When starting to install a heating system, it is necessary to calculate the volume of liquid, because this parameter is considered the main one when choosing a boiler. Only the optimal volume of coolant allows you to effectively warm up the house in the winter season. This indicator is affected by the dimensions of the pipes. When using a circulation pump, it is permissible to choose pipelines of a smaller diameter. This allows you to increase the number of heating radiators.

When choosing pipes of increased diameter at the boiler's maximum power, the coolant is underheated. This is due to the fact that the working fluid has time to cool before it reaches the extreme point of the heating system, and this is additional material costs. According to earlier calculations, for every kilowatt of boiler power, 15 liters of liquid will be needed. Based on this, a detailed calculation of the volume of water in the heating of a private house is carried out.

Heating calculation required

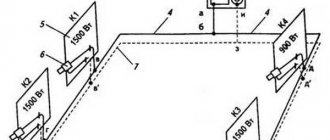

An example of a complex home heating system

First, you should determine the relevance of calculating the volume of water in the heating system or the same indicator for batteries and an expansion tank. After all, you can install these components without complex operations, guided only by personal experience and advice from professionals.

The operation of any heating system is associated with a constant change in the coolant parameters - temperature and pressure in the pipes. Therefore, calculating heating according to the volume of the building will allow you to correctly equip the heat supply based on the characteristics of the house. In addition, the direct dependence of operating efficiency on current steam meters should be taken into account. Since you can calculate the volume of water in the heating system yourself, this procedure is recommended to be performed to avoid the following situations:

- Incorrect actual thermal operating conditions that do not correspond to the calculated ones;

- Uneven heat distribution across heating appliances;

- Occurrence of emergency situations. After all, how can you calculate the volume of an expansion tank for heating if the total capacity of the pipelines and batteries is not known?

To minimize the occurrence of these situations, the volume of the heating system and its components should be calculated in a timely manner.

Calculations of heat supply parameters are carried out even before installation work. They serve as the basis for the selection of components.

Specific calculations

Let's say you need to make a calculation for a household with an area of 150 square meters. m. If we assume that 100 watts of heat are lost per 1 square meter, we get: 150x100 = 15 kW of heat loss.

How does this value relate to the circulation pump? With heat losses, there is a constant consumption of thermal energy. To maintain the temperature in the room, more energy is required than to compensate for it.

To calculate a circulation pump for a heating system, you should understand what its functions are. This device performs the following tasks:

- create a water pressure sufficient to overcome the hydraulic resistance of the system components;

- pump through pipes and radiators the volume of hot water required to effectively warm up the household.

That is, in order for the system to work, you need to adjust the thermal energy to the radiator. And this function is performed by the circulation pump. It is this that stimulates the supply of coolant to heating devices.

The next task: how much water, heated to the required temperature, must be delivered to the radiators over a certain period of time, while compensating for all heat loss? The answer is expressed in the amount of coolant pumped per unit time. This will be called the power that the circulation pump has. And vice versa: you can determine the approximate coolant flow rate based on the pump power.

Data needed for this:

- The amount of thermal energy required to compensate for heat loss. For this household with an area of 150 sq. meters this figure is 15 kW.

- The specific heat capacity of water, which acts as a coolant, is 4200 J per 1 kilogram of water, for every degree of temperature.

- Temperature delta between the water supply from the boiler and the last section of the return pipeline.

It is believed that under normal conditions this last value does not exceed 20 degrees. On average they take 15 degrees.

The formula for calculating the pump is as follows: G/(cx(T1-T2))= Q

- Q is the coolant consumption in the heating system. So much liquid at a certain temperature must be delivered to the circulation pump to the heating devices per unit of time in order for heat loss to be compensated. It is not advisable to purchase a device that has more power. This will only lead to increased electricity consumption.

- G - heat loss at home;

- T2 is the temperature of the coolant flowing from the boiler heat exchanger. This is exactly the temperature level that is needed to heat the room (about 80 degrees);

- T1 - temperature of the coolant in the return pipeline at the entrance to the boiler (most often 60 degrees);

- c is the specific heat capacity of water (4200 Joules per kg).

When calculated using the above formula, the figure is 2.4 kg/s.

Now we need to translate this indicator into the language of circulation pump manufacturers.

1 kilogram of water corresponds to 1 cubic decimeter. One cubic meter is equal to 1000 cubic decimeters.

It turns out that the pump pumps the following volume of water per second:

2.4/1000=0.0024 cubic meters m.

Next you need to convert seconds to hours:

0.0024x3600=8.64 cubic meters m/h.

Calculation of coolant volume in pipes and boiler

Heating system components

The starting point for calculating the technical characteristics of the components is to calculate the volume of water in the heating system. In fact, it is the sum of the capacity of all elements, from the boiler heat exchanger to the batteries.

