connect to the boiler expansion tank.

Expansion tank

Purpose of the expansion tank

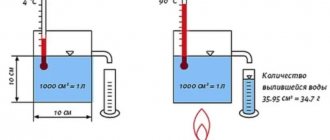

An expansion tank is needed to compensate for the coolant pressure in the heating system. The pressure difference occurs due to changes in its temperature during the heating process, since its volume changes depending on the temperature.

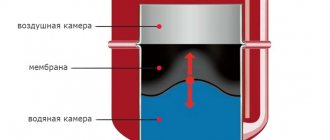

Closed heating systems use an expansion tank of a closed, hermetically sealed structure. Inside the tank there is an elastic membrane that divides it into two parts. One of the parts of the tank contains air under pressure, the coolant penetrates into the second part.

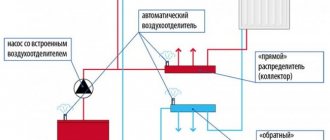

The circulation of coolant in a closed heating system is ensured using a circulation pump. In an open heating system, a pump is not needed, and therefore any container can act as a tank, into which the coolant will be drained directly from the heating pipes.

Expansion tank in a closed heating system

Common problems

Expansion tanks, like any other heating units, are subject to a number of specific problems. Let's get to know them.

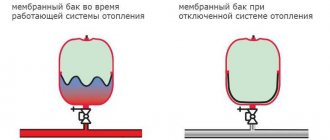

The most common breakdown of such units is the rupture of the membrane part. As a rule, this occurs due to too high pressure (above normal) or uneven loads. Please note that replaceable elements break much more often than compressed ones, since stronger materials are used for the latter, because they can be changed at any convenient time.

The problem of a damaged membrane can lead to many unpleasant consequences. For example, this often causes water to leak from the air valve.

If the membrane is not replaced in time, its rupture will lead to the fact that over time the tank will simply fail. This is due to the fact that liquid gets on the inner surface of the tank, after which it can become covered with rust and become unusable.

Please note that the old membrane should be replaced with the same part. It is advisable to contact a specialized service center for this.

Also, users quite often encounter damage to the tank body. If such a problem occurs with your equipment, it is better for you to seek help from a specialist. Do not attempt to repair damaged cabinet elements yourself, especially if you have never encountered such work before.

There are also cases when the expander boils. Most often, this problem occurs in homemade open-type structures. The main essence of this problem is the lack of circulation speed (or its complete absence).

Here are the main reasons for such breakdowns.

- Reduced wiring diameter. The main single-pipe heating circuit is usually installed with a pipe that is no less thin than DN 32.

- No slope. After the heating boiler, you need to make a so-called accelerating manifold. To do this, the pipe must be raised to the upper section of the circuit, where the expander is installed. The remaining part of the contour should be laid with a downward slope.

Many users are wondering how to fix such a serious problem without completely dismantling and reinstalling the heating system. The answer is simple - you need to install a circulation pump. This part works great in many systems (especially the open type). The pump must be placed on the return line directly in front of the boiler.

Another problem with expansion tanks is air blockage in the heating system circuit. To avoid colliding with it, you need to monitor the volume of water.

If you do not replenish it, the resulting evaporation will lead to the above problems.

Advantages of a closed heating system

- The first advantage of a closed heating system is that the tank can be installed wherever it is convenient for you, but in an open one, only in the attic or at some other high point in the system. And due to the tightness, the coolant practically does not evaporate.

- The coolant is always saturated with air in an open heating system, which leads to corrosion in heating pipes and radiators. In a closed environment, as you understand, this cannot happen.

- In a closed system, there are fewer losses in the tank than in an open system, which heats up very quickly and has increased sensitivity. Plus, the temperature difference in a closed system is smaller, which allows you to use heating equipment longer.

- The closed system is suitable for a wide variety of radiators, convectors and air curtains; you can connect a “warm floor” system. Plus, you can add an indirect heating boiler for domestic hot water to a closed system.

Expansion tank design

Tanks can be either with the ability to replace the membrane with a new one, or completely non-removable. To secure the tank to the wall, brackets and clamps may be included; to install the tank on the floor, special legs may be included. The tank membrane, in turn, can also be of different designs.

Non-separable models are equipped with a membrane in the form of a diaphragm; less commonly, a membrane in the form of a cylinder is found. It stretches under pressure, so it can be considered an independent water chamber. To replace this type of membrane, a special flange is used.