How to calculate the volume of a heating system yourself, without involving specialists or using special programs? To do this, you will need a diagram of the location of the components and their overall characteristics. The total capacity of the system will be determined by these parameters.

Volume of water in the pipeline

A significant part of the water is located in pipelines. They occupy a large part in the heat supply scheme. How to calculate the volume of coolant in a heating system, and what characteristics of pipes do you need to know for this? The most important of them is the diameter of the line. It is he who will determine the water capacity in the pipes. To calculate, just take the data from the table.

| Pipe diameter, mm | Capacity l/p.m. |

| 20 | 0,137 |

| 25 | 0,216 |

| 32 | 0,353 |

| 40 | 0,555 |

| 50 | 0,865 |

Pipes of various diameters can be used in the heating system. This is especially true for collector circuits. Therefore, the volume of water in the heating system is calculated using the following formula:

Vtotal=Vtr1*Ltr1+ Vtr2*Ltr2+ Vtr2*Ltr2…

Where Vtotal is the total capacity of water in the pipelines, l, Vtr is the volume of coolant in 1 m.p. pipes of a certain diameter, Ltr - the total length of the pipeline with a given cross-section.

In total, these data will allow you to calculate most of the volume of the heating system. But in addition to pipes, there are other heating components.

For plastic pipes, the diameter is calculated based on the dimensions of the outer walls, and for metal pipes, based on the inner walls. This can be significant for thermal systems with a large extent.

Calculation of heating boiler volume

Heat exchanger of the heating boiler

The correct volume of the heating boiler can only be found out from the data in the technical passport. Each model of this heating device has its own unique characteristics, which are often not repeated.

A floor-standing boiler can have large dimensions. This is especially true for solid fuel models. In fact, the coolant does not occupy the entire volume of the heating boiler, but only a small part of it. All liquid is located in a heat exchanger - a structure necessary to transfer thermal energy from the fuel combustion zone to water.

If the instructions from the heating equipment have been lost, the approximate capacity of the heat exchanger can be taken for calculations. It depends on the power and model of the boiler:

- Floor-standing models can hold from 10 to 25 liters of water. On average, a 24 kW solid fuel boiler contains about 20 liters in the heat exchanger. coolant;

- Wall-mounted gas ones are less spacious - from 3 to 7 liters.

Taking into account the parameters for calculating the volume of coolant in the heating system, the capacity of the boiler heat exchanger can be neglected. This figure varies from 1% to 3% of the total heat supply to a private home.

Without periodic heating cleaning, the cross-section of the pipes and the flow diameter of the batteries are reduced. This affects the actual capacity of the heating system.

Heat generator power

One of the main components of the heating system is the boiler: electric, gas, combined – it doesn’t matter at this stage. Because its main characteristic is important to us - power, that is, the amount of energy per unit of time that will be spent on heating.

The power of the boiler itself is determined by the formula below:

Wboiler = (Sroom*Wshare) / 10,

Where:

- Sroom – the sum of the areas of all rooms that require heating;

- Wdel – specific power taking into account the climatic conditions of the location (this is why it was necessary to know the climate of the region).

Typically, for different climatic zones we have the following data:

- northern regions – 1.5 – 2 kW/m2;

- central zone – 1 – 1.5 kW/m2;

- southern regions – 0.6 – 1 kW/m2.

These figures are quite arbitrary, but nevertheless provide a clear numerical answer regarding the influence of the environment on the apartment heating system.

Calculation of the volume of the heating expansion tank

Design of the expansion tank

For safe operation of the heating system, it is necessary to install special equipment - an air vent, a drain valve and an expansion tank. The latter is designed to compensate for the thermal expansion of hot water and reduce the critical pressure to normal levels.

Closed tank

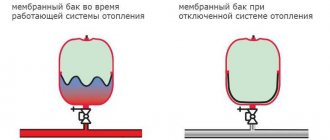

The actual volume of the expansion tank for the heating system is not constant. This is due to its design. For closed heat supply circuits, membrane models are installed, divided into two chambers. One of them is filled with air with a certain pressure indicator. It should be 10% -15% less than the critical value for the heating system. The second part is filled with water from a pipe connected to the main line.

To calculate the volume of the expansion tank in the heating system, you need to find out its filling coefficient (Kzap). This value can be taken from the table data:

Expansion tank fill factor table

In addition to this indicator, you will need to determine additional:

- The normalized coefficient of thermal expansion of water at a temperature of +85°C, E – 0.034;

- Total volume of water in the heating system, C;

- Initial ( Pmin ) and maximum ( Pmax ) pressure in the pipes.

Further calculations of the volume of the expansion tank for the heating system are performed using the formula:

If antifreeze or other non-freezing liquid is used in heat supply, the value of the expansion coefficient will be 10-15% higher. According to this method, it is possible to calculate with great accuracy the capacity of the expansion tank in the heating system.

The volume of the expansion tank cannot be included in the total heat supply. These are dependent quantities that are calculated in strict order - first the heating, and only then the expansion tank.

Open expansion tank

Open expansion tank

To calculate the volume of an open expansion tank in a heating system, you can use a less labor-intensive method. Fewer requirements are placed on it, since in fact it is necessary to control the coolant level.

The main value is the thermal expansion of water as its degree of heating increases. This figure is 0.3% for every +10°C. Knowing the total volume of the heating system and the thermal operating conditions, you can calculate the maximum volume of the tank. It should be remembered that it can only be 2/3 filled with coolant. Let's assume that the capacity of the pipes and radiators is 450 liters, and the maximum temperature is +90°C. Then the recommended volume of the expansion tank is calculated using the following formula:

Vtank=450*(0.003*9)/2/3=18 liters.

It is recommended to increase the obtained result by 10-15%. This is due to possible changes in the overall calculation of the volume of water in the heating system when installing additional batteries and radiators.

If the open expansion tank performs the functions of monitoring the coolant level, its maximum filling level is determined by the installed additional side pipe.

What is needed to expand the balcony

Since the entire structure must be very reliable, no used materials are used for its construction - all metal parts must be free of rust, not deformed and of good quality.

Also, all rolled metal should be treated with anti-corrosive to extend its service life. Materials for slab expansion:

- Metal corner 40x40 or 50x50 mm;

- Profiled pipe with a cross section of 100x50 mm;

- Band;

- Channel;

- Profiled sheeting.

Before purchasing the necessary materials, the balcony is measured and linear meters of metal parts are calculated. All calculations are performed individually, depending on the size of the balcony and how much it will increase.

Read more: Sample collective letter in defense of a manager

Since all metal parts are connected by welding, you will also need a welding machine and a welder. If you don’t know any welders, you can invite a hired worker who will complete all the welding work in 2-3 days.

Calculation of the volume of radiators and radiators

Bimetallic heating radiator in section

To perform an accurate calculation, you need to know the volume of water in the heating radiator. This indicator directly depends on the design of the component, as well as its geometric parameters.

Just as when calculating the volume of a heating boiler, the liquid does not fill the entire volume of the radiator or battery. For this purpose, the design has special channels through which the coolant flows. Correct calculation of the volume of water in a heating radiator can only be performed after obtaining the following device parameters:

- Center-to-center distance between forward and return pipelines to batteries. It can be 300, 350 or 500 mm;

- Material of manufacture. In cast iron models, the filling with hot water is much greater than in bimetallic or aluminum ones;

- Number of sections in the battery.

It is best to find out the exact volume of water in the heating radiator from the technical data sheet. But if this is not possible, you can take approximate values into account. The greater the interaxial distance of the battery, the larger the volume of coolant it will hold.

| Center distance | Cast iron batteries, volume l. | Aluminum and bimetallic radiators, volume l. |

| 300 | 1,2 | 0,27 |

| 350 | 0,3 | |

| 500 | 1,5 | 0,36 |

To calculate the total volume of water in a heating system with panel metal radiators, you should find out their type. Their capacity depends on the number of heating planes - from 1 to 2:

- For type 1 battery, for every 10 cm there is 0.25 volume of coolant;

- For type 2, this figure increases to 0.5 liters per 10 cm.

The result obtained must be multiplied by the number of sections or the total length of the radiator (metal).

To correctly calculate the volume of a heating system with designer radiators of non-standard shape, you cannot use the above described method. Their volume can only be obtained from the manufacturer or its official representative.

For example, a project for a one-story house of 100 m²

To clearly explain all the methods for determining the amount of thermal energy, we suggest taking as an example a one-story house with a total area of 100 square meters (according to external measurements), shown in the drawing. Let us list the technical characteristics of the building:

- region of construction – temperate climate zone (Minsk, Moscow);

- thickness of external fences – 38 cm, material – sand-lime brick;

- external wall insulation – foam plastic 100 mm thick, density – 25 kg/m³;

- floors – concrete on the ground, no basement;

- ceiling - reinforced concrete slabs, insulated on the cold attic side with 10 cm foam plastic;

- windows – standard metal-plastic with 2 glasses, size – 1500 x 1570 mm (h);

- the entrance door is metal 100 x 200 cm, insulated from the inside with 20 mm extruded polystyrene foam.

The cottage has half-brick (12 cm) interior partitions; the boiler room is located in a separate building. The areas of the rooms are indicated in the drawing, the height of the ceilings will be taken depending on the explained calculation method - 2.8 or 3 m.