Expansion tank design

Materials

Various materials are used in the manufacture of expansion tanks, but the most common are models with a steel body.

Currently, many people, in an effort to save money, construct such units on their own. To do this, they often use sheet materials, which are subsequently assembled into a single structure by welding. You can also use the most unexpected items to make an expansion tank, for example, plastic barrels and canisters or old gas cylinders. The use of such materials significantly reduces the cost of creating an expansion tank. Despite such a large selection of suitable raw materials, experts still recommend turning to stainless steel if you plan to assemble the tank yourself.

As for the partition in such units, most manufacturers use high-quality rubber, synthetic rubber, natural butyl rubber or EPDM raw materials. Membrane elements for such units are made from various materials, which during use can easily withstand a wide range of temperatures.

If we consider specific cases, then:

- for tanks up to 2 thousand liters, membranes marked EPDM DIN 4807 are most often used;

- Tanks with a volume exceeding the above mark are equipped with BUTYL brand membrane elements.

Calculation of tank volume

To determine the volume of the tank, you can follow the simplest path. That is, take 10% of the volume of coolant used, which is calculated at the design stage of the heating system. Or you can drain the old coolant and fill in a new one, measuring the volume with a meter.

You can also find out the volume of radiators and pipes, this way you will get the volume of the heating system, from which you will need to take 10%.

There is also a way to calculate the tank using the formula:

V=(E*C*(Pmax+1))/(Pmax+Pmin), where

E – coefficient of expansion of the coolant indicated on the packaging,

Pmax and Pmin are the maximum and minimum operating pressure of the system, respectively.

It should be said that for an open heating system no calculations need to be made, but for a closed one it is still worthwhile. Moreover, if the boiler already has a built-in tank, if its volume is insufficient, a new one is installed.

If there is insufficient tank volume, the volume of coolant decreases and the pressure in the heating system drops as it begins to drain into the sewer. If there is a critical shortage of coolant, the operation of the boiler may simply stall.

If you are at home at this moment, you will just need to add coolant. If you are not at home, the heating system will begin to defrost. And there is nothing good about operating a boiler in critical condition either.

Therefore, it is always better to carry out similar calculations and purchase a slightly larger tank than required.

Equipment selection rules

It is important to choose the right tank volume in order to adjust the pressure in the system.

The main characteristics of a membrane tank, which are oriented towards when purchasing:

- volume;

- maximum pressure;

- membrane and housing material;

- working temperature.

These criteria will ensure reliable heating operation. Insufficient or excessive tank volume will not allow normal pressure to be established in the circuit. The type and material of the membrane and housing affect the service life of the equipment. High-quality rubber can withstand a large number of expansion and compression cycles. To prevent the body from corroding, it must have a protective coating. It is worth considering the dimensions of the product and considering the installation location. Experts advise buying products from well-known manufacturers. Low product costs are often an indicator of the use of low-grade materials.

Expansion tank pressure

Some boilers have the function of manually setting pressure using an expander. Otherwise, it should be approximately 0.3 atmospheres lower than the operating pressure of the heating system in a country private house. And it is usually equal to from 1.5 to 1.8 atmospheres, resulting in approximately 1.6 atmospheres maximum or 1.2 minimum.

To measure the pressure in the tank, connect the pressure gauge to the nipple at the top of the tank, under the plastic cap. Under the cover there is a spool through which excess pressure can be released. You just need to bend the plate and release the air to normal pressure.

To increase the pressure, the car pump along with a pressure gauge should be connected to the nipple, then pump to the required level. Do not forget that all these operations must be performed when the tank is disconnected from the heating system! The coolant must be completely drained.

Installed expansion tank

Position of the expansion tank in the heating system

In a closed heating system, the tank should be installed after the boiler, but before the pump, to create a flow in the opposite direction. To connect the pump to the pipe, you need to install a tee; the tank is screwed onto a perpendicular outlet, which should have a vertical upward direction.

We recommend that you install the next tee after the tank so that a shut-off valve is installed on it. This way you can check the tank without draining the coolant. Turn off the tank and check the pressure, which should be at zero.

Summarizing all of the above, we can conclude that a closed heating system with an expansion tank is an almost universal solution for most types of boilers, radiators and other heating equipment.

Calculations for installing the tank are also highly recommended. An open heating system is mainly an option for a village house with an attic and a solid fuel boiler; in other situations such a scheme is of little use.